Production and Operations Management: Manufacturing and Services

advertisement

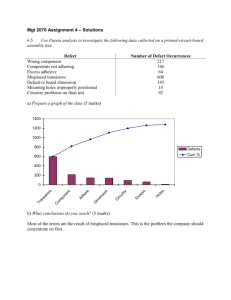

Quality Management Class 4: 2/9/11 OBJECTIVES Total Quality Management Defined Quality Specifications and Costs Six Sigma Quality and Tools External Benchmarking ISO 9000 Service Quality Measurement Process Variation Process Capability Process Control Procedures TOTAL QUALITY MANAGEMENT (TQM) Total quality management is defined as managing the entire organization so that it excels on all dimensions of products and services that are important to the customer Careful design of product or service Ensuring that the organization’s systems can consistently produce the design TQM was a response to the Japanese superiority in quality QUALITY SPECIFICATIONS Design quality: Inherent value of the product in the marketplace Dimensions include: Performance, Features, Reliability/Durability, Serviceability, Aesthetics, and Perceived Quality. Conformance quality: Degree to which the product or service design specifications are met Three Quality Gurus Define Quality Crosby: conformance to requirements Deming: A predictable degree of uniformity and dependability at low cost and suited to the market Juran: fitness for use (satisfies customer’s needs) Deming’s 14 Points Create consistency of purpose Lead to promote change Build quality into the products Build long term relationships Continuously improve product, quality, and service Start training Emphasize leadership Deming’s 14 Points Drive out fear Break down barriers between departments Stop haranguing workers Support, help, improve Remove barriers to pride in work Institute a vigorous program of education and selfimprovement Put everybody in the company to work on the transformation Shewhart’s PDCA Model 4.Act 1.Plan 3.Check 2.Do Implement Identify the improvement and the plan make a plan Is the plan working Test the plan COSTS OF QUALITY Appraisal Costs External Failure Costs Costs of Quality Internal Failure Costs Prevention Costs SIX SIGMA QUALITY A philosophy and set of methods companies use to eliminate defects in their products and processes Seeks to reduce variation in the processes that lead to product defects SIX SIGMA QUALITY (CONTINUED) Six Sigma allows managers to readily describe process performance using a common metric: Defects Per Million Opportunities (DPMO) DPMO Numberof defects Numberof opportunit ies x No.of units for error per unit x 1,000,000 SIX SIGMA QUALITY (CONTINUED) Example of Defects Per Million Opportunities (DPMO) calculation. Suppose we observe 200 letters delivered incorrectly to the wrong addresses in a small city during a single day when a total of 200,000 letters were delivered. What is the DPMO in this situation? DPMO 200 1 So, for every one million letters delivered this city’s postal managers can expect to have 1,000 letters incorrectly sent to the wrong address. x 1,000,000 1, 000 x 200,000 Cost of Quality: What might that DPMO mean in terms of over-time employment to correct the errors? SIX SIGMA QUALITY: DMAIC CYCLE Define, Measure, Analyze, Improve, and Control (DMAIC) Developed by General Electric as a means of focusing effort on quality using a methodological approach Overall focus of the methodology is to understand and achieve what the customer wants A 6-sigma program seeks to reduce the variation in the processes that lead to these defects DMAIC consists of five steps…. SIX SIGMA QUALITY: DMAIC CYCLE (CONTINUED) 1. Define (D) Customers and their priorities 2. Measure (M) Process and its performance 3. Analyze (A) Causes of defects 4. Improve (I) Remove causes of defects 5. Control (C) Maintain quality EXAMPLE TO ILLUSTRATE THE PROCESS… We are the maker of this cereal. Consumer reports has just published an article that shows that we frequently have less than 16 ounces of cereal in a box. What should we do? STEP 1 - DEFINE What is the critical-to-quality characteristic? The CTQ (critical-to-quality) characteristic in this case is the weight of the cereal in the box. 2 - MEASURE How would we measure to evaluate the extent of the problem? What are acceptable limits on this measure? 