Control Methods

advertisement

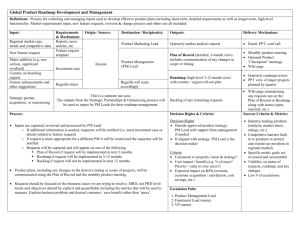

Control Plan The Quality Improvement Model Define Process Select Measures Collect & Interpret Data Maintain Current Process Purpose: •Develop a control plan to maintain the improvements for the process •Document control plan Is Process Stable ? No Investigate & Fix Special Causes Yes Improve Process Capability No Is Process Capable ? Yes Develop Control Plan to Maintain Current Process 10-1 Objectives Control Plan • Explore the steps for setting up controls for your project • Review Control Plan elements • Review the need for well documented control plans to “sustain the gains” • Introduce the concept of Mistake Proofing 10-2 Control Plan The Funneling Effect Process Maps • Identify Outputs • Identify Inputs 3 to 6 Critical Input Variables C&E Matrix Failure Modes and Effects Analysis Control Charts (SPC) Exploratory Data Analysis (EDA) Design of Experiments (ASM / DOE) A Control Plan to: “Sustain The Gains” 10-3 Three Ways to Control Key Variables in a Process Control Plan Control to a Standard Statistical Process Control Engineering Process Control 10-4 Control Strategy Roadmap Control Plan 1) Monitor variables for out of control conditions Major Focus on KPIV’S to 2) Develop alarm and recording strategy 3) Finalize process sampling plan Minimize Production of Defects 4) Document control plan for each key variable 5) Identify Opportunities for Mistake Proofing 10-5 Control Strategy Roadmap Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Key Relationships Identified After DOE Completion Strength = 6.6444 + 1.4466 Press Yield = - 1690 + 15.7 Temp + 41.7 Press 0.0338 TempSqr - 0.281 PressSqr - 0.169 TempPress What Should We Monitor? 10-6 Control Strategy Roadmap Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Strength Seems To Be In Control 10-7 Control Strategy Roadmap Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Looks Like a Problem With Yield – What Now ?? 10-8 Control Strategy Implementation Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Experimental Results Indicated Yield Is A Function Of Pressure And Temperature Remember Yield = - 1690 + 15.7 Temp + 41.7 Press 0.0338 TempSqr - 0.281 PressSqr - 0.169 TempPress Let’s Take A Look At The KPIV’s Pressure and Temperature 10-9 Control Strategy Roadmap Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Pressure seems to be in good control, though the pattern should be investigated. 10-10 Control Strategy Roadmap Control Plan Step 1 - Monitor Variables For Out Of Control Conditions Big Trouble on Temperature !! Historic Mean 124 Historic StdDev 2.7 10-11 Control Strategy Roadmap Control Plan Step 2 - Develop Alarm and Recording Strategy Process Alarms • • • • Online alarms key to process waste reduction Identify key alarm points throughout the process Do not alarm too many points – they will be ignored SPC - Control Charts are effective alarm mechanisms Data Recording • Record alarms to identify patterns of out of control conditions • Online data trending assists in monitoring process shifts • Record and analyze KPIV’s to prevent waste production Developing an Effective Process Alarm Strategy is Key To Reducing Waste and Defects 10-12 Control Strategy Roadmap Control Plan Step 3 - Finalize Process Sampling Plan • Use KPOV = f(KPIV1, KPIV2, …) predictive relationships to minimize routine process sampling • Take product samples when SPC and on-line alarms indicate out of control conditions (In theory not practice) • Be sure sample size is adequate through use of sample size calculations • Document sampling plan and communicate to production, lab, technical, order processing and other key groups 10-13 Control Plan Purpose Control Plan Step 4 - Document Control Plan For Each Key Variable… The Purpose Of An Effective Control Plan Is To: • Operate processes on target with minimum variation • Minimize process tampering (over-adjustment) • Assure that process improvements become institutionalized (ISO 9000 can assist here) • Provide for adequate training in all procedures • Identify required maintenance schedules Revise Quarterly 10-14 Control Plan Factors Impacting a Good Control Plan Step 4 - Document Control Plan For Each Key Variable… Measurement System Preliminary Analysis Measurement System Analysis %R&R, %P/T These need to be updated before proceeding Process Maps Calibration Requirements C&E Matrix Sampling & Testing Plans SPC Plans Operating Windows DOE's Improvement Activities Short Term Capability Initial Control Plan Assessment FMEA Customer Requirements Long Term Capability Control Plan Maintenance Schedules Noise Variable Compensation Trouble Shooting Aids Training Materials SOP's Reaction Plans Procedures 10-15 Control Plan Control Plan Summary Sheet Step 4 - Document Control Plan For Each Key Variable… Product: Key Contact: Phone: Date (Orig): Date (Rev): OUTPUTS Y Process Step LSL Target USL Cp Cpk Pp Ppk Measurement Technique %Variation %R&R P/T Sample Frequency Control Method Reaction Plan X Process Step LSL Target USL Cp Cpk Pp Ppk Measurement Technique %Variation %R&R P/T Sample Frequency Control Method Reaction Plan INPUTS Control Plan.XLS 10-16 Control Plan Control Plan Components Step 4 - Document Control Plan For Each Key Variable… • Process map steps • Key process output variables, targets & specs • Key process input variables with control limits • Important noise variables (uncontrollable inputs) • Short and long term capability analysis results • Designated control methods including: SPC Automated process control Checklists Mistake proofing systems Standard Operating Procedures Sampling & Testing Meas. Sys. Analysis Training Materials Maintenance schedules Reaction Plan and Procedures 10-17 Control Plan Other Tips in Documenting Improvements Step 4 - Document Control Plan For Each Key Variable… • Utilize your team and / or affected individuals • Test the procedure exactly as it is documented • Outline a method for updating procedures • Date your procedures • Destroy obsolete procedures • Have an audit plan to verify compliance • Responsibility for documenting control plan and updates Step 1 Project New Process Step 2 Step 3 Step 4 10-18 Auditing Procedures Control Plan Step 4 - Document Control Plan For Each Key Variable… • Directly By Observation Are people actually doing what the procedure says? Are all the steps being followed? Are people referring to the procedure? By asking those using the procedure Is each step in the procedure clear? Are you having difficulty in following the procedure? Could we improve the procedure and still get results? • Indirectly By Observation When was the last time the instruction was revised? 10-19 Control Plan Documentation Package Trouble Shooting Reaction Plans Capability Maps Scope Maint. Training Critical Parameters FMEA’s MSA Customer SOP’s Summary Control Plan 10-20 Summary Control Plan Explored the steps for setting up controls for your project Reviewed Control Plan elements Reviewed the need for well documented control plans to “sustain the gains” Control plan derived from tools and learning's in implementing model discussed in this course Identify person who will be accountable for control plan documentation and updates 10-21 Control Plan Exercise 1.) Your Catapult Team should complete page 13 of the blue “Catapult Process” handout. Limit yourselves to 15 minutes for this exercise. 10-22