PATS Aircraft Systems Overview Products, Services - ASQ

advertisement

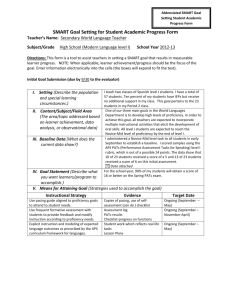

PATS Aircraft Systems Overview Products, Services & Capabilities 2012 Overview | Introduction •PATS Aircraft Systems is a long standing VIP aircraft supplier with roots in specialty aviation component manufacturing dating back nearly 40 years. •Founded on complex engineering and certification of advanced aircraft systems, PATS has provided auxiliary fuel systems and other integrated systems and components to most aircraft OEMs and hundreds of customers. •In the mid-nineties PATS began to provide Boeing and Bombardier with auxiliary fuel systems that would become the “legs” of their single-aisle airliner business jets. •In 1998, PATS opened its facility in Georgetown, Delaware, at Sussex County Airpark. Soon thereafter, PATS began to provide BBJ and other VIP aircraft customers with VIP aircraft maintenance, modification and interior completion services. •During the last 12 years, PATS has focused on supporting a OEM and VIP customer base with components and services that elevate their aircraft operations and in-flight experience. 2 Overview | Products & Services AUXILIARY FUEL SYSTEMS MANUFACTURE & INSTALLATION AICRAFT COMPONENTS MANUFACTURING AIRCRAFT MAINTENANCE AND MODIFICATIONS VVIP AIRCRAFT INTERIOR COMPLETIONS CUSTOMER ADVANTAGES 1 Maintain critical processes in-house including engineering, manufacturing, supply chain, installation and certification 2 Strong in-house R&D engineering expertise allows full support design and emergent liaison engineering requirements 3 Broad array of product and service offerings allows high-quality focus on low volume of simultaneous completion work 4 Full range of OEM-level aftermarket services and support 5 FAA ODA capable of issuing STCs and PMAs on behalf of the FAA Leverage Experience and Project Focus for Customer Benefit 3 Overview | Facility > 35,000 Sq. Ft. Dedicated Manufacturing Facility Dedicated Training & Engineering/ODA Facilities 4 Hangars house up to 7 B737 sized aircraft with full back shop capability of over 42,000 Sq. Ft. Large Single Campus Houses All Departments 4 Overview | Executive Management John Martin CEO Tiffany Coffelt Office Administrator Wilhelm Wieland VP Engineering/ Certification & Product Development Tom Spencer VP Manufacturing Programs & Supply Chain Mark Ryan VP Hangar Ops & BBJ Programs Mark Rudo VP ODA, Quality & Product Support Matt Hill VP, Business Development Sandy Taras CFO Finance & Accounting John Eichten Sr. VP Sales & Marketing Cheryl Parker VP, People Executive Team With Extensive Aerospace Experience 5 Overview | Employees World-class employee base • Non-union and cross-trained employee base secures skill of labor applied to projects BY FUNCTION HR & Administration 3% Sales & Marketing 3% Management 2% Manufacturing Management 6% Finance IT 3% 1% Mechanics/ Production 44% Quality 10% Engineering 17% Integrated Supply Chain 15% TOTAL # OF EMPLOYEES (3/1/12): 344 PATS’ Employees are the Single Most Important Asset 6 Overview | Accreditations • FAA Part 145 Repair Station • ODA – Supplemental Type Certificates (STC) • ODA – Part Manufacturer Approval (PMA) • EASA Part 145 Repair Station (+ several other regional validations) • QMI-SAI certified to ISO9001:AS9100C • Boeing BEST System Gold Supplier Status (Delivery and Quality) • FAA Diamond Award for Excellence – 2010 & 2011 Recognition for Quality and Regulatory Excellence 7 Overview | Broad Customer Base Longstanding Relationships with OEMs and Operators SNAPSHOT OF GLOBAL CUSTOMERS Relationships with Leading Aerospace Companies 8 Overview | Summary • BBJ-Focused Hangar Services – Focus on Limited Completions & Fleet MX • Leading Provider of Auxiliary Fuel Systems and Related Products and Services • Key Regulatory Certifications • FAA / EASA Repair Station Approval (in addition to numerous others) • ODA (Organization Designation Authority) for both STC & PMA • Global Product Support & Long Term Customer Relationships • Hangar & Manufacturing Business Mix - Mitigate Cyclical Market Risks • Proven Management Team / Highly Skilled Employee Base Leveraging Core Expertise for Our Valued Customers 9 II. Hangar Operations - Benefits of PATS Hangar Operations | Capabilities & Approvals OVERVIEW FAA Repair Station Certificate includes authorization to perform any type of maintenance or modifications on