Managing a Custom Harvesting Business

advertisement

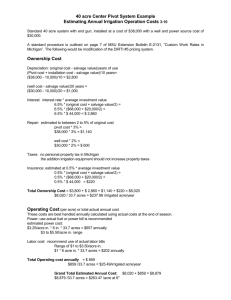

Managing a Custom Harvesting Business Sarah Roth Sr. Extension Assoc. Penn State University Penn State is committed to affirmative action, equal opportunity, and the diversity of its workforce A little bit about me… • Sr. Extension Associate in the Dept. of Agricultural Economics & Rural Sociology • 4 years at Penn State • Farm Business Management – Custom Work – Business Planning – Marketing Planning A little bit more about me… • Main audiences – Dairy producers – Custom Operators in PA, OH, NY, MD Agenda • Advantages of Hiring Custom Operators • Building a Successful Custom Operator/Client Working Relationship • Pricing • How do Changing Costs Affect the Bottom Line • Questions Producer issues Should I Have My Forage Custom Harvested? • Is labor availability/experience an issue? • Is timeliness a problem with current equipment? • Are repair costs high? • How many acres of forages need to be harvested? Labor inexperience can be costly • Machinery could get broken • Harvest efficiency can be compromised – Field efficiency – Overall timeliness – Storage quality Poor harvest timeliness can ruin quality forage • Crops become too mature • Proper storage is compromised Repair costs impact production costs • Heavier usage of machinery increases repair & maintenance expenses • Frequent breakdowns prevent machinery from being fully utilized – Fewer acreage covered Accumulated Repair Costs for Newer vs. Older Forage Harvesters $600 $500 $400 new SP old SP $300 $200 $100 Harvester age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0 0 Total repair cost per $1,000 of purchase price $700 Hourly Repair Costs for Newer vs. Older Forage Harvesters $0.45 $0.40 $0.35 $0.30 new SP $0.25 old SP $0.20 $0.15 $0.10 $0.05 Harvester age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0.00 0 Hourly repair cost per $1,000 of purchase price $0.50 Forage Harvester Comparisons: • 2-row self-propelled ($159,900) • 3-row self-propelled ($165,600) • 6-row self-propelled ($236,600) Prices from Univ. of MN, “Minnesota Farm Machinery Economic Cost Estimates for 2001” Accumulated Repair Costs for Three Forage Harvesters $120,000 $80,000 2-row SP $60,000 3-row SP 6-row SP $40,000 $20,000 Harvester age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0 0 Total repair cost $100,000 Acreage & machinery need to be matched • Excess capacity is simply money out of you pocket in terms of ownership costs Forage Harvester Field Capacity (acres/hour) Harvester 2-row SP 3-row SP 6-row SP 10-row SP Width Speed Field Efficiency 5 ft 3.5 mph 70% (Range: 1.5 - 6.0) (Range: 65 - 80%) 3.5 mph 70% (Range: 1.5 - 6.0) (Range: 65 - 80%) 3.5 mph 70% (Range: 1.5 - 6.0) (Range: 65 - 80%) 5.41 3.5 70% 7.27 7.5 ft 15 ft 25 ft Field Capacity 1.80 2.54 Field capacity (A/hr) = [width (ft) * ground speed (mph) * field efficiency (%)]/8.25 Forage Harvester Capacity Needed Area to cover Area to cover 10,000 5,000 acres acres Probability of a working day 40 % h/day Hours for this work 18 h/day days Window of opportunity 150 days Capacity needed 4.6 acres/h Probability of a working day 40 % Hours for this work 18 Window of opportunity 150 Capacity needed 9.3 acres/h vs. SP Combine Field Capacity (acres/hour) Combine Width Speed Field Efficiency #1 5 ft 3.0 mph 80% (Range: 1.5 - 6.0) (Range: 65 - 80%) 3.0 mph 80% (Range: 1.5 - 6.0) (Range: 65 - 80%) 3.0 mph 80% (Range: 1.5 - 6.0) (Range: 65 - 80%) 4.36 3.0 80% 7.27 #2 #3 #4 7.5 ft 15 ft 25 ft Field Capacity 1.45 2.18 Field capacity (A/hr) = [width (ft) * ground speed (mph) * field efficiency (%)]/8.25 SP Combine Capacity Needed Area to cover Probability of a working day 12,000 40 acres Area to cover 5,000 acres % Probability of a working day 40 % 18 h/day days vs. Hours for this work Window of opportunity Capacity needed 18 h/day Hours for this work 150 days Window of opportunity 150 Capacity needed 4.6 acres/h 11.1 acres/h Solutions to these issues • Purchase higher capacity forage harvester • Change crop rotation • Custom hire Solutions to these issues • Purchase higher capacity forage harvester • Change crop rotation • Custom hire The Producer’s Custom Harvesting Goal Acquire quality forage/feed (same or better) for lower cost of harvest Advantages of Hiring Custom Operators 6 Advantages Free up labor for remaining enterprises Free up management for remaining enterprises Concentrate efforts in fewer enterprises (specialization) Obtain higher quality products Cut input and/or production costs Increased production #1 Free up labor This allows producers to: • Time to attend to details in other parts of the business • Develop specialized knowledge instead of being jack-of-all trades • Don’t have unqualified employees driving equipment #2 Free up management • Time to analyze data and make more informed decisions • Take advantage of educational opportunities #3 Concentrate efforts • Specialization – Focus on fewer (one or two) enterprises – Dairy (milk production), heifers, hogs, beef, etc. #4 Obtain higher quality products • Custom operators provide: – Specialized knowledge in the services they perform – Timely service – Consistent quality # 5 Cut input/production costs • No need to own machinery only used for a short period of time • Depreciation • Interest • Repairs • Oil, Fuel • Taxes, Insurance, Housing • Don’t have to hire part-time summer help #6 Increase production • Higher quality forages can increase milk production • Increased production or better milk component levels generate more gross revenue The Custom Operator’s Role in Building a Successful Relationship with Producer Clients Strategies for the following Marketing Your Services Making the Deal Before Work Starts During Work When the Work is Completed Marketing Your Services Attracting Potential Clients Present a professional image both when working and while out in the community Attend professional meetings/conferences Use services such as the Custom Operators Directory, regional extension directories, professional association directories Marketing Your Services Providing Service Information Brochures and/or Website Services provided Cost tables Types of equipment used Have a knowledgeable contact person who can answer questions Making the Deal Have a Contract ! Types of Contracts Written Verbal Making the Deal Contract items to include or discuss Methods of payment Payment schedule Responsibility for providing supplies such as baler twine, ag bags, inoculants, etc. Responsibility for providing labor and equipment Anticipated schedule of work How delays will be handled Before Work Starts Have all equipment and machinery in good working condition Have a supply of commonly needed parts Make sure all supplies such as inoculants or other chemicals are ready Make sure all labor is available During Your Work Avoiding disputes Review the contract Ask and/or answer any questions that may have come up since the last time you spoke with the producer During Your Work