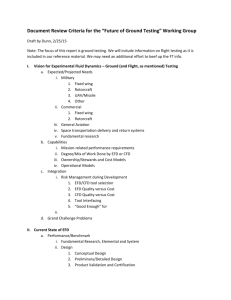

Document Review Criteria for the “Future of Ground

advertisement

Rev 4/2/15 Document Review Criteria for the “Future of Ground Testing” Working Group Draft by Dunn, 4/2/15 I. The focus of this report is ground testing. We will include information on flight testing as it is included in our reference material. We may need an additional effort to beef up the FT info. This is organized in a gap analysis structure: future vision, current state, opportunities and challenges (including “grand challenges”) The first part of this document lists the criteria for review. Please scan these prior to reviewing the paper. This is intended to show the intent of the type of info to be documented. The second part of this document lists topic areas. Please add your comments to each, as applicable. Write as much or as little as you want; we will be combining inputs for each paper. We really want to capture the author’s intent, add anything additional that you feel is important that is not captured by these topic areas. Vision for Experimental Fluid Dynamics – Ground (and Flight, as mentioned) Testing a. Expected/Projected Needs i. Military 1. Fixed wing 2. Rotorcraft 3. UAV/Missile 4. Other ii. Commercial 1. Fixed wing 2. Rotorcraft iii. General Aviation iv. Space transportation delivery and return systems v. Fundamental research b. Capabilities i. Mission-related performance requirements ii. Degree/Mix of Work Done by EFD or CFD iii. Ownership/Stewards and Cost Models iv. Operational Models c. Integration i. Risk Management during Development 1. EFD/CFD tool selection 2. EFD Quality versus Cost 3. CFD Quality versus Cost 4. Tool Interfacing 5. “Good Enough” for ii. Efficient, Cost-effective d. Grand Challenge Problems 1 Rev 4/2/15 II. Current State of EFD a. Performance/Benchmark i. Fundamental Research, Elemental and System ii. Design 1. Conceptual Design 2. Preliminary/Detailed Design 3. Product Validation and Certification b. Capabilities i. Mission area(s) Performance Availability 1. Physical condition a. Good or better condition b. Past design life c. Issues and at risk 2. Capability sustainment efficacy (maintenance, investments, skill management, operations and maintenance processes, budgets and business processes) 3. Improvement and modernization alignment with future market needs 4. Customer focus (for all customers ii. Staffing and Knowledge Management c. Integration i. Computational methods 1. Maturation of computational processes 2. How GT techniques and processes must evolve to support integration ii. Support to flight testing iii. Measurement and instrumentation technologies maturation, including teaming to define needs to measurement developers and producers (again, integrated with CFD and flight test) iv. Government and industry development, proprietary versus open source III. EFD/Ground Testing Technology Gaps and Impediments a. [Note: This is likely a work product from assessing the first two sections. Included to capture anything already identified in the references.] IV. Technology Development Plan a. [Address the gaps] Additional Considerations There will be additional info that doesn’t fit into the above categories and we still need to capture that and then figure out how it fits into our paper. The following is a start at some of this potential info. V. Internal and External Environments a. Interdependencies within the RDT&E process and risks associated with potential loss of GT capabilities 2 Rev 4/2/15 b. b. c. d. e. i. Example: Accepting higher risk by not understanding product performance such that defects appear late in the RDT&E life cycle -- very costly to fix late Facility owner needs and issues i. Mission requirements and priorities ii. Condition of facilities iii. Capability sustainment efficacy (maintenance, investments, skill management, operations and maintenance processes, budgets and business processes iv. Improvement and modernization alignment with future market needs v. Customer focus/service Producer risk management needs and issues i. [Definition note: risk management is the definition of hazards, the probability a hazard will happen, the potential severity/impact when it happens, an initial risk level assessment, development and application of specific mitigators to a high risk hazard, and a reassessment of risk with mitigators in place. Process continues until hazards are well understood and risk levels have been mitigated down to acceptable levels.] ii. Always a trade to define GT and CFD requirements to drive risk down for specific hazards iii. CFD mostly requires validation (typically via GT or FT) iv. GT and CFD also used to define some hazards Economic impacts i. United States, EU and Great Britain, Japan ii. Breakouts based on GDP, jobs, net imports/exports iii. Technology spin-offs, estimate of additional positive impact on GDP Education impact (STEM support, Environmental headwinds and support (in addition to cited above, add geopolitical considerations, overall economic indicators, national and international politics (regulations/laws, taxation, market support or not, more) VI. Needs and Capabilities a. Computational methods i. Code validation ii. Interactive development b. Flight testing investigations c. In service product anomaly investigations d. Measurement and instrumentation technologies development e. Role in RDT&E process, at each stage; percent and relative importance of knowledge gained at each stage; degree of risk identified and managed at each stage for different kinds of systems at different levels of maturation f. Market environment, growing, stagnant/mature, declining, cyclical i. Low/subsonic speed ii. Transonic speed iii. Supersonic speed iv. Hypersonic speed 3 Rev 4/2/15 Document Review Form for Capturing Information from Selected GT References References and reviewers were identified at the SciTech meeting. Each reviewer should use this form – hand or type written – to capture info as a document is