REU Paper - CURENT Education

advertisement

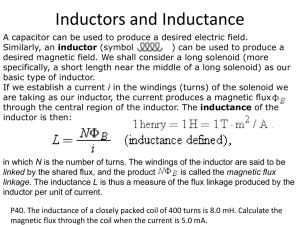

1 Increasing Inductor Power Density Using Controllable Electropermanent Magnets M. E. Lawniczak, Student Member, IEEE Abstract-- Inductive components are used widely in the power grid for the purpose of controlling power flow, regulating fault current, and providing compensation. Magnetics are also a principal component of power electronics circuits. In both cases, inductor design focuses on achieving a desired impedance while maintaining the component within its saturation limits. Recent research has shown that permanent magnets or electromagnets can be used to counteract internal flux, thus altering the saturation characteristics of the inductor. Permanent magnets exhibit a fixed magnetic field, and therefore are not controllable. Electromagnets require current to maintain the field, and therefore generate significant steady-state power loss. Electropermanent magnets differ from electromagnets in that they have zero steady-state power losses and heating issues, while maintaining the ability to electronically control the magnetic field. An electropermanent magnet consists of a permanent magnet and an electromagnet. The winding current of an electropermanent magnet can be programmatically controlled to create a magnetic field that is either on or off. Once the electropermanent magnet is switched on there is zero power being consumed while it is energized. Furthermore, there is no heat generated during the on state of the electropermanent magnet allowing the device to be low maintenance. Currently, electropermanent magnets are being used on a large scale to lift heavy objects with no chance in dropping the load in the event of a power failure. On a small scale, electropermanent magnets are being used in modular devices. Companies such as Google are working on modular cell phones where components can be added and interchanged using electropermanent magnets. Through research and analysis of permanent magnetic materials and their operational characteristics, this project will examine the use of electropermanent magnets in power electronics and power systems applications as a more power efficient means of implementing devices currently being used in motors, switched mode power supplies, and the power grid. that explain how the flux flows through a given inductor. Sections are also devoted to the experimental set up and results of measuring the saturation current of an inductor when an EPM is applied and not applied. II. DECREASING INDUCTOR SIZE When designing an inductor the size of the inductor is an unfortunate tradeoff that must be made in order to have a large inductance. Methods such as the Kg method can be used to determine the minimum core size to withstand a given maximum current, inductance and maximum flux density. An example of large inductor size is pictured below in Figure 1. Almost half of the area in the inverter is made up of inductors. Using an electropermanent magnet to cancel internal flux within the core of an inductor would enable a decrease in inductor size, decrease costs as well as decrease size of power electronics such as this inverter. Fig. 1. Approximately half of the surface area of this inverter circuit consist of inductors. III. MAGNETIC PROPERTIES OF MATERIALS Index Terms—electropermanent magnet, coercivity, remanence, inductor, saturation current, magnetic field strength, flux density. I. INTRODUCTION T HIS document explores the construction and application of electropermanent magnets for the purpose of decreasing inductor size while increasing the saturation current level of the core. It contains information regarding the characteristics of magnetic materials used to construct an electropermanent magnet, how to construct the electropermanent magnet, testing the effectiveness and application of the electropermanent magnet to an inductor. Magnetic circuit models are provided An entire branch of physics is dedicated to the study of the effects produced when a magnetic field is applied to a material. Some of the characteristics that classify these effects are permeability, remanence, intrinsic coercivity and saturation [1]. All of these characteristics are relevant in the construction and functionality of an electropermanent magnet and are described in greater detail in the paragraphs below. An electropermanent magnet is made of two magnets. The Neodymium Iron Boron magnet is a permanent magnet classified as a “hard” magnetic material. A hard magnetic material is a material that has a high coercivity. The coercivity of a magnet determines the ease with which a magnetic field can be reversed. The units for coercivity are amps per meter. The second magnet within the electropermanent magnet is the 2 Alnico 5 magnet. The Alnico 5 magnet is classified as a “soft” magnetic material, meaning it has a low coercivity. The low coercivity characteristic means that it takes a lower magnetic field strength to flip the magnetic field in the opposite direction. The low coercivity of the Alnico 5 is what allows the electropermanent magnet to switch on and off with a current pulse. The remanence characteristic classifies the magnetization left behind in a magnetic material when an external magnetic field is removed. Figure 2 compares the coercivity and remanence values of each of the magnets. remanence