AISI Design Methods for Sheathing Braced Design of Wall Studs in

advertisement

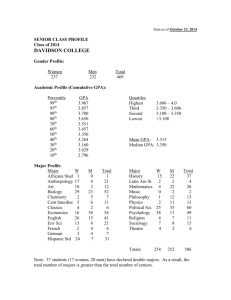

Civil Engineering at JOHNS HOPKINS UNIVERSITY Notes on AISI Design Methods for Sheathing Braced Design of Wall Studs in Compression B.W. Schafer report to AISI-COFS Design Methods Committee April 2008 Overview • Part of the AISI-COFS funded project on the design of sheathed walls with dis-similar sheathing. • Presentation developed from a report of the same name • Project updates, including full report available at www.ce.jhu.edu/bschafer/sheathedwalls • Report covers – Design methods via 1962, 1980-2004, 2007 AISI – Examination of sheathing stiffness ‘k’ – Initial summary of known demands and limit states on a sheathed wall stud in compression AISI Design Methods 1962 AISI Design Manual 1980 to 2004 AISI Spec. 2007 AISI-COFS Wall Stud Standard (S211) Winter’s method discrete spring model Simaan and Peköz shear diaphragm model “simplified” discrete spring model Basic notation I1, r1, Pcr1: strong-axis buckling perpendicular to the plane of the wall I2, r2, Pcr2: weak-axis buckling parallel to the plane of the wall e: initial imperfection 1962 AISI Design Manual 1962 AISI Specification • “The safe load-carrying capacity of a stud may be computed on the basis that the wall material or sheathing (attached to the stud) furnishes adequate lateral support to the stud in the plane of the wall, provided the wall material and its attachments to the stud comply with the following requirements:” 1962 AISI Specification 1962 AISI Design Manual • “The safe load-carrying capacity of a stud may be computed on the basis that the wall material or sheathing (attached to the stud) furnishes adequate lateral support to the stud in the plane of the wall, provided the wall material and its attachments to the stud comply with the following requirements:” fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 1962 AISI Specification 1962 AISI Design Manual • “The safe load-carrying capacity of a stud may be computed on the basis that the wall material or sheathing (attached to the stud) furnishes adequate lateral support to the stud in the plane of the wall, provided the wall material and its attachments to the stud comply with the following requirements:” fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 1962 AISI Specification 1962 AISI Design Manual • “The safe load-carrying capacity of a stud may be computed on the basis that the wall material or sheathing (attached to the stud) furnishes adequate lateral support to the stud in the plane of the wall, provided the wall material and its attachments to the stud comply with the following requirements:” fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 fastener-sheathing stiffness, k, must be at least: k min f y2 aA2 240 ,000 ,000 I 2 1962 AISI Specification 1962 AISI Design Manual • “The safe load-carrying capacity of a stud may be computed on the basis that the wall material or sheathing (attached to the stud) furnishes adequate lateral support to the stud in the plane of the wall, provided the wall material and its attachments to the stud comply with the following requirements:” fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 fastener-sheathing stiffness, k, must be at least: k min f y2 aA2 240 ,000 ,000 I 2 fasteners must have at least this much strength: Fmin keP 2 EI 2 k / a P Fastener spacing limit #1 1962 AISI Design Manual • Design basis: amax1 requires that weak-axis buckling of the stud, including contributions from the wall stiffness k, that is developed from fasteners at spacing a, is greater than or equal to the squash load of the column. Pcr 2 k @ a ,KL 2 L Af y fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 Fastener spacing limit #1 1962 AISI Design Manual • Design basis: amax1 requires that weak-axis buckling of the stud, including contributions from the wall stiffness k, that is developed from fasteners at spacing a, is greater than or equal to the squash load of the column. Pcr 2 k @ a ,KL 2 L Af y fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 id L2 Pcr 2 2 PE Winter (1960) solution for column on a stiff, continuous, foundation PE convert continuous