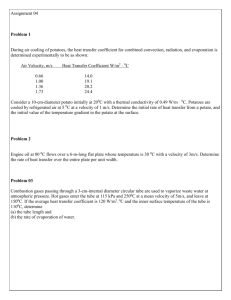

Distillation Trays

advertisement

Section Hussain Butaleb 207217011 Cooler (E-101) Heat Exchanger (E-103) Heat Exchanger (E-102) Steam Drum (V-102) Vessel (V-101) Storage Tank (T-101) Hydro Cyclone (T-102) Stripper (C-201) Distillation (C-101) Heat Exchangers and Cooler A heat exchanger is a device designed to transfer heat from one fluid stream to another without bringing the fluids into direct contact. Heat exchange equipment comes in a wide variety of forms, with an equal variety of functions. They are widely used in chemical plants, petroleum refineries, natural gas processing, refrigeration, power plants, air condition and space heating. Heat exchangers can have different size and shape depending on the application; it can be made of various materials and use various fluids for heat transfer. Types of Heat Exchanger The heat exchangers can be classified according to: Boilers and steam generators. Condensers. Radiators. Evaporators. Cooling towers Flow arrangements: Co current of parallel flow. Countercurrent flow. Cross flow (single or multiple pass). Shell and tube heat exchanger: Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle. There are several thermal design features that are to be taken into account when designing the tubes in the shell and tube heat exchangers. In addition to heating up or cooling down fluids in just a single phase, heat exchangers can be used either to heat a liquid to evaporate (or boil) it or used as condensers to cool a vapor and condense it to a liquid. Distillation set-ups typically use condensers to condense distillate vapors back into liquid. To conserve energy and cooling capacity in chemical and other plants, regenerative heat exchangers can be used to transfer heat from one stream that needs to be cooled to another stream that needs to be heated. This term can also refer to heat exchangers that contain a material within their structure that has a change of phase. This change of phase effectively acts as a buffer because it occurs at a constant temperature but still allows for the heat exchanger to accept additional heat. The transfer of thermal energy between fluids is one of the most important and frequently used processes in engineering. The transfer of heat is usually accomplished by means of a device known as a heat exchanger. The basic design of a heat exchanger normally has two fluids of different temperature separated of some conducting medium. The common design has one fluid flowing through metal tubes and the other fluid flowing around the tubes. On either side of the tube, heat is transferred by convection. Heat transferred through the tube wall by conduction. Single phase exchangers are usually of the tube and shell type. Design procedure of shell and tube heat exchanger Calculation procedure: 1) Define fluid flow rates, temperature. 2) Collect together the fluid physical properties required: density, viscosity, thermal conductivity. 3) Finding the heat load for the process stream. 4) Decide on the type of exchanger to be used. 5) Find the outlet temperature of water flow. 6) Calculate the log mean temperature difference. 7) Find out the temperature correction factor (Ft) using two dimensionless temperature ratio (R & S), choose the number of shell's and tube passes. 8) Find out the true temperature difference. 9) Assume the overall heat transfer coefficient, Uo . 10) Calculate the provisional area. 11) Choosing tube outside & inside diameter, also tube length, then calculate the area of one tube. 12) Calculate the number of tubes which is equal to the provisional area over the area of one tube. 13) Choose a triangle pitch for tube layout and get the constants K1 and n1 for two tube passes. 14) Calculate the bundle diameter. 15) Using split-ring floating head type, finds out the bundle diametrical clearance, and then calculates the sell diameter. 16) To calculate the tube side coefficient, find out the following: Tube cross sectional area. Tubes per pass. Total flow area. Tube mass velocity. Tube linear velocity. Reynolds number. Prantl number. 17) Find the heat transfer factor (jh) and calculate hi. 18) To calculate the shell side coefficient, find out the following: Choose baffle spacing. Tube pitch. Cross flow area. Mass velocity. Equivalent diameter. Reynolds number. Prandtl number. Choose 25% baffle cut, and find the heat transfer factor (jh) and calculate hs. 19) The overall heat transfer coefficient must found. 20) The pressure drop can be calculated for both tube-side and shell-side. 21) Calculate thickness of the shell. Nomenclature Symbol Definition Qh Heat load transfer in the hot side, KW. m Mass flow rate in Kg/s. T Temperature difference of the inlet and outlet. TLM Log means Temperature. T1 Inlet shell side fluid temperature (oC). T2 Outlet shell side fluid temperature (oC). t1 Inlet tube side temperature (oC). t2 Outlet tube temperature (oC). Tm True temperature difference. R Dimensionless temperature ratio. S Dimensionless temperature ratio. Ft Log mean temperature difference correction factor. A Heat transfer area Nt Number of tubes in a tube bundle. Db Bundle diameter (mm). d0 Tube outside diameter. K1 Constant. n1 Constant. Ds Shell diameter. Ac Tube cross-sectional area. di Tube inside diameter. At Total flow area. Um Tube mass velocity. Ut Tube linear velocity. ref Density. hi Film heat-transfer coefficient inside a tube. Re Reynolds number Fluid viscosity at the bulk fluid temperature, Ns/m2. Pr Prandtl number. Cp Heat capacity. kf Thermal conductivity of stream. lB Baffle spacing. pt Tube pitch Gs Mass velocity. As Cross-flow area between tubes. de Equivalent diameter. U0 The overall heat transfer coefficient. hod Fouling coefficient on outside of tube. hid Fouling coefficient on inside of tube. Pt Tube- side pressure drop (N/m²) (pa). Np Number of tube -side passes ut Tube-side fluid viscosity. L Length of one tube. jf Friction factor. w Fluid viscosity at the wall. Ps Shell-side pressure drop. P Maximum allowable internal pressure (psig). ri Internal radius of shell before allowance corrosion is added (in). Ej Efficiency of joints. S Working stress (psi). Cc Allowance for corrosion (in) Design for cooler (E-101) Q mC p T 8.35E 05 W Where: Qh = Heat load transfer in the hot side, KW. m Mass flow rate in Kg/s. T Temperature difference of the inlet and outlet. Tlm (T1 t 2 ) (T2 t1 ) 181.0804C (T1 t 2 ) ln (T2 t1 ) Where: TLM Log means Temperature. T1 Inlet shell side fluid temperature (oC). T2 Outlet shell side fluid temperature (oC). t1 Inlet tube side temperature (oC). t 2 Outlet tube temperature (oC). R S (T1 T2 ) 1.073653 (t 2 t1 ) (t 2 t1 ) =0.9314 (T1 t1 ) Tm Ft Tlm 181.0804 C Where: Tm True temperature difference. Ft Temperature correction factor=1 A Q 27955.21m2 UTm Where: A Provisional area in m2. Q Heat load in W. Tm True temperature difference. A DL 0.15072 m2 Where: