開啟檔案

advertisement

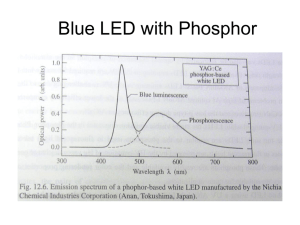

Light extraction analysis of GaN-based light-emitting diodes with surface texture and/or patterned substrate 1. Introduction LEDs are regarded as the most important light source in next-generation solid-state lighting owing to advantages in energy efficiency, long life, vivid colors, high reliability, environmental protection, safety. LED為是最重要的光源,省電、壽命長、顯色度高、可靠性高、環保、安全。 Fig. 1. Schematic diagrams of wire bonding, flip chip and ThinGaN LEDs. 2. Light extraction analysis and optimization of pyramid structure The structure parameters for the simulated GaN-based LEDs are described in Table 1. The die size is 300×300 μm2 and the absorption coefficient of active region is assumed to be 10-4 cm-1. The simulation result shows that the angle in a range of 20o to 70o of the slanted surfaces in the pyramid structure may cause larger LEE in both cases. We find that the slanted angle of 30o could be the best angle in enhancing the LEE. 模擬結果表示,金字塔結構中的斜面在20至70度範圍時,兩種情況下,皆會導致較大的LEE。我們發現,30°的傾斜角度為提高LEE的最佳角度。 Fig. 2 shows the simulated LEE in function of the reflection oefficient of the bottom reflector for the three types of bare and encapsulated LED. 圖2顯示模擬三種類型在LED 底部反射係數。 Fig. 3 shows the simulated LEE with respect to the pyramid angle in a bare LED and encapsulated LED with IPF structure without considering bottom reflection. 圖3顯示模擬相對LED金字塔角 度及封裝IPF結構 Fig. 4 shows the simulation result for wirebonded LEDs. 表面紋理及圖案化可有效 增加LEE,未封裝之LED較 封裝之LED效果更好。 Figure 5 shows the result for flip-chip LEDs. 封裝LED表面紋理之效果幾 乎消除藍寶石及樹脂透鏡 折射率之差,僅約0.2。 Fig. 6, where approaches by both surface texture and patterned substrate can effectively increase LEE. 表面紋理和圖案化皆可有 效的增加LEE。而圖案化 之效果比表面紋理好。兩 者皆被應用於封裝LED。 3. Result and discussion The effects of increasing the LEE by both encapsulating with an epoxy lens and introducing a pattern array are summarized in Fig. 7, where the reflectivity of the bottom surface is set 90%. The simulation shows that both the encapsulation and the patterned substrate with 30o pyramid array effectively increase the LEE from 200% to 300% with respect to that of a bare LED without pattern array. When both of them are applied at the same time, the LEE may be as large as 350% of that in a bare one for all three types. The simulation shows that, except flip-chip LEDs, surface texture induces an obvious effect in improving LEE in both wirebonding and Thin-GaN LEDs. But the effect in the Thin-GaN case is not as dominant as that in the wire-bonding case because the sapphire substrate is removed so that more absorption occurs when the light travels in the thin layer with multiple reflections. In contrast, the patterned substrate causes dominant effect in improving LEE in all cases with an epoxy lens. It is interesting to note that once patterned substrate is introduced, surface texture is almost no more necessary in an encapsulated LED. Owing to the advantage in heat dissipation, LEDs in flip chip and Thin GaN attract more attentions. From the optical simulation presented above, we may have two conclusions in enhancing the LEE for such two LED types. The first is that patterned substrate should be regarded as the most effective way in enhancing the LEE in an encapsulated flip-chip LED. Second, both patterned substrate and surface texture schemes are useful in enhancing the LEE in a Thin-GaN type of encapsulated LED, though patterned substrate scheme seems a little bit better. Another important result of the simulation is that we do not find any case to perform an LEE larger than 80% when