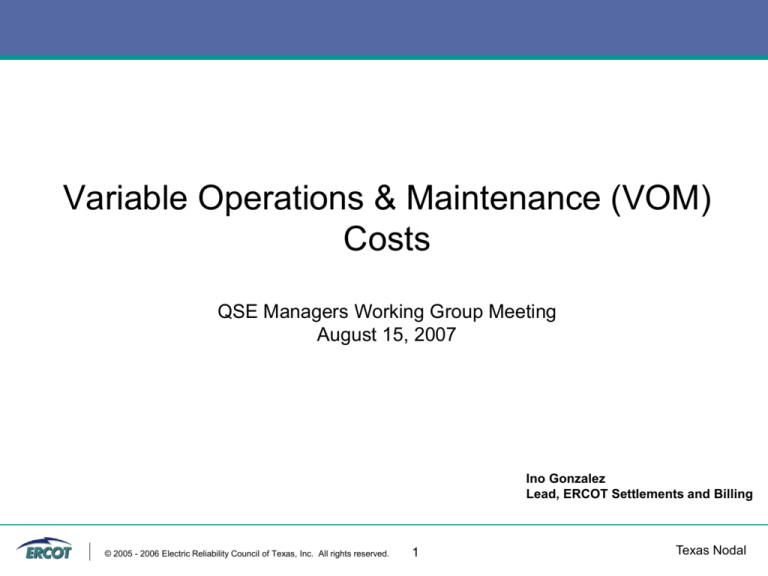

Variable Operations & Maintenance (VOM)

Costs

QSE Managers Working Group Meeting

August 15, 2007

Ino Gonzalez

Lead, ERCOT Settlements and Billing

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

1

Texas Nodal

Objectives

1. Three-Part Offer

2. Variable Operations and Maintenance (VOM) Costs

- Startup

- Minimum energy

- Energy Offer – Real Time Mitigation

3. Options for submitting VOM Costs

- PJM’s Maintenance Methodology

- California ISO approach

- Other proposals

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

2

Texas Nodal

Three-Part Supply Offer

Consists of:

Startup Offer

Minimum-Energy Offer

Energy Offer Curve

$/MWh to Operate at

Given MW Quantity

Above Low

Sustained Limit

$ to Startup

$/MWh to Operate at

Low Sustained Limit

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

3

Texas Nodal

Three-Part Supply Offer (continue)

– The Startup Offer component represents all costs incurred by a

Generation Resource in starting up and reaching breaker close.

– The Minimum-Energy Offer component represents the costs

incurred by a Resource in producing energy up to and including the

Resource’s Low Sustained Limit (LSL) after breaker close.

– The Energy Offer Curve represents

• an offer to sell energy at or above a certain price and at a

certain quantity in the DAM or

• a willingness to dispatch a given unit in Real-Time.

– Startup Offers, Minimum-Energy Offers, and Energy Offer Curves

are capped.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

4

Texas Nodal

Start-Up Offer Cap

Start-Up Offer Cap ($/start)

Plus

Verified Actual Fuel (MMBtu) x Gas % x FIP ($/MMBtu)

($/start)

VOM ($/start)

Note: Assuming a gas-fired unit

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

5

Texas Nodal

Minimum Energy Cost Cap

Minimum Energy Offer Cap ($/MWh)

@ LSL

Plus

Verified Actual Fuel (MMBtu/MWh) x Gas % x FIP ($/MMBtu)

($/MWh)

VOM ($/MWh)

Note: Assuming a gas-fired unit

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

6

Texas Nodal

Energy Offer Curve Mitigated Cap

Mitigated Energy Offer Cap ($/MWh)

Max

[ {Verified Incremental Heat Rate x FIP} + VOM ] x Multiplier

($/MWh)

14.5 (or 10.5) Heat Rate x FIP ($/MWh)

Note: Assuming a gas-fired unit

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

7

Texas Nodal

Options for creating and Verifying VOMS

Option 1: PJM Operating and Maintenance Guidelines

1.

2.

3.

4.

5.

6.

7.

8.

Uses FERC Accounts to estimate maintenance dollars

Uses Handy Whitman Index to determine Escalation Factor

CT maintenance adder based on Equivalent Service Hours

Steam Units maintenance adder based on total dollars per fuel ($/MMBtu)

Allows for Long-Term variable maintenance costs to be included

Maintenance period = rolling 20-year historical period

Uses standard equation to calculate Equivalent Service Hours

Resources no longer required to submit costs to FERC

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

8

Texas Nodal

PJM Approach – Thermal Units

Nuclear and Fossil Steam Units

Sample Formula of Maintenance Adder for the Year 1998

TMD = (A +B – C)97 X F98/F97 + (A +B – C)96 X F98/F96 + … (A +B – C)78 X F98/F78

TFuel = TFuel97 + TFuel96 + TFuel95 +……+ TFuel78

TSD = C97 X F98/F97 + C96 X F98/F96 + … C78 X F98/F78

TS = S97 + S96 + … S78

MA98 = TMD / Tfuel ($/MMBtu)

SMA98 = TSD / TS ($/start-up)

Where:

TMD = Total Maintenance Dollars (for the Maintenance Period).

