Polymer Chemistry

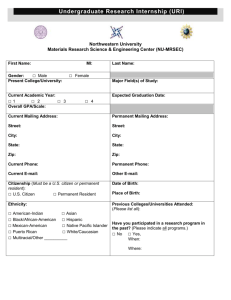

advertisement

Polymer Chemistry 저 자 : Malcolm P. Stevens Professor of chemistry at the university of Hartfort OXFORD UNIVERSITY PRESS 3rd Ed.(1999) POLYMER CHEMISTRY CONTENTS PART Ⅰ POLYMER STRUCTURE AND PROPERTIES 1. Basic principles 2. Molecular weight and polymer solutions 3. Chemical structure and polymer morphology 4. Chemical structure and polymer properties 5. Evaluation, characterization, and analysis of polymers POLYMER CHEMISTRY CONTENTS PART Ⅱ VINYL POLYMERS 6. Free radical polymerization 7. Ionic polymerization 8. Vinyl polymerization with complex coordination catalysts 9. Reactions of vinyl polymers POLYMER CHEMISTRY CONTENTS PART Ⅲ NONVINYL POLYMERS 10. Step-reaction and ring-opening polymerization 11. Polyethers, polysulfides, and related polymers 12. Polyesters 13. Polyamides and related polymers 14. Phenol-, urea-, and melamine-formaldehyde polymers 15. Heterocyclic polymers 16. Inorganic and partially inorganic polymers 17. Miscellaneous organic polymers 18. Natural polymers POLYMER CHEMISTRY Chapter 1. Basic principles 1.1 Introduction and Historical Development 1.2 Definitions 1.3 Polymerization Processes 1.4 Step-reaction Polymerization 1.5 Chain-reaction Polymerization 1.6 Step-reaction Addition and Chain-reaction Condensation 1.7 Nomenclature 1.8 Industrial Polymers 1.9 Polymer Recycling POLYMER CHEMISTRY 1.1 Introduction and Historical Development A. Development of civilization Stone age → Bronze age → Iron age → Polymer age B. Application of polymeric materials o PE milk bottles o Polyamide bulletproof vests o Polyurethane artificial heart o Fluorinated phosphazene elastomer for arctic environments POLYMER CHEMISTRY C. The purpose of this book 1. Property difference between polymer and low molecular weight compound 2. Chemistry of polymer synthesis 3. Chemistry of polymer modification POLYMER CHEMISTRY D. Development of polymer chemistry 1833년 : Berzelius, the first use of terminology, polymer 1839년 : Synthesis of polystyrene 1860s : Poly(ethylene glycol), Poly(ethylene succinate) 1900s : Leo Baekeland, synthesis of phenol formaldehyde resin 1920s : Hermann staudinger Structure of polymer(long-chain molecules), Novel Prize(1953년) 1939년 : W.H. Carothers, Nylon synthesis (Du Pont) 1963년 : Ziegler-Natta, stereoregular polymerization 1974년 : Paul Flory, polymer solution property 1984년 : Bruce Merrifield, solid-phase protein process POLYMER CHEMISTRY E. Examples of monomers and polymers Monomer CH2 CH2 CH2 CHCl Polymer CH2CH2 CH2CH2 Cl O H2C CH2 CH2CH2O HOCH2CH2OH CH2CH2O O HO CO2H O C POLYMER CHEMISTRY 1.2 Definitions A. Acoording to the amount of repeating units monomer : one unit oligomer : few polymer : many (poly – many, mer – part) telechelic polymer : polymer containing reactive end group (tele = far, chele = claw) telechelic oligomer : oligomer containing reactive end group macromer(=macro monomer) : monomer containing long chain POLYMER CHEMISTRY 1.2 Definitions B. DP : Degree of polymerization The total number of repeating units contained terminal group C. The kinds of applied monomers One kind : Homopolymer Two kinds : Copolymer Three kinds : Terpolymer POLYMER CHEMISTRY D. Types of copolymer