Resolving disputes Keep disputes private Use a mediator if necessary During Your Work Work Schedule Keep producers informed Let producers know when you expect to arrive at their farm – both day and time Inform producers if you must make an adjustment to your schedule Don’t make promises you can’t keep During Your Work Provide information If harvesting, provide information such as tons per acre, dry matter, length of chop, bushels per acres, etc. Provide relevant information for other activities performed During Your Work Delays Let producers know quickly Weather Adjust work schedule if possible Equipment/Labor Find/have replacement labor available if needed Quickly repair equipment or obtain replacement equipment while broken equipment is being fixed When The Work is Completed Getting Paid Work with the producer to find a payment schedule that is acceptable to both of you When The Work is Completed Contracting for next season Offer early contracting Possible incentives for contracting early When The Work is Completed Seek ideas for improvement Ask how your services could be more valuable to the client Ask what other services the client could use 10 Minute Break How to price services? What we’ll cover • Cost of production • Choosing a price Before you can price your services… You MUST know your COST OF PRODUCTION ! Cost of production • Will not cover how to calculate cost of production in detail • Will discuss what affects cost of production – Examples to demonstrate specific points Cost of Production • Plenty of resources that can help you determine YOUR cost of production – Local extension specialists – Spreadsheets online – Fact sheets What affects cost of production? • Machinery costs – Ownership expenses – Operating expenses – Must balance repair costs with efficiency factors when choosing machinery • Extent of services offered • Number of clients/acreage Managing Machinery Costs Ownership expenses These are fixed costs which result from owning the machinery – – – – – Depreciation Interest Taxes Insurance Housing Managing Machinery Costs Operating Expenses These are variable costs which are incurred from operating the machinery – – – – – Repairs Labor Fuel Lubrication (oil) Materials/supplies Extent of services offered Will you be offering services beyond basic harvesting? – Transportation to silo, bunker, bags, etc. – Ensiling (upright or bags) or packing (bunker) – Application of silage additives? – Grain drying – Other Number of clients • Spread out fixed costs – ↑ # of clients…↓ fixed costs per unit • Location – Machinery & equipment transportation costs • Acreage – More clients w/ fewer acreage – Fewer clients w/ greater acreage Why acreage is important • Spreading fixed costs over more acres lowers cost of production • Increases return on investment Other business expenses that need to be covered in your price • • • • • Office operations Taxes Non-machinery Insurance Unemployment Benefits – Health insurance, 401K/retirement, paid vacation What else should influence your price? • Basis for fees – Per acre – Per hour – Per ton • Profit margin – Must cover living & business reinvestment Fee basis Will fees be charged on a per ton, per acre, or hourly basis? • Per ton basis will make revenue more variable – Increased yield…increased revenue – Poor yield…lesser revenue Fee Basis • Per acre basis will result in a more stable, predictable income – Assuming you know exactly how many acres you will be harvesting Fee Basis • Hourly basis – Higher yield…increased