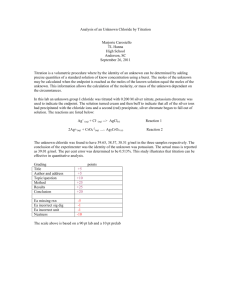

PPTB&W

advertisement

Synthesize t-Butyl (or t-Pentyl) Chloride Note: This experiment may utilize either t-Butyl Alcohol (m.p. 25.7oC) or t-Pentyl Alcohol (m.p. -9.5oC) as one of the starting reactants Text References Slayden Pavia Pavia 1/17/2015 - Exp # 21 - Tech 12 - pp. 49 - 50 - pp. 172 - 174 - pp. 681 - 702 1 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 Today’s Experiment Reaction of t-Butyl Alcohol (or t-Pentyl Alcohol) with conc. HCL to form t-Butyl Chloride (or t-Pentyl Chloride) Three-step Sn1 Nucleophilic Substitution Reaction This is a First Order Rate Reaction where the Rate of Formation of t-Butyl Chloride (t-Pentyl Chloride) is dependent only on the concentration of the Alcohol, i.e., it is independent of the amount of acid (HCL) used The strong acid (HCL) protonates the electron rich hydroxyl group (nucleophile) allowing it leave as a molecule of water This leaves a highly electrophilic carbon atom (positvely charged carbocation) that can be attacked by the negatively charged chloride anion, forming the final product 2 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 Today’s Experiment (Con’t) NOTE: Rate of Formation and Limiting Reagent are independent of each other. Thus, the Limiting Reagent must be computed Determine the limiting reagent and theoretical yield from the masses & moles of the two reactants (t-Butyl or t-Pentyl Alcohol & Conc HCl) and the stoichiometric molar ratios This experiment will require the student to separate and wash (liquid/liquid Extraction) two immiscible liquids using a separatory funnel Several steps of the experiment generate gases requiring care in using the separatory funnel and its stopcock 3 T-Butyl (t-Pentyl) Chloride Synthesis t-Butyl Alcohol (2-Methyl-2-Propanol) B.P. M.P. Density Refractive Index Mol Wgt Water Solubility - 82.4 oC 25.7 oC 0.7887 g/mL 1.3870 74.12 g/mole Soluble t-Butyl Chloride (2-Chloro-2-Methyl Propane) (507-20-0) B.P. M.P. Density Refractive Index Mol Wgt Water Solubility - 50.9 oC -26.0 oC 0.8420 g/ml 1.3857 92.5 g/mole Sl Soluble Conc HCl Molecular Wgt Molarity Density % Acid 1/17/2015 - 36.47 g/mole 12.0 moles/L 1.18 g/mL 37.3 4 T-Butyl (t-Pentyl) Chloride Synthesis t-Pentyl Alcohol (2-Methyl-2-Butanol - 102.5 oC - - 9.1 oC - 0.8096 g/mL - 1.4052 - 88.15 g/mole - Soluble B.P. M.P. Density Refractive Index Mol Wgt Water Solubility t-Pentyl Chloride (2-Chloro-2-Methyl Butane) (594-36-5) B.P. M.P. Density Refractive Index Mol Wgt Water Solubility - 85.6 oC -74.0 oC 0.8563 g/ml 1.4055 106.6 g/mole Slightly Sol Conc HCl Molecular Wgt Molarity Density % Acid 1/17/2015 - 36.47 g/mole 12.0 moles/L 1.18 g/mL 37.3 5 T-Butyl (t-Pentyl) Chloride Synthesis Stoichiometric Reaction The Mechanism 1/17/2015 6 T-Butyl (t-Pentyl) Chloride Synthesis The Stoichiometric tert-Pentyl Reaction The Mechanism 1/17/2015 7 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 Limiting Reagent Calculations The yield (mass or moles) of the washed and dried t-Butyl (t-Pentyl) Chloride product is compared to the theoretical amount of product expected, which is computed from a “Limiting Reagent” calculation using the Stoichiometric Molar Ratio The “Limiting Reagent” is that reactant whose mass (on a molar equivalent basis) is totally consumed in the reaction leaving an excess of the other reactant The “Limiting Reagent”, thus, determines the maximum amount of product that can be expected The results of the “Limiting Reagent computations” are presented in a table in the Data Report 8 T-Butyl (t-Pentyl) Chloride Synthesis Limiting Reagent Calculations (Con’t) Limiting Reagent Steps Determine the mass of the alcohol to the nearest 0.001 gram. Measure the volume of conc HCL solution to be used to the nearest 0.1 mL Compute the mass of the HCL from the volume, density, and % composition (see table) From the amounts (mass) of reactants used, calculate the number of moles of each: moles = mass / mol wgt 1/17/2015 