reviewed. Send completed reviews to Steve Dunn at steven.c.dunn@nasa.gov. Reviewer: _Eric Schuch___________________________ Reference Document Title: __Revitalizing AEDC Workforce Tech Exc AIAA2008-1611__ Date of Review: _5/31/2015__________ Please fill in each topic area, as applicable (add space as needed): I. Vision for Experimental Fluid Dynamics – Ground (and Flight, as mentioned) Testing a. List/describe future technologies/configurations in terms of Expected/Projected Needs b. What capabilities will be needed and how will they need to work and be managed? c. Integration of CFD and Ground/Flight Testing (includes risk management during research and product development) d. Grand Challenge Problems II. Current State of EFD a. Performance/Benchmark – types of capabilities/test techniques, where it works best, best practices, how do we know b. Capabilities i. Mission area(s) Performance Availability (strengths and weaknesses associated with condition, investments, capability sustainment, reliability, customer focus/satisfaction) ii. Staffing and knowledge management This paper provides a robust approach to managing and revitalizing workforce knowledge. The 6 key attributes below are expanded on in the paper. “In reviewing the almost six-decade history of AEDC, the teams found that several key attributes that historically contributed to building technical excellence are still in evidence: A. Excitement in and innovation potential of the mission B. Organizational and leadership emphasis on technical excellence C. Opportunities for the staff to be technical and create knowledge D. Technical collaboration E. Focused emphasis on developing technical people F. Knowledge archiving These six attributes link directly to the four strategic thrusts defined by the steering committee.” 4 Rev 4/2/15 Which are: “1. Management and Availability of Technical Knowledge 2. Development of the Technical Workforce 3. Enhancement of the Depth/Breadth of AEDC Technical Contributions 4. Establishment and Management of an Environment Conducive to Technical Enhancement” c. Integration i. Computational methods 1. Maturation of computational processes 2. How GT techniques and processes must evolve to support integration ii. Support to flight testing iii. Measurement and instrumentation technologies maturation, including teaming to define needs to measurement developers and producers (again, integrated with CFD and flight test) iv. Government and industry development, proprietary versus open source III. EFD/Ground Testing Technology Gaps and Impediments a. [Note: This is likely a work product from assessing the first two sections. Included to capture anything already identified in the references.] “Several areas that need extensive reengineering include: 1. Early integrated use of high-fidelity physics modeling with ground testing to determine system integration issues (e.g., airframe/structure, airframe/propulsion) as early as possible in the development cycle. Integration issues are a common cause of late defect discovery. 2. A complete reexamination of flight system, aeropropulsion system, and space & missile system ground-test approaches to try to reduce significantly the traditional number of hours used. 3. A comprehensive understanding of the impact of ground testing on late defect discovery and a corresponding development of improved testing methodologies and processes for scaling of ground data to flight conditions robust enough to avoid late defect discovery.” Under the “Fostering Technical Collaboration” section the author suggests three areas that could be focused on: An integrated use of advanced computational fluid dynamics (CFD) codes, modern design of experiments (MDOE), and "fly the mission" testing techniques to reduce the overall test hours in a wind tunnel “campaign”. Today it takes approximately 2.5 million data points in a wind tunnel test program to develop the stability and control (S&C) and performance laws database for a SUT. This amount of wind tunnel testing drives cycle time for system development, which is one of the key D&SWS effectiveness measures. A basic theoretical/experimental/computational study of scaling principles for vortex-dominated or massively separated flows. Current wind tunnel scaling principles are based on circa 1975 studies of Reynolds Number scaling of attached flows on transport configurations. For military aircraft, high angle of attack (alpha) is a more common state and can have a strong influence on structures, control response, and other design parameters (e.g., vortex breakdown on vertical tails, control surface effectiveness, control system gains). Concomitant with the high-alpha study above, the same collaborative effort could help develop a database for validation of the next generation of CFD codes. 5 Rev 4/2/15 IV. Technology Development Plan a. [Address the gaps – include anything already identified in the references.] Additional Considerations There will be additional info that doesn’t fit into the above categories and we still need to capture that and then figure out how it fits into our paper. The following is a start at some of this potential info. V. Internal and External Environments An interesting comment on cost & schedule overruns due to the lack of maturity of new technologies. I feel this makes a good case for ground test. “One of the key factors contributing to cost and schedule overruns in major acquisition programs has been the lack of maturity of new technologies injected into the system design. Recent General Accounting Office (GAO) reports have clearly illustrated the impact of immature technologies on acquisition program cost and schedule. For new technologies with a Technology Readiness Level (TRL) (Ref 7) of six or greater, cost overruns average less than three percent. On the other hand, for those acquisition programs with immature technologies, cost overruns on average approach 30 percent. (Ref 8)” VII. Needs and Capabilities (not covered above) 6