Homopolymer : -A-A-A-A-A-A-A-A- Random copolymer : -A-B-B-A-B-A-A-B- Alternating copolymer : -A-B-A-B-A-B-A-B- Block copolymer : -A-A-A-A-B-B-B-B- Graft copolymer : -A-A-A-A-A-A-A-AB-B-B-B-B- POLYMER CHEMISTRY E. Representation of polymer types (a) linear (b) branch (c) network POLYMER CHEMISTRY F. Representation of polymer architectures (a) star polymer (b) comb polymer (c)ladder polymer (d) semi- ladder (or stepladder) polymer POLYMER CHEMISTRY F. Representation of polymer architectures (e) polyrotaxane (f) polycatenane (g) dendrimer POLYMER CHEMISTRY G. Thermoplastic and thermoset (reaction to temperature) Thermoplastic : Linear or branched polymer Thermoset : Network polymer POLYMER CHEMISTRY 1.3 Polymerization Processes A. Classification of polymers to be suggested by Carothers Addition polymers : repeating units and monomers are same Condensation polymers : repeating units and monomers are not equal, to be split out small molecule POLYMER CHEMISTRY Other examples 1. Polyester from lactone (1.7) & from ω-hydroxycarboxylic acid (1.8) O O O C O R (1.7) C R O OH R CO2H O R C (1.8) + H2O POLYMER CHEMISTRY Other examples 2. Polyamide from lactam (1.9), and from ω-aminocarboxylic acid (1.10) O NH C O NH R (1.9) C R O H2N R CO2H NH R C + H2O (1.10) POLYMER CHEMISTRY Other examples 3. Polyurethane from diisocyanate and dialcohol(1.11) and from diamine and bischloroformate(1.12): OCN R NCO + HO R' OH O CNH R NH 2 + ClCO R' O CNH R NHCO R' (1.11) O O O H2N O OCCl (1.12) O R NHCO R' O + 2HCl POLYMER CHEMISTRY Other examples 4. Hydrocarbon polymer from ethylene (1.13), and from α,ω-dibromide (1.14) CH2 CH2 initiator BrCH2(CH2)8CH2Br (1.13) CH2CH2 2Na CH2CH2 + 5 2NaBr (1.14) FUNCTIONAL POLYMERS LAB POLYMER CHEMISTRY 1.3 Polymerization Processes B. Modern classification of polymerization according to polymerization mechanism Step growth polymerization : Polymers build up stepwise Chain growth polymerization : Addition polymerization molecular weights increase successively, one by one monomer Ring-opening polymerization may be either step or chain reaction POLYMER CHEMISTRY 1.4 Step-reaction Polymerization A. Monomer to have difunctional group 1. One having both reactive functional groups in one molecule A R B R X O HO R CO2H O R C + H2O (1.8) O H2N R CO2H NH R C + H2O (1.10) POLYMER CHEMISTRY 2. Other having two difunctional monomers R' A R A + B OCN R NCO + HO R' R' O CNH NHCO R' O X R (1.11) O O NH2 + ClCO R' O CNH R X OH O H2N R B OCCl (1.12) O R NHCO R' O + 2HCl POLYMER CHEMISTRY B. Reaction : Condensation reaction using functional group Example - Polyesterification O n HO nHO2C CO2H O C + nH2O (1.3) n CO2H + nHOCH2CH2OH O O C COCH2CH2O (1.4) n + 2nH2O POLYMER CHEMISTRY C. Carothers equation ( NO : number of molecules N : total molecules after a given reaction period. NO – N : The amount reacted P : The reaction conversion ) P= NO N Or NO N = NO(1 P) ( DP is the average number of repeating units of all molecules present) DP = NO/N DP = 1 1-P For example At 98% conversion DP = 1 1- 0.98 POLYMER CHEMISTRY (A) Unreacted monomer A A A A A A A A A A A A (a) B B B B B B B B B B B B (B) 50% reacted, DP = 1.3 A (b) A B A B A B A A B B A A A A A A B B B B B B B A A A A A A A (C) 75% reacted, DP = 1.7 A (c) A B A B A B A B B B B B B B B B (D) 100% reacted, DP = 3 A (d) A B A B A B A A B B A B A B A B A B A B A B B 1.5 Chain-reaction Polymerization A. Monomer : vinyl monomer χCH2=CH2 B. Reaction : Addition reaction initiated by active species C. Mechanism : Initiation R + CH2=CH2 → RCH2CH2 . . Propagation RCH2CH2 + CH2=CH2 → RCH2CH2CH2CH2 . . POLYMER CHEMISTRY TABLE 1.1 Comparison of Step-Reaction and Chain-Reaction Polymerization Step Reaction Growth occurs throughout matrix by reaction between monomers, oligomers, and polymers DPa low to moderate Monomer consumed rapidly while molecular weight increases slowly No initiator needed; same reaction mechanism throughout Chain Reaction Growth occurs by successive addition of monomer units to limited number of growing chains DP can be very high Monomer consumed relatively slowly, but molecular weight increases rapidly Initiation and propagation mechanisms different Usually chain-terminating step involved Polymerizaion rate increases initially as No termination step; end groups still reactive initiator units generated; remains relatively Polymerization rate decreases steadily as constant until monomer depleted functional groups consumed aDP, average degree of polymerization. 1.6 Step-reaction Addition and Chain-reaction Condensation A. Step-reaction Addition. O (CH2)6 + O O (1.15) (CH2)6 O POLYMER CHEMISTRY 1.6 Step-reaction Addition and Chain-reaction Condensation B. Chain-reaction Condensation CH2N2 BF3 CH2 + N2 (1.16) POLYMER CHEMISTRY 1.7 Nomenclature A. Types of Nomenclature a. Source name : to be based on names of corresponding monomer Polyethylene, Poly(vinyl chloride), Poly(ethylene oxide) b. IUPAC name : to be based on CRU, systematic name Poly(methylene), Poly(1-chloroethylene), Poly(oxyethylene) c. Functional group name : Acoording to name of functional group in the polymer backbone Polyamide, Polyester POLYMER CHEMISTRY 1.7 Nomenclature d. Trade name : The commercial names by manufacturer Teflon, Nylon e. Abbreviation name : PVC, PET f. Complex and Network polymer : Phenol-formaldehyde polymer g. Vinyl polymer : Polyolefin POLYMER CHEMISTRY 1.7.1 Vinyl polymers A. Vinyl polymers a. Source name : Polystyrene, Poly(acrylic acid), Poly(α-methyl styrene), Poly(1-pentene) b. IUPAC name : Poly(1-phenylethylene), Poly(1-carboxylatoethylene) Poly(1-methyl-1-phenylethylene), Poly(1-propylethylene) Polystyrene Poly(acrylic acid) CH 2CH CH2CH CO2H Poly(α-methylstyrene) Poly(1-pentene) CH 3 CH 2C CH2CH CH2CH2CH3 POLYMER CHEMISTRY 1.7.1 Vinyl polymers B. Diene monomers CH2CH HC CH2CH CHCH2 CH2 1,2-addition 1,4-addition Source name : 1,2-Poly(1,3-butadiene) 1,4-Poly(1,3-butadiene) IUPAC name : Poly(1-vinylethylene) Poly(1-butene-1,4-diyl) cf) Table 1.2 POLYMER CHEMISTRY 1.7.2 Vinyl copolymer Systematic Poly[styrene-co-(methyl methacrylate)] Poly[styrene-alt-(methyl methacrylate)] Polystyrene-block-poly(methyl methacrylate) Polystyrene-graft-poly(methyl methacrylate) Concise Copoly(styrene/methyl methacrylate) Alt-copoly(styrene/methyl methacrylate) Block-copoly(styrene/methyl methacrylate) Graft-copoly(styrene/methyl methacrylate) POLYMER CHEMISTRY 1.7.3 Nonvinyl Polymers O O CCH2CH2 oxy 1-oxopropane-1,3-diyl O CH2CH2 O oxy