"Medley" Presentation From Chapters 11-14

advertisement

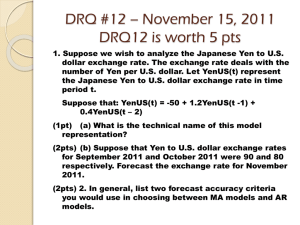

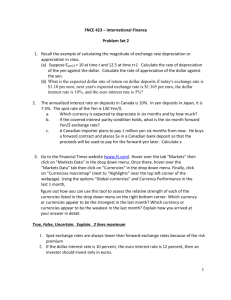

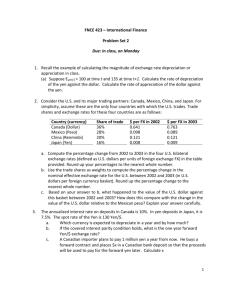

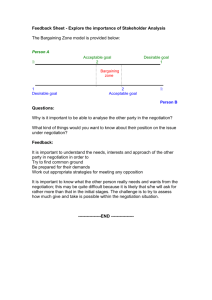

The “Medley” Presentation From Chapters 11-14 IDIS 424 Spring 2004 1 Chapter 11 Worldwide Sourcing IDIS 424 Spring 2004 2 International versus Global Sourcing What is the difference between international purchasing and global sourcing? International purchasing is the process of buying goods and services from suppliers outside your firm or business unit’s country of operation Global sourcing refers to the proactive integration and coordination of material and service requirements across worldwide business units, looking at common items, processes, technologies, designs, sourcing practices, and suppliers 3 Key International Purchasing Issues International purchasing topics… Culture Language and communication Law Total or landed cost Organization Risk management, including currency risk management Countertrade Sources of international information 4 Law The U.S. uses common or case law, which leads to lengthier and more detailed contracts than are found in countries that use code or civil law Many foreign countries do not like to deal with U.S. law and long contracts Bribery (facilitating payments) and reciprocity, while illegal in the U.S., are often not illegal oversees Have a written and signed document that describes the expectations of the buyer and seller. It does not have to look like a U.S. contract 5 Law Advanced, industrial countries have legal systems that can be trusted to treat foreign companies fairly. Developing countries may not There is no effective legal protection in many countries against intellectual property piracy. Perform a thorough reference check of prospective suppliers True international contracts exists if they follow the Convention on the International Sale of Goods (CISG). The U.S. has signed this convention 6 Total Cost Total cost in international purchasing is also called landed cost International purchasing may include many additional cost components compared with domestic purchasing… Unit price Tooling Packaging Transportation Duties/tariffs Insurance premiums 7 Total Cost International purchasing may include many additional cost components compared with domestic purchasing… Payment terms Fees and commissions Port terminal and handling fees Customs broker fees Taxes Communication costs Payment and currency fees Inventory carrying costs 8 Currency Risk Management Delivery-Triggered Adjustment Clauses A contract for 3000 castings with Nippon Steel is issued on June 1, with delivery of 1000 castings to be on June 30, July, 30 and August 30. A currency adjustment clause is written into the contract establishing a base exchange rate of 100 yen per dollar +/- 4%. Upper Boundary 104 Yen/$ 100 Yen/$ base Lower Boundary Currency Range 96 Yen/$ June 30: Yen appreciates to 90 yen per dollar. What should happen? July 30: Yen is 97 yen per dollar. What should happen? August 30: Yen moves to 100 yen per dollar. What should happen? 9 Currency Risk Management Time-Triggered Adjustment Clauses An annual contract for castings is agreed to with Nippon Steel. A time triggered currency clause is agreed to with reviews to be made quarterly. The base exchange rate is 100 yen per dollar +/- 4%. Adjustment review dates are April 1, July 1, and October 1. Upper Boundary 104 Yen/$ 100 Yen/$ Base Lower Boundary Currency Range 96 Yen/$ April 1: Yen appreciates to to 95 yen per dollar. What should happen? July 1: Yen moves to 99 yen per dollar. What should happen? July 30: Yen depreciates to 106 yen per dollar. What should happen? 