Vision for 2030

advertisement

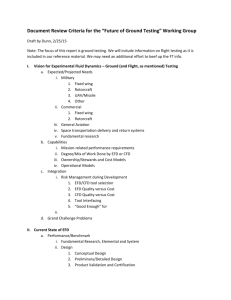

Role and Importance of Experimental and Computational Fluid Dynamics Capabilities In the United States Aerospace Industry Research, Development, Test, and Evaluation Process Working Draft by Dunn March 1, 2015 1 Content Subject Problem Environment Vision for 2030 Approach Background Progress at SciTech and Path Forward Tracking Progress Note on Engagement References Backup Slides Slide # 3 4 5 6 7-13 14-17 18 19 2 Problem The development of new or updated aerospace products in the United States requires robust national science and technology (S&T) research that feeds a development, test, and evaluation (DT&E) process for that new product. The fundamental experimental and computational tools of both the S&T and DT&E processes are not well coordinated at a National level. This puts capabilities at risk (degraded performance or closure) and forces use of tools by researchers and developers that inadequately manage risk. There is a need to define the integrated S&T and DT&E capabilities required to support the nation’s needs through the year 2030 and to ensure that national stakeholders and decision makers understand how this works and why it is important. 3 S&T and DT&E Tools: Environment 1. 2. 3. 4. 5. Experimental ground test capabilities in the United States, in many cases still at or among the best in the world, are at risk. Tightening budgets and reduced workload has driven the closure of excess capacity and, in some cases, loss of National capability. a. Capability sustainment decisions are increasingly being made with one to two year outlooks and often using local budgets that are static or shrinking. (It is expensive to operate and maintain large ground test facilities.) b. Aerospace research budgets in government, industry, and academia are at risk and have significantly declined over the last 30 years. c. Experimental workload has decreased due to government budget constraints, industry consolidation, and the changing nature of the RDT&E process utilization of computational methods. NASA capabilities are being focused on NASA direct mission support; support of technologies currently aligned with primarily military application is being limited. Expenses for ground testing facilities are often charged directly to customers while expenses for computational capabilities are often highly subsidized. There is widespread misunderstanding regarding the ability of computational methods to predict actual aerodynamic behavior, leading to the belief that experimental capabilities are no longer needed. 4 Vision for 2030 S&T and DT&E computational and experimental tools are used to design to and measure against defined requirements. Over time, many new aerospace products have become more complex, trying to address multiple needs on a single platform, often with changing requirements. DT&E life cycles have increased, often with significant defects found late, impacting time and cost. The vision for 2030 is that: • Research has provided usable new technologies, • New or updated product requirements are stable early, • The right tools are available and used in an integrated manner to develop and deliver a product in a timely and cost effective manner, • Risks are identified and mitigated to acceptable levels early in the DT&E life cycle, and • New or updated product development occurs within a total systems engineering construct. 5 Approach Accomplish a national effort that defines the appropriate S&T and DT&E tools and processes required to support a robust (cost effective, timely, at needed quality) range of new aerospace product developments. Develop a map out to the year 2030 that defines specific actions to be taken in terms of: • • • • Computational fluid dynamics, Experimental fluid dynamics, including both ground and flight testing, Risk management, related to both research and specific products across the DT&E life cycle, and Assimilation with product total systems engineering. A wealth of information (reports, studies, papers) already exists that this effort can draw on to build an integrated vision. Utilize these sources to produce a formal document and associated briefing by the end of FY16. 