A Area of one tube, m2. N t Provisional area/Area of one tube. 1 N Db d 0 ( t ) n1 1285.214 mm K1 Where: Db Bundle diameter (mm). d 0 Outside diameter (mm). N t Number of tubes. K1 & n1 are constant. Ds Db Clearance = 1337.214 mm Where: Ds Sell diameter. Db Bundle diameter (mm). Clearance = 52, split ring floating head. Ac 4 (d i ) 2 = 1.32665 mm2 Where: Ac Tube cross-sectional area. di Tube inner diameter. Tubes N t = 23184.72 Pass 2 Where: N t Number of tubes. At Ac Tubes = 0.030758 m2 Pass Where: At Total flow area. Um m = 180.7389 m/s At Where: U m Tube mass velocity. At Total flow area. m Mass flow rate in Kg/s. Ut Where: Um ref = 0.353491 m/s U t Tube linear velocity. ref Density. Re U t d i 309.9418 Where: Re Reynolds number. Fluid viscosity at the bulk fluid temperature, Ns/m2. Pr Cp kf = 5.293297 Where: Pr Prandtl number. C p Heat capacity. k f Thermal conductivity of stream. hi k f j h Re(Pr) 0.33 di = 502.75 W/m2C Where: hi Inside coefficient (W/m2 oC). j h Tube side heat transfer factor. k f Thermal conductivity of stream. Pr Prandtl number. lB Where: Ds = 222.869 mm 5 l B Baffle spacing. Ds Shell diameter. pt 1.25d 0 = 5mm Where: pt Tube pitch. d 0 Outside diameter (mm). As ( p t d 0 ) Ds l B = 0.059605 m2 pt Where: As Cross-flow area. pt Tube pitch. d 0 Outside diameter (mm). Ds Shell diameter. Gs m = 27.61555 kg/m2s As Where: Gs Mass velocity. As Cross-flow area. m Mass flow rate in Kg/s. de 1.1 2 2 ( pt 0.917 d 0 ) = 2.8402 mm d0 Where: d e Equivalent diameter (mm). d 0 Outside diameter (mm). pt Tube pitch. Re Gs d e = 52.28913 Where: Re Reynolds number. d e Equivalent diameter (mm). Gs Mass velocity. Fluid viscosity at the bulk fluid temperature, Ns/m2. Choose 25% baffle cut jh = 0.42 hi k f j h Re(Pr) 0.33 di = 5793.259 W/m2C Where: hi Inside coefficient (W/m2 oC). j h Tube side heat transfer factor. k f Thermal conductivity of stream. Pr Prandtl number. 1 1 1 U 0 h0 hod d 0 ln( d0 ) di 2k w Where: U 0 The overall heat transfer coefficient. hod Outside coefficient (fouling factor). d0 1 d0 1 0.007249 d i hid d i hi = hid Inside coefficient (fouling factor). Uo = 137.9562 L Pt N p 8 j f d i w m u 2 2.5 t 2 = 76.12681 kpa Where: Pt Tube- side pressure drop (N/m²) (pa). N p Number of tube -side passes. u t Tube-side velocity, m/s. L Length of one tube. j f Friction factor. w Fluid viscosity at the wall. Fluid viscosity at the bulk fluid temperature, Ns/m2. D Ps 8 j f s de L u s 2 l B 2 w 0.14 = 32.54424 kpa Where: Ps Shell-side pressure drop (N/m²) (pa). j f Friction factor. L Length of tube. For carbon steel t Where: t Shell thickness (in). Pri Cc = 5.476371 mm SEj 0.6 P P Maximum allowable internal pressure (psig) = 40 psi ri Internal radius of shell before allowance corrosion is added (in) = 26.32306 inch E j Efficiency of joints = 0.85 S Working stress (psi) = 13700 psi Cc Allowance for corrosion (in) = 0.125 inch Specification sheet for heat exchanger ( E-101) Equipment Name Heat exchanger Objective To cool the feed of the reactor which is contain hydrogen and nitro benzene Equipment Number E-101 Designer Hussain Butaleb Type Shell and tube heat exchanger Location After heat exchanger (E-103) Utility cooling water Material of Construction Carbon steel Operating Condition Shell Side Inlet temperature (oC) 5 Outlet temperature (oC) 170 Tube Side Inlet temperature (oC) 357.3 Outlet temperature (oC) 178 Number of passes 8 Thickness (mm) 5.476371 Number of Tube Per Pass 23184.72 Number of Tubes 185477.7 Tube bundle Diameter (m) 1337.214 LMTD (oC) 181.0804 U (W/C.m2) 137.9562 Heat Exchanger Area (m2) 27.95521 Heat Exchangers: Nomenclature Symbol Definition T1 Inlet shell side fluid temperature (°C) T2 Outlet shell side fluid temperature(°C) t1 Inlet tube side fluid temperature (°C) t2 Outlet tube side fluid temperature (°C) µ Fluid viscosity (m N s /m2) kf Thermal conductivity ( W/ m °C) Cp Mass heat capacity (kJ / Kg °C) Р Density of the fluid (Kg/ m3) Q Heat load (Kw) ∆Tlm Log mean temperature difference (°C) A Area (m2) U Overall heat transfer coefficient (W/m2. °C) do Tube outside diameter (mm) di Tube inner diameter (mm) Lt Tube length Re Reynolds number Pr Prandtl number Gs Mass velocity (m/s) lb Baffle spacing (m) T Shell Thickness ∆Pt Tube side pressure drop (N/m2) Np Number of tube side passes Ej Efficiency of joints S Working stress (psi) Cc Allowance for corrosion (in) ri Internal radius of shell Calculation procedure a. Define the duty: heat transfer rate, fluid flow rates, temperature. b. Collect together the fluid physical properties required: density, viscosity, c. Thermal conductivity. d. Select a trail value for the overall coefficient, U. e. Calculate the mean temperature difference, ΔTm. f. Calculate the area required from Q=UAΔTm. g. Calculate the bundle and shell diameter h. Calculate the individual coefficients. i. Calculate the overall coefficient and compare with the trail value. j. Calculate the exchanger pressure drop. k. Calculate thickness of the shell. l. Find the price of the heat exchanger based on the heat transfer area and the material of construction Detailed calculation procedure 1- Heat load Q = (m Cp ΔT) hot = (m Cp ΔT) cold, (kW) 2-Tube side flow , (Kg/hr) mcold Qhot C p Tcold 3- Log mean temperature Tlm T2 T1 T LN 2 T1 , (°C) T1 T1 t 2 T2 T2 t1 Where, T1: is inlet shell side fluid temperature (°C) T2: is outlet shell side fluid temperature (°C) t1: is inlet tube side temperature (°C) t2: is outlet tube side temperature (°C) 3-Calculate the mean (true) temperature ∆Tm ΔTm= Ft * ΔTlm For more than one tube passes (1 S ) ( R 2 1) LN (1 RS ) Ft 2 S ( R 1 ( R 2 1) ( R 1) LN 2 S ( R 1 ( R 2 1) R (T1 T2 ) (t 2 t1 ) S (t 2 t1 ) (T1 t1 ) Where, Ft: is the temperature correction factor R: is the shell side flow *specific heat / tube side flow*specific heat, (Dimensionless). S: is temperature efficiency of the heat exchanger, (dimensionless) 4- Provisional Area A Q UTm , (m2) Where, Area of one tube = Lt * do *π , (mm2) Outer diameter (do), (mm) Length of tube (Lt), (mm) Number of tubes = provisional area / area of one tube 5- Bundle diameter N , (mm) Db d o t K1 Where, Db: bundle diameter, (mm) Nt: number of tubes K1, n1: constants. 1 / n1 6- Shell diameter Ds = Db + (Bundle diameter clearance) , (mm) Using split-ring floating head type (bundle). From figure (A.12) we get bundle diameter clearance. 7-Tube side Coefficient Cold stream mean temperature= Tube cross sectional area = 4 t 2 t1 , (°C) 2 2 d i , (mm2) Tubes per pass = no. of tubes / number of passes Total flow area = tubes per pass * cross sectional area, (m2) Mass velocity = mass flow rate / total flow area, (kg /sec.m2) Linear velocity (ų) = mass velocity / density, (m/s) Reynolds number (Re) =ρ ų di / μ Prandtl number (Pr) = Cp μ / κ (hi di / κ) = jh Re Pr0.33 * (μ/μwall)0.14 Using Fig. to find jh 8-Shell side Coefficient Baffle spacing (Lb) = 0.2 * Ds, (mm) Tube pitch (pt) = 1.25 * do, (mm) Cross flow area (As) = (pt - do)* Ds* Lb / pt , (m2) Mass velocity (Gs) = mass flow rate / cross flow area, (kg/s.m2) Equivalent diameter for triangular arrangement (de) =1.1*(pt2-0.917do2) /do, (mm) Mean shell side temperature = (Thi +Tho)/2, (°C) Reynolds number (Re) = Gs de / μ Prandtl number (Pr) = Cp μ / κ And from fig find jh. hs = K * jh *Re *Pr (1/3) / de , W/m2.