10 Currency Risk Management Currency Hedging - Forward Exchange Contract A buying firm purchases 300,000 French motors on September 1 at a cost of 4 francs each. Delivery and payment will occur on December 1. Total contract requires payment of 1,200,000 francs Buyer takes no steps to protect contract from currency fluctuation Exchange rate on September 1: 1 franc = $.1530 Expected total cost of contract on September 1 = (300,000 x 4 x .1530) = $183,600 Exchange rate on December 1: 1 franc = $.1820 Expected total cost of contract on December 1 = (300,000 x 4 x .1680) = $201,600 Contract price increased 10% due to currency changes 11 Currency Risk Management Currency Hedging - Forward Exchange Contract A buying firm purchases 300,000 French motors on September 1 at a cost of 4 francs each. Delivery and payment will occur on December 1. Total contract requires payment of 1,200,000 francs Buyer purchases a 90 day forward exchange contract Exchange rate on September 1: 1 franc = $.1530 90 day forward rate is 1 franc = $ .1545 Expected total cost of contract with 90-day forward rate lock-in: (300,000 x 4 x .1545) = $185,400 plus bank fees 12 Sources of Information Where do we find information about worldwide suppliers? International industrial directories Trade shows Trading companies Internet External agents Trade consulates Internal sources Sales brochures and catalogs 13 Global Sourcing Benefits Purchase Price Total Cost of Ownership Purchase price decreased 15% on average 87.6% of firms report that purchase price declined 9.9% report no change 2.5% report that purchase price increased Total cost of ownership improved 11% on average 72.7% of firms report that total cost of ownership declined 24% report no change 3.3% report that total cost of ownership increased 14 Global Sourcing Benefits Supplier Quality Delivery Cycle Time Supplier quality improved 6% on average 42.6% of firms report that supplier quality improved 54.1% report no change 3.3% report that supplier quality decreased Delivery cycle time lengthened 5% on average 23.3% report that delivery cycle time shortened 34.2% report no change 42.5% report that delivery cycle time lengthened 15 Global Sourcing Benefits On-Time Delivery Performance On-time delivery performance improved 3% on average 32.3% of firms report that ontime delivery performance improved 46.7% report no change 21% report that delivery performance worsened 16 Chapter 12 Purchasing Tools and Techniques IDIS 424 Spring 2004 17 Standard ANSI Process Flow Chart Symbols Operation Decision Transport Inspection/ Approval Storage Delay 18 ANSI Process Flow Chart: Stores Requisition Process User Completes Requisition Clerk Enters Order Wait in Internal Mail Deliver to Stores Wait in Stores In-Box Pick Order Deliver to User File Requisition Check Order Y In Stock? N Notify User 19 Process Flow Charting - Considerations Document the process as it IS, not as it’s supposed to be Scope - how much of the process do you want to look at? Detail - how finely do you want to break down the process? 20 Process Flow Charting - Considerations Additional dimensions may be included in a flow chart: Information flows Time element Operations, inspections, delays, transports Average and range (or maximum) Distance moved Resources required Capacity 21 Process Flow Charting - Benefits Gain a clear understanding of how the process actually works Capacities Cycle times Highlight potential improvement opportunities Unnecessary steps Redundant steps Inefficient sequencing of steps Identification of bottlenecks 22 Value Analysis What is value analysis? The organized and systematic study of every element of cost in a part, material, process, or service to make certain it fulfills its function for the customer at the lowest total cost. It employs techniques which identify the functionality the user wants from the part, material, process or service Value = Function/Cost Function is what a part, material, process, or service does (noun and a verb) 23 Value Analysis What is value analysis? VA is a continuous improvement technique--it is not product or service cheapening!! VA workshops and the VA process are a combination of group problem solving, project management, process redesign, and continuous improvement efforts Applies to manufacturing and non manufacturing organizations Value analysis requires inter and intra organizational integration!! 