6 Background The next several slides provide background: • • • • • Research S&T “Engine” Product DT&E life cycle Complementary EFD and CFD Risk Management across the DT&E life cycle Assimilation within the Total Product System 7 Research (S&T) Engine Investments required to establish research capabilities Research Element System Integration Experimental Fluid Dynamics • Basic services infrastructure • Test capability infrastructure • Test techniques/capabilities • Measurement technologies • People trained & certified • Calibration and validation Code Development • Software tools • Adaptation to purpose • Code validation • Skilled people • Compute infrastructure Science & Technology (S&T) Capabilities Experimental Ground Test/ Laboratories Experimental Ground Test/ Laboratories Computational Methods Computational Methods Prior Research Prior Research Prior Products Prior Products Research Element: Can be aero-based or measurement/ capability/ technique – using EFD, CFD, lab or (likely) some combination. Includes researcher subject matter expertise. 8 Product Development (DT&E) Life Cycle Market Need Problem: Resulting from inadequate earlier risk management (hazard identification criticality, mitigation, and system integration) Problem Cycle PRODUCT IDEA! Multiple Research Elements, Systems Research, and Prior Product Knowledge Base Develop Fix Configure Form of Product Integrated Req’mts and Basic Concept Integrated Model/ Code Devel’mt Problem New Product Exploration [Concept Dev’mt and Selection Product Devel’mt Flight Test Initial Production Go/No-go Decision Utilize EFD/CFD for Development, Test & Evaluation Risk Management and Business Case Technical Financial Integrated performance Capitalization Market need and forces (includes Cost model, product life cycle competition) Revenue model, life cycle Includes economic climate Regulatory/government environment 9 Computational Capabilities Experimental and Computational Tool Needs Dependencies Physics Needs Experimental Capabilities How do we decompose this problem? Identify the required capabilities across the RDT&E life cycle for each major aero market area. 10 Experimental and Computational Development Co-dependencies (Example) Experimental Aerodynamics Acoustics Aerothermodynamics Hypersonic Air. Prop. Materials & Structures Measurem’t Flow Physics Flight Dynamics Crew Systems Simulators Laser/Lidar Aircraft Flight Testing Strong (A/E) Low Low Low Strong N/A Low N/A Low N/A Low N/A N/A Low low Strong N/A Low N/A N/A N/A Low Strong Strong Strong Strong Strong (A/E) Strong N/A Low N/A N/A Strong Moderate N/A Moderate Moderate Low Low Strong Moderate Moderate N/A Strong Low Low N/A N/A N/A N/A Strong Strong Strong Low Strong Moderate Moderate Moderate Moderate Moderate N/A Moderate N/A N/A N/A Low Low N/A N/A N/A N/A Low N/A Low N/A Strong Strong Codes Structures and Materials: Finite Element Methods Structural Dynamics Damage Mechanics Quantum Mechanics Computational Chemistry Molecular Dynamics Physics codes: measurement science Thermal Ultrasonic Optical (Gausian, Quantum Mechanics) Electromagnetic Radiation Transport (GRC) Flow Physics (CFD codes): Navier-Stokes (multiple methods) Acoustics (noise source/transmission) Hyp Propulsion (CFD+Combustion) Aeroelasticity / Aeroservoelasticity (A/E) Aerothermodynamics Flight Dynamics and Controls: GN&C (System ID, Adaptive) Flight Vehicle/Pilot simulation CFD for Stability and Control Aviation Operations: Air Traffic System & ATM Wake Vortex Turbulence & Weather Flight Deck (Vision Sim, Flight Mgmt) Multidisciplinary Codes: Systems Concepts Multidisciplinary Analysis Design Optimization Earth’s Atmosphere & Climate Radiative Transfer Data Assimilation Cloud Modeling Chemistry-transport (gas & aerosol) Atmospheric Trajectory Analysis Source: "Integrated Strategy for LaRC Facilities and Laboratories", developed by Charles E. Harris, March 2012 Strong Moderate Low None or N/A 11 DT&E Life Cycle Risk Management • Risk is managed over the DT&E life cycle WRT: – Complexity of what is being designed or developed – Maturity of design – Level of fidelity based on requirements definition • If risk is poorly managed, defects migrate to later phases • Methodology to match EFD and CFD tools to risk scenarios (Taken from Walker, et. al, 2015) 12 Total Product System Approaches • The complexity and cost of developing, operating, and maintaining major aerospace systems is driving efforts by