Moles of HCl can also be computed directly from the Volume and Molarity (12.0 moles/L). If this approach is used, then back calculate the mass of HCL from the moles 9 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 From the balanced reaction equation determine the molar ratio among the reactants and products i.e., how many moles of Alcohol react with how many moles of HCL to give how many moles of t-Butyl (t-Pentyl) Chloride. The ratio here is 1:1 If the ratio of moles of Alcohol to moles of HCl actually used is greater than the stoichiometric molar ratio, then the Alcohol is in “Excess” and HCl is “Limiting” If, however, the ratio of actual moles of Alcohol to moles of HCl is less than the reaction molar ratio, then HCl is in excess and t-Butyl (t-Pentyl) Alcohol is “Limiting” 10 T-Butyl (t-Pentyl) Chloride Synthesis Examples A + B C Molar ratio A:B = 1 : 1 = 1.0 Moles actually used: A = 0.05; B = 0.12 Molar ratio A:B actually used: 0.05 / 0.12 = 0.42 The ratio of A:B is less than 1.00; thus A is limiting Only 0.05 moles of the 0.12 moles of B would be required to react with the 0.05 moles of A available Since 0.05 < 0.12; then B is in excess, A is limiting 1/17/2015 11 T-Butyl (t-Pentyl) Chloride Synthesis Examples (Con’t) A + 2B C Molar ratio A:B = 1 : 2 = 0.5 Moles actually used A = 0.0069; B = 0.023 Molar ratio A:B actually used = 0.0069 / 0.023 = 0.30 The ratio A:B is less than 0.5, thus, A is limiting Only 0.0069 2 = 0.0138 moles of B are required to react with 0.0069 moles of A. Since 0.0138 < 0.023: B is in excess, A is limiting. Any actual molar ratio less than the reaction molar ratio indicates “B” is in Excess and “A” is Limiting. Any actual molar ratio greater than the reaction molar 1/17/2015 ratio indicates “A” is in Excess and “B” is Limiting 12 T-Butyl (t-Pentyl) Chloride Synthesis Examples (Con’t) In the Friedel-Crafts alkylation of Biphenyl with t-Butyl Chloride to form 4,4’-Di-tert-Butyl Biphenyl, 1.064 g of Biphenyl is reacted with 2.129 g of t-Butyl Chloride. The stoichiometric equation indicates that 2 moles of t-Butyl Chloride react with 1 mole of Biphenyl Determine the “Limiting Reagent” and the “Theoretical Yield” Amounts Actually Used Maximum Amounts Expected 1 Biphenyl + 2 t-Butyl Chloride 1 4,4’di-tert-Butylbiphenyl + 2 HCl 1/17/2015 Mol Wgt 154.211 92.565 266.43 36.55 Mass (g) 1.064 2.129 1.838 0.504 Moles 0.0069 0.023 0.0069 0.0138 In the above example, “Biphenyl” is the limiting reagent because 0.0069 moles is less than 0.023 / 2 = 0.0115 moles. Thus, a maximum of 0.0069 moles (1.838 g) 4,4’ditert-Butyl Biphenyl can be expected 13 T-Butyl (t-Pentyl) Chloride Synthesis Theoretical Yield The limiting reagent sets the maximum amount of product that can be expected The actual number of moles of product is the product of the moles of Limiting reagent and the molar ratio of product to Limiting reagent To get the mass of product simply multiply the expected moles of product by the molecular weight of the product Mass Product = Moles Limiting Reagent × Molar Ratio (Product / Reagent)× Mol Wgt Product 1/17/2015 14 T-Butyl (t-Pentyl) Chloride Synthesis Elements of the Experiment Determining the masses of the reactants (2 procedures) • Alcohol mass is determined by weighing • HCl mass is determined by computing mass from volume, density and % Composition (HCl – 37.3 %) Determining the moles of the reactants Setting up the Stoichiometric equation Determining the Limiting Reagent Determining the Theoretical Yield Mixing reagents and initiating the reaction 1/17/2015 15 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 Elements of the Experiment (Con’t) Separate product from reaction mixture Liquid/Liquid Extraction of product with H2O and NaHCO3 to Separate & Wash the product Drying the product with Anhydrous Sodium Sulfate (Na2SO4) Determining the Mass (Yield) of the Product Computing the % yield Determining the Refractive Index Adjusting Refractive Index for temperature Obtaining