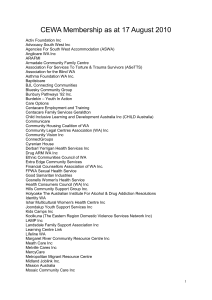

Hale & Twomey Report

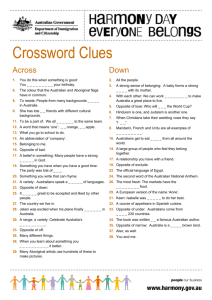

advertisement