foundation stiffness, , to discrete springs, k, and set Pcr2=Afy solve for a, you get Af y EI 2 L 2 2 2 2k a L2 2 EI 2 L2 Fastener spacing limit #2 1962 AISI Design Manual • Design basis: amax2 requires that weak-axis buckling of the stud over a length of 2a (twice the fastener spacing) must be greater than the strong-axis buckling over the entire length. Pcr 2 k 0,KL2 2a Pcr1 KL1 L fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 Fastener spacing limit #2 1962 AISI Design Manual • Design basis: amax2 requires that weak-axis buckling of the stud over a length of 2a (twice the fastener spacing) must be greater than the strong-axis buckling over the entire length. Pcr 2 k 0,KL2 2a Pcr1 KL1 L fastener spacing, a, must be less than 8EI 2 k amax1 2 2 A fy a max 2 Lr2 2r1 Equating Pcr1 and Pcr2 implies KL 1 KL 2 r1 r2 Insure weak-axis buckling over 2a does not control solve for a, you get L 2a r1 r2 1962 AISI Design Manual minimum stiffness k • Design basis: kmin is the same as the amax1 design check. Pcr 2 2 PE id L2 Af y PE EI 2 L 2 2 2 2k a L2 2 EI 2 L2 (from Winter 1960) fastener-sheathing stiffness, k, must be at least: sub in for E and , solve for k k min f y2 aA2 240 ,000 ,000 I 2 Pcr 2 k @ a ,KL 2 L Af y fastener strength 1962 AISI Design Manual • Design basis: forces developed in an imperfect, but stiff continuous foundation under the design load P, should be carried by the fasteners, plus Winter adds some interesting empirical corrections. Winter (1960) defines forces developed in a stiff continuous foundation supporting an imperfect column sreq d o id 1 id act Fmin sreq a 2 2k a Fmin e kid 1 kid k act fasteners must have at least this much strength: Fmin keP 2 EI 2 k / a P fastener strength (continued) 1962 AISI Design Manual Fmin kid e 1 kid k act again, Winter uses the solution for buckling of a column on a stiff continuous foundation, this time to find the ideal stiffness id (kid): Pcr 2 2 PE id L id 2kid a 2 PE which results in and PE 2 EI 2 / L2 Pcr 2 P kid P 2 2EI 2 a 2 after substitution and rearranging, we find Fmin ek act P 2 2 EI 2 a k act fasteners must have at least this much strength: k id P this ends, rational derivation and Winter introduces empiricism Fmin keP 2 EI 2 k / a P fastener strength (continued) Fmin ek act P 2 2 EI 2 a k act k id P 1. assume kact=kid only under first denominator term 2. remove 2 under the radical in first term as well 3. remaining kact = k results in fasteners must have at least this much strength: Brace forces resulting from Example 11 of 1962 design manual note kact=80kid Fmin keP 2 EI 2 k / a P fastener strength (continued) 1962 AISI Design Manual Fmin ek act P 2 2 EI 2 a k act k id P 1. assume kact=kid only under first denominator term 2. remove 2 under the radical in first term as well 3. remaining kact = k 2% “rule” 0.02 Fmin( P) fasteners must have at least this much strength: 0.015 P Fmin2( P) results in Brace forces resulting from Example 11 of 1962 design manual note kact=80kid 0.01 P Fmin 0.005 0 0 2000 4000 6000 P 8000 1 10 4 keP 2 EI 2 k / a P 1962 AISI Design Manual Summary of 1962 Specification • The fastener-sheathing stiffness must insure the following condition is met Pcr 2 k @ a ,KL 2 L Af y • The fastener-sheathing strength must insure the following condition is met Fmin e k k 2 k id 1 where kid P 2 a 8EI 2 • In addition to insure adequate performance in the face of potential defects Pcr 2 k 0,KL2 2a Pcr1 KL1 L • If the above conditions are met Pcr=Pcr1 (strong-axis). 1962 AISI Design Manual Critique of 1962 Specification • The fastener-sheathing stiffness must insure the following condition is met Pcr 2 k @ a ,KL 2 L Af y useful, but arbitrary, does not even insure that strong axis controls • The fastener-sheathing strength must insure the following condition is met Fmin k e k 2 k id 1 couched in something theoretical, but in the end empirical, not wholly consistent with current approaches • In addition to insure adequate performance in the face of potential defects Pcr 2 k 0,KL2 2a Pcr1 KL1 L arbitrary, realistic? • If the above conditions are met Pcr=Pcr1 (strong-axis). Underlying theory not directly applicable, no torsional-flexural buckling check, to my knowledge none of us have ever even done a k test!? 1980 to 2004 AISI Spec. 1980 to 2004 AISI Specification • Also known as the Simaan and Peköz method, or the shear diaphragm model, or the “D4 method”. Existed from 1980 to 2004 in Spec. Section D4. Abandoned in favor of a return to Winter’s method, more or less. • Why was the method abandoned? • What can we learn from the “mistakes”? 