Report

advertisement

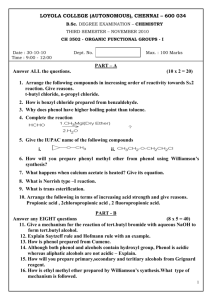

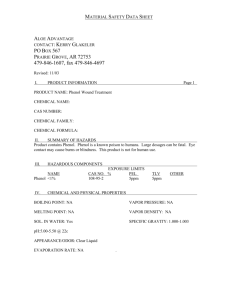

KUWAIT UNIVERSITY Literature Survey Phenol Production By Cumene Peroxidation Group 1 Introduction: phenol are a manufactured class of weakly acidic compounds that is soluble in water , they are related to organic compounds , that naturally occur in most of food production ,also used as a slimicide , disinfectant in medical issues . Phenols are also called phenolics; they are class of aromatic organic compounds that consists of one or more of hydroxyl groups that are attached to an aromatic hydrocarbon group. Phenol is a benzene cycle derivative, it's the simplest part of the phenolic chemicals, its chemical formula is C6H5OH, and its structure is a hydroxyl group (-OH) bonded to phenyl group. Synonyms of phenol include carbolic acid, benzophenol and hydrobenzene. It is found Solid in the natural state at a temperature of 25 Celsius, Mild acidity, Needs handled carefully to avoid burns; it is used in industrial processes since Extracted directly from crude oil and is considered basic material for the manufacture of many materials, such as plastics, building materials, medicines and polymers. HISTORY: Phenol was detected the first time in 1834 where it was extracted from tar, In 1912 was used phenol disinfectant for wounds in medical surgery operations, Germans used phenol in World War II to kill prisoners by injecting their bodies. World production and consumption: Country phenol capacity in thousands of tons per year united states 1430 Japan 1230 Korea 530 Taiwan 380 Saudi Arabia 640 China 200 Italy 480 Brazil 1870 Spain 600 Kuwait 600 France 195 Company Ineos Phenol Sunoco Mitsui Shell CEPSA Quimica Polimeri Europa FCFC MtVemon Phenol(sabic) Kumho Dow Taiwan Prosperity Mitsubishi chemicals Ghiba Phenol Georgia Gulf LG Chem Chang Chun PC Rhodia NOVAPEX Phenol capacity in thousands of tons per year 1870 800 750 600 600 480 400 340 330 300 200 250 230 230 200 200 195 180 Bisphenol A accounted for 49% of global phenol consumption in 2010, followed by phenol-formaldehyde resins at 25%. Bisphenol A and phenol-formaldehyde resins are produced in all regions. USES: Phenol is used in building materials, transportation, detergents and medical products drops ear, nose,Mouthwash,Aspirin),Phenol prevents to Kabrulaktam for making nylon, Mistake contains phenol, a substance important medical; Phenol is used in the execution Of cosmetics and sun shields and hair dyes, Phenol is used in cosmetic surgery, where he Is still dead skin. Physical and chemical properties : Oxygen Molecular weight 32 g/mole Molecular formula O2 Boiling/condensation point -183 °C (-297.4°F) Melting/freezing point -218.4 °C (-361.1°F) Critical temperature -118.6°C(-181.5°F) Vapor density 1.105 (air =1) Specific volume (ft3/lb) 12.0482 Gas density (lb/ft3) 0.083 Cumene Molecular weight 120.2 g/mole Color Clear colorless Boiling point 152.4°C (306.6°F) Melting point Physical state and appearance Specific gravity Vapor pressure Vapor density Oder threshold Water/oil dist.coef. Solubility -96 °C (-140.8 °F) liquid 0.862 (water=1) 8mmof Hg (@20°C) 4.41 (Air=1) 1.2ppm 3.7 Very slightly soluble in cold water Phenol Physical state and appearance Solid Odor distinct, aromatic , somewhat sickening sweet Taste burning Molecular weight: 94.11 g/mole Color: colorless to light pink Boiliong point 182 c Melting point 42 c Critical temperature 694.2 c Specific gravity 1.057 Vapor density 3.24 Odor threshold 0.048 ppm Water /oil dist.coff 1.5 Solubility easily soluble in cold water . hot water Acetone: Physical state and appearance Liquid. Odor Fruity. Mint-like. Fragrant. Ethereal Taste Pungent, Sweetish Molecular weight 58.08 g/mole Color colorless Ph not available Boiliong point 56.2 c ( 133.2 f ) Melting point -95.35 c( -139.6 f) Critical temperature 235 c ( 455f) Specific gravity : 0.79 ( water =1 ) Vapor density 2 ( air =1 ) Volatility not available Odor threshold 62 ppm Water /oil dist.coff -0.2 Lonicity ( in water ) : not available Dispersion propertiers see solubility in water Solubility easily soluble in cold water . hot water Process description: Phenol production routes: Phenol can be produced by 3 main routes; 1) Cunene peroxidation process 2) Chlorobenzene – sulfunation process 3) Sulfunation process In our literature survey we will concentrate on cumene peroxidation process because it is very well known in which 95% of phenol world production is manufactured using this route. As for the other two routes we will not consider them as useful routes for the following reasons: 1) Lower conversion per pass in chlorobenzene – sulfunation process. 