Collimation in the ILC BDS

advertisement

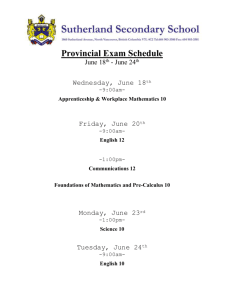

Collimation in the ILC BDS Carl Beard ASTeC Daresbury Laboratory •People •Requirement •Recent Successes •Future Aims People Task Leader – Nigel Watson (B’ham) Damage Studies L. Fernandez (ASTeC), A.Bungau (Manc) R. Barlow (Manc) G. Elwood (RAL), J. Greenhaulgh (RAL). Wakefield Simulation and TDR C. Beard (ASTeC), J. Smith (Lanc), R. Jones (Manc), R.Carter (Lanc), S Jamison (ASTeC), P Corlett (ASTeC)… I. Zagorodnov (DESY), M.Kärkkäinen, W.Müller, T.Weiland (TEMF) Beam Tests (T-480 Experiment) Frank Jackson…plus most of the above SLAC ESA Team – Steven Malloy, Mike Woods… Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Need for Collimation Reduce the background levels in the detector, by removing halo particles built up over the long linac. Collimators are introduced, as a result of this the change in impedance has detrimental effects to the beam quality. Machine Protection, in the event of a beam miss-steer. The collimators have to be robust to withstand the full impact of several ILC Bunches. Design / optimisation of spoiler jaws (geometry and materials) for wakefield and beam damage performance Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Objectives Development of Advanced EM modelling methods Benchmarking of wakefield calculations against experiments SLAC ESA beam test / data analysis RF bench tests (training/code comparisons) Tracking simulations with best models of wakefields Simulations of beam damage to spoilers Material studies using beam test Submitted 7 papers at EPAC, several EUROTeV reports/memos Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Collimator Parameter and Beam Parameters Beam Energy, GeV 250, 500 Material Cu, Ti, C Penetration (mm) 2 to 10 e- Particles/bunch 2 x 1010 Copper Fracture temperature ~200 °C (473 K) Melting temperature 1085 °C (1357.77 K) Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Collimator Proposals 2 mm, 10mm 250, 500 GeV eTi/C 0.6 Xo of Ti alloy leading taper (gold), graphite (blue), 1 mm thick layer of Ti alloy 0.3 Xo of Ti alloy each side, central graphite part (blue). Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Cu+Graphite spoiler Carbon zones 250 GeV: σx = 111 µm, σy= 9 µm 500 GeV: σx = 79.5 µm, σy= 6.36 µm ∆T [K]; 250 GeV e- ∆T [K]; 500 GeV e- 2 mm from top 465 K 860 K 10 mm from top 440 K 870 K Difference -5% 1% Fracture temp. Melting temp. Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Cu zones Ti / Graphite Spoiler Temperature data in the left only valid the Ti-alloy material. Top increase of temp. in the graphite ~400 K. Dash box: graphite region. 540 K 405 K 400 K 270 K 2 mm deep from top ∆Tmax = 575 K per a bunch of 2E10 e- at 500 GeV Ti alloy and graphite spoiler σx = 79.5 µm, σy= 6.36 µm Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 [L.Fernandez, ASTeC] Fluka Benchmark Fluka Prediction of beam Damage (Evaporated material not considered Measurements of Beam damage crater in cooper on the FFTB. 700 Measurements courtesy of SLAC, Marc Ross et al. Melted area (um^2) 600 500 400 300 200 100 0 0.5 1 1.5 2 Incident e-/um^2 (+/- 2 sigma)x10^7 2.5 3 Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Damage Studies Beam tests are being planned to benchmark the Fluka/Geant Simulations No electron beam is available with sufficient intensity Or probability to hit the same point due to beam jitter. Dynamic Simulations in ANSYS are being studied in support of the FLUKA/GEANT Simulations Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Wakefield Analysis Instant solution for only simple geometry Analytical Formula Simulation Fast Results – Limited by Resolution/ confidence Bench Tests (TDR) Good indicator – poor resolution Tests with Beam Real life measurements, slow turnaround time for measurements Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Simulation and Wire tests Loss Parameter 2.5 2 Launch Pulse Transmitted Signal 1.5 Volts 1 TDR and TDT are being used to measure the Impedance of a vessel and its loss factor 0.5 0 1E-09 -0.5 1.2E-09 1.4E-09 1.6E-09 1.8E-09 2E-09 2.2E-09 -1 -1.5 Time (s) Current TDR and TDT measurements are limited to 10 ps Pulse lengths. Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Achieving a 1 ps Pulse (In development) Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 MAFIA Simulations 15 500 micron bunch 10 2mm offset 1.2mm offset 0.8mm offset 0.4mm offset Wakepotential (V/pC) 5 0 0 0.001 0.002 0.003 0.004 0.005 0.006 -5 -10 -15 Distance Z (mm) 8 y = 0.5856x3 - 1E-14x2 + 0.4088x - 1E-13 6 Kick Factor (V/pC/mm) 4 2 0 -2.5 -2 -1.5 -1 -0.5 0 0.5 1 1.5 2 2.5 -2 -4 0.5mm Bunch -6 Poly. (0.5mm Bunch) -8 Beam Off set (mm) Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Limitations / Advances Limiting the simulations to short structures or only sufficient resolution for >>300 um bunch length. A new technique is being applied to allow full structures to be simulated with substantially higher resolution Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 MAFIA/HFSS GDFIDL / ECHO 2 &3D Beam Tests in ESA Simple Shapes to allow benchmarking with Calculations/Code Geometric Wakefields Resistive Wall Wakefields Surface Roughness Slot Side view Beam view Side view Beam view =/2rad =335mrad 38 mm 1 Slot r=1/2 gate r=1.9mm 1 7 mm h=38 mm r=1.4mm h=38 mm 335mrad r=1.4mm 2 38 mm 168mrad r=1.4mm 2 208mm 1=/2 rad 335mrad 3 r=1.4mm 2=168mrad 3 L=1000 mm 28mm =/2rad r=3.8mm 4 159mm 4 7mm r1=3.8mm r2=1.4mm =298mrad =168mrad r1 =3.8mm Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 r2 =1.4mm T-480 Experiment 2 doublets BPM BPM Two triplets BPM ~40m BPM ~16m Vertical mover Wakefields measured in running machines: move beam towards fixed collimators Problem Beam movement oscillations Hard to separate wakefield effect Solution Beam fixed, move collimators around beam Measure deflection from wakefields vs. beam-collimator separation Many ideas for collimator design to test… Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 T-480 Experiment 2 doublets BPM BPM Two triplets BPM ~40m BPM ~16m Vertical mover Wakefields measured in running machines: move beam towards fixed collimators Problem Beam movement oscillations Hard to separate wakefield effect Solution Beam fixed, move collimators around beam Measure deflection from wakefields vs. beam-collimator separation Many ideas for collimator design to test… Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Wakefield Box Ebeam=28.5GeV ESA sz ~ 300mm – ILC nominal sy ~ 100mm (Frank/Deepa design) Magnet mover, y range = .4mm, precision = 1mm Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Initial Comparison of Results Analytical: 0.562 V/pC/mm MAFIA: 0.408 V/pC/mm Beam Test 0.556 V/pC/mm Just selecting one ref run (same slot ref) run q1 dq1 599 -7.13552E-12 3.69547E-12 624 -6.36929E-13 3.4007E-12 1491 1.26302E-11 1.10968E-12 w. mean 9.96031E-12 1.01441E-12 w. mean chisq-3.13033E-12 2.38158E-12 kf 1.771965811 kf (using chisq) -0.556893046 chisq/n 0.811254 1.153441 73.30665 % 0.180466779 10.18455 0.423690061 -76.08105 Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006 Future Work Continue study into beam damage/materials In the process of designing a 4th beam test Collimators designed and built in EU, to be installed at SLAC ESA. 3rd Physics run Mar/April 2007 Application of the Moving Mesh Technique TDR Measurements with Optically generated 1 ps Pulse. Combine information on geometry, material, construction, to find acceptable baseline design regarding all of Wakefield optimisation Collimation efficiency Damage mitigation Carl Beard – Cockcroft SAC Meeting 23rd – 24th November 2006