Experiment 7

advertisement

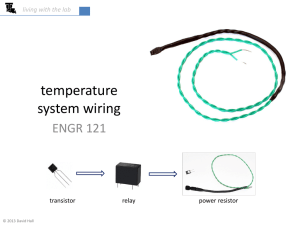

Lab Experiment No. 7 Cooling Fan Control Circuit I. Introduction This lab experience involves a project rather than an experiment. The project is to build and test circuits that use a thermistor to control temperature by activating a cooling fan. II. The Thermistor: Theory of Operation A thermistor is a resistor constructed from special material having a resistivity significantly sensitive to temperature [1,2]. This material allows the resistance of the thermistor to exhibit a predictable variation over a wide range of temperature. These devices are used as temperature sensors, current limiters, bias current compensators, and circuit protectors. The resistance-temperature (RT) characteristics of thermistors are very non-linear. For example, the RT characteristics of one class of thermistors is modeled with an exponential equation derived from the Steinhart-Hart equation for [2] Rt T Rt To e 1 1 B T To (1) In this equation, T is the ambient temperature in °K, To is the reference or nominal temperature (usually 300.15°K or 27°C), Rt(To) is thermistor resistance at the nominal temperature, and B is a model parameter in °K. The plot of a RT curve for a typical thermistor with a nominal temperature resistance of 6KΩ for two values of B is shown in Figure 1. Over small ranges of temperature, the RT curve exhibits a near straight-line behavior. In these ranges, the resistance of a thermistor can be approximated with a first-order relationship to temperature modeled by TCR Rt T Rt To 1 T To 100 (2) where TCR is the temperature coefficient in %/°C. If the TCR is positive, the thermistor is referred to as a positive temperature coefficient (PTC) device and Rt increases as temperature increases. Conversely, if TCR is negative, then Rt decreases with an increase in temperature and the thermistor is a negative temperature coefficient (NTC) device. The TCR for a typical PTC thermistor is on the order of 0.2%/°C to 0.5%/°C while that for a NTC device is between –5%/°C to –3%/°C. III. Fan Control Circuits There are two versions for the fan control circuit used in this project. The schematic of the first version (Ckt. 1) is shown in Figure 2 where a 5KΩ NTC thermistor RT is connected to a 10KΩ trim pot (R1) to form a voltage divider. The thermistor is placed next to an object (target) whose ambient temperature is to be regulated by the cooling fan. The voltage from the divider provides the excitation (Vin) to the 555 timer which is configured as a Schmitt trigger [3]. Assuming the currents into pins 2 and 6 of the 555 are very small, V in is expressed as Vin Rt T Rt T R1 VCC (3) where Rt(T) is the temperature dependent resistance of RT. The output of the 555 (Vo) drives a pair of 2N3904 NPN bipolar junction transistors (BJT) Q1 and Q2 to control a cooling fan and the light-emitting diode (LED) D1. The LED provides visual indication of the fan’s condition. The voltage transfer curve (VTC) of the control circuit is shown in Figure 3. At the target’s nominal operating temperature (T o), Rt(To) is about 5KΩ such that Vin is slightly larger than 8V which is the ‘high’ threshold voltage (VTH) of the Schmitt trigger. The value for Vin at To can be adjusted by trimming R1. At this point, Vo is approximately equal to zero volts causing Q1 and Q2 to be turned off such that the fan and LED are also turned off. As the target’s temperature begins to increase, R t(T) begins to decrease causing Vin to decrease as well. When Vin reaches the ‘low’ threshold voltage (VTL), the Schmitt trigger changes state causing Vo to immediately increase to the supply voltage 12V. This voltage is large enough to cause Q1 and Q2 to conduct, and to turn on the fan and the LED. By positioning the fan to direct a flow of cool air toward the target, its temperature will begin to decrease such that Rt(T) and, consequently, Vin