Kimia Teknik_07

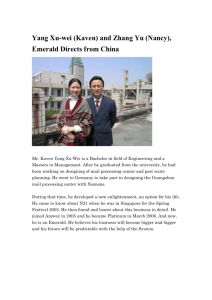

advertisement

14/15 Fall semester Engineering Chemistry Instructor: Rama Oktavian Email: rama.oktavian86@gmail.com Office Hr.: M.13-15, Tu. 13-15, W. 13-15, Th. 13-15, F. 09-11 Korosi Korosi : Peristiwa perusakan atau degradasi material logam akibat bereaksi secara kimia dengan lingkungan Korosi Contoh: Korosi dari logam yang disebabkan oleh air pada umumnya merupakan hasil dari reaksi kimia dimana permukaan logam teroksidasi membentuk iron oxide (rust). Korosi Korosi merupakan proses oksidasi yang terjadi pada suhu yang rendah Korosi merupakan proses elektrokimia Adanya kontak secara kimia dan elektrik antara Anode, electrode pada sel elektrolit yang memberikan elektron. Cathode, electrode pada sel elektrolit yang menerima elektron Korosi • Korosi dapat terjadi karena: -- Karakteristik dari logam yang memberikan elektron. -- Adanya reaksi oksidasi dan reduksi yang disebakan oleh electron tersebut. • Laju korosi dipengaruhi oleh: -- Suhu -- Konsentrasi dari reaktan dan produk -- mechanical stress & erosion -- the energy state of the metal Korosi Korosi • Two reactions are necessary: 2 -- oxidation reaction: Zn Zn 2e (anodic reaction) -- reduction reaction: 2H 2e H 2 (gas) (cathodic reaction) • Other reduction reactions: -- in an acid solution O2 4H 4e 2H2O Zn + 2HCl → ZnCl2 + H2 -- in a neutral or base solution O2 2H2O 4e 4(OH) Korosi Galvanic couple: Two metals electrically connected in a liquid electrolyte wherein one metal becomes an anode and corrodes, while the other acts as a cathode. Korosi • Two outcomes: --Metal sample mass --Metal sample mass --Metal is the anode (-) --Metal is the cathode (+) o Vmetal 0 (relative to Pt) Standard Electrode Potential o Vmetal 0 (relative to Pt) Korosi • EMF series metal Au Cu Pb Sn Ni Co Cd Fe Cr Zn Al Mg Na K • Metal with smaller o Vmetal +1.420 V +0.340 - 0.126 - 0.136 - 0.250 - 0.277 - 0.403 - 0.440 - 0.744 - 0.763 - 1.662 - 2.262 - 2.714 - 2.924 o Vmetal (i.e., more active) corrodes.Ex: Cd-Ni cell o DV = 0.153V EMF: Electromotive Force Korosi The EMF of a standard Ni-Cd galvanic cell is -0.153 V. If the standard half-cell EMF for the oxidation of Ni is -0.250 V, what is the standard half-cell EMF of cadmium if cadmium is the anode? Solution: The standard half-cell EMF of the cadmium can be calculated by considering the half-cell reactions: Korosi Rusting of iron The oxidation reaction that will occur at the local anodes is Fe → Fe2+ + 2e- (anodic reaction) The reduction reaction that will occur at the local cathodes is A piece of iron immersed in oxygenated water, ferric hyroxide [Fe(OH)3] will form on its surface O2 + 2H2O + 4e- → 4OH(cathodic reaction) Korosi • Ranks the reactivity of metals/alloys in seawater Platinum Gold Graphite Titanium Silver 316 Stainless Steel Nickel (passive) Copper Nickel (active) Tin Lead 316 Stainless Steel Iron/Steel Aluminum Alloys Cadmium Zinc Magnesium Korosi Consider a magnesium-iron galvanic cell consisting of a magnesium electrode in a solution of 1 M MgSO4 and an iron electrode in a solution of 1 M FeSO4. Each electrode and its electrolyte are separated by a porous wall, and the whole cell is at 25°C. Both electrodes are connected with a copper wire. Mg 25°C Fe a)Which electrode is the anode? 1.0 M 1.0 M b)Which electrode corrodes? Mg+ 2 solution Fe 2+ solution c)In which direction will the electrons flow? d)In which direction will the anions in the solution move? e)In which direction will the cations in the solution move? f)Write an equation for the half-cell reaction at the anode. g)Write an equation for the half-cell reaction at the cathode. Korosi a) The magnesium electrode is the anode. b) The magnesium electrode corrodes since the anode in a galvanic cell corrodes (oxidizes). c) The electrons will flow from the anode, Mg, to the cathode, Fe. d) The SO42− anions will flow toward the magnesium anode. e) The cations will flow toward the iron cathode. f) The oxidation reaction