°C Overall heat transfer coefficient d d o LN o 1 1 1 di do 2K w di U o ho hod 1 hid do di 1 hi ,(W/m2.°C) 9- Pressure drop Tube side u 2 L / di 2.5 , (KPa) Pt N p 8 j f M /Mw 2 Where, ΔPt: tube side pressure drop (N/m2= pa) Np : number of tube side passes u : tube side velocity (m/s) L: length of one tube, (m) Use the fig.(A.14) Shell side Linear velocity = Gs /р D p s 8 j f s do L u 2 lb 2 M M w 0.14 Where, L: tube length, (m) lb: baffle spacing(m) Use fig.(12.30) to get jf. 10-Shell thickness t t: shell thickness (in) P : internal pressure (psig) ri: internal radius of shell (in) EJ: efficiency of joints S : working stress (psi) Cc: allowance for corrosion (in) Pri Cc SE j 0.6 P Sample Calculation: Heat exchanger (E-103) Shell side Prameter Unit Inlet Outlet Mean Tempreture Ti C 30 177 103.5 k W/m.C 1.37E-01 1.49E-02 0.075769 Mass Density ρ kg/m3 1191.8 1.35E+00 596.5761 Viscosity μ mPa.s 2.40E+00 7.54E-03 1.203118 Specfic Heat Cp KJ/Kg.K 142.9 165.67 154.285 Heat Of Vaporization KJ/kg Mass Flow Rate kg/s Thermal Conductivty 1.92E+02 5.448889 Tube side Prameter Unit Temperture ti C Thermal Conductvity Inlet Outlet Mean 184.81 163.87 174.34 W/m.C 2.06E-01 0.19891 0.202635 Mass Density kg/m3 0.2473 0.28409 0.265695 Viscosity mPa.s 1.20E-02 1.14E-02 0.011703 Specfic Heat Cp KJ/Kg.K 30.727 30.585 30.656 Mass Flow Rate kg/s 0.249167 Q = (m Cp ΔT) hot = 1.05E+03 KW T1 C 30 T2 C 177 t1 C 184.81 t2 C 163.87 Tlm T2 T1 T LN 2 T1 T lm= -44.36445101 °C Using one shell pass and one tube passes R (T1 T2 ) (t 2 t1 ) R= 7.020057307 S (t 2 t1 ) (T1 t1 ) S= 0.13526258 Using fig to find Ft Ft= 1 = -44.364451 °C Tm Ft * Tlm assume U=160 W/m2°C Provisional area m2 = 147.3956 A Q UTm Choose, Assume Outler diameter (do) 50 mm Assume inside diameter (di) 4 mm Assume Length of tubes (L) 10 m Area of one tube = Lt * do *π = 0.019635 m2 Number of tubes Nt = provisional area / area of one tube= 7506.796 tube As the shell – side fluid is relatively clean use 1.25 triangular pitch. N Bundle diameter Db= d o t K1 1 / n1 K1= 0.319 N1= 2.142 Db= 5494.096 mm Use a split – ring floating head type. Bundle diametrical clearance = 77 mm Shell diameter, Ds = Db + bundle diametrical clearance Ds= 5571.096 mm Tube – side coefficient 2 2 d i = * (26 E 3) = 1.26E-05 m2 4 4 Tube cross sectional area = Tubes per pass = Nt = 7506.796 1 Total flow area(area/pass) = tube per pass * cross sectional area = 0.094333 m2 Linear velocity (ut) = mass velocity/density = 9.941288 m/s The coefficient can be calculated from the following equation hi d i j h Re Pr 0.33 Kf w 902.7943 Re ud i 1.770509 Pr Cp Kf From figure jh= 3.00E-03 hs = 90.33455W/m2.C Assume that the viscosity of the fluid is the same as at the wall 1 w Shell - side coefficient Choose baffle spacing Lb= Ds 1114.219 mm 5 Tube pitch (pt)=1.25*do= 62.5 mm ( pt d o ) * Ds * Lb 1.241484 m 2 pt Cross-flow area As= 1.1 2 pt 0.917d o 2 0.035503 mm do Equivalent diameter de = Re = 129.5142 Pr = 486.7794 Choose 25% baffle cut. From figure jh= 7.00E-02 hs = 285.1998 W/m2.C Overall heat transfer coefficient d d o LN o 1 1 1 di 2k w U o ho hod Uo= 143.8143 (W/m2 °C) Acceptable Pressure drop: d o d i 1 hid do di 1 hi Tube side From figure for Re = 902.7943 jf= 3.00E-03 Neglecting the viscosity correction term u 2 L / di 2.5 pt N p 8 j f / w 2 pt 1477.507 pa Shell side From figure for Re = 129.5142 jf= 7.00E-02 Neglecting the viscosity correction term D Pt 8 j f s de Lt lb u 2 2 w Pt 12.20782 pa Shell thickness P= 5.2752 psig ri = 109.667 in S= 13,700 psi EJ =0.85 Cc = 0.125 in t = 0.174693 in = 4.437197 mm 0.14 Heat Exchanger (E-103) specification sheet E-103 Equipment Name To heat the nitro benzene feed by the reactor Objective (R-101) product Hussain Butaleb Designer Type Shell and tube heat exchanger Location After heat exchanger (E-102) Carbon steel Material of Construction Quartz wool – Glass wool Insulation Operating Condition Shell Side Inlet temperature (oC) 30 Outlet temperature (oC) 77 Tube Side Inlet temperature (oC) Number of passes 184.81 Outlet temperature (oC) 163.87 1 Number of Tubes 7506.796 Tube bundle Diameter (mm) 5571.096 Thickness (mm) 4.437197 Q total (W) 1.05E+06 LMTD (oC) -44.3645 U (W/m2 oC) 143.8143 Heat Exchanger Area (m2) 147.3956 Sample Calculation: Heat exchanger (E-102) Shell side Prameter Unit Inlet Outlet Mean Tempreture Ti C 311.64 184.81 248.225 k W/m.C 2.47E-01 2.06E-01 0.226535 Mass Density ρ kg/m3 0.21182 2.47E-01 0.22956 Viscosity μ mPa.s 1.48E-02 1.20E-02 0.013364 Specfic Heat Cp KJ/Kg.K 31.52 30.727 31.1235 Heat Of Vaporization KJ/kg Mass Flow Rate kg/s Thermal Conductivty 2.60E+02 5.449167 Tube side Prameter Unit Temperture ti C Thermal Conductvity Inlet Outlet Mean 114.06 249 181.53 W/m.C 1.94E-01 0.24214 0.218045 Mass Density kg/m3 9.54E-02 7.07E-02 0.083072 Viscosity mPa.s 1.04E-02 1.33E-02 0.011838 Specfic Heat Cp KJ/Kg.K 29.045 29.525 29.285 Mass Flow Rate kg/s 4.318056 Q = (m Cp ΔT) hot = 1.42E+03 KW T1 C 311.64 T2 C 184.81 t1 C 114.06 t2 C 249 Tlm T2 T1 T LN 2 T1 T lm= 66.61273864 °C Using one shell pass and one tube passes R (T1 T2 ) (t 2 t1 ) R= 0.939899214 S (t 2 t1 ) (T1 t1 ) S= 0.682963863 Using fig to find Ft Ft=0.85 = 56.62082784 °C Tm Ft * Tlm Assume U= 135 W/m2°C Provisional area = 185.5697 m2 A Q UTm Choose, Assume Outler diameter (do) 25 mm Assume inside diameter (di) 22 mm Assume Length of tubes (L) 1 m Area of one tube = Lt * do *π = 0.000491 m2 Number of tubes Nt = provisional area / area of one tube= 378039.5 tube As the shell – side fluid is relatively clean use 1.25 triangular pitch. N Bundle diameter Db= d o t K1 K1= 0.319 1 / n1 N1= 2.148 Db= 16810.04 mm Use a split – ring floating head type. Bundle diametrical clearance = 78 mm Shell diameter, Ds = Db + bundle diametrical clearance Ds= 16888.04 mm Tube – side coefficient 2 2 d i = * (26 E 3) = 0.00038 m2 4 4 Tube cross sectional area = Tubes per pass = 378039.5 Total flow area(area/pass) = tube per pass * cross sectional area = 143.7052 m2 Linear velocity (ut) = mass velocity/density = 0.361711 m/s The coefficient can be calculated from the following equation hi d i j h Re Pr 0.33 Kf w 55.84426 Re ud i 1.589860751 Pr Cp Kf Assume that the viscosity of the fluid is the same as at the wall 1 w From figure jh= 2.50E-02 hi 8.806477 (W / m 2 C ) Shell - side coefficient Choose baffle spacing Lb= Ds 3377.608 mm 5 Tube pitch (pt)=1.25*do= 31.25 mm ( pt d o ) * Ds * Lb 11.40824 m 2 pt Cross-flow area As= 1.1 2 pt 0.917d o 2 0.017751 mm do Equivalent diameter de = Re = 634.4598 Pr = 1.727612687 Choose 25% baffle cut. From figure