HDI Polyisocyanates: Toxicity and Airborne Guidelines

advertisement

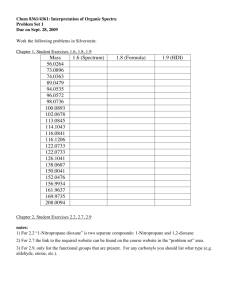

HDI Polyisocyanates: Toxicity and Airborne Concentration Guidelines Painting Issues in the Aerospace Industry: RT244 2000 AIHCE Chemical Structures Hexamethylene Diisocyanate(HDI) Monomer HDI Biuret (Polyiso) Commercial product contains higher mol. wt. oligomers and a small percentage of residual HDI monomer Chemical Structure HDI Isocyanurate Trimer (Polyiso) Commercial product contains higher mol. wt. oligomers and a small percentage of residual HDI monomer Molecular Weight and Vapor Pressure HDI HDI Biuret Monomer HDI Trimer Mol. Wt. 168 >500 >500 VP mmHg 20o C 1.1x10-2 9.3x10-6 5.2x10-9 Typical 2-Component PU Paint Formulations Highest Lowest HDI in Polyiso 1.6% 0.2% Polyiso in Paint ~30% ~7% HDI in Paint 0.5% 0.014% Volatility HDI polyisocyanate is essentially nonvolatile at room temperature Even at oven temperatures up to 300 F no airborne polyisocyanate was found Airborne HDI polyisocyanate found only during spray application Inhalation Exposure Potential HDI Monomer HDI Polyiso Non-Spray, Room Temp. Low None Non-Spray, Oven Mod.-High None Spray Low-Mod. Low-High Burning Mod.-High No Data During Paint Application Potential for inhalation of HDI monomer is low (spray or non-spray) Potential for inhalation of HDI polyiso can be high during spray application Not surprising since there is typically 62500 times more polyiso than monomer in the mixed paint Why Study Polyisocyanate Toxicity and Exposure? In 2-component (2K) PU paints used as topcoats in the aerospace industry, there is isocyanate present during application Spraying is most common method Most of isocyanate groups are on polyiso Spray painter’s most significant isocyanate exposure potential is to polyiso aerosol Purpose To describe the selection criteria for toxicity studies to be used in this evaluation and To provide a brief description of the studies and the biologic endpoint selected. Selection Criteria for Toxicity Studies Test substance is HDI monomer or HDI polyisocyanate and not paint formulations Common test species across studies Route of exposure is inhalation Repeated exposure designs preferred to acute exposure Comparable duration of exposure with analytically determined exposure concentrations Multiple concentrations (dose response) Studies with No-Observed-Adverse-Effect-Level Relevance to potential worker exposures Subchronic Toxicity Study Design Exposure Regimen: 6h/day, 5d/wk for 13 wks Exposure Atmosphere Characterization Air Concentration Vapor: N-4-nitrobenzyl-N-n-propylamine in midget impingers in series; HPLC quantification Aerosol: Filtration; nitro-reagent reaction and HPLC quantification Subchronic Toxicity Study Design (continued) Exposure Atmosphere Characterization Particle Size Distribution Laser velocimetry Cascade impactor • gravimetric • chemical analysis Subchronic Toxicity Study Endpoints In-life Body weights Clinical signs Urinalysis Hematology Clinical chemistry Post-sacrifice Gross pathology Organ weights Complete histopathology Subchronic Inhalation Toxicity Study with HDI Monomer Test species: Fischer 344 rats Exposure regimen: 0, 0.01, 0.04 & 0.14 ppm vapor Findings: Ocular irritation only during exposure; histopathologic lesions of nasal cavity Target organ: Respiratory tract NOAEL: *0.005 ppm or 0.034 mg/m3 (*Estimated from subacute and chronic studies) Source: Shiotsuka, R.N., 90-day inhalation toxicity study with 1,6-hexamethylene diisocyanate (HDI) in rats, Bayer Corp., 1988. Subchronic Inhalation Toxicity Study with Biurettype HDI Polyisocyanate Test species: Wistar rats Exposure regimen: 0, 0.4, 3.5 & 21 mg/m3; aerosol Particle size distribution: 1.4 - 3.3 um MMAD Findings: increased lung wts; proliferative lesions in lower lung with septal thickening Target organ: Respiratory tract NOAEL: 3.4 mg/m3 Source: Pauluhn, J., Desmodur N 3200, Untersuchsungen zur subchronischen