that occurs at the magnesium anode is: Mg → Mg2++2e− g) The reduction reaction that occurs at the iron anode is: Fe2++2e−→ Fe . Korosi Tipe – tipe korosi: 1) 2) 3) 4) 5) 6) 7) 8) Uniform or general attack corrosion Galvanic or two-metal corrosion Pitting corrosion Crevice corrosion Intergranular corrosion Stress corrosion Erosion corrosion Selective leaching or dealloying Korosi 1. Uniform/general attack (korosi umum) ⇒ Korosi yang umum terjadi pada baja. ⇒ Akibat adanya reaksi kimia atau elektro kimia yang merata pada permukaan logam Pencegahannya : a. penggunaan material yang tepat dan pelapisan (coating), b. inhibitor (suatu zat yang ditambahkan dalam konsentrasi yang kecil ke lingkungan untuk menurunkan laju korosi), c. proteksi katodik. Korosi 1. Uniform/general attack (korosi umum) Korosi 2. Galvanic corrosion (korosi galvanis) Terjadi akibat adanya beda potensial antara dua benda yang terhubung secara elektrolit. Logam yang ketahanan korosinya kurang: anodik logam yang ketahanan korosinya tinggi : katodik Korosi 3. Crevice corrosion (korosi celah) Korosi lokal yang sering terjadi pada celah atau daerah yang dilindungi. Penyebabnya: adanya larutan yang terjebak pada lubang dari permukaan gasket, lap joint, atau kotoran yang terjebak dibawah baut atau pada kepala rivet. Pencegahannya: sangat sulit. Cara lain dengan mengkondisikan dalam kelembaban yang rendah (low humidity) Daerah yang kemungkinan terkena korosi. Korosi 4. Pitting corrosion (korosi sumur) Serangan korosi mengakibatkan terjadinya lubang-lubang pada logam. Diameter lubang relatif kecil. Korosi 5. Erosion corrosion (korosi erosi) Proses korosi yang dipercepat dengan adanya gesekan antara fluida korosif dengan permukaan logam. Pencegahannya: • Pelapisan (coating) dengan permukaan yang keras. • Proteksi katodik. Korosi 6. Stress corrosion (korosi tegangan) Sering juga disebut stress corrosion cracking, yaitu retak (crack) yang disebabkan oleh tegangan tarik (tensile stress) dan korosi yang spesifik. Contoh : hydrogen embrittlement Korosi PENCEGAHAN KOROSI Korosi dapat dikontrol dengan berbagai cara. Pertimbangan utama adalah masalah ekonomi, terutama akibat yang ditimbulkannya . Kontrol terhadap korosi Pemilihan material: -Logam -Non logam Coating (pelapisan): -Logam -Organik -Non organik Disain: -menghindari konsentrasi tegangan -menghindari kontak dengan logam tidak sejenis -menghindari adanya jebakan air Proteksi katodik dan anodik Kontrol lingkungan. (temperatur, konsentrasi oksigen dll). Korosi Metallic Selection General rules for metallic selection – For reducing or, nonoxidizing conditions such as air-free acids & aqueous solutions, Ni & Cu alloy are often used. – For oxidizing conditons, Cr containing alloy are used. – For extremely powerful oxidizing conditions, Ti & its alloy are commonly used. Korosi Coatings Metallic, inorganic, & organic coatings are applied to metals to prevent or reduce corrosion – Metallic coating eg.; Zinc coating on steel (sacrificial anode) – Inorganic coating (ceramics & glass) eg.; Glass-lined steel vessels – Organic coating eg.; paints, varnishes & lacquers Korosi Alteration of Environment 4 general methods of altering an environment to prevent or reduce corrosion are: – Lower the system temperature to lower the reaction rates and thus reduce corrosion. Certain exceptions exist, such as seawater, for which the temperature should be raised rather than reduced. – Decrease the velocity of corrosive fluids such that erosion corrosion is reduced while fluid stagnation is avoided. – Remove oxygen from water solutions. – Reduce the concentration of corrosive ions in a solution which is corroding a metal. Cathodic protection The protection of a metal by connecting it to a sacrificial anode or by impressing a DC voltage to make it cathode Eg; – sacrificial anode – Impressed current Cathodic protection of an underground pipeline by using sacrificial Mg anode Cathodic protection of an underground tank by using impressed currents