the absorption coefficient in the active layer is as high as 104 cm-1, and the pad of the electrode as well as current spreading are not considered. Since the simulation parameters cannot be applied to all LEDs, we cannot conclude that it is impossible to perform an LEE larger than 80% in the approaches presented in this paper. However, we may regard 80% as an upper limit to reach in LEE. 4. Summary In this paper, we have applied Monte Carlo ray tracing to simulate enhancement of LEE in three different types of bare LEDs and encapsulated LEDs with introducing pyramid array. The simulation showed that the pyramid with slanted surface at an angle from 20o to 70o can increase LEE effectively. Moreover, the LEE can be increased to as high as 350% when a patterned substrate is introduced to all three types of encapsulated LEDs in comparison with an unpatterned bare LED. The simulation also shows that in encapsulated LEDs, surface texture contributes less in a flipchip type than in the other two LED types, while the patterned substrate is useful in increasing the LEE in all types. 在本文中,我們採用Monte Carlo ray追踪,利用三種不同類型的LED和封裝, 引入棱錐陣列,以模擬增強LEE。模擬結果顯示,金字塔傾斜表面從20度到70 度能有效增加LEE。此外,LEE增加到高達350%時,以圖案化封裝LED與未封 裝之LED比較顯示:在封裝的LED中,圖案化的基材是在提高LEE中最有用的。 Air-voids embedded high efficiency InGaN-light emitting diode. The improvement of the external quantum efficiency of InGaN-light emitting diodes LEDsis an important and essential issue to enable solid state lightings to replace traditional fluorescent lamps. 改善氮化銦鎵發光二極體之外部量子效率使固態照 明取代傳統的螢光燈為一重要且基本的問題。 The patterned sapphire technology might be one of the promising methods for a high efficiency InGaN-LED because it can improve both the IQE and LEE simultaneously. 圖案化藍寶石技術可能是一高效率的InGaN-LED,因 為它可以同時提高IQE和LEE。 Although it is possible to form various shaped patterns on a sapphire substrate as masking patterns and etching methods, the excessively roughed substrate could easily raise epitaxial growth problems such as pits generation and rough surface. Therefore, the technology that can maximize the light extraction using a proper pattern is important for a high efficiency PS-LED. FIG. 1. The procedure of the air-voids formation between GaN and a patterned sapphire substrate. Figure 1 shows the procedure of the air-voids formation between a patterned sapphire and GaN epitaxial layer. 顯示圖案化藍寶石和GaN外層氣孔形成過程。 最終形成一個倒六角錐形狀的空氣空隙半 球格局。 FIG. 2. a Microscope image of the front surface and b SEM image of the cross section of the wafer after 15 s etching in 280 °C H3PO4 and H2SO4 mixed chemical. c SEM image of the cross section of the wafer after the regrowth of LED structure. FIG. 4. Color online Ray tracing result of the a PS-LED and b AVELED. c LEEs of each face top, four-sides, and bottom of PS-LED and AVE-LED. FIG. 3. (a) The schematic structure of the AVE-LED. (b) Optical power of FS-LED, PS-LED, and AVE-LED as injection current. The LED chip size was 600250 m2 with 100 nm indium tin oxide transparent metal on the p-GaN side as shown in Fig.3a. Figure 3b is the chip level optical power of the three LEDs as injected current. The ray density in the sapphire substrate of the AVE-LED is smaller than that of the PS-LED due to the top direction reflection of the light by air voids as shown in Figs.4a and 4b, the smaller incident angle of the light into the sapphire substrate enhanced the light extraction through the bottom face. However, as shown in Figs. 4a and 4b, the AVE structure decreased the light extraction through the four side faces from 26.8% to 20% due to the decreased ray density inside the sapphire substrate. As a result, the total LEE of AVE-LED increased up to 16% more than the PS-LED in the simulation. Enhance Light Emitting Diode Light Extraction Efficiency by an Optimized Spherical Cap-Shaped Patterned Sapphire Substrate. 