jh= 2.00E-02 hs = 197.2752 W/m2.C Overall heat transfer coefficient d d o LN o 1 1 1 di 2k w U o ho hod d o d i Uo= 152.4811 (W/m2 °C) Acceptable Pressure drop: Tube side From figure jf= 2.50E-02 Neglecting the viscosity correction term 1 hid do di 1 hi u 2 L / di 2.5 pt N p 8 j f / w 2 pt 0.104043 pa Shell side From figure for Re = 634.4598 jf= 2.00E-02 Neglecting the viscosity correction term D Pt 8 j f s de Lt lb u 2 2 w Pt 40.31546 pa Shell thickness P= 14.7 psig ri = 332.4411 in S= 13,700 psi EJ =0.85 Cc = 0.125 in t = 0.544973 in = 13.84232 mm 0.14 Heat Exchanger (E-102) specification sheet E-102 Equipment Name to heat hydrogen feed from the reactor (R-101) Objective product Designer Hussain Butaleb Type Shell and tube Location After reactor (R-101) Material of Construction Carbon steel Insulation Quartz wool – Glass wool Operating Condition Shell Side Inlet temperature (oC) 311.64 Outlet temperature (oC) 184.81 Inlet temperature (oC) 114.06 Outlet temperature (oC) 249 Number of passes 1 Number of Tubes 378039.5 Tube bundle Diameter (m) 16888.04 Thickness (mm) 13.84232 Q total (W) 1.42E+03 LMTD (oC) 56.62083 U (W/m2 oC) 152.4811 Heat Exchanger Area (m2) 185.5697 Tube Side Steam Drum (V-102) A steam drum is a standard feature of a water-tube boiler. It is a reservoir of water/steam at the top end of the water tubes. The drum stores the steam generated in the water tubes and acts as a phase-separator for the steam/water mixture. The difference in densities between hot and cold water helps in the accumulation of the "hotter"-water/and saturated-steam into the steam-drum. Since the drum serves at high pressures and temperatures, it is expensive to manufacture and there is considerable economic incentive to keep it as small as possible. Two Phase Separator Design: A vapor-liquid separator is a device in which a liquid and vapor mixture is fed and the liquid is fall by gravity to the bottom of the vessel while the vapor travels upward to the top of the vessel. These separators are used after flashing a hot liquid across a valve (flash drum) .The most reason for using vapor-liquid separators is to recover valuable products. Design Procedure: 1. State assumptions. 2. Calculate the settling velocity in m/s using the following equation: U t 0.07 ( L V ) V , Where ρL is the liquid density (kg/m3) and ρv is the gas density (kg/m3). 3. Calculate the actual settling velocity in m/s by: Ua=0.15Ut. 4. Calculate the volumetric flow rates for both the vapor ( Vv) and liquid (VL) in m3/susing: VV mV VL mL V And L , Where mv, L is the mass flow rate for vapor and liquid in kg/h respectively. 5. Get the cross-sectional area in terms of Dv (minimum vessel diameter, m): Ac Dv 2f v 4 , Where fv is the fraction of the total cross-sectional area occupied by vapor which equals 0.5. 6. Get an expression for the vapor residence time for the droplets to settle to liquid surface in terms of Dv: tr hv , Ua Where hv is the liquid level (m), hv=0.5Dv. 7. Get an expression for the actual residence time in terms of Dv: tra Lv , Uv Where Lv is the vessel length (m), Lv=4Dv. And Uv is the vapor velocity (m/s), Uv Vv . Ac 8. Find the value of Dv by equalizing tr and tra. (Solve tr-tra=0). Then find the length of the separator Lv=4Dv. 9. Calculate the thickness of the separator using the following equation: t Pri Co , SE j 0.6P Where P is the operating pressure in psig (P=405 psig), ri is the radius of the vessel (ri=Dv/2 (in)), S is the stress value of carbon steel (S=13700 psia), Ej is the joint efficiency (Ej=0.85 for spot examined welding), and Cc is the corrosion allowance (Cc=1/8 in). These values were obtained from the metals table (in the Appendix B). Assumptions: The horizontal separator is assumed not to have a demister pad. Detailed Calculation: Operating conditions: T= 208 oC P= 264 psig. Design Consideration: rL= 1220 kg/m3 r V= 8.197 kg/m3 mv= 20243.31 kg/h mL= 24400 kg/h Calculating the settling velocity: ( L V ) U t 0.07 V = 0.85111 m/s Calculating the actual velocity: Ua = 0.15Ut = 0.15* = 0.12767 m/s Calculating both vapor and liquid volumetric flow rates: o VV VL mL L mV = 0.686 m3/s V = 0.00556 m3/s Expressing the cross-sectional area in terms of Dv: o Ac Dv 2f v 4 * Dv 2 *0.5 4 = 0.393 Dv2 m2 Expressing the residence time in terms of Dv: o tr hv = 3.916 Dv s Ua Expressing the actual residence time in terms of Dv: Uv Vv = 1.746Dv-2 m/s Ac Finding the value of Dv: Lv = 2.291 Dv3 s Uv o tra o tr-tra= Dv - Dv3 = 0 Dv= 1.3074 m Lv=4Dv= 4*1.3074 = 5.2296 m Calculating the thickness of the vessel: Ej =0.85 S = 13700 psi Cc = 0.125 in ri = Dv/2 = 0.6537 o t Pri Co SE j 0.6P = 0.7165 in = 0.0182 m Time hold up = 14.5 hr Volume = 9.946999 m3 Steam Drum Specification Sheet V-102 Steam Drum Equipment Name Separate the steam (upward) from the water Objective liquid (downward) Equipment Number V-102 Designer Hussain Butaleb Type Horizontal Separator Location After heater (E-105) Material of Construction Carbon steel Insulation Glass wool Operating Condition Operating Temperature (oC) 208 Operating Pressure (psig) 264 Liquid Density (kg/m3) 1220 Gas Density (kg/m3) 8.197 Gas Flow rate (kg/h) 20243.31 Liquid Flow rate (kg/h) 24400 1.3074 Height (m) 5.2296 Design Considerations Dimensions Diameter (m) Vessel (V-101) A vapor-liquid separator is a device in which a liquid and vapor mixture is fed and the liquid is fall by gravity to the bottom of the vessel while the vapor travels upward to the top of the vessel. These separators are used after flashing a hot liquid across a valve (flash drum) .The most reason for using vapor-liquid separators is to recover valuable products. Vertical separators have the advantage of lower space requirement and easy to install control systems. Material of insulation depends on the operating temperatures, since temperature in the separator is not high so the possible materials that cover the temperature are glass fiber and mineral wool. Design Procedures and Equations: Properties 3342 Vapor flow rate (Mv) Kg/h Liquid flow rate (ML) Kg/h 44000 Vapor density (ρv) Kg/m3 0.20298 Liquid density (ρL) Kg/m3 1014.4 Inlet Pressure (P) psi 25 Max allowable working stress (S) psi 13700 Efficiency expressed as a fraction (Ej) 0.85 Allowance for corrosion (Cc) Steel density 0.125 Kg/m3 7700 1- To estimate the settling velocity of the liquid droplets: 1 ut = 0.07 X [ (ρl − ρv ) 2 ρv ] = 4.948033 m/s ut = settling velocity, m/s ρv = vapor density, kg/m3 ρl = liquid density, kg/m3 2- Volumetric flow rate: Vv = lv = kg ) s kg Vapor density ( 3) m = 4.573521 m3/s kg ) s kg liquid density ( 3) m = 0.012049 m3/s Vapor flow rate ( liquid flow rate ( 3- Volume held in vessel VHV = 10 * 60 * Lv = 7.229232 (m3) 4- Minimum vessel diameter Dv = [(4 * Vv ) / (pi * Us )]0.5 = 1.085111 (m) =42.72091 (in) Dv = minimum vessel diameter, m Vv = gas, or vapor volumetric flow rate, m3/s 5- Liquid depth Hv = VHV / [(pi / 4) * (Dv )2 ]= 7.821212(m) ri = Dv / 2= 3.99962 (m) = 0.542556 (in) Thickness = Cc + [(P * ri ) / (S * Ej – 0.6 * P)]= 0.170917 (in) =0.004341 (m) h = [3 * (Dv / 2)] + Dv + Hv + 0.4 = 10.93399 (m) CC = allowance for corrosion, in. Ej = efficiency of joints expressed as a fraction. S = maximum allowable working stress, psi. rj = inside radius of the shell, before corrosion allowance is added, in. 6- Area of vessel : Area of vessel = 2*pi*(dv/2)*ht= 37.25483 (m2) 7- Metal Volume of metal Vm = area of vessel*thickness = 0.161734 (m3) Weight of metal Wm= Vm*Steel density= 1245.35 (kg) Specification sheet for separator V-101 Separator Equipment Name To separate hydrogen (vapor) from the Objective aniline and water (liquid) Equipment Number V-101 Designer Hussain Butaleb Type Vertical Location After cooler E-104 Material of Construction Carbon Steel Insulation Glass wall and quartz Operating Condition Operating Temperature (oC) 40 Operating Pressure (psi) 25 Dimensions Diameter (m) 1.085111 Height (m) 10.93399 Storage Tank (T-101) A storage tank is a container, usually for holding liquids, sometimes for compressed gases (gas tank). The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers. Storage tanks are available in many shapes: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom and dish bottom. Large tanks tend to be vertical cylindrical, or to have rounded corners transition from vertical side wall to bottom profile, to easier withstand hydraulic hydrostatically induced pressure of contained liquid. Most container tanks for handling liquids during transportation are designed to handle varying degrees of pressure. The top space in the tank for the vapor pressure of the component will be 12 % of the tank volume. Design and Calculation: For Tank (T-101) 1- Assume: Cylindrical tank Square shape from inside (D=0.2H) Daily storage (time hold-up=12 hr) 2-Volume of the liquid: Volume of the liquid = Total mass flow rate in* time hold-up = 190.8 m3 Where time hold-up is the time where the liquid is hold inside the tank =12 hours. 3- The total volume: The total volume=volume of liquid/0.12 = 1590 m3 4-The actual diameter: The actual diameter=(5*the total volume/π)^(1/3) = 13.62948 m 5- The actual high: The actual high = 0.2* diameter = 2.725895 m 6-Area of the storage tank: Area of the storage tank =V/H = 583.2946 m2 7- Thickness: The best materiel is construction is carbon steel. t = (P r i / S E – 0.6P) + Cc P : internal pressure (kpa gage) r i : internal radius of shell (m) E : efficiency of joints = 0.85 S : working stress (kpa) = 94500 Cc : allowance for corrosion (m ) = 0.003175 ri(m) = 6.814738 t(m) = 0.01178 8- Vapor pressure: Vapor pressure = Log10 P* = A- (B/C+T) = 760 mmhg Specification sheet of Tank T-101 Equipment Name T-101 Objective NitroBenzene feed tank Designer Hussain Butaleb Location The first equipment Material of Construction Carbon steel Insulation Quartz Wool Operating Condition Operating Temperature (oC) 30 Diameter (m) 13.62948 Operating Pressure (Pisa) 14.7 Height (m) 2.725895 Feed Flow Rate (kmole/h) Vapor Pressure (atm) 127.0822199 Thickness (m) 1 Total Area (m2) 0.01178 583.2946 Hydro cyclone (T-102) Hydrocyclones, also known as liquid cyclones, are an important device for the separation of solid-liquid suspensions. The principle employed is centrifugal sedimentation, i.e., the particles in the suspension are subjected to centrifugal forces, which cause their separation from the fluid. Like centrifuges, which make use of the same principle, hydrocyclones do not have moving parts, require a low installation and maintenance investment and are simple to operate. Hence, these devices are widely utilized in mineral, chemical, petrochemical, textile and metallurgical industries. The hydrocyclone separates solid and liquid or liquid and liquid by the difference in density between the fluid and the material to be separated in this equipment. Due to the fluid acquires a spiraling motion caused by the tangent feeding, the material of larger density is thrown against the wall of the hydrocyclone and dragged to the underflow while the one of smaller density proceeds for the overflow, forming a free vortex (outer vortex) and a forced vortex (inner vortex) in agreement with Figure ………… The typical proportions of the hydrocyclone are shown in figure ……… Design equations: 𝑑50 = 4.5 [ 𝐷𝑐 3 𝜇 ] 𝐿1.2 (𝜌𝑠 − 𝜌𝐿 ) Where 𝑑50 = 𝑡ℎ𝑒 𝑝𝑎𝑟𝑡𝑖𝑐𝑙𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑓𝑜𝑟 𝑤ℎ𝑖𝑐ℎ 𝑡ℎ𝑒 𝑐𝑦𝑐𝑙𝑜𝑛𝑒 𝑖𝑠 50% 𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡, 𝜇𝑚 𝐷𝑐 = 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 𝑜𝑓 𝑡ℎ𝑒 𝑐𝑦𝑐𝑙𝑜𝑛𝑒 𝑐ℎ𝑎𝑚𝑝𝑒𝑟, 𝑐𝑚 𝜇 = 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑦, 𝑐𝑒𝑛𝑡𝑖𝑝𝑜𝑖𝑠𝑒 (𝑚𝑁 𝑠 ) 𝑚2 𝐿 = 𝑓𝑒𝑒𝑑 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 𝑙/𝑚𝑖𝑛 𝜌𝐿 = 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 𝑜𝑓 𝑡ℎ𝑒 𝑙𝑖𝑞𝑢𝑖𝑑, 𝑔/𝑐𝑚3 𝜌𝑠 = 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 𝑜𝑓 𝑡ℎ𝑒 𝑠𝑜𝑙𝑖𝑑, 𝑔/𝑐𝑚3 Thickness: The best materiel is construction is carbon steel. t = (P r i / S E – 0.6P) + Cc P : internal pressure (kpa gage) r i : internal radius of shell (m) E : efficiency of joints S : working stress (kpa) Cc : allowance for corrosion (m ri(m) t(m) Area (m2) = 3.14*r2*h Volume (m3) = area*h /3 Tank (T-102) T-102 is a simple solid separator used to separate solids from the mixture. Hydrocyclone was chosen because it is a simple separator that can be used over the particle size range from 4 to 500 𝜇𝑚. The efficiency of the hydrocyclone is assumed to be 95% and according to equation …… Where 𝜇 = 7 𝑐𝑃 𝐿 = 295.18 𝐿 𝑚𝑖𝑛 𝜌𝑠𝑜𝑙𝑖𝑑 = 1.601808 𝜌𝑎𝑖𝑟 = 1.2344 𝑔 𝑐𝑚3 𝑔 𝑐𝑚3 𝐷𝑐 3 (7) 50 = 4.5 [ ] (295.18)1.2 (1.601808 − 1.2344) The chamber diameter of the hydrocyclone Dc = 8.127753 cm Height = 1.6 m The best materiel is construction is carbon steel. t = (P r i / S E – 0.6P) + Cc P : internal pressure (kpa gage) r i : internal radius of shell (m) E : efficiency of joints = 0.85 S : working stress (kpa) = 94500 Cc : allowance for corrosion (m ) = 0.003175 ri(m) = 0.004064 t(m) = 0.003189 Area = 82.97183 m2 Volume = 44.25164 m3 Specification sheet for hydro cyclone (T-102) T-102 Equipment Name To separate the air from the solid waste Objective catalyst Designer Hussain Butaleb Location After the reactor (R-101) Material of Construction Carbon steel Operating Condition Volumetric flow rate (Air) 161.887 Chamber Diameter Dc (cm) 8.127753 Volumetric flow rate (Solid) 133.2925 Thickness (cm) 3.189 Distillation Column and Stripper Distillation is probably the most widely used separation process in chemical and allied industries. The separation of liquid mixtures by distillation depends on differences in volatility between the components. The greater the relative volatilities, the easier the separation. The basic equipments required for continuous distillation are a reflex column, a condenser, and a reboiler. Vapor flows up the column and liquid counter-currently