major producers and owners to manage products from “cradle to grave” using total system approaches; examples: – NASA’s Comprehensive Digital Transformation Plan, Strategic Space Technology Investment Plan, and Virtual Research and Design (Digital Twin) – USAF Digital Thread – [Industry examples . . .] • The S&T and DT&E tools addressed in this effort typically are embedded as part of these comprehensive system life cycle management processes 13 Progress at SciTech and Path Forward 1. The goal at SciTech was to expand the skill base to include computational expertise, update the scope to define specific deliverables, and define detailed activities for the next six months a. 2. Met with a combined CFD and EFD group to develop how we could work together, building on the CFD Vision 2030 report a. 3. Held two formal meetings and several planned one-on-one interactions to develop support/advocacy and for integration with other efforts Well attended and good interest in teaming; need a cross-cutting working group Met for a full team meeting and mapped out plan and actions (more info on following three pages) a. EFD team to develop GT meta-analysis based on major publications assessing the GT environment; defined specific actions to complete b. In parallel, assemble joint team to organize the approach for producing an integrated assessment of EFD and CFD requirements across the RDT&E life cycle. Seeking funded effort. c. AIAA cross-cutting team to develop information advocacy briefing for nonengineers based on report foundational info 14 Product 1: EFD (GT) Meta-Analysis 1. Logistics a. b. c. d. e. Writing team formed at SciTech from current working group members Defined 18 reports/papers to review, including reviewers and a common review format to support information synthesis Reviews planned to be complete by 31 March 2015 A core writing team was formed to combine reviews and produce the analysis. Draft document by June 1, 2015; complete for presentation at SciTech 2016 2. Form/Product a. b. c. d. Organize the information into a SWOT format (Strengths, Weaknesses, Opportunities, Threats) assessment over time – project forward toward 2030. Review the CFD Vision 2030 Report to map out primary needs for different product groups Align the GT meta-analysis construct with the CFD Vision 2030 Report construct Prepare a formal conference paper to document the findings. 15 Product 2: RDT&E EFD/CFD Vision 2030 1. Logistics a. Form a core writing team and an advisory review team from multiple (related) technical communities i. ii. iii. iv. b. c. Proposing a funded effort with a National chair and significant participation from industry, academia, and government across the technical disciplines; CFD Vision 2030 report cost $350k Builds on CFD Vision 2030 report, the GT meta-analysis, and other information sources. Discussions about possibly holding a workshop; TBD. i. d. Computational modeling/simulation Experimental ground testing Experimental flight testing Advanced measurement techniques Aligned with other efforts (i.e., DoD digital thread) Define audience and expected report impact 2. Form/Product a. b. c. Start in Summer or Fall 2015; funding dependent. Support a panel discussion at AIAA SciTech 2015 Forum 360 Produce a “reach for” reference report document for decision makers and stakeholders 16 Product 3: RDT&E Information Advocacy Briefing 1. Logistics a. b. Build an information advocacy briefing on the technical foundation of the RDT&E EFD/CFD Vision 2030 report Purpose is to educate about the importance of EFD and CFD capabilities in the new/updated product RDT&E process and the resulting aero industry role and contribution to the Nation i. c. Based on the expectation that most stakeholders and decision-makers don’t understand the EFD/CFD tools required for the RDT&E process Communicates in forms financial and political (non-engineering) people can understand and use – why this is important to them i. Interact with educator and political functionaries for advise, review, and input -- need to produce in a form that will be understood d. Produced by representatives from multiple AIAA TC’s (cannot be part of the funded report effort) a. 2. Utilize and support AIAA public policy function Form/Product a. b. c. Product is sourced, peer-reviewed Powerpoint briefing Present at Aviation 