Joraa001_presentation

advertisement

A Constraint Programming Approach to

Solving a Ship Loading Problem

Andreas Jordan

Professor Markus Stumptner

Background

• Currently, load plans for amphibious ships are

• created by ‘dragging and dropping’ representative size

boxes into a trim and stability software program.

• There is a requirement for some automated support

• when planning loads for both the amphibious ‘mother

ships’ and associated watercraft conducting landings /

withdrawals.

2

Objectives

• The primary objective

• minimise the space used by the loads => minimising the

number of amphibious ships and watercraft to conduct

operations.

• Near-optimal solutions preferred within the order of

seconds

• The load must also produce a stable load plan

3

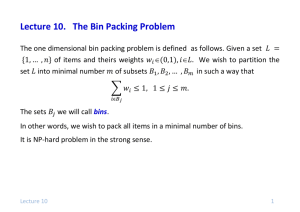

Problem Description

• Belongs to the general class of “Bin Packing Problems”

• Description:

• The packing of a finite number of rectangles into a number of larger

sized bins where:

• No items are allowed to extend past the edges of the bin nor any overlap

permitted.

• The challenge is to assign all the items, with no overlap, to the minimum

number of bins with their edges parallel to those of the bins.

• Problem is NP-Hard (ie. cannot be solved in polynomial time)

• Exhaustive search impractical. Therefore, heuristical

methods are required for most practical problems.

4

Sourcing Software

• Description of problem readily lends itself to modelling as a

Constraint Optimisation Problem (COP)

• Possible choices:•

•

•

•

•

Matlab

Eclipse

Prolog

ILOG CPLEX®

Comet

• Selection criteria

•

•

•

•

Acquisition costs

Optimised libraries with pre-built constraint-reasoning functionality

Availability of Global Constraints (eg. selectMin)

=> Comet

5

Modelling as a Constraint Optimisation Problem

• Determine the finite domain decision variables

•

•

•

•

Packing – establishes a relationship between an item and a bin. eg.

Load – tracks the current load of each bin

X – represents x-positions within each bin

Y – represents y-positions within each bin

• Domains

• Items – represents the number of items to be packed

• Bins – total number of bins

• Constraints

• Constrain load of bin

• Constrain placement of items within bin

• Minimise the number bins used to pack items

6

Packing Heuristic Selection

• Several packing algorithms exist, including:• Finite-First-Fit

• Bottom-Left-Fill

• …and many more

• Most not suitable for this application:• they typically require items to be sorted in non-decreasing order

• no advantage taken of additional attributes (eg. weight)

• Key requirements, including:• Prioritisation of items – Strict, Flexible and None

• Stability of packing (lateral and longitudinal)

• Can make no assumptions about the distribution of item sizes

7

Packing Barrier (Heidelberg et al,1998)

• Nine barrier types

•

•

•

•

C, RL, LR, LCR, CLR, LRC, RCL, RLC, CRL

Barrier composed of (up to) 5 segments

Pack item into lowest barrier

LX, LY, CX, RX, RY represent cartesian barrier coordinates

LX

C

RL

LR

LCR

CLR

LRC

RCL

RLC

CRL

LY

RY

CX

RX

Packed items

8

Representing Variables in Comet

• Example

• var<CP>{int} packing[Items](cp, Bins);

• Explanation

• Var<CP> - declaration for a finite domain decision variable

• {int} – declares that the domain comprises discrete integers

• packing[Items] – name of variable where “Items” represent the

range of variables associated with ‘packing’

• (cp, Bins) - range of valid integer values that each variable can

take.

• This representation allows the constraint solver to reason

• packing[1] = 1..12

•…

• packing[100] = 1..12

9

Representing Constraints in Comet

Solver<CP> cp();

//declare the variables

Solve<cp>{

//post the constraints

//Constraint which ensures that the load of any bin is less than

or equal to a bins capacity

forall(b in Bins)

cp.post((load[b] == sum(i in Items)

(packing[i]==b)*itemWeight[i]) && load[b] <= binCapacity_) ;

} using{

//non deterministic search

}

10

Preliminary Results

• 4 items

==== Post-processing Results ====

Solution found with: 2 bins

load[43800,42000,0,0,0,0,0,0,0,0]

packing[1,2,1,1]

x[0,0,34,44]

y[0,0,0,0]

#Choices = 8

#fail = 0

Time: 0 seconds

==== End ====

• 8 items

==== Post-processing Results ====

Solution found with: 2 bins

load[45400,44000,0,0,0,0,0,0,0,0]

packing[1,2,1,1,1,2,2]

x[0,0,34,0,18,0,15]

y[0,0,0,96,96,96,96]

#Choices = 39728

#fail = 158149

Time: 4 seconds

==== End ====

• >8 items (using Windows machine with 2GB RAM)

• runs out of virtual ram after approximately 3 hours

11

Further Work

• Implement item placement based on multi-tiered

priorities

• Incorporate centre-of-gravity calculations to build

solutions already favouring a stable load

• Automatic barrier adjustment after failing to insert any

items

• Adjust upper bound on item length to be uppermost

adjacent level plus/minus a tolerance, t.

• Incorporate No-Go zones

12

Thankyou

• Questions?

Source:

Wikipedia

…different watercraft and ship types should be considered

Source: http://www.tomw.net.au/technology/transport/amphibious.shtml

13

References

• Dyckhoff, H 1990, 'A typology of cutting and packing problems', European

Journal of Operational Research, vol. 44, no. 2, pp. 145-159.

• Sexton, J, et al. 2004, Efficient Solutions in Load Planning, DEFENCE

SCIENCE AND TECHNOLOGY ORGANISATION SALISBURY

(AUSTRALIA) SYSTEMS SCIENCES LAB.

14