1. Introduction Light emitting diodes (LEDs) have wide applications in a variety of fields such as backlit illumination, commercial lighting, lamp decoration, etc1. Accordingly, GaN-based semiconductors as the most promising materials for fabrication of blue and white LEDs since p-GaN was successfully doped by Akasaki have recently attracted intensive interests. LED在照明領域中有廣泛的應用,例如:背光照明、商業照明、燈飾、etc等等。GaN基板半導體為最好的材料製造藍光和白光的LED燈。 Of particular concern is the patterned sapphire substrate (PSS) technology, which has been developed recently and can improve the external quantum efficiency on the premise of high-quality of growth of LEDs’ wafers. 特別值得關注的是圖案化藍寶石基本(PSS)技術,可提高LED外部量子效率。 2. Modeling The simulation in this work includes the following steps, building the basic LED structure and patterns, Defining the light source, tracing ray and collecting data. 模擬包括以下步驟,建造LED基本結構和模式,定義光源,追踪光線和收集數據。 Fig. 2. (Color online) The working flow to build patterns on sapphire substrate. (a) Alignment of spherical cap-shaped patterns on the sapphire’supper surface, (b) the corresponding pits on the lower surface of n-GaN of LED chip, (c) enlarged spherical cap-shaped pattern unit. Fig. 3. Comparison between (a) rectangular arrangement and (b) hexagonal arrangement of PSS patterns. Table II details the luminous flux from each facet of the models whose patterns are in rectangular or in hexagonal arrangement,respectively. 詳述模型中每個面的光通量,其模式為矩形 或六角排列。 Analysis function from TracePro verifies that the luminous flux collected from target plates is exactly equal to the luminous flux from the corresponding LED facet. 3. Simulation The spherical cap-shaped pattern in this work is based on hemispherical pattern of PSS, by changing the height and the diameter of its hemispherical units. We focus on three parameters of the pattern to study their influence on LED’s efficacy, respectively. These parameters, include (1) intercepted ratio (IR), which is defined as the ratio between the spherical cap’s height and the radius of the corresponding hemisphere, (2) edge spacing, and (3) radius of the pattern. Figure 4 shows the definition of these parameters. 針對三個參數來研究其對LED的影響力,分別為球形高度和半徑半球比率、間隔、半徑。 4.2 Influence from edge spacing 4. Results and Discussion 4.1 Influence from intercepted ratio Figure 5(a) is the luminous flux from top, bottom and side facets from a LED chip grown on a spherical cap-shaped PSS with a fixed radius of 2.4 m as a function of the IR, or, height. 圖六(左)顯示LED總光通量在球 形與PSS不同半徑功能所截取的 比例。發現隨著所截取的高度 增加,光流量總數上升,再緩 慢下降,達到紅外的範圍是從 60%到85%的最大值。光通量 達到高峰,逐漸總和隨著高度 的增加。 間距增大,側面光通量上升,圖案的數目變小相對導致較少的光線反射到 頂部和底部,因此,頂部和底部光通量下降。 4.3 Influence from radius 以上討論得知,總光通量達到最大時所截取的比率是60%和85%,同時在頂部和 底部之間,0.8截獲比率間距等於半個半徑。 5. LED Wafer Fabrication Fig. 11. The as-prepared spherical cap-shaped PSS with 3.4 m in radius,2.78m in height, and 1.7m in edge spacing. (a) In-plane SEM image and (b) the low-magnification cross-sectional TEM image after epitaxial growth of LED structure. In practice, the patterns are distributed in hexagonal arrangement, rather than the rectangular one as in the simulations. 6. Summary Fig. 12. (Color online) Comparison of EL spectra from LED chips grown on HPSS, up-to-date commercial PSS, and SCPSS. These results straightforwardly prove our simulation expectations that spherical cap-shaped PSS is more effective to enhance LED efficacy even compared with the hemispherical PSS, and the spherical cap-shaped pattern of 3.4m in radius, 2.78m in height, and 1.7m in edge spacing would be the optimal. 