the Infrared Spectrum 16 T-Butyl (t-Pentyl) Chloride Synthesis Macro Scale Procedure: Obtain vial of t-Butyl (or t-Pentyl) Alcohol from instructor’s desk Note: Melting point of t-Butyl Alcohol is near room temperature and could be solid if lab is cold. Warm vial with hands to melt Weigh the vial and contents; record in pre-lab Setup cork ring on iron ring to support funnel Transfer sample to 125 ml Separatory Funnel using a long stem glass funnel Reweigh the vial. In your report calculate the Mass of tButyl (or t-Pentyl) Alcohol In your report compute the Moles of the Alcohol 1/17/2015 17 T-Butyl (t-Pentyl) Chloride Synthesis Macro Scale Procedure (Con’t): Add 25 mL, measured to nearest 0.1 mL, of concentrated HCl to the separatory funnel In your report calculate Mass of HCL (vol(mL) * density(g/mL) * % comp (37.3)) In your report compute the moles of HCL Note: As an alternative, the Moles of HCl can be computed directly from the Volume and Molarity of Conc. HCl. (Back calculate to get mass) 1/17/2015 In your report set up the Stoichiometric Equation, determine the Limiting Reagent, and calculate the Theoretical Yield 18 T-Butyl (t-Pentyl) Chloride Synthesis Macro Scale Procedure (Con’t): Stopper the funnel, firmly holding the stopper with your finger, and gently swirl the mixture for approximately one (1) minute Invert the funnel and slowly open the stopcock to vent pressure Close stopcock; swirl the mixture again; and again release the pressure Repeat this process for 3-4 times until gas release is minimized Two layers will form in the funnel Note: Based on the densities of the organic layer and the aqueous layer (H20, HCl, etc.) determine which layer is on top 1/17/2015 19 T-Butyl (t-Pentyl) Chloride Synthesis Drain the aqueous reaction mixture into a large beaker In the following steps the organic layer will be extracted once with Water, two (2) times with Sodium Bicarbonate (NaHCO3), and again with water The Extraction procedure must be done in an expeditious manner as t-Butyl (t-Pentyl) Chloride is unstable in Water and Sodium Bicarbonate Note: This can be one Procedure ● Retain the organic fraction in the Separatory Funnel and the separated aqueous fraction in the waste beaker 1/17/2015 20 T-Butyl (t-Pentyl) Chloride Synthesis ● Add 10 ml of Distilled Water to the crude product in the separatory funnel ● Swirl the mixture for 30 seconds ● Carefully invert the funnel and slowly open the stopcock to release any excess gas ● Close the stopcock and repeat the mixing/venting process for about 60 seconds ● Drain the aqueous phase into the waste beaker ● Retain the organic phase (top layer) in the separatory funnel 1/17/2015 21 T-Butyl (t-Pentyl) Chloride Synthesis ● Add 10 mL of 5% aqueous Sodium Bicarbonate (NaHCO3) to the funnel containing the organic layer ● Note: The Sodium Bicarbonate reacts with any aqueous acid (HCL) in the organic layer releasing Carbon Dioxide gas Be careful when venting the gas! ● Repeat the mixing and venting process several times until gas is no longer being vented ● Allow the layers to separate; and drain the aqueous layer again into the waste Erlenmeyer flask ● Repeat the washing process with a second 10 mL portion of 5% NaHCO3 ● Wash the organic layer again with 10 mL Distilled Water 1/17/2015 22 T-Butyl (t-Pentyl) Chloride Synthesis After removing the aqueous layer to the waste beaker, drain the organic layer into a 100 mL, clean, dry beaker With instructors help, add Anhydrous Sodium Sulfate to the crude product, swirling the mixture until it is clear Note: See p. 695-699 in Pavia for techniques on determining dryness of sample Transfer the clear product into a clean, dry, pre-weighed 50 mL Erlenmeyer flask Weigh the flask and contents Determine the mass of product by difference Calculate the percentage yield Determine the Refractive Index; Correct for Temperature Obtain IR Spectrum 1/17/2015 23 T-Butyl (t-Pentyl) Chloride Synthesis Semi-Micro Scale Procedure (Do not use