values add and the magnetization is permanent. When a negative current pulse is applied the magnetic field of the Alnico 5 magnet is flippd and is opposite to the magnetic field of the Neodymium Iron Boron magnet, turnng the EPM off. Figure 6 includes the magnetic circuit models for the electropermanent magnet in the on and off state. Fig. 2. Comparison of magnetic characteristic between NIB and Alnico 5. The remanence values are utilized in the off and on stage of the electropermanent magnet. When the electropermanent magnet is in the off stage the remanence values of the two magnets cancel and the net magnetization is zero. When the electropermanent magnet is on the remanence values are added together created a strong magnetization. The permeability of a material describes the ability of flux to flow through a material. The permeability of the Neodymium and Alnico 5 magnet is 2.1 and 1.05, respectively. The permeability will be brought up again later in this paper when the reluctance is calculated. The linearity and nonlinearity of the permeability is characterized in the hysteresis loop. The magnetic characteristics of a material are evident in the shape of the hysteresis loop. Figure 3 illustrates the hysteresis loop for a soft and hard magnetic material. The hysteresis loops for Alnico 5 and Neodymium would look similar to the hysteresis loops below, however the height y-intercept of the loops would be at the same, 1.2 [T]. Fig.5. The different phases of the electropermanent magnet. The polarity of the current pulse applied to the coil is related to the location of the flux density at that moment [6]. Fig.6. The magnetic circuit on the left represents the electropermanent magnet in the ON state. The magnetic circuit on the right represents the electropermanent magnet in the OFF state. IV. CONSTRUCTING THE ELECTROPERMANENT MAGNET Fig. 3. Hysteresis Loop for a soft and hard magnetic material. The phases of the electropermanent magnet are illustrated in Figure 4. In the first phase when zero current is applied to the coil the remanence values cancel and the magnet is off. When a positive current pulse if provided the direction of the current flow determines the direction that the magnetic field strengths will point. When the current is removed from the coil the When constructing an electropermanent magnet the magnetic characteristics described above are critical to the EPM’s ability to switch on and off using a minimum amount of current. If the coercivity of the magnetic material is too large than the initial current pulse may exceed the overall power consumption of simply using an eletromagnet. Great care should be taken when selecting the materials to be used. The magnets used need to be the same length and not necessarily the same width. This is due to the inverse relationship between the area of the magnet and the reluctance. This is explained in more detail in the calculations section. In this project, two electropermanent magnets were constructed using 10mm and 6.35mm length magnets. Figure 7 is a photo of each othe EPMs. The 10mm is on the right and the 6.35mm model on the left. Throughout the paper the EPMs will be referred to as EPM A and EPM B. EPM B was not used because it was later discovered that an Alnico 8 magnet had been epoxied to the component instead of Alnico 5 . The coercivity of the Alnico 8 magnet is approximately 1000 kA/m and required a large 3 current pulse to flip the magnetic field strength. The small length of the magnets left a small window area and an adequate amount of turns could not be wrapped around in order to obtain a reasonable current. Attempts were made to build other EPMs however the ferrite was very brittle and shattered when cutting/ sanding. The Alnico 5 material was also very difficult to cut through. Since long rods of the material were ordered small nicks were placed where the magnet was intended to be shortened and then using leverage and a chisel the magnet was snapped. The ferrite pieces on either side of the magnet were constructed from ETD cores and have a width of 12.7 mm and thickness of 5.08 mm. The length of the ferrite pieces for the 6.35 mm length magnet should have been extended to create a larger window area for wrapping the copper wire. determined by the intrinsic coercivity, H [kA/m] and the length of the magnet, 𝑙 [m] . 𝑚𝑚𝑓 = 𝐻𝑙 The reluctance of the material is determined by Equation (4) ℛ= 𝑙𝑚 𝜇0 𝜇𝑟𝐴𝑐 (4) Where 𝑙 m [m], is the mean length of the material, 𝜇0 is the permeability of free space[𝐻 ∙ 𝑚−1 ], 𝜇𝑟 is the relative permeability of the material and the cross-sectional area, 𝐴𝑐 [m2]. Combining Hopkinson’s Law with equation (5), the flux can be controlled by the area of the magnetic material. 𝑚𝑚𝑓 = Фℛ Fig. 7. The model on the left consists of 2 10mm length magnets (EPM A). The model on the right consists of 2 6.35 mm length magnets (EPM B). (3) (5) Increasing the length of the magnet has no effect on the flux generated by the EPM. Notice the mmf and reluctance both have a linear relationship to the length of the magnet. The increase in both mmf and reluctance has no effect on the flux. Increasing the area of the magnet however does have an inverse relationship with Reluctance. Therefore increasing the cross section area of the material decreases the reluctance and increases the flux. A. Calculating the current required to switch the EPM V. USING FEMM TO SIMULATE FLUX DENSITY The flux density, B [T] is related to the magnetic field, H [A/m] using equation 3. 