Group Project #6 Example - CU Ideas Research Group

advertisement

Group Project 6 – Investigation of Response Features

The third step in the SHM process is based on extracting damage-sensitive features from tested data,

which will then be analyzed to gain a better understanding of the health of the structure1. This paper

investigates the effectiveness and feasibility of six different response features.

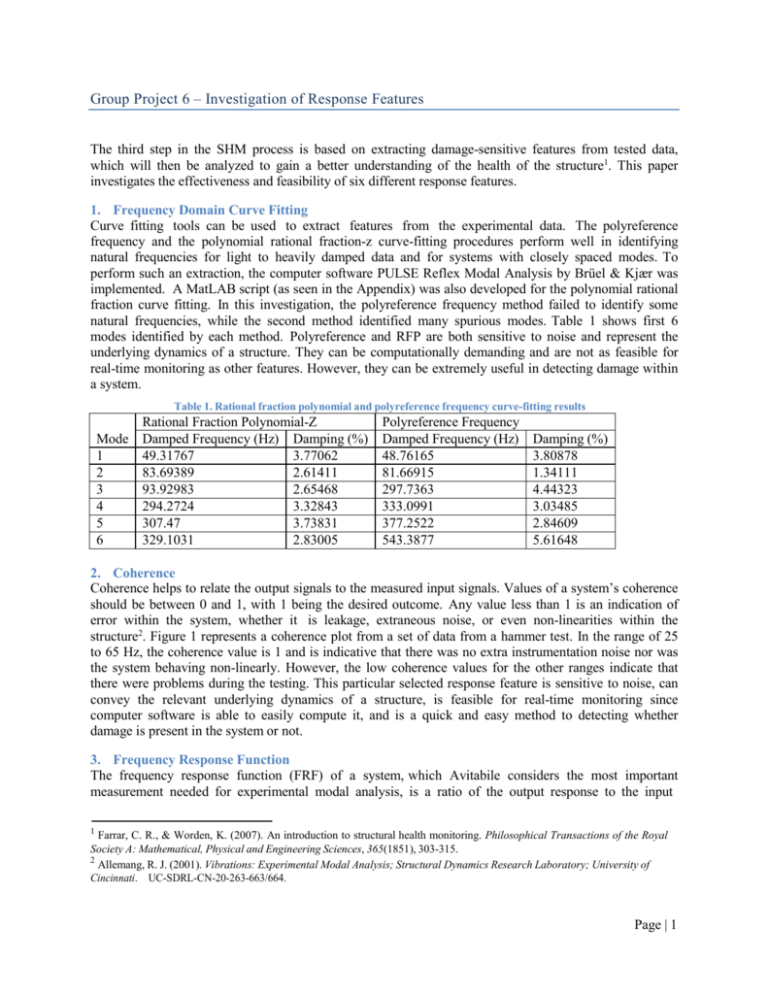

1. Frequency Domain Curve Fitting

Curve fitting tools can be used to extract features from the experimental data. The polyreference

frequency and the polynomial rational fraction-z curve-fitting procedures perform well in identifying

natural frequencies for light to heavily damped data and for systems with closely spaced modes. To

perform such an extraction, the computer software PULSE Reflex Modal Analysis by Brüel & Kjær was

implemented. A MatLAB script (as seen in the Appendix) was also developed for the polynomial rational

fraction curve fitting. In this investigation, the polyreference frequency method failed to identify some

natural frequencies, while the second method identified many spurious modes. Table 1 shows first 6

modes identified by each method. Polyreference and RFP are both sensitive to noise and represent the

underlying dynamics of a structure. They can be computationally demanding and are not as feasible for

real-time monitoring as other features. However, they can be extremely useful in detecting damage within

a system.