Boeing B737 Series (100-900), B727 Series (100-200), Bombardier CL-600-2B19 and Embraer ERJ-190-100-ECJ aircraft International and domestic authorizations and ratings include: PART 145 REPAIR STATION FAA Limited Airframe Rating (727, 737, CRJ, ERJ) FAA Limited Accessory Rating FAA Limited Radio Rating FAA Limited Powerplant Rating EASA 145 Acceptance Certificate AFS Manufacturing and Installation SFAR 88 system upgrades BBJ Authorized Service Center Scheduled maintenance inspections including A, B and MAINTENANCE C checks AND Avionic systems installations and upgrades MODIFICATIONS SATCOM, GPS, TAWS, EGPWS Live TV, IFE, CMS EFB and flight deck upgrades Brazil ANAC Organization Certificate U.A.E. GCAA Organization Approval Bermuda DCA Approved Maintenance Aruban DCA Acceptance Certificate Belarusian Aviation Committee Approval Smoke and fire detection/suppression installation VVIP Interior installations, refurbishments and reconfigurations Structural and Composite repairs Winglet installation Provides design approvals for aircraft modifications utilizing its in-house engineering team and Designated Engineering Representatives, Designated Airworthiness Representatives and Designated Manufacturing Inspection Representatives ORGANIZATION Allows Company to certify products for airworthiness DELEGATION 41 ODAs active in the USA AUTHORIZATION PMA ODA enables PATS to issue PMA supplements for manufactured parts Broadly Capable and Globally Accredited 11 Hangar Operations | Interior Completions Experience In the early 2000’s, PATS began to perform interior completions concurrently with the AFS installation at PATS (reduced downtime to the customer). The first completion was awarded and delivered in 2002 (BBJ2 , 737-800). Since that time PATS has completed a total of 20 VIP Interior Completion aircraft. PATS “niche” in the completions industry has been supporting Head of State interior completions with 9 aircraft delivered in such configurations. Most recently, PATS delivered its 13th BBJ completion ahead of schedule and with a multi-configuration STC certified by the PATS ODA. Boeing Business Jets Bombardier CRJ 200 Embraer Lineage 1000 13 3 4 AFS Partner to BBJ Since Inception… 20 Delivered Completions 12 Hangar Operations | Interior Completions Experience Model Customer BBJ2 Head of State Interior , September 2002 BBJ VIP Corporate , October 2003 BBJ Head of State, January 2004 BBJ2 Head of State, January 2004 BBJ Head of State , September 2004 BBJ Head of State , July 2005 BBJ2 Head of State, February 2006 BBJ VIP Corporate, January 2007 BBJ Head of State – Total of 3 Aircraft, January 2008 BBJ2 Head of State, August 2007 BBJ VIP Corporate, January 2008 CRJ200 EMB190 BBJ CRJ200 VIP Interior Conversion – 3 Total Aircraft, 2009 Embraer Lineage 1000 – 4 Total Aircraft, 2009-2010 VIP Corporate, July 2010 (Early Delivery) Consistent Deliveries Since Program Outset 13 Hangar Operations | Project Management Approach PATS believes that complex interior completion projects are most successfully approached with full customer involvement and interaction. A few key elements of this approach are ingrained in the way we choose to organize and staff our important interior completion projects: Project Based Hangar Organization Our Hangar Operations Business Unit is organized in teams and talent areas by focus to include auxiliary fuel systems installations, aircraft maintenance & modifications and interior completions. Interior completions project teams have a clearly defined structure for departmental and overall program accountability. Key functions are dedicated to the project to ensure “A” level focus and performance Customer Specific Project Management Each project is unique, and rightfully so. Therefore PATS staffs each individual interior completion project with specific personnel and expertise to best match the unique requirements for the project. This might include designers, special equipment experts and/or persons speaking a customer language. Team Oriented Approach with Focus on Communication 14 Hangar Operations | Critical Process Control PATS maintains all key project departments and expertise in-house Design & Engineering Planning & Procurement Manufacturing & Quality Control Customer Service & Support Complete suite of in-house capabilities to provide streamlined customer solutions OVERVIEW PATS ADVANTAGES Structural, mechanical and electrical systems