2016 or SciTech 2017 Forum 360 Disseminate for use across AIAA 17 Tracking Progress 1. This plan, including additional detail and periodic progress reports, will be posted on a website created to support this effort at: https://info.aiaa.org/tac/ASG/GTTC/Future%20of%20Ground%20Test %20Working%20Group/Forms/AllItems.aspx 2. Monthly progress phone calls will occur from March through the end of the 2015 3. Progress will be tracked by Dunn and interim work products will be posted on the website Please direct any questions and/or comments to Dr. Steven Dunn at steven.c.dunn@nasa.gov 18 Note on Engaging This could be great work and excellent reports and briefings – that nobody reads or uses. We must define our audience – what stakeholders and decisionmakers need this information to help with what they do? Thus, we also must develop an engagement plan. Not just for the authors, major players, and “higher-ups”, but for how we can build a groundswell of support so people from all walks and stations will engage locally! 19 Backup Slides 20 Aero Industry Markets Annual Market* ($B) USA World XXX.X SUBSONIC TRANSONIC XXX.X 0 0.7 1.2 SUPERSONIC (Mach Number) [Note: Where to include RDT&E capability investment and sustainment? Embedded or separate?] HYPERSONIC 5 X.X XX.X X.X X.X XX.X XX.X FIXED WING XX.X XX.X FIGHTERS, ISR, HS BOMBERS X.X XX.X GEN. AVIATION X.X XX.X UAVs X.X XX.X MISSILES X.X XX.X SPACE LAUNCH TRANSPORATION, SUBORBITAL TRANSPORTATION X.X X.X 18+ RESEARCH (Academia, Industry, Government) ROTORCRAFT * Data Source: Teal Group/Aboulafia Commercial Transports, Some Bombers ENTRY, DESCENT, LANDING FROM SPACE 21 Aerospace Industry Economic Engine Research New Product Development US Economy World Economy Spin-offs (non-aero) - Technologies - New Products Environment • Market (customer) needs • Safety requirements and expectations • Stovepiped national capabilities • Uncertain space strategy • Sluggish US economy • Gov’t regulation generally increasing • Uncertain gov’t economic policies Forces • National defense and force projection needs • US and international competition • Speed to market • Minimalist budget thinking • Government vs. industry roles • Low initial cost vs. life cycle best value 22 Why Is This Important? The aerospace/aeronautics industry is critical to the well-being of the United States in terms of the: • • Economy – Aviation (Civil and General)* – Aerospace Total** • – $1.3 trillion in total U.S. economic activity 10.2 million direct and indirect jobs $47.2B positive trade balance >5% of USA GDP >$1.5 Trillion in freight transport per year $63.5B positive trade balance National defense – • o o o o o – – Provides for many of the strategic and tactical needs of the warfighter, including strike; air superiority; command, control, intelligence, surveillance, and reconnaissance; and airlift Homeland defense and security (air and space) Initial product/capability development before transitioning to commercial applications Quality of life – Aviation safety – Provides a key component to disaster recovery and law enforcement activity, as well as humanitarian operations. – Spin-off technologies used for a variety of purposes – Earth climate investigation tools and technologies Exploration and learning (education and growth) – Provides inspiration for STEM education fields – Learn more, to figure out things we don't understand, and to explore the unknown * NASA ARMD Strategic Vision 2013 ** Aerospace Industries Association, 2013 23 Consider . . . "As part of my participation in the military, my conviction is that even if the research and development is made for military purposes, the experience shows in civil aviation profits. So I believe that what will help in the military is not only for making war, but contributes very much to the progress of technology in general.“ Dr. Theodore Von Karmin in 1944 “Remember that the seed comes first; if you are to reap a harvest of aeronautical development, you must plant the seed called experimental research.” Col Hap Arnold in 1937 "research is a peace-time thing and ...moves too slowly to be done after you get into trouble.“ Dr. Robert Milliken in 1934 All taken from sourced quotes in Daso, 1996. 24 Engaging . . . “We learn by hooking into what we already know.