Table 1. Rational fraction polynomial and polyreference frequency curve-fitting results

Rational Fraction Polynomial-Z

Mode Damped Frequency (Hz) Damping (%)

1

49.31767

3.77062

2

83.69389

2.61411

3

93.92983

2.65468

4

294.2724

3.32843

5

307.47

3.73831

6

329.1031

2.83005

Polyreference Frequency

Damped Frequency (Hz)

48.76165

81.66915

297.7363

333.0991

377.2522

543.3877

Damping (%)

3.80878

1.34111

4.44323

3.03485

2.84609

5.61648

2. Coherence

Coherence helps to relate the output signals to the measured input signals. Values of a system’s coherence

should be between 0 and 1, with 1 being the desired outcome. Any value less than 1 is an indication of

error within the system, whether it is leakage, extraneous noise, or even non-linearities within the

structure2. Figure 1 represents a coherence plot from a set of data from a hammer test. In the range of 25

to 65 Hz, the coherence value is 1 and is indicative that there was no extra instrumentation noise nor was

the system behaving non-linearly. However, the low coherence values for the other ranges indicate that

there were problems during the testing. This particular selected response feature is sensitive to noise, can

convey the relevant underlying dynamics of a structure, is feasible for real-time monitoring since

computer software is able to easily compute it, and is a quick and easy method to detecting whether

damage is present in the system or not.

3. Frequency Response Function

The frequency response function (FRF) of a system, which Avitabile considers the most important

measurement needed for experimental modal analysis, is a ratio of the output response to the input

1

Farrar, C. R., & Worden, K. (2007). An introduction to structural health monitoring. Philosophical Transactions of the Royal

Society A: Mathematical, Physical and Engineering Sciences, 365(1851), 303-315.

2

Allemang, R. J. (2001). Vibrations: Experimental Modal Analysis; Structural Dynamics Research Laboratory; University of

Cincinnati. UC-SDRL-CN-20-263-663/664.

Page | 1

response. Here, to quantitatively represent the characteristics of the FRF, the area under the curve of FRF

will be employed, computed as: Area FRF( f )df . The effectiveness of this FRF measure can be

easily illustrated using the following example, shown in Figure 2. Although there is no distinct variation

of the resulting FRF between two tests, a considerable variation of that computed Area is noticed: the

area under FRF of Test 2 is less than that of Test 1, and that difference, which can be approximated to

2.1%, can’t be neglected. The frequency response function is sensitive to noise and can reflect the

underlying dynamics of a structure. The FRF is an efficient procedure and is able to be used during

real time monitoring. Overall, the FRF is an important feature for experimental modal analysis and

is helpful for detecting damage within a system.

Figure 1: Coherence of hammer testing

90

80

Magnitude

70

60

50

40

30

20

10

0

0

50

100

Frequency (Hz)

150

200

Figure 2: Illustrative example to demonstrate the effectiveness using the area under the curve of FRF to feature the FRF

4. Modal Assurance Criterion (MAC)

MACis an experimental modal analysis tool used to help identify damage within a system. MAC, which

is a statistical indicator, is a leased squares based form of linear regression analysis3. The computer

software PULSE Reflex Modal Analysis by Brüel & Kjær was used to perform this analysis. Figure 3

represents the MAC information that was obtained. MAC is not very sensitive to noise and can reflect the

underlying dynamics of a structure. Although MAC requires numerous computational requirements and is

not feasible for real time monitoring, it can be a very helpful tool in detecting damage within a system,

especially when comparing a numerical model of a plate to measured data.

3

Pastor, M., Binda, M., & Harčarik, T. (2012). Modal assurance criterion. Procedia Engineering, 48, 543-548.

