Conceal or accommodate the building services

advertisement

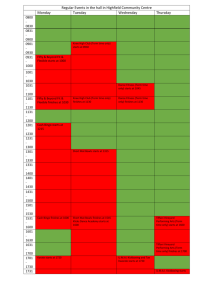

Chapter 22 Selecting Interior Finishes Finishes Functional Parameters Durability Acoustical performance Fire safety Relationship to mech. & elect. services Changeability Fire resistance Aesthetics Design compliance / enhancement Interior Finishes One of the purposes Conceal or accommodate the building services Equipment & distribution systems: Mechanical (HVAC) Plumbing (water, sewer,storm) Sprinkler Electrical (power, communication, etc.) Vertical transportation Others: computer connections, vacuum, etc. MPE System Installation Shafts - vertical runs of pipe, duct, wiring, elevators, etc. Concealment and prevention of fire migration Suspended Ceilings - Horizontal runs of MPE Floors - services cast into floor, access flooring Plumbing Chases - water, sewer Mechanical Spaces - rooms, penthouse, roof, basement, mezzanines Horizontal runs of Piping Horizontal Runs of Duct Sprinkler Duct Duct Cable Tray Electrical Plumbing Overhead Rough-in: High Rise Corridor Electrical Cable TV Plumbing Sprinkler Unistrut Overhead Rough-in; Low Rise Hotel Corridor Plumbing Chase Plumbing Underground MPE Rough-in for Elevated Slab Electrical Plumbing Sleeves Partition Rough-in Plumbing Electrical Partition Framing to Conceal Fan Coil Unit Rooftop Equipment HVAC Equipment Heating & Cooling HVAC Equipment Cooling Tower (“ground” or roof mounted) Roof Top Mechanical & Electrical Space (concealed) Fiberglass Construction - Communications Transmission Mechanical Equipment Room Electrical Panels Interior Finishes Sequence Overhead Rough-in (duct, pipe, electric home runs/service) AND MPE Vertical Distribution Systems (plg, duct, elec.) Partition Framing (CMU, metal framing) Partition Rough-in (plg, elec., communications, etc.) Ceiling Framing & Rough-in (DW, acoustic grid, lights, HVAC, etc.) Cabinetry, Built-in equipment and furnishes Ceiling Finishes, Wall Finishes, Floor Finishes Sequence depends on: Type of materials / systems used Interior Finishes Sequence Primary Considerations for Sequence: Need for subsequent operations - framing/RI Priority for Location EX. - electric pipe vs. sewer Durability of material Ability to withstand unconditioned Space- cabinetry/doors Ability to withstand construction abuse - soft vs. hard tile Project Schedule Requirements Availability - lead time, field measurements Considerations for Selecting Interior Finishes Appearance Durability & Maintenance Acoustic Criteria Fire Criteria Relationship to MPE services Changeability Cost Toxic Emissions Appearance Present / Carry out a particular Concept Interior space - usage, feel, form, etc. Lighting Color Pattern Texture etc. Durability & Maintenance “Highly durable finishes generally cost more…” Selection generally determined by “need”/use Intensity of use - “wear & tear” Water resistance requirements Cleanliness & maintenance requirements Examples “hard” flooring in an airport vs. carpet in an office drywall ceilings in a hospital vs. acoustic in retail/office CMU in public restrooms or mechanical room vs. drywall VWC in a corridor vs. paint Acoustic Criteria “Interior finish materials strongly affect the quality of listening conditions and the levels of acoustic privacy inside a building.” (They absorb or reflect sound - space use typ. determines) Sound Transmission Class (STC) of Partitions A measure of sound transmission Full scale testing to determine STC rating Can also use a field test to verify Requires - proper construction partition, sealing MPE penetrations, doors, etc. Acoustic Criteria Ways to Reduce Sound Transmission Proper selection of materials / components Floors, ceilings & walls Proper installation Sound absorbing insulation Resilient partition mountings Isolation of equipment Sound Insulation and Resilient Mountings to reduce sound transmission ‘Insulates’ floor and Seals joint between partitions & floor Cement/Gypsum Self-Leveling Floor Covering to reduce floor-to-floor sound transmission Equipment Isolation Mount Fire Criteria Typically governed by Building Codes Concerned with: Combustibility Flame spread (how quickly fire spreads / material burns) Fuel Contributed Rating (combustibility of material) Smoke Developed Rating (smoke contribution) “smoke, not heat, is the primary killer in building fires” Fire Resistance “Smoke” caulking @ MPE penetrations Fire Resistance Ratings Full Scale Tests to determine an assembly’s rating Must maintain physical & structural integrity Not permit passage of flame or hot gases Insulate to keep cool the side not exposed to the fire Openings Restricted in size Must be protected to prevent passage of fire/gases Doors - rated Duct - Fire/smoke dampers Piping - sleeves and sealant Pneumatically Operated Fire Damper Fire Damper with Fusible Link Rated Opening in Exit Corridor Rating Label on Corridor Doors Changeability How permanent are the interior finishes? Office, Retail Changes in services and finishes often Lighter, easily changed construction materials acoustic clg., drywall, moveable partitions, carpet, etc. Government Building, Theater Changes in services and finishes less often / seldom Heavier, harder to change construction materials drywall clg., plaster, CMU, stone, hard tiles Cost First (initial) Cost Installed cost Highly important with tight budget and/or short life Life-Cycle Cost First cost + maintenance + replacement + energy costs Important if: Building useful life is long Ownership is retained over an extended period Budget considerations allow higher initial cost Toxic Emissions of Materials Solvents, finishes, etc. Airborne fibers Susceptibility to mold/mildew Radon Gas Sick Buildings Trends in Interior Finish Systems Components vs Single system Constructed to accommodate change EX: partitions anchored to grid, modular Heavy to Lighter Materials EX: plaster/CMU to drywall, hard tiles to vinyl/carpet Less dead load, often less cost Wet systems to “Dry” systems Plaster to gypsum drywall to acoustic Terrazzo to hard tile to carpet/vinyl