2 – MEASURE (CONTINUED) Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. Upper Tolerance Limit = 16 + .05(16) = 16.8 ounces Lower Tolerance Limit = 16 – .05(16) = 15.2 ounces 2 – MEASURE (CONTINUED) We go out and buy 1,000 boxes of cereal and find that they weight an average of 15.875 ounces with a standard deviation of .529 ounces. What percentage of boxes are outside the tolerance limits? Lower Tolerance = 15.2 Process Mean = 15.875 Std. Dev. = .529 Upper Tolerance = 16.8 What percentage of boxes are defective (i.e. less than 15.2 oz)? Z = (x – Mean)/Std. Dev. = (15.2 – 15.875)/.529 = -1.276 NORMSDIST(Z) = NORMSDIST(-1.276) = .100978 Approximately, 10 percent of the boxes have less than 15.2 Ounces of cereal in them! STEP 3 - ANALYZE - HOW CAN WE IMPROVE THE CAPABILITY OF OUR CEREAL BOX FILLING PROCESS? Decrease Variation Center Process Increase Specifications STEP 4 – IMPROVE – HOW GOOD IS GOOD ENOUGH? MOTOROLA’S “SIX SIGMA” 6s minimum from process center to nearest spec 12s 6s 3 2 1 0 1 2 3 MOTOROLA’S “SIX SIGMA” Implies 2 ppB “bad” with no process shift. With 1.5s shift in either direction from center (process will move), implies 3.4 ppm “bad”. 12s 3 2 1 0 1 2 3 STEP 5 – CONTROL Statistical (SPC) Use Process Control data from the actual process Estimate distributions Look at capability - is good quality possible Statistically monitor the process over time ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: FLOW CHART Material Received from Supplier No, Continue… Inspect Material for Defects Defects found? Yes Can be used to find quality problems Return to Supplier for Credit Diameter ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: RUN CHART Can be used to identify when equipment or processes are not behaving according to specifications 0.58 0.56 0.54 0.52 0.5 0.48 0.46 0.44 1 2 3 4 5 6 7 8 Time (Hours) 9 10 11 12 ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: PARETO ANALYSIS 80% Frequency Can be used to find when 80% of the problems may be attributed to 20% of the causes Design Assy. Instruct. Purch. Training ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: CHECKSHEET Monday Billing Errors Wrong Account Wrong Amount A/R Errors Wrong Account Wrong Amount Can be used to keep track of defects or used to make sure people collect data in a correct manner Number of Lots ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: HISTOGRAM Can be used to identify the frequency of quality defect occurrence and display quality performance 0 1 2 Data Ranges 3 4 Defects in lot ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: CAUSE & EFFECT DIAGRAM Possible causes: Machine Man The results or effect Effect Environment Method Material Can be used to systematically track backwards to find a possible cause of a quality problem (or effect) ANALYTICAL TOOLS FOR SIX SIGMA AND CONTINUOUS IMPROVEMENT: CONTROL CHARTS Can be used to monitor ongoing production process quality and quality conformance to stated standards of quality 1020 UCL 1010 1000 990 LCL 980 970 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 SIX SIGMA ROLES AND RESPONSIBILITIES 1. 2. 3. 4. Executive leaders must champion the process of improvement Corporation-wide training in Six Sigma concepts and tools Setting stretch objectives for improvement Continuous reinforcement and rewards THE SHINGO SYSTEM: FAIL-SAFE DESIGN Shingo’s argument: SQC methods do not prevent defects Defects arise when people make errors Defects can be prevented by providing workers with feedback on errors Poka-Yoke includes: Checklists Special tooling that prevents workers from making errors ISO 9000 AND ISO 14000 Series of standards agreed upon by the International Organization for Standardization (ISO) Adopted More A in 1987 than 