adhesives

advertisement

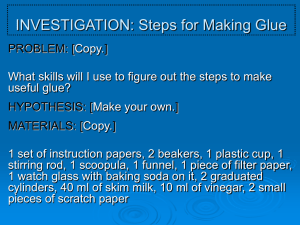

ADHESIVES 3 JOINERY ADHESIVES TWO MAIN INGREDIENTS – RESIN – GLUE SOLID SOLVENT – KEEPS LIQUIFIED UNTIL APPLIED ADHESIVES How does glue work? Specific adhesion - results from strong molecular attraction between the wood and the glue and for this to occur, the adhesive must penetrate the wood cells and "wet" the fibers. Cohesion - the force which makes the glue stick to itself. This is the solid glue "line" in a joint. It is the strongest when the two pieces to be joined are machined so they mate as closely as possible ADHESIVES HOW DO ADHESIVES CURE? SOME HARDEN (SOLVENT EVAPORATES) SOME CHANGE CHEMICALLY SOME HARDEN AS THEY COOL ADHESIVES GLUE PROPERTIES WORKABILITY DURABILITY ADHESIVES WORKING PROPERTIES SHELF OR POT LIFE OPEN ASSEMBLY TIME CLOSED ASSEMBLY TIME (IN CLAMP) CURE TIME (FULL STRENGTH) SANDABILITY WORKING TEMPERATURE RANGE STRENGTH ADHESIVES Hide Glue Polyvinyl Resin Glue (PVA) Aliphatic Resin Glue (Modified PVA) white glue – longer open time, harder to sand yellow glue – shorter open time, easier to sand Polyurethane glue – Gorilla Glue Contact Cement water based 3M Fast Bond 30 solvent based 3M Scotch Brand types ADHESIVES glue types-liquid hide Hide Glue - Titebond Liquid Hide provides superior creep-resistance, offers excellent sandability and is unaffected by finishes. Its sensitivity to moisture allows for easy disassembly of parts, a critical benefit in antique restoration or the repair of musical instruments. ADHESIVES types-PVA Titebond® Glue The cabinetmaker's standard. Titebond Original Wood Glue is the industry standard for woodworking. A ready-to-use aliphatic resin adhesive with outstanding strength. Also Titebond Dark Wood glue for dark woods is available It provides a strong initial tack and fast speed of set to reduce clamp time. It also develops a bond stronger than the wood itself, offers excellent sandability and is unaffected by finishes. The cabinetmaker's standard. Sets fast, sands easily and resists moisture. Available in regular original wood glue formula or in dark color formula for dark color woods. ADHESIVES types-PVA Titebond® II Premium Wood Glue Works great outdoors. Titebond II Premium Wood Glue is the only leading brand, one-part wood glue that passes the ANSI Type II waterresistance specification. It is ideal for exterior wood-working projects, including outdoor furniture, birdhouses, mailboxes, planters and picnic tables. Polyaliphatic Resin Polymer Titebond II Premium provides a strong initial tack, fast speed of set, superior strength and excellent sandability. It is FDA approved for indirect food contact (cutting boards) and is ideal for radio frequency (R-F) gluing systems. ADHESIVES polymer type – advanced Titebond™ III Ultimate Wood Glue Superior waterproof wood glue is ideal for exterior and interior woodworking! Available in five sizes. Stronger, safer, easier to clean up and less expensive than polyurethane glues. Allows eight minutes of open time and has an application temperature as low as 47º F. One hour clamp time! Cleans up with water. Does not foam. ADHESIVES types Titebond® Polyurethane Glue Good for indoors or outdoors. Titebond Polyurethane Glue is a breakthrough in adhesive technology. It is the only polyurethane glue to combine a long 20 minute working time with a short 45 minute clamp time. It is a versatile, professional-strength glue specifically formulated for multi-purpose applications. In addition to its superior wood-to-wood performance, Titebond Polyurethane Glue is ideal for metals, ceramics, most plastics, HPL, Corain, stone and other porous/non-porous materials. It is ready-to-use, offers excellent sandability and is unaffected by finishes. ADHESIVES types Gorilla Glue The original premium quality polyurethane glue now available in a smaller size! Gorilla bonds virtually everything, indoors or outdoors! No mixing required. Bonds wood, stone, metal, ceramics and plastics without a glue