𝐵 = 𝑢𝐻 (1) The magnetic field strength for EPM A was designed to have twice the magnetic field strength of the coercivity to ensure the magnet would be completely demagnetized or magnetized. If too low of a magnetic field strength is applied the EPM will not retain its intended state. Using H=100 [kA/m] and 𝑙=10 [mm] and n= 62, which was determined simply be wrapping as many turns as possible around the magnet. Using the following equation 𝐻𝑙 = 𝑛𝑖 The femm software was used to provide a visual of how the flux generated by the electropermanent magnet would distribute through the core of the inductor. The flux in the femm simulations were consistent with the flux calculated in LT spice and hand calculations and were therefore reliable. The magnetic circuit model for the electropermanent magnet attached to an inductor is pictured in the figure below. (2) the current needed to switch the Alnico 5 magnet in EPM A was calulated to be 16[A]. When applying current to flip the magnet, at 8[A] the magnet exhibited some magnetization or demagnetization (depending on the polarity of the current pulse). However, when the current was removed from the EPM the magnetization disappeared. The current level had to reach 16[A] in order to be permanently magnetized or demagnetized. B. Calculating the Flux Generated by the Electropermanent Magnet The magnetic materials each have an internal magneto motive force, 𝑚𝑚𝑓 [A] and reluctance, ℛ [H-1]. The mmf is Fig. 8. The magnetic circuit model for the EPM attached to an inductor. Figure 9 shows the femm simulation for the magnetic circuit model pictured above. The EPM is placed across an air gap. The high reluctance of the air gap encourages the flux generated from the EPM to flow in the opposite direction. The configuration is effective and flux is passed through each leg of the inductor. The model could be further improved by distributing more of the flux in the empty spaces around the electropermanent magnet. This could be achieved by decreasing the length of the magnet. The area of the magnet could then be increased ensuring that the flux generated from 4 the electropermanent magnet remains the same. Figures 10 and 11 are other examples of femm simulations. Ultimately, the flux from the EPM will need to be distributed such that the maximum flux is subtracted from the internal flux of the inductor. If flux from the EPM is in the same direction as the internal flux that portion of the core is in danger of saturating, having an effect on the performance of the inductor. The flux from the EPM has a canceling effect with the flux generated by the inductor coil in the middle and right leg of the inductor (enclosed in purple), the flux flowing to the left leg however has a summing effect (enclosed in red). Fig. 9. An effective geometry for applying the EPM to the inductor such that the flux is distributed through each leg of the core. Fig. 12. The areas where the flux generated by the EPM is canceling internal flux of the inductor is enclosed in purple. The red enclosure indicates where flux from the EPM is adding to the internal flux, which could saturate that leg of the core. VI. MEASURING THE INDUCTANCE EXPERIMENTALLY Fig. 10. This simulation was modeled experimentally and had the greatest effect on the inductance than any other configuration. This configuration is not as practical however because so much excess flux is surrounding the inductor. This flux may interfere with other components in the circuit. Fig. 11. This simulation has large air gaps near the base of the inductor. The flux looks for the path of least reluctance and therefore flows through only a short segment below where the EPM is placed. An RLC machine was used to measure the inductance of different sized cores, with and without EPMs attached. The simulation in Figure 9 was tested experimentally. The inductor used an ETD29 core with .0075 mill air gaps. The inductance measured was 1.3 mH. When EPM A was attached to the side of the core the inductance fell to 940 𝜇𝐻. This was less of a change than was expected. This may be due to the mismatched widths of the EPM and the inductor and poor contact being made. This low drop in inductance compared to the next setup described is still being investigated. Another configuration measured experimentally is shown in Figure 12. The inductor has no air gaps and an inductance of 1 mH. When EPM A was applied on the top of the inductor the inductance fell to 330 𝜇𝐻. This suggests that the flux generated by EPM A is saturating the core causing over a 50% decrease in inductance. Fig. 13. EPM A causes the 1 mH inductor to drop to 330 𝜇𝐻. Confirming the influence an EPM can have on internal flux of an inductor. 