time to harvest = increased revenue – Lower yield…less time needed to harvest = decreased revenue – Must balance with acreage being harvested Profit Margin • Many operators forget to factor this into their pricing calculations • How much do you want and/or need for the following? – Family living expenses (if not included in labor wages) – Reinvestment into the business Other Pricing Methods • What is your neighbor/competition charging? • State custom rate guides • What will producers pay? Use these numbers only for comparison! Pricing Example Yearly Expenses Amount Machinery Ownership Depreciation $ 198,333.33 Interest $ 40,788.91 Taxes, Insurance, Housing $ 19,600.00 Machinery Operating Repairs & Maintenance $ 169,000.00 Fuel $ 116,160.00 Lubrication $ Labor $ 228,000.00 1,340.28 General Business Expenses Taxes $ 8,000.00 Non-machinery Insurance $ 20,000.00 Unemployment contributions $ 6,840.00 Benefits $ 36,000.00 Business Operating Supplies $ 5,000.00 Other $ 20,000.00 Miscellaneous Total $ 849,062.52 Additional Information Acres harvested (2 harvesters) 20,000 Cutterhead hours (2 harvesters) 1,500 Yield per acre (tons) 8 Pricing Example Cont. Income needed to cover expenses Per year $ 849,062.52 $ per acre $ 42.45 $ per ton $ 5.31 $ per cutterhead hour $ 566.04 Income needed to receive 5% profit above costs Per year $ 891,515.65 $ per acre $ 44.58 $ per ton $ 5.57 $ per cutterhead hour $ 594.34 Income needed to receive 10% profit above costs Per year $ 933,968.77 $ per acre $ 46.70 $ per ton $ 5.84 $ per cutterhead hour $ 622.65 Price Risk • Can come in a variety of forms • Changes in – – – – Acres harvested Crop Yield Operating expenses Amount of competition How do changing costs affect the bottom line? • Increasing operating expenses decrease your profit margin • Need to know the range of variability in input/operating prices that you can afford with given rates Examples • The following examples have the following assumptions: – 2 forage harvester – Supporting machinery & equipment – Labor wage = $9.50/hour Fuel Price Change Example Scenario 1 Amount Yearly Expenses Scenario 2 Amount Machinery Ownership Depreciation $ 198,333.33 $ 198,333.33 Interest $ 40,788.91 $ 40,788.91 Taxes, Insurance, Housing $ 19,600.00 $ 19,600.00 Repairs & Maintenance $ 169,000.00 $ 169,000.00 Fuel $ 116,160.00 $ 174,240.00 Lubrication $ 1,340.28 $ 1,340.28 Labor $ 228,000.00 $ 228,000.00 Taxes $ 8,000.00 $ 8,000.00 Non-machinery Insurance $ 20,000.00 $ 20,000.00 Unemployment contributions $ 6,840.00 $ 6,840.00 Benefits $ 36,000.00 $ 36,000.00 Business Operating Supplies $ 5,000.00 $ 5,000.00 Other $ 20,000.00 $ 20,000.00 $ 849,062.52 $ 927,142.52 Machinery Operating General Business Expenses Miscellaneous Total Additional Information Acres harvested (2 harvesters) 20,000 20,000 Cutterhead hours (2 harvesters) 1,500 1,500 8 8 Yield per acre (tons) Fuel Price Change Example Scenario 1 Amount Yearly Expenses Scenario 2 Amount Machinery Ownership Depreciation $ 198,333.33 $ 198,333.33 Interest $ 40,788.91 $ 40,788.91 Taxes, Insurance, Housing $ 19,600.00 $ 19,600.00 Repairs & Maintenance $ 169,000.00 $ 169,000.00 Fuel $ 116,160.00 $ 174,240.00 Lubrication $ 1,340.28 $ 1,340.28 Labor $ 228,000.00 $ 228,000.00 $ 8,000.00 $ 8,000.00 $ 20,000.00 $ 20,000.00 Unemployment contributions $ 6,840.00 $ 6,840.00 Benefits $ 36,000.00 $ 36,000.00 Business Operating Supplies $ 5,000.00 $ 5,000.00 Other $ 20,000.00 $ 20,000.00 $ 849,062.52 $ 927,142.52 Machinery Operating General Business