160 countries prerequisite for global competition? ISO 9000 an international reference for quality, ISO 14000 is primarily concerned with environmental management THREE FORMS OF ISO CERTIFICATION 1. First party: A firm audits itself against ISO 9000 standards 2. Second party: A customer audits its supplier 3. Third party: A "qualified" national or international standards or certifying agency serves as auditor EXTERNAL BENCHMARKING STEPS 1. Identify those processes needing improvement 2. Identify a firm that is the world leader in performing the process 3. Contact the managers of that company and make a personal visit to interview managers and workers 4. Analyze data Process Control Process Variation Process Capability Process Control Procedures Variable data Attribute data BASIC FORMS OF VARIATION Assignable variation is caused by factors that can be clearly identified and possibly managed Example: A poorly trained employee that creates variation in finished product output. Common variation is inherent in the production process Example: A molding process that always leaves “burrs” or flaws on a molded item. TAGUCHI’S VIEW OF VARIATION Traditional view is that quality within the LS and US is good and that the cost of quality outside this range is constant, where Taguchi views costs as increasing as variability increases, so seek to achieve zero defects and that will truly minimize quality costs. High High Incremental Cost of Variability Incremental Cost of Variability Zero Zero Lower Target Spec Spec Upper Spec Traditional View Lower Spec Target Spec Upper Spec Taguchi’s View PROCESS CAPABILITY Process limits Specification How limits do the limits relate to one another? PROCESS CAPABILITY INDEX, CPK Capability Index shows how well parts being produced fit into design limit specifications. X LTL UTL - X C pk = min or 3s 3s As a production process produces items small shifts in equipment or systems can cause differences in production performance from differing samples. Shifts in Process Mean PROCESS CAPABILITY – A STANDARD MEASURE OF HOW GOOD A PROCESS IS. A simple ratio: Specification Width _________________________________________________________ Actual “Process Width” Generally, the bigger the better. PROCESS CAPABILITY C pk X LTL UTL X Min ; 3s 3s This is a “one-sided” Capability Index Concentration on the side which is closest to the specification - closest to being “bad” THE CEREAL BOX EXAMPLE We are the maker of this cereal. Consumer reports has just published an article that shows that we frequently have less than 16 ounces of cereal in a box. Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. Upper Tolerance Limit = 16 + .05(16) = 16.8 ounces Lower Tolerance Limit = 16 – .05(16) = 15.2 ounces We go out and buy 1,000 boxes of cereal and find that they weight an average of 15.875 ounces with a standard deviation of .529 ounces. CEREAL BOX PROCESS CAPABILITY Specification or Tolerance Limits Upper Spec = 16.8 oz Lower Spec = 15.2 oz Observed Weight Mean = 15.875 oz Std Dev = .529 oz C pk X LTL UTL X Min ; 3s 3s 15.875 15.2 16.8 15.875 C pk Min ; 3(.529) 3(.529) C pk Min.4253; .5829 C pk .4253 WHAT DOES A CPK OF .4253 MEAN? An index that shows how well the units being produced fit within the specification limits. This is a process that will produce a relatively high number of defects. Many companies look for a Cpk of 1.3 or better… 6-Sigma company wants 2.0! TYPES OF STATISTICAL SAMPLING Attribute (Go or no-go information) Defectives refers to the acceptability of product across a range of characteristics. Defects refers to the number of defects per unit which may be higher than the number of defectives. p-chart application Variable (Continuous) Usually measured by the mean and the standard deviation. X-bar and R chart applications Statistical Process Normal Behavior Control (SPC) Charts UCL LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time CONTROL LIMITS ARE BASED ON THE NORMAL CURVE x m -3 -2 -1 Standard deviation units or “z” units. 