A = Total dollars in FERC Account 512.

B = Total dollars in FERC Account 513.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

9

Texas Nodal

PJM Approach – Thermal Units

Where:

C=

Costs included in FERC Accounts 512 and

513 that a company determines are start-up related.

F=

Escalation Factor for a particular year (Handy - Whitman Index.)

TFuel = Total fuel burn or heat released (for same years as used in TMD).

Fuel =

Total annual fuel consumed.

TS =

Total Starts

TSD =

Total Start maintenance Dollars

S=

Number of Starts per year.

MA =

Maintenance Adder ($/unit of fuel or heat)

SMA =

Start Maintenance Adder ($/start-up)

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

10

Texas Nodal

PJM Approach – Thermal Units

Comments:

1. Total Maintenance Dollars (TMD) plus Total Start maintenance Dollars

(TSD) cannot exceed Total dollars in FERC Accounts 512 and 513.

2. Units with less than seven years of history are considered immature. Such

units can be assigned their calculated MA and/or SMA, or a forecast value,

subject to approval by the PJM MMU.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

11

Texas Nodal

PJM Approach – Combustion Turbines

Combustion Turbine Maintenance Cost Calculation

• The Maintenance Adder for combustion turbines will be calculated and

applied on a "per equivalent service hour" basis. The calculation will be

based on actual operation and escalated maintenance expenses for all

available years in the Maintenance Period.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

12

Texas Nodal

PJM Approach – Combustion Turbines

CALCULATION OF HISTORICAL RATE

Equivalent service hours (ESH)

ESH = (A x Number of Starts) + Z hours + (B x Y hours)

Where:

A = Cyclic starting factor (A = 5.0 for aircraft - type CT's; A = 10.0 for

industrial - type CT's)

For example, the incremental maintenance charged to one start on an industrial type CT is equivalent to the incremental maintenance attributable to ten hours of

base load operation.

B = Cyclic peaking factor (B = 3.0 for all CT's)

This means that the additional incremental maintenance charged to the incremental

energy between base and peak loads is equivalent to the incremental maintenance

attributable to three hours of base load operation.

Z = Total unit operating hours at any load level.

Y = Hours above base load temperature limit.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

13

Texas Nodal

PJM Approach – Combustion Turbines

Note: ESH must be calculated using all available history in the

Maintenance Period. PJM members may propose alternative cyclic

starting factors or cyclic peaking factors for individual units. Such

alternative factor proposals should include supporting documentation

(e.g., manufacturer recommendation) of this new factor, to be reviewed

for approval by the PJM MMU, on a case-by-case basis.

Total Maintenance Dollars (TMD) sample calculation for 1998

TMD = D97 x F98/F97 + D96 x F98/F96 + … D78 x F98/F78

Where:

D = Total dollars in FERC Account 553 for a particular year.

F = Escalation Factor for a particular year based on Handy - Whitman Index.

Note: TMD must be calculated for the same historical period as ESH.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

14

Texas Nodal

PJM Approach – Combustion Turbines

Equivalent Hourly Maintenance Cost (in $/hour) (EHMC)

ESH = TMD / EHMC EHMC = TMD / ESH

Where:

TMD = Total maintenance dollars

ESH = Equivalent service hours

Comments:

•

Units with less than seven years of history are considered immature.

Such units can be assigned either their calculated EHMC, or a forecast

value, subject to approval by the PJM MMU.

•

If any unit in a block is at least seven years old, then all like units on

the block may be considered mature.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

15

Texas Nodal

PJM Approach – Combustion Turbines

APPLICATION OF EHMC TO FUTURE OPERATION

Rates assigned to future operation.

Starting Maintenance Cost ($/start) = A x EHMC

Where:

A = Cyclic starting factor as defined above

Hourly Maintenance Cost ($/Hour) = EHMC

This hourly value is assigned as a capacity cost and is independent of unit

loading.

Peak Incremental Maintenance Rate ($/MWh) = B/peak pickup X EHMC

B = Cyclic peaking factor as defined under Section

Peak pickup is equal to the difference between a CT's energy outputs at base

and at peak loading levels.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

16

Texas Nodal

PJM Approach – Combustion Turbines

Comments:

1. The above formulations are applicable for determination of Maintenance

Adders for both aircraft and industrial type combustion turbines.

2. CT incremental costs can be developed and applied on either a unit-by-unit

basis or by groups of units.

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

17

Texas Nodal

PJM Approach – Combustion Turbines

Example: Combustion Turbine Maintenance Adder

(Industrial Unit)

Peak Hours

y = 200 Hrs.