這些模擬結果證明,球形藍寶石基板能 有效提升LED的功效。 In summary, a new way to optimize spherical cap-shaped PSS for highly efficient LEDs has been proposed in this work. After a series of simulations, optimal parameters for this spherical cap-shaped PSS have been obtained. When the intercepted ratio of the spherical cap unit of the pattern is in the range of 60 to 85%, the total luminous flux of spherical cap-shaped PSS reaches the maximum value, and when the edge spacing between units stays about the half radius of the original hemisphere, both the top and the bottom luminous flux keep at a higher value range. In the end, the total luminous flux of spherical cap-shaped PSS with 3.4 m in radius, 2.78 m in height, and 1.7 m in edge spacing exhibits the highest LED light extraction yield. Through simulations, it is confirmed that spherical cap-shaped PSS whose intercepted ratio is set as 0.8 and edge spacing is the half radius of hemisphere is more effective to improve LEDs’ light extraction. The bottom and the total luminous flux further increased by 5–8 and 10–15%, respectively. In practice, we can take advantages of spherical cap-shaped PSS by using the flip-chip LED packaging with an improvement of more than 10% in light extraction yield even compared with the hemispherical PSS. In addition, the height of spherical cap-shaped PSS is much smaller than that of hemispherical PSS in the case of the same radius. This indicates that spherical cap-shaped PSS needs less photo-resistance and shorter etching duration, and consequently saves fabrication cost, and is therefore very promising for industrial mass production. 當球形截獲率在60%至85%的範圍內,球面總光通量達到最大值,球 形藍寶石基板需較短的蝕刻時間,因此節省了製造成本。 White light emitting diodes with super-high luminous efficacy We fabricated three types of high luminous efficacy white light emitting diodes (LEDs). The first was a white LED with a high luminous efficacy (ηL) of 249 lmW−1 and a high luminous flux (φv) of 14.4 lm at a forward-bias current of 20 mA. This ηL was approximately triple that of a triphosphor fluorescent lamp (90 lmW−1). The blue LED used as the excitation source in this white LED had a high output power (φe) of 47.1mW and a high external quantum efficiency (ηex) of 84.3%. The second was a highpower white LED, fabricated from the above high-power blue LED, and had a high φe of 756mW at 350 mA. φv and ηL of the high-power white LED were 203 lm and 183 lmW−1 at 350 mA, respectively. The third was a highpower white LED fabricated from four high-power blue LED dies. φv and ηL of the high-power white LED were 1913 lm and 135 lmW−1 at 1A, respectively. The white LED had a higher flux than a 20W-class fluorescent lamp and 1.5 times the luminous efficacy of a tri-phosphor fluorescentlamp (90 lmW−1). 此二極管是使用三極的二級管,首先白光LED的高發光效益(ηL) of 249 lmW−1,而高發光通量(φv) of 14.4 lm的前端基極電流為20ma。 三機色的熒光燈泡是ηL的三倍也就是90 lmW−1。藍光LED的激發來 源是在白光LED中,並且有著很高的輸出功率(φe) of 47.1mW還有 著多數外部量子功率(ηex) of 84.3%。其次,白光LED燈是有個高輸 出,要製造白光LED必須要有高輸出的藍光LED還有高通量為 756mW在350 mA,同時白光LED的φv 和 ηL分別為203 lm 和 183 lmW−1。 自從使用氮化銦鎵的藍光LED在1993年商業化之後,這也證明了有著可觀的 利益,在1996年使用藍光LED晶片加上黃熒光粉結合製造出白光LED。這些熒 光粉轉換成白光LED代表著固態照明的創新,因此它們很小、很亮、可長時 間照明、而且可簡單的操作。白光LED主要用在液晶顯示器(LCD)的背光源, 現在白光LED甚至有著更高的功效用在固態照明器材,因為都是用白光LED燈 來替換白熾燈還有熒光燈泡。 