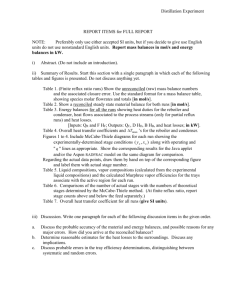

Distillation Column Control System Optimization

advertisement

DISTILLATION CONTROL Dr. Prakash Karpe Control & Elec. Eng. Supt. ConocoPhillips San Francisco Refinery, Rodeo 1 Distillation Column Control Control Objectives Qc L V D Rectification Stages F R = L/D Stripping Stages QH B • Two Control objectives – Inventory control – Composition control 2 Degrees of Freedom Analysis • From control perspective, degrees of freedom of a process is defined as number of variables that can or must be controlled. – Helps to avoid over- or under-control of processes. • Degrees of freedom (to control) = No. of rationally placed control valves – A control valve represents a manipulated variable (MV) 3 Degrees of Freedom Analysis Flash Vessel (Separator) V F F,T,P,xi Disturbances B 4 Inventory Control • For steady state operation of a process, all inventories must be controlled – Vapor inventories are maintained by pressure control – Liquid inventories are maintained by level control 5 Degrees of Freedom Analysis Flash Vessel (Separator) Degrees of Freedom = 0 V PC F F,T,P,xi Disturbances LC B 6 Degrees of Freedom Analysis Typical Distillation Column Inventory Control PC V LD L D TD F TB QH LB LC B Degrees of Freedom = 3 7 Liquid Inventory Control Level Control • Reflux drum level control – LD - L or LD – D? • Richardson’s rule: – Use the largest stream to control level. – Guidelines: • L/D < = 1 : Use LD – D pairing • L/D > = 5 : Use LD – L pairing • For 1 < L/D < 5, use scheme proposed by Rysjkamp – (L+D) – D and L/D – L pairings 8 Two Common Level Control Schemes • Level control dilemma – Tight flow control? • Oscillating level – Tight level control? • Oscillating product flow • Averaging or nonlinear level control • Tight level control 9 Common Level Control Schemes • Averaging (nonlinear) level control – Used when product is a feed to a downstream process • Examples – Train of lightends columns – Reflux drum level control • Tight level control – Used when product goes to tankage or a surge drum or process requires low hold up • Use P-only controller with KC = 4 • Examples – Reboiler level control – FCC Main Frac and Vacuum column bottoms (coking concern) – Dirty wash oil draw level control • Control hydrostatic P in the draw line 10 Vapor Inventory Control Common Pressure Control Schemes Partial Condensers Off gas rate > 0 • Common Problems – If off gas is routed to a compressor, reflux drum P is controlled leading to tower P swings. 11 Common Pressure Control Schemes Partial Condensers Off gas rate > 0 or = 0 • Common Problems – If off gas is routed to a compressor, reflux drum P is controlled leading to tower P swings. – Inert gas, typically noncondesables, can cause downstream process problems 12 Common Pressure Control Schemes Total Condensers Flooded Condenser Off gas rate = 0 • Common Problems – If P equalizing line is not used, P in the reflux drum swings. – If condensed liquid is introduced into the drum from top w/o dip leg, vapor in the drum can collapse. 13 Common Pressure Control Schemes Total Condensers Hot Vapor Bypass Off gas rate = 0 • Common Problems – Bypass line inadequately sized – If drum top surface is not insulated, P can swing with ambient changes. The effect is less pronounced for high P columns. 14 Degrees of Freedom Analysis Typical Distillation Column Composition Control PC V LD L D TD F TB QH LB LC B Degrees of Freedom = 3 15 Composition Control Problem • Number of MV’s = 3 – – – – – – Reflux flow: L Distillate flow: D Reboiler heat: QH Reflux ratio Product/ feed ratio Steam/ feed ratio • Need three controlled variables (CV’s) • Possible CV’s – Reflux drum level: LD – Distillate composition: xD – Appropriate temperature in rectification section (TD) – Bottoms composition: xB – Appropriate temperature in stripping section (TB) • Control problem – How do we pair CV’s and MV’s? 16 Composition Control • Fundamental manipulated variables – Feed split or cutpoint variable • Fraction of the feed that is taken overhead of out of the bottom – Increasing distillate flow will increase bottom purity and decrease distillate purity, etc. – Fractionation variable • Energy that is put into the column to achieve separation – Increasing the reflux ratio or the reboiler duty will increase both distillate and bottoms purity – Feed split has more pronounced impact on product purity than fractionation variable (exception low purity, < 90%, products) – It is almost impossible to control any composition in the column if the feed split is fixed. 