Specialty engineering including cooling, smoke and flammability Finite element modeling 3D modeling Software; CATIA v5, AutoCAD, SolidWorks, NASTRAM Streamlined procurement Planning and kitting services AFS tanks fabrication and repair APU fabrication and assembly Avionics fabrication and assembly Computer integrated manufacturing Precision sheet metal fabrication and assembly Chemical corrosion treatment and paint shop 24/7 parts and service support Rotable / exchange inventory Complete aircraft and crew logistical support Drives development of new products and installations Leverage of purchasing power of customer benefit ISO 9001:2000 and AS9100 registered Increased control of delivery schedule Large site provides large capacity for inventory storage Internal auditing process and corrective/preventive action process Greater degree of quality control Provides greater knowledge of customer requirements through large history of projects Specialized internal team to specifically translate customer requirements into final products Vertically integrated manufacturing Shortens lead-times Wide variety of capabilities and qualifications provides one-stop convenience for customers Maximizes product value-add Control of Key Processes Mitigates Risk 15 Hangar Operations | Facilities and Efficiencies PATS’ Interior Completion Aircraft are segregated in hangar locations which provided direct and efficient access to materials receiving, backshops and program team offices. Receiving Dock Back Shops Stockroom Key Departments Program Offices Efficient and Well Organized Hangar Facility 16 III. Manufacturing - Benefits of PATS Manufacturing | Auxiliary Fuel Systems Boeing & Bombardier Sole Source Supplier • • • PATS AFS extends the range of the 737NG and CRJ200 to create the venerable BBJ and CL850 products Installed in every BBJ and CL850 delivered Long term contracts in place for ongoing supply Total AFS Experience • • PATS has manufactured, delivered and supported over 1,000 individual tanks and 250 systems Currently PATS supports AFS STCs including 737NG, B757, B767, Fokker 100, CL850 and CRJ200 Services • • • • AFS re-configuration service bulletins Full product support including repair, maintenance, technical liaison services, spares and AOG support In-house ODA for unique technical / certification requirements Opportunity to perform additional systems installations or provisioning for customer prior to induction for completion work Industry Leader in Auxiliary Fuel Systems 18 Manufacturing | Products & Services Auxiliary Power Unit Installation Kits • PATS has produced, delivered and supported APUs for Lear 60, Hawker 7/8/9 class, Dash 8, Cessna, Falcon 50 and other programs. • These kits require craftsmen in all fields of fabrication from precision sheet metal and avionics assembly to world class machining. Hollingsead International Products Our products include: • ARINC Trays, Tray Hardware: Extractors, Front and Rear Holddowns, Guide Pins, etc. • Avionics Racks and Enclosures Our services include: • Tray and Racking System engineering and data development • Manufacture of installation kits • Prototype design and manufacture and 24-hour AOG Service Capability to Support Broad Customer Needs In House 19 Manufacturing | Products & Services Precision Machining • CNC Milling, Drilling and Routing Precision Sheet Metal • CNC Punching and Break Forming • Shearing, Tig Welding, Precision Assembly, Avionics Tray Fabrication, Avionics Extractors and Thumb Screws Electronic Assembly • Wire Processing, Laser Markings, Complex Harness Assembly, Pull Testing and Electronic Racks. Certifications • ISO 9001:2008 Certified • AS 9100C Certified Capability to Support Broad Customer Needs In House 20 IV. Engineering & Certification - Benefits of PATS Engineering & Certification | Concept to Reality PATS employs internal designers and external designer relationships to translate the customer culture and design concepts into reality with tremendous accuracy and customer satisfaction. Example below of an aircraft layout becoming a delivered aircraft and the precise nature with which the original concept matches the final result. Elevation Drawing Artist Drawing Computer Rendering Actual Photo Ability to Translate Concepts into Reality 22 Engineering & Certification | Engineering In-House and Vendor Relationships Drive Efficient Results Complete Engineering Design, Systems