Figure 3. The spectra of the ultra-high Ra white LED, the conventional white LED and CIE Standard Illuminates(D50). All of Tcp are 5000 K. Figure 3 shows the spectrum of an ultrahighRa whiteLED(UHR-white), with a Tcp of 5000 K. The spectra of a CIE Standard Illuminates (D50) and a conventional white LED (Tcp = 5000 K), fabricated using only YAG phosphor, are also shown in figure 3. In UHR-white, the amount of luminescence in the blue–green and red regions was significantly enhanced compared with a conventional white LED. CIE標準發亮(D50)和一個傳統的白光LED(TCP= 5000 K)中,製作只使用YAG熒光體, 如圖3所示:在UHR-白色與傳統的白光LED相比,所 述量在藍綠色和紅色區域中顯著增強。 Analyses of light extraction efficiency in GaN-based LEDs grown on patterned sapphire substrates LEE = EQE(n ) / IQE(n ) (A)Schematic diagram of LED LED之示意圖。 (B)Top-view SEM photograph of PSS PSS之SEM頂示圖 照片。 Light output power changes with injection currents. 光輸出功率的 變化與注入電 流。 it is worth note that IQE of LEDs on PSS were 51.44% and 54.64% ,increasing about 3.179.59% from 49.86% of Conventional LEDs. These results indicate that PSS technique has improved the light output power of GaNbased LEDs, and the enhancement in LEE is much larger than that in IQE of LEDs. So the better performance of LEDs on PSS mainly benefits from the enhancement in LEE. LEE = EQE(n ) / IQE(n ) 通常LEE被認為是根據不同的 注入電流,EQE取決於光功 率與注入的電流量。IQE可以 獲得來自EQE與不變的LEE, 如上圖所示。 With the rate equation analysis method, LEE and IQE of the three types of GaN-based LEDs were analyzed. The results were listed in Table 1. LEE of the LEDs with pattern heights of 1.7 μm and 1.9 μm were found to be 72.78% and 73.97%, increasing about 19.14% and 21.08% compared with 61.09% in reference LEDs. And, 隨著速率分析方法,LEE和IQE三種類型的GaN-based 進行了分析,結果為左圖表。 LEE在1.7微米和1.9微米時為72.78%和73.97%, 而其中值得注意的是,PSS的IQE的數據分別為 51.44%和54.64%,與傳統的49.89%相比,上升了 3.17%-9.59%。這結果表示了,PSS技術具有改進 GaN-based LED的光輸出功率。 Modified Cone Shapes on Patterned Sapphire Substrates for High Performance InGaN LED Applications In this study, GaN-based light emitting diodes (LEDs)were prepared on the cone-shaped patterned sapphire substrates (PSSs) by metal-organic chemical vapor deposition. To improve the epilayer quality and device performance of LEDs, the PSSs were further wet etched to form the modified top-tip cone shapes.With increasing the wet etching time to 3 min, the LED grown on the coneshaped PSS has 53% and 8% enhancement in light output (@ 20 mA) as compared with that on conventional sapphire substrate (CSS) and the cone-shaped PSS without wet etching, respectively. 為了改善LED的外延層的質量和器件性能,在GaN-based LED上裝置藍寶石基板透過金屬有機化學氣相沉積,該PSS中為進一步濕蝕刻以形成改性 頂頭圓錐形狀。隨著濕法刻蝕時間3分鐘,在LED上生長圓錐形的PSS具有光增強53%和8%輸出(在20 mA)的作為與常規相比藍寶石襯底(CSS) 和圓錐形的PSS無濕蝕刻。 InGaN LEDs were fabricated on the PSSs with modified top-tip cone shapes. The influences of different cone shapes on the epilayer quality and device performance were investigated.By means of the modification in the top tip of pattern shape and the removal of some dry-etched induced damage on sapphire surface, a higher crystal quality in epilayer and better device performance can be achieved. The optimum wet etching time was obtained at 3 min. As an injection current of 20 mA was applied, the LED grown on this substrate had the largest improvement in epilayer quality and light extraction than those on the other PSSs. It indicates that the wet etching process employed to cone-shaped PSSs is potentially useful in LED device. 不同形狀錐上的影響外延層的質量和器件性能進行了調查。通過本變形例 中的圖案形狀的頂部前端裝置與一些幹蝕刻引起的損傷對去除藍寶石表面, 在外延層和更好更高質量的結晶器件性能得以實現。最佳的濕法刻蝕在3 分鐘得到的時間。 