Page | 2

543.4

0.00

0.01

0.00

0.01

0.03

1.00

Polyreference Frequency

Modes

48.8

81.7

297.7

333.1

377.3

543.4

Polyreference Frequency

48.8 81.7 297.7 333.1 377.3

1.00 0.00 0.01 0.00 0.01

0.00 1.00 0.01 0.02 0.01

0.01 0.01 1.00 0.05 0.01

0.00 0.02 0.05 1.00 0.03

0.01 0.01 0.01 0.03 1.00

0.00 0.01 0.00 0.01 0.03

Rational Fraction Polynomial-Z

Modes 49.5 62.5 87.8 94.7 291.3 295.5

48.8 1.00 0.29 0.01 0.05 0.02 0.01

81.7 0.00 0.54 0.99 0.87 0.59 0.28

297.7 0.01 0.01 0.00 0.02 0.14 0.21

333.1 0.00 0.18 0.02 0.10 0.18 0.43

377.3 0.01 0.12 0.01 0.08 0.01 0.06

543.4 0.00 0.02 0.01 0.02 0.08 0.08

Figure 3: MAC for Polyref curve fitting (left) and CrossMAC for comparing RFP and Polyref (right)

5. Log decrement

Estimating the dampening coefficient of the time history data can be done using the log decrement

method across the duration of the response. The extracted dampened value is that of an analogous single

degree of freedom system. Figure 4 presents a log decrement procedure that has been performed. Log

decrement is not sensitive to noise and cannot reflect the underlying dynamics of a structure. It does

require computational requirements and is therefore not typically used during real time monitoring. Log

decrement is an efficient tool in detecting damage within a structure.

Figure 4: Log decrement results

6. Temporal moments

Temporal moments, analogous to statistical moments, are numerical values that are descriptive of the

overall nature of the output waveform. Each order represents a different temporal moment, with k = 0 – 4

being most common for Structural Health Monitoring applications. The temporal moments for these

orders are, Energy, Central Time, RMS Duration, Skewness, and Kurtosis, respectively. The following

table (Table 2) shows the temporal moments for the fifth test, accelerometers one and five. Temporal

moments are not sensitive to noise and can reflect the underlying dynamics of the structure. There are

some computational requirements making them not ideal for real-time monitoring. However, temporal

moments can be extremely useful in detecting damage within a system.

Table 2: Temporal Moments for the Fifth Test

Temporal Moment

Energy

Central Time

RMS Duration

Skewness

Kurtosis

Accelerometer 1

0.0274

0.3741

7.2783

162.43

3.89E+03

Accelerometer 5

0.0336

0.5244

10.8442

252.7172

6.16E+03

Page | 3

Appendix

MatLAB Rational Fraction Polynomial curve fitting for the frequency domain data

function mainrfp

rec=xlsread('Datatest.xls'); %get the test data, which contains the mangitude

%of each node for each frequency domain

omega=xlsread('Omega.xls'); %get the frequency domain

[alpha,par]=rfp(rec(:,1),omega,15);%the number of 15 is selected that 15

%natural frequency will be generated; and this function is to fit the

%tested frequency spectrum

plot(omega,rec(:,1),'r'), hold on;% plot the figure of test data on node #1;

%here,the number of 1 is selected to figure the frequency response spectrum

%of node #1

xlabel('Frequency (rad/sec)'),ylabel('Magnitude (dB)'),%plot the x and y

%lable of the figure

plot(omega,20*log10(abs(alpha)),'b'), hold off,%plot the estiamted frequency

%response spectrum of node #1

xlswrite('Node1.xlsx',par);%write the estimated natural frequency, damping

%ration, and etc. in to a xlsx file

end

Shown in below is an illustrative application of the MatLab code in the Appendix:

140

80

Test data

Fitted curve

60

Test data

120

Fitted curve

100

40

Magnitude (dB)

Magnitude (dB)

80

20

0

60

40

20

-20

0

-40

-20

-40

-60

-80

0

-60

1000

200

400

600

Frequency (rad/sec)

800

1000

3 modes (frequency from 0 to 1000 Hz)

1200

1400

1600

1800 2000 2200 2400

Frequency (rad/sec)

2600

2800

3000

3200

8 modes (frequency from 1000 to 3200 Hz)

Page | 4