Integration and Analysis Team Dedicated Project Engineer assigned to each Completion Project Electrical Design, Integration, Analysis and Test Plan Development Structural Design, Interface Loads, Structural Substantiation, Decompression, etc. Mechanical Systems Design, Integration, Analysis and Test Plan Development Specialty Engineering such as Flammability, Smoke & Thermal Analysis In-House Personnel Drive Critical Expertise Areas to Results KEY CUSTOMER BENEFITS Core Program Staff are Functional Program Leaders to Ensure Schedule Compliance Long Standing external Vendor Relationships Key to Program Efficiency Portfolio of Data/Experience from Past HOS Aircraft Engineering Talent and Performance Key to Success 23 Engineering & Certification | Certification PATS’ ODA Status Provides a Distinct Risk Mitigation ODA program developed by the FAA to replace and expand the former DAS designations to safely and more efficiently manage an expanding workload for certification of aircraft projects by FAA departments Granted selectively to applicants that maintain certain expertise and capability to manage the complex certification process for ancillary aircraft systems or components PATS is one of 41 STC ODAs in the United States and has also attained the PMA ODA, giving it the ability to develop, manufacture and modify aviation parts and systems PATS is unique in that the STC ODA supports both manufactured aircraft systems/components (AFS, etc.) and interior completion STCs Delegates key FAA responsibilities to ODA staff to minimize review time On-site ODA staff provide immediate reaction to customer cert requirements KEY CUSTOMER BENEFITS Enables more precise and efficient aircraft projects Reduced time between STC paperwork completion and issuance of STC Enables PATS to design, manufacture and certify its product offerings at a pace conducive to customer driven schedule requirements Schedule and Certification Risks Mitigated by In-House ODA 24 Engineering & Certification | IP Portfolio Extensive IP portfolio PATS owns an extensive library of Supplemental Type Certificates, Patents and Proprietary Data Numerous Executive Cabin Interior Configurations and Modifications Various Airbus & Boeing Aircraft Avionic Racking Systems STCs Hollingsead standard and custom tray assemblies – Box-Mount ™ – and insertion/extraction front hold-downs for numerous aircraft and component OEMs applications Company owns 350 STCs including • • • • • • • AFS tanks for B-737 / BBJ, B-757, B-727, B-767 AFS tanks for Fokker F-100 AFS tanks for Bombardier CL-850 SFAR No. 88 kits STCs Custom cabin configurations CRJ-200 Over 60 STCs for installation of APU systems STCs for Hollingsead International products (smoke detectors, fire suppression and avionics racks & trays) 109 PMAs and routinely applies for and receives PMA supplements for after market support Portfolio Evidences Experience in Design and Certification 25 V. Product Support Product Support| Global Support & Training Global Product Support Team PATS offers full warranty and aftermarket support of all products and services through a global Product Support organization including numerous customer service representatives, field service technicians, technical publications, AOG parts stocking, technical services and reliability monitoring. Our mix of OEM and individual customers plus years of experience delivering products and services has resulted in a broad network of capable repair facilities throughout the world and a mobile team of broadly trained interior systems and field service maintenance technicians. Product Training PATS provides classroom instruction and aircraft side instruction based on syllabus authored by a dedicated training administrator at a detail level selected by the customer. PATS’ normal interior systems syllabus will provide flight deck and cabin systems training to customer selected staff including systems overview, LRU locations and removal/replacement requirements, systems operation – ground and flight and systems troubleshooting and required test equipment. All training materials shall be provided at no additional charge. Team to Support Global Customer Operations 27 VII. Contacts Matthew Hill Vice President, Business Development Phone: 302.253.6372 Email: matthew.hill@patsaircraft.com John Eichten Senior Vice President, Sales & Marketing Phone: 302.253.6132 Email: john.eichten@patsaircraft.com