line. 100 percent waterproof. Environmentally safe once cured. Specifications Coverage: minimum of a 1/2 oz. per Sq. ft. Single-sided Open Working Time: 20 minutes or more Clamping Time:1-4 hrs. at 68°-130° F. Heavy hardwoods may require longer Cures: 90% in 1-4 hrs. 100% in 24 hrs. Temp. Range: 40-130° best at 68-130° Moisture Content: Best results from 10-25% Below 10%, apply water to non glue surface. Shelf Life: 3 yrs. + unopened. Up to 1 yr opened Expansion: Non-thermoplastic. Will not expand or contract in the glue line after hardening. ADHESIVES types - PVA Titebond® Wood Molding Glue Titebond Wood Molding Glue is the thickest, fastest-drying glue available for use with porous and semi-porous materials. It is ideal for finish trim, crown molding, baseboards, window casings and other applications requiring a professionalstrength, no-run wood glue. Titebond Wood Molding provides a strong initial tack and fast speed of set, yet allows realignment of working pieces. It also develops a bond stronger than the wood itself, offers excellent sandability and is unaffected by finishes. ADHESIVES Contact Adhesive types water based 3M Fast Bond 30NF solvent based 3M Scotch Grip Contact Adhesive 10 Uses – Plastic Laminate, veneers, edgebanding ADHESIVES types Your brain after using water based contact cement ADHESIVES Your brain after using solvent based contact cement types ADHESIVES Hot Melt Glue types ADHESIVES types – hot melt ADHESIVES clamping THREE REASONS TO USE CLAMPS: DRY FIT KEEP PARTS ALIGNED WHILE GLUE CURES MOST GLUES REQUIRE PRESSURE BRINGS MEMBERS INTO CONTACT SQUEEZE OUT AIR THIN OUT GLUE –NO THICKER THAN A PIECE OF PAPER ADHESIVES clamping Clamp Layout – 1” from edge and 8” to 10” intervals ADHESIVES clamping ADHESIVES clamping WOODEN CAULS ADHESIVES clamping HOW MUCH PRESSURE IS REQUIRED? Low Density Woods – 100 to 150 PSI Medium Density Woods – 150 to 250 PSI ALDER High Density Hardwoods – UP to 300 PSI PINE RED OAK HPL – 30 to 80 PSI Veneer – 100 to 125 PSI ADHESIVES clamping How Much Pressure Can Be Exerted By A Clamp? Wood Screw Clamp – 800 to 1000 # Bar Clamp – Up to 2000# C-clamp – 1000# Spring Clamp – 25# GLUING & WOOD MOVEMENT Wood Is Hygroscopic Most Movement Occurs Tangentially Wood Cups Towards The Bark Side GLUING AND WOOD MOVEMENT OVERALL EFFECT GLUING AND WOOD MOVEMENT OVERALL EFFECT WOOD MOVEMENT & GLUING Least Effective Joint Alignment TANGENTIAL FACE TANGENTIAL FACE WOOD MOVEMENT & GLUING More Effective RADIAL FACE TANGENTIAL FACE WOOD MOVEMENT & GLUING RADIAL FACE RADIAL FACE Most effective JOINERY SIDE GRAIN JOINTS STRONG JOINERY FLAT GRAIN JOINTS STRONG JOINERY END GRAIN TO END GRAIN WEAK JOINERY END GRAIN TO SIDE GRAIN WEAK JOINERY – OPEN MORTISE & TENON mortise & tenon JOINERY THROUGH TENON mortise & tenon JOINERY dado PLAIN DADO JOINERY STOP DADO dado JOINERY lap END LAP JOINERY RABBET JOINT corner joints JOINERY corner joints SPLINED CORNER JOINT JOINERY corner joints LOCK SHOULDER JOINERY DOVETAIL corner joints JOINERY miter MITER JOINT WITH SPLINE JOINERY EDGE TO EDGE SPLINE JOINT edge to edge DOWELED JOINTS The Strength Of A Doweled Assembly Is Directly Related To: The Tensile Strength Of The Dowels The Distance Between The Dowel Centers Half The Distance Between The Dowel Center And The Shoulder 3/ 8 " 1 1/ 4" 3/ 8 " DOWEL PLACEMENT 2” STILE & RAIL Strength of Dowels Distance between centers + ½ center of one dowel to shoulder 11/4” + (3/8”/2) = 1 7/16 1 7/16 X Sheer Strength of Dowel Increasing the distance between the dowel centers is twice as effective as increasing the shoulder between the dowel and the edge of the rail. DOWEL PLACEMENT 2” STILE & RAIL Strength of Dowels Distance between centers + ½ center of one dowel to shoulder 1” + (½”/2 ) = 1 ¼ DOWEL PLACEMENT 2” STILE & RAIL Strength of Dowels Distance between centers + ½ center of one dowel to shoulder Example: 3/8” + (3/4”/2) = 3/4 DOWEL PLACEMENT MAX. EFFECTIVE DOWEL LENGTHS (8:1) Dowel Diameter 1/4” 3/8” 1/2” Dowel Length 2” 3” 3 ½”