“ “… scientists being able to explain what they do and why it is important.” From a seminar at the Alan Alda Center for Communicating Science, at Stony Brook University, New York, 2013 25 Risk of Losing Key National EFD Capabilities Is Increasing • Factors driving risk – – – – – – – – – – Aging and inefficient physical infrastructure Workforce demographics Maintenance stretched across old and repurposed facilities New/updated capability and productivity investments Organizational stovepiping by capability owners Funding models/methods variability/inconsistency Cyclical and declining workloads Tightening sustainment budgets Understanding (lack) of role of GT in the aero RDT&E process Short term outlooks for political cycles and business performance • Demonstrated responses to these risks – Reduced sustainment and investment (degrades capabilities) – Reduced availability (block, sequential, spaced, limited operations) – Reduced or eliminated capabilities and/or capacities • Facility/capability stand down or mothball • Facility/capability abandonment/closure 26 Challenges Notional Organizational Alignment (Each organization has a strategy and associated plans) US DoD NASA AFRL US Government LaRC AFTC WFF & GFSC DARPA AEDC MDA Others Rotorcraft Others FAA Industry • • Multiple Markets – See chart Many with RDT&E Capabilities Army Armaments International • • • Missiles Fundamental Research Military Applications Civilian Applications Aircraft Navy Missiles Armaments Academia 27 Economics of Ground Testing A Possible Scenario Equation: Capability Development and Sustainment Costs versus Direct and Indirect Benefit to the US and the World • Assume – – – – Market economy complete product turnover over next 30 years Average 2% annual growth across all market segments Baseline is FY2012 Existing GT capabilities are sunk cost • Costs – Develop and sustain capabilities – Invest in new technologies and applications (capabilities and efficiencies) • Benefits – GT contribution to research feeds new product development – GT contribution to new product risk management [show relative to contribution at each step of the RDT&E process] – Estimate range and dollar value of impacts Extreme case: All EFD facilities are closed/mothballed by 2020 Likely case: EFD workload will continue to decline and capabilities and capacities will decline by a like amount 28 Working Group Literature Review Initial Draft of Topic Areas From literature and personal experience/opinion • Build on legacy of today and yesterday; project forward – Research needs – Product development needs • Workload projections by market, US and world – By speed range, mission (within market), new products • • • • • • • • • • Evolving roles and use of EFD and CFD Detections of product problems, early and for remediation Aero market spin-offs/contributions to other markets Facility/capability risk factors: status, how being addressed, impacts Environment factors and market forces over next years EFD as part of the product business case Capability investment projections Why are facilities being/have been closed? Why is work not there? Misconceptions in the public domain. Risk posture/allowable risk 29 Possible Work Breakdown Structure for the Integrated CFD/EFD Role in the RDT&E Process I. Product Process A. B. C. D. Research Development Test Evaluation II. Market Areas, Mission Needs, Projections III. Tools Overview A. Experimental Testing and Measurement 1. Ground Testing 2. Flight Testing 3. Measurement Technologies B. Computational Modeling and Simulation IV. Ground Test Computational Dependencies A. Computational Discipline Trajectory (CFD Vision 2030) B. Ground Test Discipline Trajectory (Ongoing Lit Review and Meta-Analysis) C. Overlay D. Flight Test Interfaces E. Measurement Technologies Integration V. Define the Path Forward: Prepare the Integrated Roadmap to 2030 A. Develop an Integrated Master Schedule 1. 2. 3. 4. 5. Related (and adjustable) to needs Identified dependencies Major milestones Specific, actionable products Cost estimates where available; further study will be required as scope and timing becomes more specific B. Develop a work prioritization methodology that balances: 1. 2. 3. 4. National needs Technical Risk Business Case Organizational Needs C. Develop an initial (even notional) product responsibility matrix D. Propose how this work product will be maintained and updated 30