this procedure unless specifically instructed to do so by Instructor) Obtain vial of t-Butyl (t-Pentyl) Alcohol ( 4 mL) from instructor’s desk Note: Melting point of t-Butyl Alcohol is near room temperature and could be solid if lab is cold. Warm vial with hands to melt Weigh the vial and contents to nearest 0.001 g; record in notebook Transfer sample to Centrifuge Tube using a long stem glass funnel Reweigh the empty vial Calculate Mass of t-Butyl Alcohol Calculate Moles of t-Butyl Alcohol 1/17/2015 24 T-Butyl (t-Pentyl) Chloride Synthesis Semi-Micro Scale Procedure (Con’t): Add 8 mL, measured to nearest 0.1 mL, of concentrated HCl to the Centrifuge tube In your report calculate Mass of HCL from the Volume, Density, % composition Note: This calculation is different from Alcohol mass, therefore, it is a separate procedure Compute Moles of HCl Note: As an alternative, the Moles of HCl can be computed directly from the Volume and the Molarity of Conc. HCl In the report, setup the Stoichiometric balanced equation Determine the Limiting Reagent 1/17/2015 25 T-Butyl (t-Pentyl) Chloride Synthesis Semi-Micro Scale Procedure (Con’t): Calculate the Theoretical Yield Note: Each computation in the Limiting Reagent/ Theoretical Yield determination must be set up and all calculations shown Screw the sealing cap onto the Centrifuge Tube and shake the tube gently for about 10 minutes. Be sure to unscrew the cap carefully every minute or so to vent any gases that may form Two layers will form in the funnel 1/17/2015 Note: Based on the densities of the organic layer (t-Butyl Chloride) and the aqueous layer (H20, HCl, etc.) determine which layer is on top Remove the Aqueous layer using a Pasteur Pipet Place the aqueous waste in a waste beaker 26 T-Butyl (t-Pentyl) Chloride Synthesis Semi-Micro Scale Procedure (Con’t): The Extraction procedure that follows must be done in an expeditious manner as t-Butyl Chloride is unstable in Water and Sodium Bicarbonate Extract (wash) the organic product, once with 10 mL Distilled Water, twice with 10 mL 5% Sodium Bicarbonate (NaHCO3) and once again with water Be sure to vent gases carefully, especially with NaHCO3 Note: This is one Procedure 1/17/2015 Each time, remove the Aqueous layer using a Pasteur Pipet Place the aqueous waste in the waste beaker 27 T-Butyl (t-Pentyl) Chloride Synthesis Semi-Micro Scale Procedure (Con’t): Add Anhydrous Sodium Sulfate to the crude product, swirling the mixture until it is clear Note: See p. 713-716 in Pavia for techniques on determining dryness of sample 1/17/2015 Decant the clear material into clean, dry, pre-weighed Erlenmeyer Flask Weigh the flask and contents Compute mass of product by difference Compute the % yield Determine the Refractive Index; Correct for Temperature Obtain IR Spectrum 28 T-Butyl (t-Pentyl) Chloride Synthesis 1/17/2015 The Report The “Purpose” should reflect the type of reaction and principle reactants involved. It should also reflect introduction of any new techniques that you are to become familiar The “Approach” is a sequential step by step overview of the principle procedures to be used, including calculations, such as mass, moles, limiting reagent, and theoretical yield determinations It should also reflect how the results will be quantified, such as yield and percent yield The “Procedures” should be stated in the student’s own words, using short, concise statements in “List” form 29 T-Butyl (t-Pentyl) Chloride Synthesis The Report (Con’t) In the “Summary” section summarize the “Results”, i.e. an overview in paragraph form of the experimental results obtained In the “Conclusion” section consider the following questions: ● What was the Molar ratio of HCl to t-Butyl Alcohol and what was the impact of this ratio on the selection of the Limiting Reagent and the amount of product expected? ● Provide details of the Refractive Index and IR Spectrum analysis confirming the product obtained was indeed t-Pentyl Chloride 1/17/2015 30