2013/14 HKPC Annual Report Value One Minute Annual Report

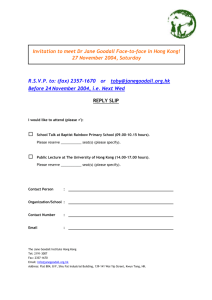

advertisement