0 1 2 3 z CONTROL LIMITS We establish the Upper Control Limits (UCL) and the Lower Control Limits (LCL) with plus or minus 3 standard deviations from some xbar or mean value. Based on this we can expect 99.7% of our sample observations to fall within these limits. 99.7% LCL UCL x EXAMPLE OF CONSTRUCTING A P-CHART: REQUIRED DATA Sample No. of No. Samples 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Number of defects found in each sample 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 STATISTICAL PROCESS CONTROL FORMULAS: ATTRIBUTE MEASUREMENTS (P-CHART) T o ta l N u m b e r o f D e fe c tiv e s Given: p = T o ta l N u m b e r o f O b s e rv a tio n s sp = p (1 - p) n Compute control limits: UCL = p + z sp LCL = p - z sp EXAMPLE OF CONSTRUCTING A P-CHART: STEP 1 1. Calculate the sample proportions, p (these are what can be plotted on the p-chart) for each sample Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 n Defectives 100 4 100 2 100 5 100 3 100 6 100 4 100 3 100 7 100 1 100 2 100 3 100 2 100 2 100 8 100 3 p 0.04 0.02 0.05 0.03 0.06 0.04 0.03 0.07 0.01 0.02 0.03 0.02 0.02 0.08 0.03 EXAMPLE OF CONSTRUCTING A P-CHART: STEPS 2&3 2. Calculate the average of the sample proportions 55 p = 1500 = 0.036 3. Calculate the standard deviation of the sample proportion sp = p (1 - p) = n .036(1- .036) = .0188 100 EXAMPLE OF CONSTRUCTING A P-CHART: STEP 4 4. Calculate the control limits UCL = p + z sp LCL = p - z sp .036 3(.0188) UCL = 0.0924 LCL = -0.0204 (or 0) 9A-56 EXAMPLE OF CONSTRUCTING A P-CHART: STEP 5 5. Plot the individual sample proportions, the average of the proportions, and the control limits EXAMPLE OF X-BAR AND R CHARTS: REQUIRED DATA Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Obs 1 10.682 10.787 10.78 10.591 10.693 10.749 10.791 10.744 10.769 10.718 10.787 10.622 10.657 10.806 10.66 Obs 2 10.689 10.86 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 Obs 3 10.776 10.601 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 Obs 4 10.798 10.746 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 Obs 5 10.714 10.779 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 EXAMPLE OF X-BAR AND R CHARTS: STEP 1. CALCULATE SAMPLE MEANS, SAMPLE RANGES, MEAN OF MEANS, AND MEAN OF RANGES. Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Obs 1 10.682 10.787 10.78 10.591 10.693 10.749 10.791 10.744 10.769 10.718 10.787 10.622 10.657 10.806 10.66 Obs 2 10.689 10.86 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 Obs 3 10.776 10.601 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 Obs 4 10.798 10.746 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 Obs 5 10.714 10.779 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 Averages Avg 10.732 10.755 10.759 10.727 10.724 10.705 10.735 10.624 10.710 10.732 10.748 10.768 10.733 10.783 10.692 Range 0.116 0.259 0.171 0.221 0.119 0.143 0.274 0.669 0.132 0.179 0.163 0.250 0.349 0.158 0.103 10.728 0.220400 EXAMPLE OF X-BAR AND R CHARTS: STEP 2. DETERMINE CONTROL LIMIT FORMULAS AND NECESSARY TABLED VALUES x Chart Control Limits UCL = x + A 2 R LCL = x - A 2 R R Chart Control Limits UCL = D 4 R LCL = D 3 R From Exhibit TN 8.7 n 2 3 4 5 6 7 8 9 10 11 A2 1.88 1.02 0.73 0.58 0.48 0.42 0.37 0.34 0.31 0.29 D3 0 0 0 0 0 0.08 0.14 0.18 0.22 0.26 D4 3.27 2.57 2.28 2.11 2.00 1.92 1.86 1.82 1.78 1.74 EXAMPLE OF X-BAR AND R CHARTS: STEPS 3&4. CALCULATE X-BAR CHART AND PLOT VALUES UCL = x + A 2 R 10.728 - .58(0.2204 ) = 10.856 LCL = x - A 2 R 10.728 - .58(0.2204 ) = 10.601 1 0 .9 0 0 UCL 1 0 .8 5 0 M ea n s 1 0 .8 0 0 1 0 .7 5 0 1 0 .7 0 0 1 0 .6 5 0 1 0 .6 0 0 LCL 1 0 .5 5 0 1 2 3 4 5 6 7 8 S am p le 9 10 11 12 13 14 15 EXAMPLE OF X-BAR AND R CHARTS: STEPS 5&6. CALCULATE R-CHART AND PLOT VALUES UCL = D 4 R ( 2.11)(0.2204) 0.46504 LCL = D3 R (0)(0.2204) 0 0.800 0.700 0.600 0.500 R 0.400 UCL 0.300 0.200 0.100 LCL 0.000 1 2 3 4 5 6 7 8 9 Sample 10 11 12 13 14 15