will start to increase. When Vin reaches VTH, Vo immediately drops to zero volts which turns Q 1 and Q2 off. As a result, the fan and LED are also turned off to complete the operating cycle. The schematic for the second version (Ckt. 2) of the control circuit is shown in Figure 4. In this circuit, the pchannel junction field-effect transistor (PJFET) J1 and the 10KΩ trim pot R1 make a current source that forces current into the thermistor RT. The operation of this circuit to control the cooling fan is basically identical to that of the first version. IV. Components and Instruments The components and instruments required for this lab are listed below. Components: Resistors: 100Ω 1KΩ (2) 10KΩ trim pot NTC thermistor Capacitors: 0.01µF (2) 10µF Active devices: IC: 555 timer Red LED NPN BJT: 2N3904 (2) PJFET: J271 Instruments: Power supply Agilent E3620A Multimeter Agilent 34401A Additional: 12V cooling fan Tool box Breadboard Hook-up wire V. Project Procedure Both circuit versions described above are to be built and tested in the lab. The following tasks are to be performed. (a) Download, store, and print data sheets for the components listed below NTC502-RC thermistor (Xicon) 555 timer (Fairchild Semiconductor Corp. or National Semiconductor Corp.) NPN BJT 2N3904 (Fairchild Semiconductor Corp.) PJFET J271 (Fairchild Semiconductor Corp.) (b) Obtain a fan from the GTA. Confirm the operation of the fan by connecting it to the Agilent E3620A power supply. Connect the red lead to positive (+) and the black lead to negative (−). Adjust the voltage to 12V and verify that the fan is operational. If the fan does not operate, obtain another from the GTA. (Note: Be sure to return all fans to the GTA after the project is completed.) (c) Build Ckt. 1 shown in Figure 2 on your breadboard. Follow the breadboard layout shown in the photo in Figure 5. Place the fan and thermistor connections at the far end of the breadboard for convenient access. (d) With the power supply voltage Vps of 12V, adjust R1 such that Vin is slightly larger than 8V. Measure and record Vin, and indicate that the fan and LED are off. (e) Use a heat source (hair dryer) to blow hot air onto the thermistor. Measure and record V in when the fan and LED turn on. This voltage should be slightly less than 4V. (f) Remove the heat source and direct the air flow from the fan onto the thermistor. Measure and record V in as the temperature of the thermistor decreases to nominal. As V in exceeds 8V, the fan and LED should turn off. (g) Repeat (c) through (f) for Ckt. 2 shown in Figure 4. VI. References [1] M. Sapoff and R.M. Oppenheim, “Theory and application of self-heated themistors,” Proc. IEEE, vol. 51, pp. 1292-1305, Oct. 1963. [2] E.A. Boucher, “Theory and applications of thermistors,” Chemical Instrumentation, vol. 44, no. 11, pp. A935-A966, Nov. 1967. [3] S. Franco, Design with Operational Amplifiers and Analog Integrated Circuits, 3rd Edition, The McGrawHill Companies, Inc., New York, NY, 2002. (ISBN 0-07-232084-2) 1 10 3 Resistance (Kohms) 100 10 1 0.1 50 25 0 25 50 Temperature (C) 75 100 125 150 B = 3900K B = 4100K Figure 1 RT curve for a typical thermistor Agilent power supply +VCC red C1 10F 25V R1 black 10K trimpot C2 8 2 Vps 555 timer Vin 6 12V RT Rt(T) D1 red LED fan 5K NTC thermistor 3 Vo R2 1K R4 C3 0.01F Q1 R3 1K 1 Q1, Q2 - 2N3904 Figure 2 Fan control circuit Ckt. 1 with a thermistor in a voltage divider 100 0.01F Q2 Vo 12V fan on hysteresis band fan off 0V VTL 4V 0V VTH 8V 12V Vin increasing <---- T ----> decreasing Figure 3 Control circuit VTC Agilent power supply +VCC red C1 10K trimpot R1 10F 25V D1 red LED fan black C2 8 J1 2 Vps 555 timer Vin 6 12V 3 Vo R2 1K R4 C3 0.01F Q1 R3 1K 1 RT Rt(T) 5K NTC thermistor J1 - J271 Figure 4 Fan control circuit Ckt. 2with a thermistor driven by a current source 100 0.01F Q1, Q2 - 2N3904 Q2 Figure 5 Breadboard layout Ckt. 1