A scheduling based in MILP for non

advertisement

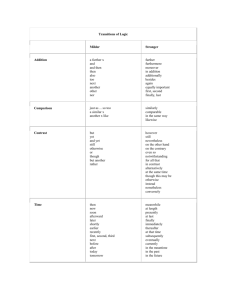

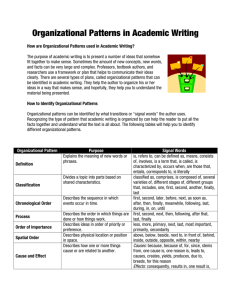

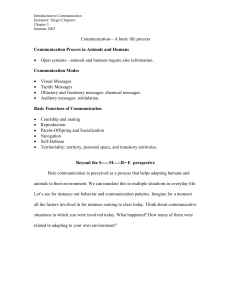

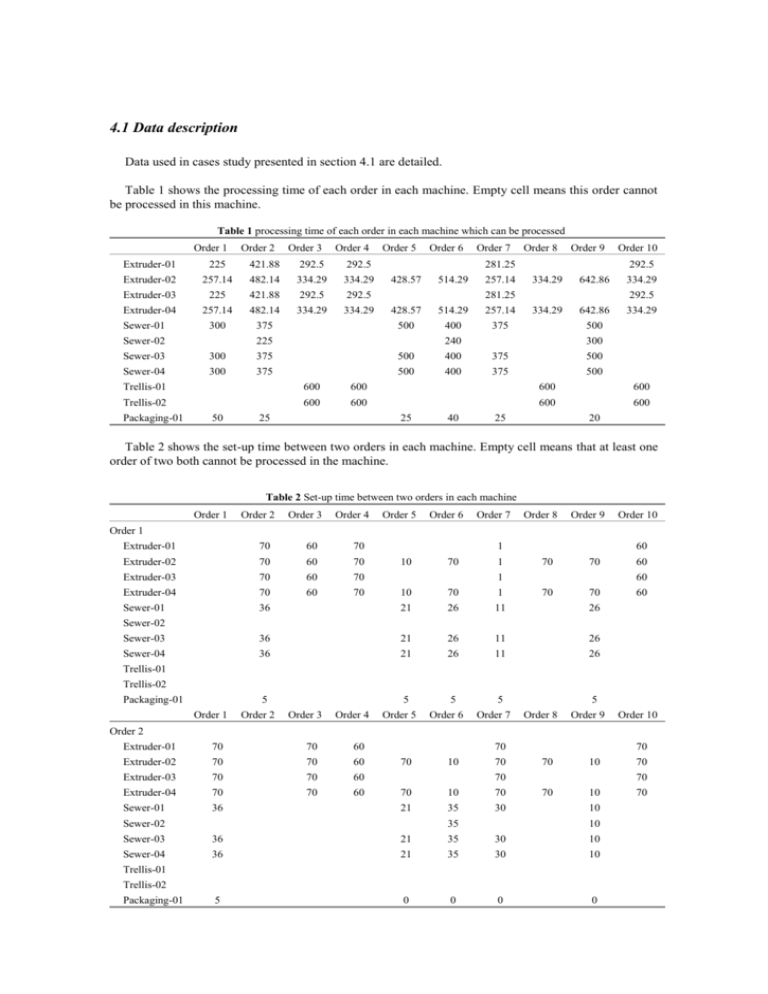

4.1 Data description Data used in cases study presented in section 4.1 are detailed. Table 1 shows the processing time of each order in each machine. Empty cell means this order cannot be processed in this machine. Table 1 processing time of each order in each machine which can be processed Order 3 Order 4 Extruder-01 Order 1 225 421.88 292.5 292.5 Extruder-02 257.14 482.14 334.29 334.29 Extruder-03 225 421.88 292.5 292.5 Extruder-04 257.14 482.14 334.29 334.29 300 375 Sewer-01 Sewer-02 Order 2 Order 5 Order 6 Order 7 Order 8 Order 9 281.25 428.57 514.29 257.14 428.57 514.29 257.14 500 400 375 292.5 334.29 642.86 334.29 334.29 642.86 334.29 281.25 225 Order 10 292.5 500 240 300 Sewer-03 300 375 500 400 375 Sewer-04 300 375 500 400 375 500 500 Trellis-01 600 600 600 600 Trellis-02 600 600 600 600 Packaging-01 50 25 25 40 25 20 Table 2 shows the set-up time between two orders in each machine. Empty cell means that at least one order of two both cannot be processed in the machine. Table 2 Set-up time between two orders in each machine Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 1 Extruder-01 70 60 70 Extruder-02 70 60 70 1 Extruder-03 70 60 70 Extruder-04 70 60 70 10 70 1 Sewer-01 36 21 26 11 26 Sewer-03 36 21 26 11 26 Sewer-04 36 21 26 11 26 5 5 5 5 5 10 70 1 60 70 70 1 60 60 70 70 60 Sewer-02 Trellis-01 Trellis-02 Packaging-01 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 2 Extruder-01 70 70 60 Extruder-02 70 70 60 Extruder-03 70 70 60 Extruder-04 70 70 60 Sewer-01 70 70 10 70 70 70 10 70 10 70 70 70 10 70 36 21 35 30 Sewer-03 36 21 35 30 10 Sewer-04 36 21 35 30 10 5 0 0 0 0 Sewer-02 35 10 10 Trellis-01 Trellis-02 Packaging-01 70 70 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 3 Extruder-01 60 70 10 Extruder-02 60 70 10 Extruder-03 60 70 10 Extruder-04 60 70 10 60 70 70 70 70 60 0 10 70 10 70 60 60 0 0 0 Sewer-01 Sewer-02 Sewer-03 Sewer-04 Trellis-01 5 5 0 Trellis-02 5 5 0 Packaging-01 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 4 Extruder-01 70 60 10 Extruder-02 70 60 10 Extruder-03 70 60 10 Extruder-04 70 60 10 70 70 70 70 10 10 70 10 70 70 70 70 70 10 10 10 Sewer-01 Sewer-02 Sewer-03 Sewer-04 Trellis-01 5 5 5 Trellis-02 5 5 5 Packaging-01 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 5 Extruder-01 Extruder-02 10 70 70 70 70 10 60 60 70 Extruder-04 10 70 70 70 70 10 60 60 70 Sewer-01 21 21 25 30 5 Sewer-03 21 21 25 30 5 Sewer-04 21 21 25 30 5 5 0 0 0 0 Extruder-03 Sewer-02 Trellis-01 Trellis-02 Packaging-01 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 6 Extruder-01 Extruder-02 70 10 70 70 70 70 70 10 70 Extruder-04 70 10 70 70 70 70 70 10 70 Sewer-01 26 35 25 35 Extruder-03 Sewer-02 20 35 20 Sewer-03 26 35 25 35 20 Sewer-04 26 35 25 35 20 Trellis-01 Trellis-02 Packaging-01 5 Order 1 0 Order 2 0 Order 3 Order 4 Order 5 0 Order 6 Order 7 0 Order 8 Order 9 Order 10 Order 7 