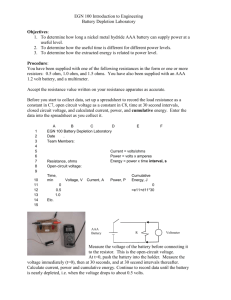

Final Documentation 4915 - Department of Electrical Engineering

advertisement