Expenses Taxes Non-machinery Insurance Increase of $78,080 Miscellaneous Total Additional Information Acres harvested (2 harvesters) 20,000 20,000 Cutterhead hours (2 harvesters) 1,500 1,500 8 8 Yield per acre (tons) Fuel Example Cont. Income needed to cover expenses Per year $ 849,062.52 $ 927,142.52 $ per acre $ 42.45 $ 46.36 $ per ton $ 5.31 $ 5.79 $ per cutterhead hour $ 566.04 $ 618.10 Per year $ 891,515.65 $ 973,499.65 $ per acre $ 44.58 $ 48.67 $ per ton $ 5.57 $ 6.08 $ per cutterhead hour $ 594.34 $ 649.00 Per year $ 933,968.77 $ 1,019,856.77 $ per acre $ 46.70 $ 50.99 $ per ton $ 5.84 $ 6.37 $ per cutterhead hour $ 622.65 $ 679.90 Income needed to receive 5% profit above costs Income needed to receive 10% profit above costs Fuel Example Cont. Income needed to cover expenses Per year $ 849,062.52 $ 927,142.52 $ per acre $ 42.45 $ 46.36 $ per ton $ 5.31 $ 5.79 $ 566.04 $ 618.10 $ 891,515.65 $ 973,499.65 $ 44.58 $ 48.67 $ per ton $ 5.57 $ 6.08 $ per cutterhead hour $ 594.34 $ 649.00 Per year $ 933,968.77 $ 1,019,856.77 $ per acre $ 46.70 $ 50.99 $ per ton $ 5.84 $ 6.37 $ per cutterhead hour $ 622.65 $ 679.90 Need $3.91/acre, $0.48/ton, or Income needed to$52.06/cutterhead receive 5% profit above costs Per year hour more just to $ per acre breakeven $ per cutterhead hour Income needed to receive 10% profit above costs Fuel Example Cont. Income needed to cover expenses Per year $ 927,142.52 42.45 $ 46.36 5.31 $ 5.79 566.04 $ 618.10 Per year $ 891,515.65 $ 973,499.65 $ per acre $ 44.58 $ 48.67 $ per ton $ 5.57 $ 6.08 $ per cutterhead hour $ 594.34 $ 649.00 Per year $ 933,968.77 $ 1,019,856.77 $ per acre $ 46.70 $ 50.99 $ per ton $ 5.84 $ 6.37 $ per cutterhead hour $ 622.65 $ 679.90 $ per acre $ per ton $ per cutterhead hour $ 849,062.52 Prices @ 10% profit$ $ enough to cover a $1 $ increase in fuel price Income needed to receive 5% profit above costs Income needed to receive 10% profit above costs 20% Operating Increase Example 20% increase in operating costs Yearly Expenses Amount Amount Machinery Ownership Depreciation $ 198,333.33 $ 198,333.33 Interest $ 40,788.91 $ 40,788.91 Taxes, Insurance, Housing $ 19,600.00 $ 19,600.00 Machinery Operating Repairs & Maintenance $ 169,000.00 $ 202,800.00 Fuel $ 116,160.00 $ 139,392.00 Lubrication $ $ Labor $ 228,000.00 $ 273,600.00 Taxes $ 8,000.00 $ 8,000.00 Non-machinery Insurance $ 20,000.00 $ 20,000.00 Unemployment contributions $ 6,840.00 $ 6,840.00 Benefits $ 36,000.00 $ 36,000.00 Business Operating Supplies $ 5,000.00 $ 5,000.00 Other $ 20,000.00 $ 20,000.00 1,340.28 1,608.34 General Business Expenses Miscellaneous Total $ 849,062.52 $ 971,962.58 Additional Information Acres harvested (2 harvesters) 20,000 20,000 Cutterhead hours (2 harvesters) 1,500 1,500 8 8 Yield per acre (tons) 20% Operating Increase Example 20% increase in operating costs Yearly Expenses Amount Amount Machinery Ownership Depreciation $ 198,333.33 $ 198,333.33 Interest $ 40,788.91 $ 40,788.91 Taxes, Insurance, Housing $ 19,600.00 $ 19,600.00 Machinery Operating Repairs & Maintenance $ 169,000.00 $ 202,800.00 Fuel $ 116,160.00 $ 139,392.00 Lubrication $ $ Labor Increase of $122,900.06 1,340.28 1,608.34 $ 228,000.00 $ 273,600.00 $ 8,000.00 $ 8,000.00 Non-machinery Insurance $ 20,000.00 $ 20,000.00 Unemployment contributions $ 6,840.00 $ 6,840.00 Benefits $ 36,000.00 $ 36,000.00 Business Operating Supplies $ 5,000.00 $ 5,000.00 Other $ 20,000.00 $ 20,000.00 General Business Expenses Taxes Miscellaneous Total $ 849,062.52 $ 971,962.58 