Extruder-01 1 70 60 70 Extruder-02 1 70 60 70 Extruder-03 1 70 60 70 Extruder-04 1 70 60 70 Sewer-01 11 Sewer-03 Sewer-04 60 10 70 70 70 10 70 70 70 30 30 35 35 11 30 30 35 35 11 30 30 35 35 60 60 60 Sewer-02 Trellis-01 Trellis-02 Packaging-01 5 Order 1 0 Order 2 0 Order 3 Order 4 Order 5 0 Order 6 0 Order 7 Order 8 Order 9 Order 10 Order 8 Extruder-01 Extruder-02 70 70 10 10 60 70 70 60 10 70 70 10 10 60 70 70 60 10 Trellis-01 5 5 5 Trellis-02 5 5 5 Extruder-03 Extruder-04 Sewer-01 Sewer-02 Sewer-03 Sewer-04 Packaging-01 Order 1 Order 2 Order 3 Order 4 Order 5 Order 6 Order 7 Order 8 Order 9 Order 10 Order 9 Extruder-01 Extruder-02 70 10 70 70 60 10 70 60 70 Extruder-04 70 10 70 70 60 10 70 60 70 Sewer-01 26 10 5 20 35 Extruder-03 Sewer-02 10 20 Sewer-03 26 10 5 20 35 Sewer-04 26 10 5 20 35 Trellis-01 Trellis-02 Packaging-01 5 Order 1 0 Order 2 0 Order 3 Order 4 Order 5 0 Order 6 0 Order 7 Order 8 Order 9 Order 10 Extruder-01 60 70 0 10 Extruder-02 60 70 0 10 60 Extruder-03 60 70 0 10 Extruder-04 60 70 0 10 Trellis-01 0 5 5 Trellis-02 0 5 5 70 70 60 10 70 10 70 60 70 70 60 Sewer-01 Sewer-02 Sewer-03 Sewer-04 Packaging-01 Order 10 4.2 Results Results data are shown taking into account two possible objective functions, makespan minimization and delay minimization. Every instance has been implemented on the modeler AIMMS 3.13 and solved with CPLEX v12.4 in a PC Intel Core I3, OS Windows 7 and NVIDIA graphic card of 4 GB. 4.2.1 Makespan cases study Four instances are presented in makespan case study. Table 3 shows the features of each instance. Instance 1 is composed by 10 order and every machines where objective function is minimizing makespan. Instance 2 is similar to instance 1 with the exception that extruder 1 is unable (i.e., because of maintenance activities). Instance 3 is similar to instance 1 with the exception that order 9 and 10 are not considered. Instance 4 is similar to instance 3 with the exception that objective function is minimizing every finish time in each stage. Table 3, Instance features in minimizing makespan Instance Orders Machines Objective function Instance 1 10 4 Extruders, 4 sewers, 2 trellis, 1 packaging Minimize makespan Instance 2 10 3 Extruders, 4 sewers, 2 trellis, 1 packaging Minimize makespan Instance 3 first 8 orders 4 Extruders, 4 sewers, 2 trellis, 1 packaging Minimize makespan Instance 4 first 8 orders 4 Extruders, 4 sewers, 2 trellis, 1 packaging Minimize every finish time In table 4 solving time, iteration, constraints, variables and optimal solution are shown. A relevant solving time difference between instance 1 and 2 is shown because of the machine removal. A relevant constraint and variable amount between instances 1 and 2 in respect of 3 and 4 are shown because of the order removal. Solving time between instance 1 and 3 is decreased considerably. Solving time between instance 4 and 3 is increased because of the fact that objective function has more variables to minimize. Instance 4 has not a good objective function since minimum makespan is not ensured. There are not relevant differences between