Optics Communications Study of light extraction efficiency of flip-chip GaN-based LEDs with different periodic arrays Secondly,by comparing micro-cone arrays with micro-pyramid arrays,the micro-cone arrays were superior to micro-pyramid arrays in terms of enhancing LEE.Lastly,the truncated cone arrays and truncated cone hole arrays with different upper radius were studied.The results indicated that the truncated cone arrays in top radius of less than 0.4 um showed a certain enhancement of the LEE and about 3 times LEE improvement was obtained as R top=0.2 μm and h=1.0 μm, compared with the planar flip-chip LEDs.Our results will provide important theoretical implications in development of high-power and high-brightness LEDs. 比較圓錐微結構和金字塔型微結構,圓錐型的微結構在增強出射光方面優於金 字塔型的微結構。截一段錐微結構和一段上半部被截取的錐形微結構做不同 半徑的比較。結果圓錐微結構和planar flip-chip LEDs相比在頂端半徑小於 0.4um顯示一個增加一定的出光率和3次LEE得到改善於Rtop=0.2μm和h=1.0μm 我們的結果提供重要的理論在影響高功率和高亮度LED的發展。 1.In our simulations the wavelength of the light source was 465 nm. Light rays of 40,000 2. The refraction index and the absorption coefficient of GaN material were set as 2.5and 10 per millimeter , respectively 3.For convenience, the bottom surface of the n-GaN and the top surface of the p-GaN were prescribed as the surface sources, which the thickness of the QWs active region was neglected. Results and discussion The period (a) and the radius (R) of the patterned arrays were fixed at 1.2 μm and 0.5 mm, respectively ,while the height of the arrays was allowed tovary from 0 mm to 2.5 μm. Fig. 3 plotted the LEE of flip-chip GaN-based LEDs with different periodic arrays as afunction of the height(h) at λ=465 nm . From Fig. 3, the LEDs with the four different periodic arrays showed the enhancement of the LEE at different heights.The LEE of the LEDs with micro-cone arrays significantly increased from 7.5% to 37.7% with the height of the periodic arrays in the range of 0–2.5 mm. Improving light-emitting diode performance through sapphire substrate double-side patterning The PSS pattern used in the simulation had a diameter of 3 μm, pitch of 6 μm, and a height of 3 μm. The cone-shaped bump had the largest light extraction efficiency at around 36.5%. The hemisphere also had a high light extraction efficiency of around 35.4%. The first insight would indicate that the hemisphere would have the highest efficiency because all of the incidental light would be perpendicular to the surface. However, since the numerous light rays that are emitted in a three-dimensional structure are determined by the minimization of the reflection that reduces the probability of it passing through the absorption layer resulting in the probability of the reflection angle changed by the pattern stays within the critical angle between the GaN and the epoxy When the hole depth increased to around 2 μm, the light extraction efficiency increased. On the other hand, when the depth increased by more than 2 μm, the efficiency decreased. Fig. 2 The modeling of the patterns on the sapphire substrate. (a) Hemisphere, (b) cone, (c) truncated-cone, (d) pyramid, (e) truncated-pyramid, (f) square pillar, and (g) cylinder. Results and discussion Light outcoupling effect in GaN light-emitting diodes via convex microstructures monolithically fabricated on sapphire substrate Results and Discussion As shown in the inset of Fig. 5, theηIQE of LEDs with and without CMs were averagely estimated to be 35 and 24%, respectively,indicating that the ηIQE of the LED with CMs was increased 38% compared to that of the conventional LED. Such an increment in ηIQE may be attributed to the reduction of dislocation density through CMs-induced lateral growth behavior as shown in previous works [14]. In the EL output power measurement, further the EL output power of the LED with CMs was 2.4 times higher than that of the conventional