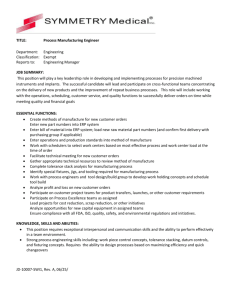

Design for Manual Assembly

advertisement

Manual Assembly Corrado Poli Mechanical and Industrial Engineering UMass Amherst ©Fall 2001 Two Phases of Assembly • Handling Can be done • Manually • Insertion •Automatically Manual Handling (Affected primarily by geometry) Bins Workstation Fixture Operator Operator • Reaches into the bin • Grasps the part • Transports and orients the part • Pre-positions it Manual Insertion (Affected by both the part geometry AND the part/parts to which it is placed/fastened/mated to.) Bins Workstation Fixture Operator • Operator - places/fastens part onto a partially completed assembly/subassembly Automatic Assembly (free transfer/non-synchronous system) Gravity Feed Track Bowl Workhead Feeder Assembly Machine - Workcarrier Buffer Stock Buffer Partially completed assembly Space transferring to next station Workstations • Parts emptied into a bowl feeder which contain orienting devices. • Parts exit feeder go down track in preparation for insertion. Four Station Automatic Assembly System for Irrigation Mini-Drippers (Rotary Indexing Machine) Mini-dripper has a base, body, regulator and cover. Schematic of assembly system Automatic Handling (From “Handbook of Feeding and Orienting Techniques for Small Parts,” by Boothroyd, Poli and Murch) Bowl Feeder Orienting system for cup shaped parts Cost of An Assembly • Number of parts • Ease with which the parts can be > Handled > Inserted Rule #1 - Eliminate Parts • Outright elimination of parts. (screws, nuts, washers, etc.- use snap fits) • Combining 2 or more distinct parts into a single molded, cast or stamped part. 9 parts 2 parts Eliminate Fasteners • If not possible, reduce the number or variety • Incorporate the fastening function with another feature 1 screw 4 screws Snap • Screws aren’t expensive - driving them is! Can Parts Be Combined? • Since there is no relative motion between the parts - and • Since these parts can be made of the same material •Why not combine them? Rule #2 -Design Parts • So they can be easily handled and Bins Workstation Fixture Operator • Inserted Factors Affecting Manual Handling Time (Cost)* Part • Symmetry > End-to-end > Rotational • Size • Thickness • Mass * Reference: G. Boothroyd, “Assembly Automation and Product Design,” Marcel Dekker, NY, 1992 And If the part is Easy to Grasp and Manipulate with One Hand and No Tools Examples of Symmetry • Parts with end-to-end symmetry Dowel pin washer pin • Parts with no end-to-end symmetry nail bulb screw disk key Examples of Rotational Symmetry • Parts with rotational symmetry. washer pin screw bulb • Parts with no rotational symmetry. disk key Illustrations of Size and Thickness size Illustrations of Light and Heavy Mass Light Heavy Parts are Difficult to Grasp and Manipulate •Nest Do not nestorortangle tangle (and degree of severity) Flexible - two hands to keep orientation prior to insertion (belts, chains, gaskets) Slippery (ball bearings with oil) Parts are Difficult to Grasp and Manipulate - continued •Need Grasping Tools (tweezers, magnets, snap rings, ) • Two hands Due to part size/thickness Due to obscured view/access Heavy Large • Fragile Computer chip Expansion board Parts are Difficult to Grasp and Manipulate - continued • Sharp/hot/ undesirable to touch • Sticky Grease on ball bearing Part with adhesive Factors Affecting Manual Insertion* •Ease of alignment (provide feature to ease insertion) •Ease of insertion No chamfers Chamfers Dog point (affected by clearance, jamming, wedging, pushing against a force) chamfers Negative clearance (press fit) Push against a force Part jams on corners Same clearance, no jamming * Reference: G. Boothroyd, “Assembly Automation and Product Design,” Marcel Dekker, NY, 1992 Factors Affecting Manual Insertion continued •Obstructed view and/or obstructed access Task: Place battery in shaver. View clear? Need to rely on tactile sensing? Access clear? Is there a feature that restricts access to the operator? •Self-locating, no need to hold Additional Considerations • Insert vertically from above (i.e. don’t fight gravity) No Yes •Provide features/obstructions to prevent incorrect assembly of the part. Additional Considerations • Eliminate difficult to control operations - welding, brazing, gluing, etc • Eliminate extra operations such as special adjustments, torque adjustments etc. Additional Considerations • Design products into sub-assemblies that can be assembled and tested separately. • ‘De-couple’ manual and machine operations. • Group manual assembly operations to optimize line balancing. Assembly Analysis Three choices to analyze an assembly: • Precise quantitative method - such as the Boothroyd approach*. Precision needed if you need to do process planning. • Use an approximate approach during configuration stage of design? Assembly Advisor Allow 7-9 sec/part (Compromise approach) (Fails to focus attention on characteristics that make assembly difficult) * Reference: G. Boothroyd, “Assembly Automation and Product Design,” Marcel Dekker, NY, 1992 Assembly Advisor Combining Parts If Cdcx<5: yes! Question: Is the design on the right, which contains fewer parts, less costly?