17 Manipulation of Fundamental Variables for Composition Control • Fractionation Variables – L/D – QH/ F (steam to feed ratio) – L/F • High purity columns or dual product purity columns • DeC3’s, DeC4’s, DIB’s, etc. • Feed Split Variables – D or B flow (direct control scheme) • FCC Main Fracs, Crude and Vacuum column side cuts – L or QH (indirect control scheme) • Level adjusts the product flow indirectly 18 Controlled Variables for Composition Control • Stage temperature (Inferential control) – Useless for aij < 1.2 • Online analyzer – High economic gains – aij < 1.2 • Temperature control – Special cases – Difficult separations ( 1.2 < aij < 1.5) • Flat temperature profiles • Use differential temperatures ( DT = Tm – Tk) between stages for control • Example – HVGO quality control – Extremely easy separations (high aij) • Nonlinear in nature • Steep temperature profile • Use temperature profile control • Tavg = (Tk + Tm)/ 2 , etc. 19 Composition Control Temperature Sensor Location • Locate TI on the stage whose temperature shows maximum sensitivity to one of the available MV’s – From simulation calculate (dTi / dD)L,B, (dTi / dL)D,B , (dTi / dB)L,D and (dTi / dQ)L,D where Ti is the temperature of stage i. Locate TI at the stage where (dTi / dD)L,B , etc., is maximum. • For calculating the derivatives, vary B, D, L and Q in the column specs only by small amount, e.g., by +0.5% and -0.5%. Calculate average derivative. • Scale each variable by dividing it by its span in order to calculate the derivatives. The derivative will be a dimensionless number. • Use high precision numbers 20 Optimum Temperature Sensor Location Most common Mistake! TC 21 Optimum TI Location for Columns with Side Draws • Locate the TI in the vapor space one – two stages below the product draw for product EP control – This temperature (P-compensated) correlates well with the product EP – Example • Atmos column diesel 95% pt control 22 TI Location for Side Draw L TI D TC F 23 Special Cases Draw Tray Control • Total Draw Tray – Control tray level by product draw – Control pumpback on flow control – Control p/a on flow control p/a duty as CV • In fuel vacuum columns maximize duty FC LC LT FC 24 Special Cases Draw Tray Control • Partial Draw Tray – Level on the tray is fixed by the outlet weir height. There is no level control FC FC LT FC 25 Special Cases Stripping Steam Flow • Bottom stripping steam – Maximize to 8 – 12 lb stm per bbl of product – Fixed flow control • Side stripping steam – Minimize to meat front end spec – Use steam/ product ratio control 26 Distillation Control Case Study: Deisobutanizer Control Joyce Kaumeyer Sr. Consulting Engineer Prakash Karpe Control & Elec. Eng. Supt. ConocoPhillips San Francisco Refinery, Rodeo 27 Deisobutanizer PIC A PIC B SW Fuel Gas Partially Flooded Condenser Flooded Accumulator LIC IC4 TI OVHD Low Level Override FIC RFLX SS Tray 1 FI IC4 Tray 13 IC4 TI 13 Feed 1 AI Tray 25 IC4 Feed 2 Tray 37 Tray 45 TIC 45 Tray 60 LIC FIC NC4 NC4 NC4 AI PIC STM Steam NC4 Partially Flooded Reboiler LIC COND FI STM Condensate 28 Tower Operation • Tower Pressure Control – By Overhead Product Rate • Tower Temperature Control – Tray 45 By Condensate Level (Steam) • Composition Control – Operator Adjusts Reflux Rate Based on Lab / On-line Analyzer • Tower Feed from Various Upstream Units – Large Rate Swings 29 Deisobutanizer Control Objectives • Control IC4 Product, IC4 Concentration – Reduce Variability & Control Closer to Specification • Improve Tower Pressure Control – Reflux / Product Rate = 5 / 1 • Change Existing Temperature / Composition Control • Reduce NC4 Product, IC4 Concentration 30 Deisobutanizer Modified Controls PIC A PIC B SW Fuel Gas Partially Flooded Condenser Flooded Accumulator TI TDIC OVHD OVHD LIC IC4 Low Level Override FIC RFLX SS Tray 1 FIC IC4 Tray 13 IC4 TI 13 Feed 1 AI Tray 25 IC4 Feed 2 Tray 37 Tray 45 TI 45 Tray 60 LIC FIC NC4 NC4 NC4 AI UIC PIC STM Steam Partially Flooded Reboiler NC4 BTU LIC COND FI STM Condensate 31 IC4 Product On-line Analyzer Vs. Delta Temperature Correlation 100.0 98.0 % 96.0 94.0 92.0 90.0 Analyzer IC4 DT Predicted IC4 32 IC4 Product IC4 / Delta Temperature Correlation %IC4 = 100.3 – 1.4464 * (Delta T) Process Dynamics • Deadtime: 19 minutes • Lagtime: 102 minutes 33 Modified Tower Operation • Tower Pressure Control – By Reflux Rate • Tower Heat Input Control – By Condensate Level (Steam) • Composition Control – Operator Adjusts TDIC Setpoint Based on Lab / On-line Analyzer • Tower Feed from Various Upstream Units – Large Rate Swings 34 Tower Pressure Control Before and After Before After 35 IC4 Product %IC4 IC4 Product 100.0 98.0 96.0 94.0 92.0 90.0 High Pentanes 88.0 Steam Increase Start New Control IC4 36 NC4 Product %IC4 Isobutane Giveaway in n-Butane 6.0 % Start New Control Initial Implementation phase Operator Training 5.0 4.0 3.0 2.0 1.0 0.0 37 Future • ARC – Add AIC Cascaded to TDIC • Requires improved analyzer performance – Add Heat Input Feed-Forward to AIC -OR• DMC – Requires improved analyzer performance – Hold for DCS platform conversion to Refinery Standard 38