down the column. The vapor and liquid are brought into contact on plates or packing. Part of the condensate from the condenser is reflex back to the top of the column, while part of the bottom liquid is vaporized in the reboiler and returned to provide the vapor flow. In the section below the feed , the more volatile component and stripped from the liquid and this is known as stropping section .Above the feed, the concentration of the more volatile components is increased and this is called enrichment ,or more commonly, the recifying section. Stripping works on the basis of mass transfer. The idea is to make the conditions favorable for the component, A, in the liquid phase to transfer to the vapor phase. This involves a gas-liquid interface that A must cross. The total amount of A that has moved across this boundary can be defined as the flux of A, NA. Stripping is mainly conducted in trayed towers (plate columns) and packed columns, and less often in spray towers, bubble columns, and centrifugal contactors. The Different Types of Distillation There are several methods of distillation depending on the procedure and the instrument setup. Each distillation type is used for purification of compounds having different properties. Following are the common types. Simple Distillation Simple distillation is practiced for a mixture in which the boiling point of the components differ by at least 70° C. It is also followed for the mixtures contaminated with nonvolatile particles (solid or oil) and those that are nearly pure with less than 10 percent contamination. Double distillation is the process of repeating distillation on the collected liquid in order to enhance the purity of the separated compounds. Fractional Distillation Those mixtures, in which the volatility of the components is nearly similar or differs by 25° C (at 1 atmosphere pressure), cannot be separated by simple distillation. In such cases, fractional distillation is used whereby the constituents are separated by a fractionating column. In the fractionating column, the plates are arranged and the compound with the least boiling point are collected at the top while those with higher boiling point are present at the bottom. A series of compounds are separated simultaneously one after another. Fractional distillation is used for the alcohol purification and gasoline purification in petroleum refining industries. Steam Distillation Steam distillation is used for the purification of mixtures, in which the components are temperature or heat sensitive; for example, organic compounds. In the instrument setup, steam is introduced by heating water, which allows the compounds to boil at a lower temperature. This way, the temperature sensitive compounds are separated before decomposition. The vapors are collected and condensed in the same way as other distillation types. The resultant liquid consists of two phases, water and compound, which is then purified by using simple distillation. Steam distillation is practiced for the large-scale separation of essential oils and perfumes. Vacuum Distillation Vacuum distillation is a special method of separating compounds at pressure lower than the standard atmospheric pressure. Under this condition, the compounds boil below their normal boiling temperature. Hence, vacuum distillation is best suited for separation of compounds with higher boiling points (more than 200°C), which tend to decompose at their boiling temperature. Vacuum distillation can be conducted without heating the mixture, as usually followed in other distillation types. For the separation of some aromatic compounds, vacuum distillation is used along with steam distillation. Short Path Distillation Thermal sensitive compounds can also be separated by following short path distillation. In this technique, the separated compounds are condensed immediately without traveling the condenser. The condenser is configured in a vertical manner between the heating flask and the collecting flask. Similar to vacuum type, the pressure is maintained below the atmospheric pressure. Short path distillation is used for the separation of organic compounds with high molecular weight, especially in the pharmaceutical industries. Another method of classifying distillation is based on the column type used in the process. There are two types of distillation columns namely, batch and continuous. Columns for the distillation process can be of the following types: 1. The 'PACKED' Tower. 2. The 'TRAY' Tower. 1. THE PACKED TOWER As its name implies, the packed tower is a vertical, steel column which contains 'Beds' of packing material which are used to bring the rising vapours into intimate contact with falling liquid within the tower. The heat added to the mixture before entering the tower partially vaporises the mixture and the vapours rise up the tower and begin to cool. The liquid falls towards the bottom of the tower. At the tower bottom, in general, more heat is added to the liquid by a 'Reboiler' which may be steam heated or a fuel fired furnace type. The addition of heat here causes more vapours to rise up the column. As the two phases of the mixture - falling liquid and rising vapour - come together, light components are stripped out of the liquid and enter the gas phase while heavy components in the vapour are condensed into the liquid phase. In this way, as the vapour rises and gradually cools, it becomes lighter and, as the liquid falls, it becomes hotter and heavier. With this type of distillation column there is generally only a top and bottom product. The quality of the products depends upon the height of the tower, the number of contacting devices, the tower temperature and pressure and their control, and the velocity of the rising vapours. The type of packing materials used, also plays a part in the separation process. Distillation Packing types: 2. THE TRAY TYPE TOWER This is also a tall, cylindrical column. Inside, a series of trays are placed, one above the other. The trays are used to bring the rising vapour and falling liquid into intimate contact. Tray towers do the same job as packed towers but they are very much more efficient in the separation process than packed towers and, they are also more costly. There are various types of tray in use and the type selected depends upon the degree of product purity required, the type of fluids, fluid velocity and other process parameters of the system. Distillation Trays: Sieve or Perforated Trays Sieve trays are made from a flat perforated plate which allows the passage of vapor through the liquid. They are the most economical tray option when low turndown is required. They have better anti-fouling characteristics and lower pressure drop than valve or bubble cap trays. Perforations are typically 1/2” diameter, but Ambani Metals can provide designs with smaller hole size. Valve Trays Ambani Metals valve trays