inhalationstoxizitat an der ratte nach OECD-richtline No. 413, Bayer AG, 1988. Subchronic Inhalation Toxicity Study with Isocyanurate Polyisocyanate Test species: Wistar rats Exposure regimen: 0, 0.5, 3.3 & 26.4mg/m3; aerosol Particle size distribution: 1.5 um MMAD Findings: clinical signs, increased lung wts, flow obstruction in pulmonary function tests, pulmonary fibrosis Target organ: Respiratory tract NOAEL: 3.3 mg/m3 Source: Pauluhn, J., Desmodur N 3300, Study of the subchronic inhalation toxicity to rats in accordance with OECD Guideline No. 413, Bayer AG, 1987. Discussion/Summary of Toxicity Studies All subchronic studies showed compound-related effects due to sequalae of repeated acute irritation Respiratory tract was the target organ Based on mass concentration, the NOAELs for the HDI monomer (0.034 mg/m3) was approximately two orders of magnitude lower than that for the polyisocyanates of HDI (range: 3.3 to 3.4 mg/m3) History of Polyiso Tox. And Exp. Studies by Producers Acute inhalation toxicity tests first run in the mid 1970s 21 day and 90 day inhalation toxicity tests run in the mid 1980s Workplace air monitoring ongoing since the late 1970s, both monomer and polyiso UK Isocyanate Control Limits 1983, Silk and Hardy paper, “Control Limits for Isocyanates”,Ann. Occup. Hyg. Vol. 27,pp.333339 Basic Hypothesis: Inhalation of aerosols containing polyisocyanates “…is no different from the inhalation of monomer vapours as regards their ability to cause adverse respiratory effects and sensitization.” UK Isocyanate Control Limits Control Limits 8 hr TWA -- 20ug NCO/m3 10 min TWA(STEL) -- 70ug NCO/m3 We would now refer to this as a TRIG limit as it is based on the airborne concentration of Total Reactive Isocyanate Groups Total Mass vs. TRIG HDI Diisocyanate Monomer Total Molecular Mass/Wt. = 168 Mass or wt. Of 2 N, 2 C and 2 O found in the two isocyanate functional groups = 84 Therefore, 50% of the mass/wt. is reactive isocyanate groups (TRIG) Thus a Total Mass Concentration of 0.034 mg/m3 = a TRIG Conc. of 0.017 mg/m3 Total Mass vs. TRIG HDI Polyisocyanate Since the commercial product is a mixture of oligomers of varying molecular mass/wt., the conversion must be done using a measured NCO (TRIG) percentage A major HDI polyiso product currently in use has an NCO (TRIG) percentage of 21.6 Therefore, a Total Mass conc. of 0.5 mg/m3 = a TRIG conc. of 0.11 mg/m3 Total Mass vs. TRIG 8 Hour Concentration Guidelines Total Mass vs. TRIG STEL/C Conc. Guidelines Why Not Accept Silk & Hardy Hypothesis? At the time (1983) only acute LC50 data was available and monomer and polyiso results were quite similar BUT, workers are not exposed to hundreds of mg/m3(LC50 range) Janko (AIHAJ 1992) and Myer (AIHAJ 1993) reported workplace ranges of <1 to 30mg/m3 (or <1 to 6.5 mgTRIG/m3) of airborne HDI polyisocyanate. Why Not Accept Silk & Hardy Hypothesis Subchronic inhalation toxicity tests were run on HDI monomer, HDI biuret and HDI trimer in the mid ‘80s. These studies exposed the animals to polyisocyanate concentrations in the same range as was found in field survey studies (Janko and Myer) Monomer vs. Polyiso Toxicity Comparison Tox. Test HDI TRIG mg/m3 Polyiso TRIG mg/m3 Polyiso HDI LC50-4 hr 155-175 30-248 Similar 90 day (NOAEL) 0.017 0.71-0.73 42 “No Difference” Hypothesis Wrong At concentrations and exposure patterns like those found in the workplace, the rat studies showed that NCO groups found on HDI polyisocyanate molecules were clearly much less toxic than an equal number of diisocyanate monomer NCO groups. In other words, in this case, the Silk and Hardy “no difference” hypothesis is clearly wrong. Conclusion Measuring airborne TRIG concentrations nonspecifically in an HDI polyisocyanate spray painting operation and comparing the results to the UK-HSE control limits would greatly overestimate the risk (~42 fold). On the other hand, a good TRIG method may be useful for thermal decomposition situations.