ethylene oxy C C terephthaloyl POLYMER CHEMISTRY * Representative Nomenclature of Nonvinyl Polymers Monomer structure Polymer repeating unit Source or Common Name IUPAC name O H2C CH2 HOCH2CH2OH CH2CH2O CH2CH2O Poly(ethylene glycol) O H2N(CH2)6NH2 HO2C(CH2)8CO2H Poly(ethylene oxide) Poly(oxyethylene) Poly(oxyethylene) O NH(CH 2)6NHC(CH2)8C Poly(hexamethylene Poly(iminohexanesebacamide) or Nylon6,10 1,6-diyliminosebacoyl) cf) Table 1.3 POLYMER CHEMISTRY 1.7.4 Nonvinyl copolymers a. Poly(ethylene terephthalate-co-ethylene isophthalate) O O OCH2CH2O C O C OCH2CH2OC C O b. Poly[(6-aminohexanoic acid)-co-(11-aminoundecanoic acid)] O NH CH2 5 C O NH CH2 10 C POLYMER CHEMISTRY 1.7.5 End Group H OCH2CH2 OH α-Hydro-ω-hydroxypoly(oxyethylene) POLYMER CHEMISTRY 1.7.6 Abbreviations PVC Poly(vinyl chloride) HDPE High-density polyethylene LDPE Low-density polyethylene PET Poly(ethylene terephthalate) POLYMER CHEMISTRY 1.8 Industrial Polymers a. The world consumption of synthetic polymers : 150 million metric tons per year. 1) Plastics : 56% 2) Fibers : 18% 3) Synthetic rubber : 11% 4) Coating and Adhesives : 15% b.Styrene-butadiene copolymer Synthetic rubber, PET Fiber (polyester) Latex paint Plastic (bottle) POLYMER CHEMISTRY 1.8.1 Plastics 1) Commodity plastics LDPE, HDPE, PP, PVC, PS cf) Table 1.4 2) Engineering plastics Acetal, Polyamide, Polyamideimide, Polyarylate, Polybenzimidazole, etc. cf) Table 1.5 3) Thermosetting plastics Phenol-formaldehyde, Urea-formaldehyde, Unsaturated polyester, Epoxy, Melamine-formaldehyde cf) Table 1.6 4) Functional plastics Optics, Biomaterial, etc. POLYMER CHEMISTRY TABLE 1.4 Commodity Plastic Type Abbreviation Low-density polyethylene LDPE High-density Polyethylene Polypropylene HDPE PP Poly(vinyl chloride) PVC Polystyrene PS Major Uses Packaging film, wire and cable insulation, toys, flexible bottles housewares, coatings Bottles, drums, pipe, conduit, sheet, film, wire and cable insulation Automobile and appliance parts, furniture, cordage, webbing, carpeting, film packaging Construction, rigid pipe, flooring, wire and cable insulation, film and sheet Packaging (foam and film), foam insulation appliances, housewares, toys POLYMER CHEMISTRY TABLE 1.5 Principal Engineering Plastics Type Acetala Polyamideb Polyamideimide Polyarylate Polybenzimidazole Poltcarbonate Polyeseterc Polyetheretherketone Polyetherimide Polyimide Poly(phenylene oxide) Poly(phenylene sulfide) Polysulfoned Abbreviation POM PAI PBI PC PEEK PEI PI PPO PPS Chapter C Where Discussed 11 13 13 12 17 12 12 11 11 13 11 11 11 POLYMER CHEMISTRY TABLE 1.6 Principal Thermosetting Plastics Type Abbreviation Phenol-formaldehyde Typical Uses Chapter Where Discussed PF Electrical and electronic equipment, automobile parts, utensil handles, plywood adhesives, particle board binder Urea-formaldehyde UF Similar to PF polymer; also treatment of textiles, coatings Unsaturated polyester UP Construction, automobile parts, boat hulls, marine accessories, corrosion-resistant ducting, pipe, tanks, etc., business equipment Epoxy - Protective coatings, adhesives, electrical and electronics applications, industrial flooring highway paving materials, composites Melamine-formaldehyde MF Similar to UF polymers; decorative