1980 to 2004 AISI Spec. Practical limitations of D4 method • “The design expressions are complex. The design expressions do not give credit to the presence of supplementary steel bridging which is typically installed in order to align members and to provide necessary structural integrity during erection and in the completed structure. Provided there is adequate steel bridging, the imperfect sheathing approach in Section D4 (a) can produce a lower capacity than an all steel approach. The most popular sheathing, gypsum wallboard, is seen by some as too moisture and load cycle sensitive to act as a reliable structural brace for the service life of a structure. Other restrictions in Section D4 (a) are for the most part impractical for typical use.” (Trestain 2002). 1980 to 2004 AISI Spec. Theoretical limitation of the D4 Method • For the most part Winter’s method may conceptually be understood as a column supported by discrete springs: • The D4 method has never been presented with an equivalent mechanical model, instead it is always described as a summation of energies (column bending + shear distortion of diaphragm), what is underneath the hood? 1980 to 2004 AISI Spec. Consider the shear energy term L 1 2 0 Q z dz shear energy Ds “shear” angle du z z y z dz 2 1980 to 2004 AISI Spec. Consider the shear energy term L 1 2 0 Q z dz shear energy Ds “shear” angle du z z y z dz 2 equivalence with rotational spring foundation: Ds L 1 2 0 Q y dz D 2 L 1 2 0 y 2 dz 1980 to 2004 AISI Spec. Consider the shear energy term mechanically equivalent model to shear diaphragm L 1 2 0 Q z dz shear energy Ds “shear” angle du z z y z dz 2 equivalence with rotational spring foundation: Ds L 1 2 0 Q y dz D 2 L 1 2 0 y 2 dz considering discrete fasteners 1980 to 2004 AISI Spec. D4 method summary • The method was abandoned for numerous practical reasons, and now can be seen to have a serious theoretical limitation • However, lots of great and complicated mechanics in the D4 method. Torsional-flexural buckling is treated thoroughly (even for dissimilar and one-sided sheathing). • The role of shear in deforming the sheathing is real, but have to be careful with how that actually braces the stud 2007 AISI-COFS Wall Stud Standard (S211) 2007 AISI-S211 Wall Stud Standard • “Wall stud assemblies using a sheathing braced design shall be designed assuming that identical sheathing is attached to both sides of the wall stud and connected to the bottom and top horizontal members of the wall to provide lateral and torsional support to the wall stud in the plane of the wall.” • “Both ends of the stud shall be connected to restrain rotation about the longitudinal stud axis and horizontal displacement perpendicular to the stud axis.” Further, in B1.2(b) it is prescribed that the global buckling load of a stud, with fasteners spaced distance “a” apart shall be determined ignoring any sheathing contribution (i.e. k = 0) over a distance of 2a, i.e.: Pcr k 0,KL x L ,KL y 2a ,KL t 2a 2007 AISI-COFS Wall Stud Standard (S211) Pcr by AISI-S211-07 • It is assumed that the sheathing provides enough stiffness that Pcr ignoring the sheathing over a length equal to twice the fastener spacing, a, is always less than Pcr considering the sheathing: 0 ,KL y buckling 2a across a defective fastener 0,KLx L ,KLt 2a assumed minbuckling Pcryofkthe@stud a ,KL y L engaging all fasteners PcrTF k 0,KLx L; k Pcr by AISI-S211-07 2007 AISI-COFS Wall Stud Standard (S211) • It is assumed that the sheathing provides enough stiffness that Pcr ignoring the sheathing over a length equal to twice the fastener spacing, a, is always less than Pcr considering the sheathing: 0 ,KL y buckling 2a across a defective fastener 0,KLx L ,KLt 2a min P k 0 ,KL 2a cry y PcrTF k 0,KLx L ,KLt 2a assumed assumed minbuckling Pcryofkthe@stud a ,KL y L engaging all fasteners