have better turndown and slightly higher efficiency than sieve trays. Ambani Metals offers different valve selections including fixed valves, floating valves and combination valves. Valve trays cost more than sieve trays, but are more economical than bubble cap trays. One Piece Valve This is the most commonly used valve. This design features integral legs for tray decks up to 1/4” thickness. Anti-stick dimples are standard. Other options include heavy/light valve combination, flush designs and non-rotating tabs in the tray deck. 3 Piece Valve This valve consists of a light weight orifice plate, a valve, and a restraining cage. This design is recommended for higher turndowns. Fixed Valve This valve is integral with the tray deck. This is the preferred option for fouling conditions. However, it provides lower turndown and less efficiency than floating valves. One Piece Rectangular Valve < Ambani Metals offers rectangular valves, caged valves, and also venturi type openings to provide lower pressure drop. Bubble Cap Trays Bubble cap trays are best suited for applications with low liquid flows and/or high turndown ratios. In terms of capacity, however, they are slightly lower than valve or sieve trays. They are also the most expensive tray option. Dual Flow Trays Dual flow trays are sieve trays that do not have downcomers. The term dual flow comes from the countercurrent flow of the vapor and liquid through the perforations. Typical perforation sizes range between 1/2” and 1” in diameter. Dual flow trays best suit systems containing a moderate to high solids content or polymerizable compounds. High open area dual flow trays have a higher capacity and lower pressure drop than comparably spaced fractionation trays. However, their primary drawback is their narrow operating range. Most often, they are efficient when used in smaller tower diameters. Dual flow trays are also sensitive to levelness and may be subject to gross liquid and vapor flow partitioning through the deck if not level. Baffle Trays Because of their open design, baffle trays are used in applications requiring high capacity, fouling resistance and low pressure drop. Vapor-liquid contacting takes place when the vapor passes through a curtain of liquid falling between trays, or through rivulets of liquid flowing through tray deck perforations. Tray decks may be level or slightly inclined and typically occupy 40-60% of the tower cross-sectional area. “Disk and donut” trays have circular baffles and are a popular variant of this deign. Baffle trays are well suited for heattransfer applications including heavy oil refining and petrochemical oil refining and petrochemical heat transfer services with high solids or petroleum coke content. High Strength Trays For applications with potentially damaging uplift surges, Ambani Metals can equip trays with special heavy duty features. These include special fasteners, increased tray thickness or additional support beams. Depending upon specific operating criteria, design adjustments can be made to take into account parameters such as corrosion, temperature, vibration and pressure surges. Contact your Ambani Metals separation specialist for design assistance. Design and equations for distillation: Nomenclature Symbol Definition FLv Liquid vapor flow factor Lw Liquid mass flow rate (kg/s) Vw vapor mass flow rate (kg/s) ρv Vapor density (kg/m 3) ρL Liquid density (kg/m 3) uf flooding vapor velocity (m/s) u`v flooding at maximum flow rate (kg/s) Ac Total column cross sectional area (m2) Dc Column diameter (m) Ad cross sectional area of down comer (m2) An Net area (m2) Aa Active area (m2) Ah Hole area (m2) Aap Clearance area (m2) Ap Perforated area (m2) how Weir crest (mm) liquid u`h Min. vapor velocity (m/s) hd Dry plate drop (mm) hr Residual head (mm) hap Out let weir height (mm) hdc Head loss in downcomer (mm) T thickness of cylindrical shell (in) P maximum allowable internal pressure (psi) S maximum allowable working stress (psi) Ri : inside radius of shell (in) Ej efficiency of joint expressed as fraction Cc allowance for corrosion (in) Design procedures: 1. Collect, or estimate, the system physical properties. 2. Select trial plate spacing. 3. Calculate Nmin. 4. Calculate the height of the column. 5. Calculate the column diameter based on flooding consideration. 6. Make a trial plate layout: downcomer area, active area, hole area, hole size, weir height. 7. Calculate the weeping rate. 8. Calculate the plate pressure drop. 9. Calculate downcomer back-up. 10. Calculate residence time. 11. Calculate heat transfer area for the condenser and reboiler. 12. Calculate thickness. 13. Calculate cost. Equations: Lquid vapor flow rate: For top and bottom: FLV L V v L 0.5 Where: FLV= liquid vapor flow rate. L= liquid flow rate. V= vapor flow rate. Find K1 from figure: Flooding velocity: ( V ) U f K 1 L V 0.5 Where: Uf= flooding velocity. K1= constant. Actual velocity: U V Percentage Flooding x U f Where: Uv= actual velocity. Maximum volumetric flow rate: Vmax MwtV V Where: Vmax= maximum volumetric flow rate. MwtV= vapor molecular weight. Nmin: Nmin = (log(xd/1-xd)*(xw/1-xw)) /(log volatility) Net area required: Anet Vmax UV Anet= net area required. Diameter: 4 D Anet 0.5 Where: D = diameter. Max volumetric liquid rate: max volumetric liquid rate Where: L=liquid flow rate. Choose plat pass from figure Column area: AC 4 D2 Where: AC= column area. Net area: An AC Ad LxMwt L Where: An= net area. Active area: Aa Ac 2 Ad Aa= active area. Hole area: Ah 0.1xAa Ah= hole area. From figure get lw/Dc ; Weir length: weir length 0.75D Wier crest: max liquid rate max how 750 L xweir length 2 3 2 min liquid rate 3 min how 750 L xweir length Where: how= weir crest. Vapor velocity: U h (min) K 2 0.9(25.4 hole diameter) Where: Uh= vapor velocity. Choose Turndown percentage = 70% From figure get K2 Actual min. vapor velocity: 0.5 actual min . vapor velocity min . vapor rate Ah Where: Ah= hole area. From figure get Co Pressure drop through dry plate: U hd 51 h Co 2 V L Where: hd= pressure drop through dry plate. Co= orifice coefficient. Residual head: hr Where: 12.5 x10 3 L hr= residual head. Height of bottom edge of apron above plate: hap hw 10 Where: hap= height of bottom edge of apron above plate. hw= weir height. Area under apron Aap : area under apron Aap weir lengthxhap Back-up in downcomer: max . liquid rate hdc 166 xA L ap hb hw hdc ht how Where: hb= back-up in downcomer. Downcomer residence time: tr Where: tr= downcomer residence time. Lwd= minimum liquid flow rate. hb xAdx L Lwd 2 UV volumetric flow rate An Thickness: Pxri CC t SxEj 0.6 xP Where: t= thickness. P= pressure. r= radius. S= working stress. Ej= efficiency of joints. CC= allowance for corrosion. Design for distillation: Properties: Top properties Vapor rate (V) = ρv = MW = Liquid rate (L) = ρL = MW = Surface Tension = 2.91E+03 kmol/hr 3.28769 kg/m3 107.2743 2.42E+03 