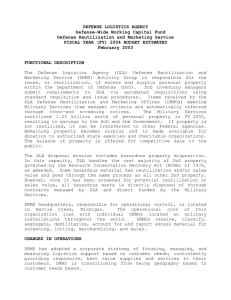

DRMS

advertisement

DRMS “Bringing Our Service To The Customer” Presented to: Lorna B. Estep, SES, Deputy Director for Supply, Directorate of Logistics, Headquarters Air Force Materiel Command Steven G. Schmidt, SES, Deputy Center Director, NASA Dryden Research Center, Edwards ARB November 2007 SR-71, Disposal Operations Multi-Service, Agency & Contractor Involvement Edwards Air Force Base NASA Air Force Materiel Command Defense Reut & Mktg Service MCLB Security NASA Drain/Purge Contract AFMC Roll-Off Contract Defense Logistics Agency Marine Corp Logistics Base MCLB Safety Scrap Venture Tri-Rinse Shredder APCD/DTS C permits Hw Contractor AFMC Support Team MCLB Environment al DRMS SR-71 Team Coordinating Disposition Efforts SV Roll-Off Contractor DEMAN Contractor Tri-Rinse Fuel Contracto r SR-71, Disposal Plan In Progress May 07 Jun 07 Jul 07 Aug 07 Sep 07 Oct 07 Nov 07 Dec 07 AFMC/A4SM (SR-71 Project officer) and DRMS Program Manager conducted a preliminary site visit 21 May – 21 June. AFMC/DRMS teamed to initiate disposal action for NON Sensitive “H” conditioned support equipment. DRMS contractor mutilated on site, witnessed by DRMS and removed 192,000 lbs of residue. AFMC/DRMS staff on site segregating SR-71 parts by disposal method/process Continue improving disposal process Identified, segregated and consolidate electronic equipment, components, test sets, and circuit cards for shipment on DEMAN task orders. Successfully shipped 132,760 lbs to date. Final DEMAN task order for approx. 25,000 lbs scheduled for shipment Nov 10th AFMC/DRMS/SV workforce on site to uncrate, segregate and stage property eligible for shredding Tri-Rinse Shredding start date Sept 29th Identified asbestos containing property, segregated and place on disposal contract for ultimate destruction (burial) A total of 229,520 lbs of asbestos shipped in (44) Roll-off containers. Receipt, offload & actual burial witnessed and Certified/Verified by CORs Identified end items with hazardous constituents, i.e. gas cylinders, support equipment containing fluids. AFMC funded NASA contractor to drain/purge on site. Utilized Tri-Rinse shear and shredding process to dispose of end items as scrap SR-71, Disposal Plan Mutilation Process In Action Shear with 17K lbs pressure Small shredder manually feed Large shredder crane feed All (3) operating simultaneously SR-71, Asbestos Disposal Plan Complete Asbestos loaded for departure CORs Witness Burial Process CORs observed receipt/off-load Certified/verified destruction by burial SR-71, Disposal Plan Challenge & Solution • Challenge - During the first hour of full operations the main shredder experienced a hydraulic leak • The loss of hydraulic pressure immediately shut down the entire system. • One of the hydraulic hoses separated from the coupling and resulted in the release of approx 10-15 gallons of hydraulic fluid • Solution - The spill was immediately isolated, contained, and cleaned up by the Tri-Rinse staff in accordance with the provisions of their contract • The spilled hydraulic fluid was contained on the rubber containment mats under the shredder and with the addition of absorbent and absorbent pillows • The contaminated absorbent was place on a DRMS HW disposal contract & removed SR-71, Disposal Plan Challenge & Solution • Challenge - During the shredding process we experienced a fire that was caused by hot metal mixed with the shredded wooden boxes, crates & packing materials • Smoke was immediately detected by the operator and a DRMS employee monitoring the operation • Attempts by the SR-71 team to distinguish the smoldering content with fire extinguishers failed • The Fire Department was immediately called and extinguished the fire • Solution – We placed a spotter with a water hose to observe the shredding process and continuously wet down the content as it enters the roll-off