LED at normal operation current, 20 mA. Based on our results, the increase in ηLEE was estimated to be 73.5%, presumably due to dominantly resulted from the enhanced light extraction by CM array.Fig. In order to understand the out coupling effect on the enhanced light extraction of the LEDs with CM array, both an optical simulation, i.e., Light Tool based on Monte Carlo method, and far field EL measurement have been carried out as shown in Fig. 6. In the simulation, the CM shape was assumed to be a hemisphere and the light loss by metals such as pad and transparent conducting layer was ignored. As shown in Fig. 6(a) and (b), compared to that of the conventional LED grown on flat sapphire, the light extraction efficiencies for top and bottom directions were increased up to 227% and 335%, respectively, while that for side wall directions was slightly increased by 26%. It clearly indicates that the light extraction from the LED with CMs is higher than that from the conventional LED because of the enhanced light coupling effect on the CM arrays of a substrate toward top and bottom directions rather than four sidewall directions. As shown in Fig. 6(c), relatively high gain peaks in the simulation result have revealed near angles of 0-5, 40-45 and 60-65 degree, respectively, which can be dominantly contributed to the light outcoupling effect. Such tendency reasonably agreed with experimental result. Fig. 5. EL output power of LEDs with and without CMs as a function of injection current. The inset shows IQE values of the two LED samples depending on excitation power density. Fig. 6. Ray tracing results of the (a) conventional LED and (b) the LED with CMs. (c) The simulated and measured farfield EL intensity ratios (gain) of two LED samples as a function of polar angles.. Object Rays Flux 0 0 0.00000 1 10 0.250648E-02 ITO_UP 2 12 0.199227E-04 ITO+P-GAN 3 0 0.00000 ITO_FRONT 4 0 0.00000 ITO_BACK 5 0 0.00000 ITO_RIGHT 6 0 0.00000 ITO_LEFT 7 16 0.429968E-01 P-GaN+P-ALGAN 8 0 0.00000 P-GaN_FRONT 9 0 0.00000 P-GaN_BACK 10 0 0.00000 P-GaN_RIGHT 11 0 0.00000 P-GaN_LEFT 12 435 0.142782E-01 P-ALGAN+MQW 13 0 0.00000 P-ALGAN_FRONT 14 0 0.00000 P-ALGAN-BACK 15 0 0.00000 P-ALGAN_RIGHT 16 0 0.00000 P-ALGAN_LEFT 17 364 0.226059E-02 MQW+NGAN 18 0 0.00000 MQW_FRONT 19 0 0.00000 MQW_BACK 20 0 0.00000 MQW_RIGHT 21 1 0.219450E-07 MQW_LEFT 22 14 0.273980E-01 N-GAN+U-GAN 23 0 0.00000 N-GAN_FRONT 24 3 0.502421E-07 N-GAN_BACK 25 1 0.167715E-07 N-GAN_RIGHT 26 2 0.335143E-07 N-GAN_LEFT 27 6 0.565054E-02 UV1 28 10 0.871892E-02 UV2 29 0 0.00000 U-GAN+SAPPHIRE 30 0 0.00000 U-GAN_FRONT 31 0 0.00000 U-GAN_BACK 32 0 0.00000 U-GAN_RIGHT 33 0 0.00000 U-GAN_LEFT 34 1781 5.73329 SAPPHIRE+METAL 35 10 0.164759E-01 SAPPHIRE_FRONT 36 6 0.127900E-01 SAPPHIRE_BACK 37 10 0.532303E-02 SAPPHIRE_RIGHT 38 7 0.104774E-01 SAPPHIRE_LEFT 39 0 0.00000 METAL_DOWN 40 0 0.00000 METAL_FRONT 41 0 0.00000 METAL_BACK 42 0 0.00000 METAL_RIGHT 43 0 0.00000 METAL_LEFT 44 4034 13.3850 ABS_UP 45 849 3.09621 ABS_FRONT 46 796 2.95263 ABS_BACKT 47 801 2.79939 ABS_RIGHT 48 832 2.95186 ABS_LEFT -------------------------TOTAL 10000 31.0672 !!宣告單位 UNITS MM 'lm' WAVELENGTH 550 NM !!物件寬度 L=0.15 W=0.15 !!圓 K1=-0.002 !!曲率半徑 C1=0 !!圓錐 常數 !!宣告界質特性(折射率及吸收系數) MEDIA 2.0 ABSORB 330 'ITO' 2.45 ABSORB 10 'PGAN' 2.35 ABSORB 10 'PALGAN' 2.54 ABSORB 130 'MQW' 2.42 ABSORB 10 'NGAN' 2.42 ABSORB 10 'UGAN' 1.78 ABSORB 0.004 'SAPPHIRE' 0.67 ABSORB 1.53E5 'METAL' 1.78 ABSORB 0.004 'UV' !!宣告界面特性 COATING PROPERTIES 0 0 'ABSORB' 0.9 0 'R‘ !!光線消失條件設定 HALT 10000 1.E-6 CUTOFF 1.E-18 5000 RAYNO=10000 !!光線數 FLUXNO=100 !!流明數