instance 1 makespan and instance 3 makespan since trellis stages is a bottleneck. Table 4, Computational data Instance Solving time in seconds Iterations Constraints Variables (integers) Optimal solution in minutes, makespan Instance 1 65 461.782 485 316 (262) 1497.5 Instance 2 5490 38.130.055 455 295 (241) 1698.14 Instance 3 1.68 9.747 323 221 (117) 1496.5 Instance 4 355 2.573.473 323 232 (177) 1518.18 Figure 1 to figure 4 shows orders configuration for each instance. In figures are shown each order processed in the corresponding machine. Void between orders is at least the set-up time, that is, set-up time and idle time is shown between orders. Fig. 1 Instance 1, configuration orders Fig. 2 Instance 2, configuration order Fig. 3 Instance 3, configuration order Fig. 4 Instance 4, configuration order 4.2.2 Due date cases study Two instances are presented for due date case study. First one shows the performance of advance de due date to an earliest data. Second one shows the performance of a higher penalty in a relevance order. Instance 5 shows who model performances with the first eight orders. Every order has a due date of 1500 minutes. Every order accomplish as is shown in the figure 5. Fig. 5 Instance 5, configuration order with the same due date for every order Instance 5 is composed by 310 constraints, 228 variables (which 177 integers), solving in 125 iterations and spending a solving time of 0.06 seconds. Now, in the same instance, due date for order 5, 7 and order 8 were changed to 1350, so that, with the previous configuration there will be a delay in mentioned orders. Before executing, configuration changes as is shown in figure 6. Orders 5, 7 and 8 are manufactured before its due date. Fig. 6 Instance 5, configuration order changing due date for order 4 and 6 Once due date in orders 5, 7 and 8 are changed, model is solved in 137 iterations spending a solving time of 0.08 seconds. In instance 6, there exist an earliness due date for every order, that is, every order must finish before than 1200. As is shown in figure 7, order 8 has a delay. Fig. 7 Instance 6, configuration order with the same due date for every order The same tardiness penalty was considered for every order. Now we assume order 8 cannot be delayed because of the relevance, so a higher penalty is added to order 8 in order not to have a delay, certainly a penalty of 50 units (rest of penalty orders are 1 unit). Figure 8 shows a new configuration where order 8 is not delayed, in opposition, order 4 is delayed. Instance 6 is composed with the same amount of constraints and variables as the previous instance and it is solved in 4474 iterations spending a solving time of 0.94 seconds. Fig. 8 Instance 6, configuration order adding a high penalty to order 8 Once a penalty of order 8 is changed, model is solved in 4609 iterations spending a solving time of 0.70 seconds. Distinctiveness is worth highlighting. Solving time in makespan instances are greater than solving time in due date instances, which is more efficient working (from the standpoint of scheduling) with due dates.