Service Hours

Z = 2000 Hrs. (Total Base Peak Hours)

No. of Starts = 300 Peak Pickup = 5 MW

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

18

Texas Nodal

PJM Approach – Combustion Turbines

Calculation

1. TMD = $100,000 (Actual historical maintenance data escalated to present

value).

2. A = 10, B = 3 (Note: A = 5 for aircraft engine CT's).

Equivalent Hourly Maintenance Cost = EHMC

EHMC = $100,000 / [ (10X300) + 2,000 + (3X200) ] = $17.86 /Hr.

3. Calculation of maintenance rates

Starting Maintenance Cost = A X EHMC = 10 x $17.86 = $178.60/start

Hourly Maintenance Rate = EHMC = $17.86/Hr.

Peak Incremental Maintenance Rate = B/(peak pickup) x EHMC

Peak Incremental Maintenance Rate = 3 X $17.86/5 = $10.72/MWh

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

19

Texas Nodal

Options for creating VOM Costs

Option 2: QSE Specific Methodology

Approved by ERCOT in advance

Pros

Applicable to specific resource company

Cons

May be difficult to verify by ERCOT

May require additional ERCOT staffing

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

20

Texas Nodal

Options for creating VOM Costs

Option 3: Use a fix value for VOM

California ISO uses a $6/MWh value

May fix value by unit type

May fix value for each cold, intermediate and hot start

Pros

No need to verify

Easy for market to understand

No need for additional ERCOT staffing

Cons

Market has to agree to actual value (s)

May not represent true VOM costs

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

21

Texas Nodal

Options for creating VOM Costs

Option 4: Use actual VOM submitted by resource

Actual VOM of resource

Values signed by an officer of company

Values signed by a licensed (PE) engineer in state of Texas

Pros

Simple verification

No need for additional staff

Cons

ERCOT will have some limited verification

ERCOT may audit anytime

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

22

Texas Nodal

Typical VOM Values

Table 1: Generic Unit Characteristics (in 2005 Dollars)

Variable O&M

($/MWh)

Fixed O&M ($/kWyr)

Minimum

Downtime (Hrs)

Minimum Uptime

(Hrs)

Combined Cycle

$ 2.50

$ 21.00

8

6

2 Blocks, each 50% at FLHR

Combustion

Turbine <100 MW

$ 7.00

$ 15.00

1

1

One block

Combustion

Turbine >100 MW

$ 7.00

$ 15.00

1

1

One block

Steam Turbine

[coal] >200 MW

$ 1.00

$ 35.00

12

24

4 blocks, 50% @ 106%FLHR, 15% @ 90%, 30% @ 95%, 5% @ 100%

Steam Turbine

[coal] <100 MW

$ 3.00

$ 45.00

6

8

Steam Turbine

[coal] <200 MW

$ 3.00

$ 35.00

8

8

Steam Turbine

[gas] >200 MW

$ 3.00

$ 30.00

8

16

Steam Turbine

[gas] <100 MW

$ 5.00

$ 34.00

6

10

Steam Turbine

[gas] <200 MW

$ 4.00

$ 30.00

6

10

Steam Turbine

[oil] >200 MW

$ 3.00

$ 30.00

8

16

Steam Turbine

[oil] <100 MW

$ 5.00

$ 34.00

6

10

Steam Turbine

[oil] <200 MW

$ 4.00

$ 30.00

6

10

Unit Type & Size

Heat Rate Shape

4 blocks, 25% @ 118%FLHR, 30% @ 90%, 35% @ 95%, 5% @ 103%

4 blocks, 25% @ 118%FLHR, 30% @ 90%, 35% @ 95%, 5% @ 103%

Source: US Department of Energy: CRA No.D08554-00

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

23

Texas Nodal

Typical VOM Values

Table 3. Gas Turbine Non-Fuel O&M Costs (Year 2000)

1 MW

5 MW

Variable (service contract) ($/kWh)

0.0045

0.0045

Variable (consumables) ($/kWh)

0.0001

0.0001

40

10

Fixed ($/kWh @ 8000 hrs/yr)

0.0050

0.0013

Total O&M Costs ($/kWh)

0.0096

0.0059

Electricity Capacity

O&M Costs 14

Fixed ($/kW-yr)

(14) O&M costs are based on 8,000 operating hours expressed in terms of annual electricity generation

Source: Technology Characterization: Gas Turbines; Climate Protection Partnerships Division,

Environmental Protection Agency, Washington, DC. February 2002

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

24

Texas Nodal

Summary - Options for creating VOM Costs

Option 1: PJM Operating and Maintenance Guidelines

Option 2: QSE Specific Methodology

Option 3: Use a fix value for VOM by resource type

Option 4: Use actual unit VOM submitted by resource

What is the best option?

© 2005 - 2006 Electric Reliability Council of Texas, Inc. All rights reserved.

25

Texas Nodal