panels, counter and table tops, dinnerware 14 14 12 11 14 1.8.2 Fibers 1) Cellulosic : Acetate rayon, Viscose rayon 2) Noncellulosic : Polyester, Nylon(Nylon6,6, Nylon6, etc) Olefin (PP, Copolymer(PVC 85%+PAN and others 15%; vinyon)) 3) Acrylic : Contain at least 80% acrylonitrile (PAN 80% + PVC and others 20%) POLYMER CHEMISTRY 1.8.3 Rubber (Elastomers) 1) Natural rubber : cis-polyisoprene 2) Synthetic rubber : Styrene-butadiene, Polybutadiene, Ethylene-propylene(EPDM), Polychloroprene, Polyisoprene, Nitrile, Butyl, Silicone, Urethane 3) Thermoplastic elastomer : Styrene-butadiene block copolymer (SB or SBS) POLYMER CHEMISTRY TABLE 1.7 Principal Synthetic Fibers Type Cellulosic Acetate rayon Viscose rayon Noncellulosic Polyester Nylon Olefin Acrylic Description Cellulose acetate Regenerated cellulose Principally poly(ethylene terephthalate) Includes nylon 66, nylon 6, and a variety of other aliphatic and aromatic polyamides Includes polypropylene and copolymers of vinyl chloride, with lesser amounts of acrylonitrile, vinyl acetate, or vinylidene chloride (copolymers consisting of more than 85% vinyl chloride are called vinyon fibers) Contain at least 80% acrylonitrile; included are modacrylic fibers comprising acrylonitrile and about 20% vinyl chloride or vinylidene chloride 1.8.4 Coating and Adhesives 1) Coating : Lacquer, Vanishes, Paint (Oil or Latex), Latex 2) Adhesives : Solvent based, Hot melt, Pressure sensitive, etc. Acrylate, Epoxy, Urethane, Cyanoacrylate POLYMER CHEMISTRY TABLE 1.8 Principal Types of Synthetic Rubber Type Description Styrene-butadiene Copolymer of the two monomers in various proportions depending on properties desired; called SBR for styrene-butadiene rubber Polybutadiene Consists almost entirely of the cis-1,4 polymer Ethylenepropylene Often abbreviated EPDM for ethylene-propylene-diene monomer; made up principally of ethylene and propylene units with small amounts of a diene to provide unsaturation Polychloroprene Principally the trans-1,4polymer, but also some cis-1,4 and 1,2 polymer; also known as neoprene rubber Polyisoprene Nitrile Butyl Mainly the cis-1,4 polymer; sometimes called “synthetic natural rubber” Copolymer of acrylonitrile and butadiene, mainly the latter Copolyner of isobutylene and isoprene, with only small amounts of the Latter Contains inorganic backbone of alternating oxygen and methylated silicon atoms; also called polysiloxane (Chap. 15) Elastomers prepared by linking polyethers through urethane groups (Chap. 13) Silicone Urethane 1.9 Polymer Recycling a. Durability of polymer property 1) Advantage : Good materials for use 2) Disadvantage : Environmental problem b. Treatment of waste polymer : Incinerate, Landfill, Recycling ex) Waste Tire : Paving materials Waste PET : To make monomer ( hydrolysis ) To make polyol ( glycolysis ) POLYMER CHEMISTRY TABLE 1.9 Plastics Recycling Codea Number Letters Plastic 1 PETEb Poly(ethylene terephthalate) 2 HDPE High-density polyethylene 3 V or PVC 4 LDPE 5 PP Polypropylene 6 PS Polystyrene 7 OTHER Poly(vinyl chloride) Low-density polyethylene Others or mixed plastics aAdopted by the Society of the Plastics lndustry (SPI). bPET is the more widely accepted abbreviation. POLYMER CHEMISTRY