5 This shows that the EPM is in fact strong enough to have a great effect on the internal flux of the inductor. The next step will involve using pieces of ferrite material constructed around the inductor in such a way that the EPM’s flux is always canceling the internal flux of the inductor. flux within the inductor’s core. VII. MEASURING THE SATURATION CURRENT Using the ETD 29 core with an inductance of 1.3 mH the saturation current was measured with the inductor alone and with EPM A attached to the side. The hypothesis was that when the core saturated at a calculated current, a drop in inductance would occur. After applying the EPM, the flux from the EPM would cancel some of the internal flux of the inductor allowing a greater current to be applied to the inductor before saturating. This would be seen as a shift right of the original NO EPM curve. The hypothesized graph is displayed in Figure 14. The test set up is pictured in the schematic in Figure 15. An RLC machine was used to measure the inductance. An ideal current was emulated using a DC voltage source with an internal resistance. A 1 mH inductor was placed in series with the DC source to decrease any fluctuations in the signal. A large capacitor was used in series with the RLC machine to ensure that the small sinusoidal current produced by the RLC machine to measure the inductance did not go back towards the DC voltage source. The DC source was incremented by .1 [A] until the core saturated. The DC source however interfered with the readings of the RLC machine and the data was not reliable. The data collected is pictured in Figure 16. Notice the inductor immediately saturates whether the EPM is applied or not. The shoulder drop off that was expected in the hypothesized graph was not seen in the collected data. It is possible that if the current values between 0 and .1 amps were zoomed in on the expected shoulder drop off of the inductance could be seen. However .1 amps is the smallest amount the DC source can be incremented by and greater accuracy is not possible with this particular set up. It should also be noted that using equation (6) the saturation current for the inductor was hand calculated and was expected to saturate around 2.3 [A]. 𝐼𝑠𝑎𝑡 = 𝐵𝑠𝑎𝑡 𝐴𝐶 𝑛 (𝑅𝑐 +𝑅𝑔 ) (6) Fig. 15. The experimental set up for testing the saturation current of the inductor. Fig. 16. The experimental results show an immediate saturation in the core when the EPM is and is not applied. It is believed the DC source has distorted the readings of the RLC meter. The next experimental set up to measure the saturation current of an inductor will apply transformer theory. The circuit schematic is depicted in Figure 17. A second winding will be put around the coil of the ETD29 and the dc voltage source and series impedance will be reflected to the left and the saturation current measured. The DC voltage source will need to begin at 5[A] and the impedance will be seen as 5X larger, which may help alleviate the problem of the DC source interfering with the RLC measurements. This experimental setup should provide more reliable measurements. Fig. 14. The hypothesized shoulder drop off of an inductor with and without an EPM applied. The shift right of the curve suggest an internal cancelation of Fig. 17. The next experimental set up to measure the saturation current of an inductor will use transformer concepts to reflect a greater impedance of the DC source to the left side. 6 VIII. CONCLUSION This research has shown that the electropermanent magnet can generate enough flux to saturate a core. If this flux can be routed in such a way that all of the flux generated by the EPM cancels the internal flux of the core, then decreasing inductor size while maintaining a higher saturation current will be achievable. Future work on this project include obtaining custom fabricated magnets with different magnetic field directions so that innovative geometries can be created between the inductor and the EPM. Furthermore, new EPMs that require less power for the switching of the magnet will be configured. This will include magnets with greater area and greater window area (for more turns). Other experimental set ups will be hypothesized and tested for greater accuracy. Also, inductors with other geometries such as the toroid will be tested for efficient flux distribution. During this phase of the research the flux created from the current pulse was not considered, however this will also be further investigated. IX. REFERENCES [1] R. Clarke (2008, Aug.) "Magnetic Properties of Materials" [Online]. Available: http://info.ee.surrey.ac.uk/Workshop/advice/coils/mu/ [2] R. Erickson, Fundamentals of Power Electronics Palo Alto, Calif., 1961, p. 497-850. J. T. Ludwig, (1960, July). Inductors Biased with Permanent Magnets, p. 273-278. G. M Shane, S. D. Sudhoff, “Design Paradigm for Permanent-MagnetInductor – Based Power Converters,” IEEE Transactions on Energy Conversion, Vol. 28, No. 4 December 2013. Z Dang, J. Qahouq, "Evaluation of High Current Toroid Power Inductor with NdFeB Magnet for DC-DC Power Converters," Alabama, 2015. A. N Knaian, "Design of Programmable Matter," Ph.D. dissertation, Dept. of Electrical Engineering and Computer Science, Masachusetts Institute of Tehcnology, Cambridge, MA, College Park, 2000. [3] [4] [5] [6] X. BIOGRAPHIES Maeve Lawniczak is a senior in Electrical Engineering at the University of Tennessee. She is interested in wearable technology and wearable devices. She has worked with the Center for Biotechnology at the University of Tennessee converting signals from detected bioluminescence cells to a digital output. She is currently working with Dr. Costinett researching applications of electropermanent magnets into the power grid. Maeve is on the board of Systers, which aims to recruit, mentor and retain women in EECS and is a student ambassador of CURENT.