Additional Information Acres harvested (2 harvesters) 20,000 20,000 Cutterhead hours (2 harvesters) 1,500 1,500 8 8 Yield per acre (tons) 20% Operating Increase Example Income needed to cover expenses Per year $ 849,062.52 $ 971,962.58 $ per acre $ 42.45 $ 48.60 $ per ton $ 5.31 $ 6.07 $ per cutterhead hour $ 566.04 $ 647.98 Income needed to receive 5% profit above costs Per year $ 891,515.65 $1,020,560.70 $ per acre $ 44.58 $ 51.03 $ per ton $ 5.57 $ 6.38 $ per cutterhead hour $ 594.34 $ 680.37 Income needed to receive 10% profit above costs Per year $ 933,968.77 $1,069,158.83 $ per acre $ 46.70 $ 53.46 $ per ton $ 5.84 $ 6.68 $ per cutterhead hour $ 622.65 $ 712.77 20% Operating Increase Example Income needed to cover expenses Per year $ 849,062.52 $ 971,962.58 $ per acre $ 42.45 $ 48.60 $ per ton $ 5.31 $ 6.07 $ 566.04 $ 647.98 Need $6.15/acre, $0.76/ton, or Income needed to receive 5% profit above costs $81.94/cutterhead Per year hour more just to $ per acre breakeven $ per ton $ per cutterhead hour $ per cutterhead hour $ 891,515.65 $1,020,560.70 $ 44.58 $ 51.03 $ 5.57 $ 6.38 $ 594.34 $ 680.37 Income needed to receive 10% profit above costs Per year $ 933,968.77 $1,069,158.83 $ per acre $ 46.70 $ 53.46 $ per ton $ 5.84 $ 6.68 $ per cutterhead hour $ 622.65 $ 712.77 20% Operating Increase Example Income needed to cover expenses Per year $ 849,062.52 $ 971,962.58 $ per acre $ 42.45 $ 48.60 Prices not enough to$ $ per cutterhead hour $ cover a 20% increase in operating Income needed to receive 5% profit above costs expenses Per year $ 5.31 $ 6.07 566.04 $ 647.98 $ per ton 891,515.65 $1,020,560.70 $ per acre $ 44.58 $ 51.03 $ per ton $ 5.57 $ 6.38 $ per cutterhead hour $ 594.34 $ 680.37 Income needed to receive 10% profit above costs Per year $ 933,968.77 $1,069,158.83 $ per acre $ 46.70 $ 53.46 $ per ton $ 5.84 $ 6.68 $ per cutterhead hour $ 622.65 $ 712.77 How can you protect your profits? • Regularly analyze your business expenses • Price high enough to cover any expected changes in operating expenses How can you protect your profits? • Add surcharge fees into your contract • Lock in prices all possible items that may fluctuate in price – Fuel, oil, supplies Resources • Penn State – http://www.das.psu.edu/dcn/catforg/ – http://farmmanagement.aers.psu.edu • University of Wisconsin – http://www.uwex.edu/ces/crops/uwforage/dec _soft.htm Visit online: http://farmmanagement.aers.psu.edu Or Contact me at: Phone: 814-863-8645 Email: sarahroth@psu.edu Penn State is committed to affirmative action, equal opportunity, and the diversity of its workforce Hourly Repair Costs for Three Forage Harvesters $60 $40 2-row SP $30 3-row SP 6-row SP $20 $10 Harvester age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0 0 Hourly repair cost $50 Hourly Repair, Fuel, and Labor Costs for Three Forage Harvesters $90 $80 $60 2-row SP $50 3-row SP $40 6-row SP $30 $20 $10 Harvester Age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0 0 Hourly cost $70 Repair, Fuel, and Labor Costs per Acre for Three Forage Harvesters $40 $35 $25 2-row SP $20 3-row SP 6-row SP $15 $10 $5 Harvester age (hours) 4000 3800 3600 3400 3200 3000 2800 2600 2400 2200 2000 1800 1600 1400 1200 1000 800 600 400 200 $0 0 Cost per acre $30 Total Cost per Acre for Three Forage Harvesters, 10-year life 400 300 250 2-row SP 200 3-row SP 6-row SP 150 100 $54 50 $42 $30 Acres/year 1800 1700 1600 1500 1400 1300 1200 1100 1000 900 800 700 600 500 450 400 350 300 250 200 175 150 125 0 100 Total Cost per Acre 350