min Pcry PcrTF k 0,KLx L; k k @ a ,KL L y PcrTF k 0,KLx L; k @ a ,KLt L Pcr by AISI-S211-07 2007 AISI-COFS Wall Stud Standard (S211) • It is assumed that the sheathing provides enough stiffness that Pcr ignoring the sheathing over a length equal to twice the fastener spacing, a, is always less than Pcr considering the sheathing: 0 ,KL y buckling 2a across a assumed defective fastener 0,KLx L ,KLt 2a min P k 0 ,KL 2a cry y PcrTF k 0,KLx L ,KLt 2a assumed minbuckling Pcryofkthe@stud a ,KL y L engaging all fasteners min Pcry PcrTF k 0,KLx L; k k @ a ,KL L y PcrTF k 0,KLx L; k @ a ,KLt L validity of assumption depends on the stiffness k, as k0 definitely not a valid assumption 2007 AISI-COFS Wall Stud Standard (S211) AISI-S211-07 Commentary • Wall Stud Standard provides only minor guidance, primarily wall stud design is left to rational analysis. • However, the commentary provides one such rational analysis method, relying primarily on the 2% rule for fastener demands. • Let us revisit the classic derivation to better understand the implications of the 2% rule. 2007 AISI-COFS Wall Stud Standard (S211) 2% rule in AISI-S211-07 Commentary • Consider the basic derivation (supplementing the commentary) 2007 AISI-COFS Wall Stud Standard (S211) 2% rule in AISI-S211-07 Commentary • Consider the basic derivation (supplementing the commentary) Finally solving for the bracing force: note, 1%P, not 2%P, but brace force is a function of k and do can be higher or lower 2007 AISI-COFS Wall Stud Standard (S211) Comparison of 1962 and 2007 methods 1962 AISI Design Manual Analyze any design AISI 2007 (S211-07) Pcr minPcry , PcrTF where Pcry k 0 ,KL y 2a PcrTF k 0,KLx L ,KLt 2a and 2%P for fasteners Prescribed failure mode AISI 1962 Pcr Pcrx KLx L * subject to Pcry k 0,KL y 2a Pcrx KL x L Pcry k @ a ,KL y L Af y and ~2%P for fasteners * It is important to note that AISI 1962 did not include torsional-flexural buckling and PcrTF<Pcrx though as torsional resistance is increased PcrTF will asymptote to Pcrx. Looking towards new methods.. Limit states (abridged) • Stud – Global buckling (F, T, FT – including sheathing) • should the stud be checked assuming defective fastener? – Local buckling (probably ignore sheathing) – Distortional buckling (probably including sheathing) • should the stud be checked assuming a defective fastener? • Connections – Stud-fastener-sheathing connection – Track-fastener-sheathing connection – Stud-to-track connection • Sheathing • Construction loads (requires all-steel check) Limit states (abridged) state of development... • Stud – Global buckling (F, T, FT – including sheathing) • should the stud be checked assuming defective fastener? – Local buckling (probably ignore sheathing) – Distortional buckling (probably including sheathing) • should the stud be checked assuming a defective fastener? • Connections – Stud-fastener-sheathing connection – Track-fastener-sheathing connection – Stud-to-track connection • Sheathing • Construction loads (requires all-steel check) Up to date work on bracing a stud Sheathing k y ( y ) G ( y ) x( y ) sin( y L ) d x( y ) y ( y) cos( ) dy L L G y ( y) cos( ) L L w x Sheathing k y F( y ) ( 2 1 ) wt / n ( y ) G ( y ) F ( y) k x( y ) x w k 2π Gwt a sin Ln 2L When sheathing k matters? • If ksheathing<10kfastener... probably matters ktotal 1 1 kfastener 1 ksheathing kfastener 0.8 ktotal ( ) fastener 0.6 sheathing kfastener 0.4 0.2 0 0.1 1 10 ksheathing ( ) kfastener 100 Getting past flexure... • Support of the stud exists for other DOF as well, and in some cases preliminary characterization has been done Overview • Part of the AISI-COFS funded project on the design of sheathed walls with dis-similar sheathing. • Presentation developed from a report of the same name • Project updates, including full report available at www.ce.jhu.edu/bschafer/sheathedwalls • Report covers – Design methods via 1962, 1980-2004, 2007 AISI – Examination of sheathing stiffness ‘k’ – Initial summary of known demands and limit states on a sheathed wall stud in compression All for now, Thank you... Current Modeling Stress distribution at Peak Load (Gray color represents yielding - connections) Lab – General View 1 Lab – CFS specimens for scale