24 Value Analysis Value Analysis Workshop Steps Information Phase Speculative Phase Analytical Phase Execution Phase Conclusion Phase 25 Chapter 13 Strategic Cost Management IDIS 424 Spring 2004 26 Cost-related Concepts A cost driver is any factor that affects costs. A change in the cost driver will cause a change in the total cost Cost management are actions that managers take to satisfy customers while continuously reducing and controlling costs 27 Cost Behavior Cost behavior refers to the way costs change with respect to a change in an activity level or cost driver Typical cost behavior patterns include: Fixed costs Variable costs Mixed costs Semifixed costs Semivariable costs 28 Cost Behavior Patterns Fixed costs are costs that do not change with changes of a cost driver Variable costs are costs that increase directly and proportionately with changes of a cost driver Mixed costs are costs that have both a fixed and a variable component 29 Framework for Cost Management High “Unique Products” “Critical Products” “Generics” “Commodities” Risk Low Low High Value (Cost, Service, Administration) 30 Generics Low Value, Low Risk Strategies Critical Factors Standardize / consolidate Reduce cost of acquisition Metrics: Total Delivered Cost Reduction Percent of CGS Improvement Transportation cost reduction 31 Commodities High Value, Low Risk Strategies Critical Factors Leverage preferred suppliers Reduce cost of materials Metrics Price change improvement to market index 32 Unique Products High Risk, Low Value Strategies Critical Factors: Preferred suppliers High costs when cost/quality problems occur Metrics Unit price cost reduction - Actual to actual prices for same items Target prices achieved, “Should cost” $ Total Delivered Cost Reduction 33 Critical Products High Risk, High Value Strategies Critical Factors Strategic supplier partnerships High costs when cost/quality problems occur Metrics Target prices achieved Unit price cost reduction - Actual to actual prices for same items Joint cost savings sharing 34 Chapter 14 Negotiation IDIS 424 Spring 2004 35 Purchase Negotiation Negotiation Overview- Negotiation is a process of formal communication, either face to face or via electronic means, where two or more people come together to seek mutual agreement about an issue or issues The process involves the management of time, information, and power It is a time-consuming process that requires extensive planning and a commitment of resources--90% of the negotiation process involves preparation, not execution 36 Purchase Negotiation Negotiation Overview- Negotiation involves relationships between people, not just organizations The primary objective of a purchase negotiation is to reach an agreement that satisfies both parties Negotiation is an opportunity to create value within the supply chain Good negotiators are not born--they develop their skills through practice 37 Negotiation Framework Identify or Anticipate a Purchase Requirement Determine if Purchase negotiation Negotiation is involves a five-step process Required Plan for the Negotiation Conduct the Negotiation Execute the Agreement 38 Negotiating Tactics Examples of Tactics Honesty/Openness Planned concessions Price Increase Best and Final Offer Silence Scarcity Strong Initial Offer Use of power Low Ball High Ball Phantom Quotes or Offers 39 Win-Win Negotiation Characteristics of win-lose negotiation- Rigid negotiating positions Argument over a fixed amount of value Strict use of power by one party over another Adversarial competition played out at the negotiating table Characteristics of win-win negotiation- Parties try and understand each other’s needs and wants Parties build on common ground and work together to develop creative solutions that provide additional value Primary use of power is to focus on common rather than personal interests Likely to engage in open sharing of information 40 Win-Win Negotiation Win-win negotiation applies only to certain situations- Strategically important items or services Trust between parties exists Both parties endorse a win-win approach Discussion Question: How does a negotiator know when his or her counterpart is taking a win-win approach? 41 Negotiation Conclusions Successful purchasing negotiators share some common attributes- They realize that training, planning, and practice are required to become an effective negotiator They have higher negotiating goals and aspirations than their counterparts They are destined to be among an organization’s most valued professionals 42