BIM to Budget: Follow the Money from Autodesk®

Revit® to Constructware®

Chris Russell

Director of Information Systems/Process Development

Tom Clavelle

Executive VP & CFO

© 2011 Autodesk

Phones

Please turn off your cell phone!

© 2011 Autodesk

Questions for you:

How many of you are Architects/Engineers?

How many of you are GC/CM?

How many of you are Owners?

© 2011 Autodesk

Questions for you:

How many of you are using Revit®?

How many of you are using Autodesk® Quantity Takeoff?

How many of you are using Timberline Estimating and/or Timberline Accounting?

How many of you are using Autodesk® Constructware®?

© 2011 Autodesk

Seminar Objectives:

Illustrate the “perfect world” flow of BIM information from a contractor’s

perspective

Identify the benefits of using a Model in the preconstruction phase

Identify the hurdles that exist in the current utilization of a Model

Facilitate the sharing of actual project experiences amongst attendees

© 2011 Autodesk

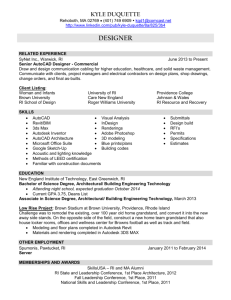

Company Profile:

Engelberth Construction, Inc.

Based in Burlington, Vermont

Founded in 1972

Work in Northern NE

Annual Revenues $80 - $120M

80% Repeat Customers

150 Employees – 60 Office / 90 Field

12 Person Preconstruction Team

No Architects on Staff

Institutional / Higher Ed, Health Care, Commercial

© 2011 Autodesk

What is BIM?

The PROCESS of generating and managing building data throughout its life

cycle, supported by digital technology.

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Engelberth’s BIM Process & Tools

Extracting quantities from the model (Revit ®, QTO )

Materials (quantities)

Working with Assemblies

(QTO , Sage Timberline Estimating® )

Working with cost (Sage Timberline Estimating® / Office®)

Creating ($$ and hrs) for Subcontractor, Labor, Equipment, Material

Creating a workable Budget

Making the Budget work for you

(Autodesk ® Constructware® / Sage Timberline Office®)

Using the budget for Subcontracts and Purchase Orders

Using the budget for Changes (Cost Management process)

© 2011 Autodesk

The Model (Autodesk Revit ®)

Benefits:

Provides more information; quicker access

Provides contractor with a better visual understanding of project

Increases speed of takeoff

Reduces errors in takeoff

© 2011 Autodesk

Model (Autodesk Revit ®)

It all starts here..

© 2011 Autodesk

Model (Autodesk® Revit®)

Preparing for QTO..

Views (Floor Plans, Elevations, 3D Model)

Create a DWF or DWFX

(Documented by Autodesk)

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Quantification (QTO®)

Benefits:

Working with quantities is much easier than traditional takeoff

Linking objects to assemblies allows processing of large groups of

takeoff very quickly and more accurately than by hand.

Direct link to Timberline Estimating

Provides upfront pricing capability for design team (if desired)

Future Links - Scheduling and Constructability

© 2011 Autodesk

Quantification (QTO®)

Importing the DWF(X)

Performing quantity takeoff

© 2011 Autodesk

Quantification (QTO®)

Importing The Catalog… (Timberline Estimating Database)

© 2011 Autodesk

Quantification (QTO®)

Assemblies:

A group of items that have to be put

together to produce a completed

product.