kmol/hr 1050.493 kg/m3 122.5036 4.74E+01 N/m Bottom properties Vapor rate (Vm) = ρv = MW = Liquid rate (Lm) = ρL = MW = Surface Tension = 2.90E+03 kmol/hr 3.906938 kg/m3 1.23E+02 2.91E+03 kmol/hr 981.5581 kg/m3 123.0347 3.77E+01 N/m Calculation: Number of Stages (No. of stages)min = 5 Efficiency = 75% (Assumed) Actual stages = 6 Liquid vapor flow rate: For top: v L 0.5 FLV L V v L 0.5 FLV L V = 0.046591 For bottom: Where: FLV= liquid vapor flow rate. L= liquid flow rate. V= vapor flow rate. Take tray spacing 0.75 m Find K1 from figure: Bottom K1 =1.00E-01 Top K1 = 1.5E-01 Flooding velocity: For top: = 0.063308 0.5 ( V ) = 12.66702 m/s U f K 1 L V 0.5 ( V ) = 7.147454 m/s U f K 1 L V Where: K1= constant. Design for 85% flooding at maximum flow rate Actual velocity: For top: U V Percentage Flooding x U f = 10.76697 m/s For bottom: U V Percentage Flooding x U f = 6.075336 m/s Maximum volumetric flow rate: For top: Vmax MwtV = 3.26E+01 m3/s Vmax MwtV = 1.84E+01 m3/s V For bottom: Where: MwtV= vapor molecular weight. Xw= 0.990221 Xd= 0.724112 Volatility= 0.45 Nmin= 4.574458 V Net area required: For top: Anet Vmax = 3.440657 m2 UV Anet Vmax = 3.437593 m2 UV For bottom: Take downcomer area as 12% of total Diameter: 4 D Anet 0.5 = 2.09 m Max volumetric liquid rate: max volumetric liquid rate LxMwt L = 0.101322 m3/h Where: L=liquid flow rate. Column area: AC 4 D 2 = 3.440759 m2 Net area: An AC Ad = 3.027868 m2 Active area: Aa Ac 2 Ad = 2.614977 m2 Hole area: Ah 0.1xAa = 0.261498 m2 Taking Weir height (hw) = 50 mm Hole diameter (dh) = 5 mm Plate thickness = 5 mm Weir length: weir length 0.75D = 1.611658 m Wier crest: 2 max how max liquid rate 3 = 118.5807 mm liquid 750 L xweir length min liquid rate min how 750 L xweir length 2 3 = 93.48587 mm liquid Vapor velocity: U h (min) K 2 0.9(25.4 hole diameter) 0.5 = 6.900747 m/s Actual min. vapor velocity: actual min . vapor velocity min . vapor rate = 49.19689 m/s Ah Where: Ah= hole area. Pressure drop through dry plate: U hd 51 h Co 2 V L = 1648.089 mm liquid Where: hd= pressure drop through dry plate. Co= orifice coefficient. Residual head: hr 12.5 x10 3 L = 12.73485 mm liquid Height of bottom edge of apron above plate: hap hw 10 = 40 mm liquid Where: hap= height of bottom edge of apron above plate. hw= weir height. Area under apron Aap : area under apron Aap weir lengthxhap = 0.064466 m2 Back-up in downcomer: 2 max . liquid rate = 410.0589 mm hdc 166 xA L ap hb hw hdc ht how = 2.408044 m Downcomer residence time: tr hb xAdx L = 9.813 s Lwd Where: tr= downcomer residence time. Lwd= minimum liquid flow rate. UV volumetric flow rate = 6.070 An Thickness: Pxri CC = 5.0 mm t SxEj 0.6 xP Where: For carbon steel t= thickness. P= pressure. r= radius. S= working stress. Ej= efficiency of joints. CC= allowance for corrosion. ri = 41.20204 in P= 20 psi S= 13700 psi Ej = 0.85 Cc = 1.25E-01 in (for carbon steel) Specification sheet of distillation (C-101) Distillation Equipment Name Objective To mix hydrogen gas with nitrobenzene gas C-101 Equipment Number Designer Hussain Butaleb Location After cooler (E-101) Material of Construction Carbon steel Insulation Mineral wool Operating Condition Operating Temperature (oC) 140.9 Operating Pressure (psi) 30 Feed Flow Rate (kgmol/h) 497.520473339072 Diameter (m) 2.09 Height (m) 6.6 Thickness (mm) 5 Stripper (C-2101) Typical applications: Stripping is commonly used in industrial applications to remove harmful contaminants from waste streams. One example is decontaminating soils almost completely. Steam is also frequently used as a stripping agent for water treatment. Volatile organic compounds are partially soluble in water and because of environmental considerations and regulations, must be removed from groundwater, surface water, and wastewater. These compounds can be present because of industrial, agricultural, and commercial activity. Packed column: There are a number of advantages to the packed column design. Improvements can yield proof of about 190, and the still can be run either continuously or on a batch basis. On a small scale, packed columns are inexpensive to build and quite easy to operate. However, on a large scale the design presents problems. Design of Stripper Columns: 1- Estimate the slope m from equilibrium data of process. 2- Calculate the amount mGm/Lm, and y1/y2 to determine NOG from figure. Assume 38mm and 1.5 ceramic interlocks saddles. 3- Calculate Flow of liquid vapor: FLV Lw Vw V L 4- Design for pressure drop 125mmH2O/m packing and get K4 from the figure. 5- Calculate percentage flooding = (K4 / K4 @flooding )^.5 *100 6- Calculate Vmin and V actual: Vmin = L(x1-x2)/m(y1-y2) V actual = Vmin *1.5 7- Calculate gas mass flow rate per unit column cross sectional area. 8- Calculate column area required in m² = gas flow rate /V*w 9- Calculate diameter and round of diameter and approximate area. 10- Estimate packing size to column diameter ratio. 11- Estimating HOG and height of the column using figures and equations: 12- Get HOG = Hg + ( HL * mGm/Lm), and z = HOG * NOG. Stripper (C-201) (Packed) Feed Property Gas Liquid Flow rate (Kg/h) 2.28E+03 6.47E+03 Flow rate (Kgmole/h) 1.17E+02 3.59E+02 Density р (Kg/m3) 0.648029375 947.674435 Viscosity µ (N s/m2) 9.27E-03 2.77E-01 Molecular weight (g/mol) 19.44657143 18.0370529 Surface tension (N/m) - 58.4970599 m slop of the equilibrium = 0.0625 m Gm/Lm = 2.04E-02 y1/y2 = 32.30769231 From fig: NOG = 0.5 Column Diameter Gas Flow rate = 6.33E-01 Kg/s Liquid Flow rate = 1.797301255 Kg/s Select 38mm (1 1/2) in ceramic Intalox saddles From Table: Fp = 35 m-1 FLV = 0.074209109 Design for pressure drop 125mm H2O/m packing From Figure: K4 = 2.2 At flooding K4 = 4 Percentage Flooding = 74.16198487 % L (kg/h) x1 x2 y1 y2 y2' m 7101 0.018787 0.006161 0 0.99975 0.000003 0.0625 Vmin V actual = Vmin *1.5 1434.874335 2152.311502 V*w = 2.577539424 Kg/m2.s Column Area required = 2.46E-01 m2 Actual Diameter = 1 m Column Area = 0.78525 m2 Packing size to column diameter ratio = 26.3157895 Large packing size can be considered Percentage of flooding for selected diameter = 2.32E+01 Estimate for HOG DL= 1.8E-09 m2/s DV= 0.00000152 m2/s (Sc)v = 9406.149061 μ /ρ*DL (Sc)L = 162563.2521 μ /ρ*DL L*w = 2.28882681 From Figure 11.41 K3= 1 From Figure 11.42 ψh= 24 From Figure 11.43 φh= 1.00E-01 HOG can be expected to be around = 5 m Estimate Z(height) = 2.5 m Diameter Correction =1 m f1=f2=f3 =1 HG = 36.4529333 m HL = 11.93595174 m HOG = 3.67E+01 m Z = 18.3 m Specification sheet of stripper (C-201) Stripper Equipment Name Objective To separate water and aniline (vapor) from waste water (liquid) C-201 Equipment Number Designer Hussain Butaleb Location After aniline-water tank (T-202) Material of Construction Carbon steel Insulation Mineral wool Operating Condition Operating Temperature (oC) 100.1 Operating Pressure (psi) 15 Feed Flow Rate (kgmol/h) 475.9659 Diameter (m) 1 Height (m) 18.3 HOG 36.7 NOG 0.5