© 2011 Autodesk

Quantification (QTO®)

Assign to Item…

Assemblies:

Material

Labor (Sub and Self performed)

Equipment

© 2011 Autodesk

Quantification (QTO®)

Defining the items takeoff Type…

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Quantification (QTO®)

Exporting…

(Sage Timberline Estimating®)

© 2011 Autodesk

Estimating (Sage Timberline Estimating®)

Benefits:

Review of data in estimating is easy to understand and can be

reported in many ways for review

The estimate can be easily modified for location and seasonal

conditions

Direct link to Timberline Accounting (converts phase codes to

cost codes)

© 2011 Autodesk

Estimating (Sage Timberline Estimating®)

With a little magic…

Values for Materials, Labor, Equipment, Subcontractors are created

In $$ and work hours

© 2011 Autodesk

Estimating (Sage Timberline Estimating®)

Finalize Estimate

Export via the Linking Report

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Accounting (Sage Timberline Office®)

Importing

Ready for actual costs to be charged against the budget

© 2011 Autodesk

Accounting (Sage Timberline Office®)

Review Budget and Hours

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Project Management (Autodesk Constructware®)

Benefits:

Cost Management process is effective for managing change (CE, RCO, OCO,

etc.)

The Budget module allow us to connect the budget cost codes back to the model

Future Benefits - Submittals, RFIs and all Cost Management documents

visible and eventually stored in the model.

Future Benefits – Connecting change orders to the pricing cycle as

discussed above.

© 2011 Autodesk

Project Management (Autodesk Constructware®)

Importing into Budget

Create Subcontracts and POs linked to Budget

© 2011 Autodesk

Project Management (Autodesk Constructware )

Cost Events (Changes)

Process to Request for Change Order (RCO)

Process RCO to Owner Change Order (OCO)

Process OCO to Sub Change Order and

Purchase Order Change Orders (POCO)

Send RCO to Owner and Architect

For Approval

For new Detail / Redesign

© 2011 Autodesk

BIM to Budget Process

Model

Quantification

(Revit)

(QTO)

Project

Management

Estimating

(Timberline)

(Constructware)

Accounting

(Timberline)

© 2011 Autodesk

Demo

The Model

Creating DWF(X)

Quantification

Import Timberline Estimating Database

Model Takeoff

Export to Timberline Estimating

Estimating

Open file created by QTO

Exporting for Estimating

Accounting

Export for Timberline Accounting

Importing into Constructware

© 2011 Autodesk

Challenges / Hurdles

The Model (Revit ®)

How complete is the design? Is it detailed enough for takeoff?

Does the design take into account how the project will be built (i.e.

phasing)?

Who creates the model file for takeoff?

Liability concerns

© 2011 Autodesk

Challenges / Hurdles

Quantification (QTO):

Assemblies have to be designed to work efficiently with this process

The first time linking objects to Assemblies can be time consuming

Estimating (Sage Timberline Estimating ®):

Ongoing database maintenance is required to maintain efficiency

© 2011 Autodesk

Challenges / Hurdles

Accounting (Sage Timberline Office ®):

We had to create a manual export from Accounting to

Constructware (Access)

Project Management (Autodesk Constructware ®):

No current connection back into the model

© 2011 Autodesk

Class Review

Extracting quantities from the model (Revit ®, QTO ® )

Materials (count and quantities)

Working with Assemblies

(QTO ® , Sage Timberline Estimating ® )

Working with cost (Sage Timberline Office ®)

Creating ($ and hrs) for Subcontractor, Labor, Equipment, Material

Creating a workable Budget

Making the Budget work for you

(Autodesk Constructware ®)

Using the budget for Subcontracts and Purchase Orders

Using the budget for Changes (Cost Management process)

© 2011 Autodesk

Questions:

Chris Russell

Director of Information

Systems/Process Development

Engelberth Construction, Inc.

Chris.Russell@engelberth.com

802-846-2316

Tom Clavelle

Executive VP & CFO

Engelberth Construction, Inc.

Tom.Clavelle@engelberth.com

802-846-2314

© 2011 Autodesk

Thank you!

Autodesk, AutoCAD* [*if/when mentioned in the pertinent material, followed by an alphabetical list of all other trademarks mentioned in the material] are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right to alter product and

services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document. © 2011 Autodesk, Inc. All rights reserved.

© 2011 Autodesk

© 2011 Autodesk

© 2011 Autodesk

© 2011 Autodesk

Back

© 2011 Autodesk