2) The sulfunation process requires operating with high temperature which means more recurring costs as well as using large batch cycles with lower productivity Cumene peroxidation process: Cumene production: Cumene is produced by mixing benzene with propylene in the presence of acid catalyst. This mixing process is also known as alkylation process. In the alkylation reaction the most commonly used catalyst is zeolite because it gives 99% yield cumene Phenol production: The production of phenol occurs with two main reactions, the first one is cummene oxidation to cumene peroxide which is the intermediate product of the reaction. Fresh cumene is pumped into a drum while recycled cumene is being treated with water and weak caustic in order to remove organic acids. In addition, cummene from AMS hydrogenation section is being added to fresh cummene feed as well as the concentration section and acetone refining section. The treated cumene is combined with fresh cumene to enter the oxidizer at PH (6-8) and temperature (110°c - 115°c) with 25% conversion. The lower the temperature of the operating conditions of the oxidizer the lower the conversion. Two oxidizers are being used in the oxidation process. then the product which contains cumene peroxide, water, and unconverted cumene is being cooled before it is introduced to the charcoal absorbers were spent air is being released and the remain mixture enters a decanter were the remain cumene is desorbed with low pressure followed by condensing steam and cumene decantation .next, the decanted cumene enters a caustic was to treat the cumene with weak caustic before combining it to the fresh feed. Concentration section: Cumene hydro-peroxide (CHP) is concentrated to 75 – 85 wt % before it is decomposed to phenol and acetone The concentration section recovers UN reacted cummene. CHP is being concentrated by vaporizing cumene in a preflash coloumn at low pressure; the 2 columns are operated under vacuum to minimize the temperature needed to concentrate CHP. Vacuum can be generated by an ejector system. The concentrate CHP is then introduced to the decomposition section Decomposition section: This section involves the decomposition of concentrated CHP in the presence of the sulfuric acid catalyst at a medium temperature of 70°c - 80°c This section provides the plant with high phenol yield and conversion of dicumylperoxide to AMS with a yield of 90% Sulfuric acid is injected via injection pumps to provide the catalyst required for CHP decomposition to phenol and acetone. the effluent from the decomposer is heated using medium pressure steam such that DMPC ( dimethylphenylcarbinol ) traces are dehydrated at a very high yield of DCP ( dicumylperoxide ) to AMS (alpha-methylstyrene ) 90% yield is achieved Neutralization section: Acid catalyst is added in the decomposition section must be neutralized. This section is very important to prevent yield loss due to side reaction Also it's very important to avoid corrosion in the units required. The section is neutralized by injecting an amount of diamene which does not need to be removed which means lower capital cost because we don’t need a separator. In addition it doesn’t require water addition so we don’t have to deal with waste water treatment. Acetone refining section: Acetone is one of the main by-products of CHP oxidation. The plant production economics depends on the production of high quality acetone ( 99% pure) . Water is injected to the crude acetone column in order to increase the volatility and maintain the bottom temperatures. The most common impurities are removed from acetone columns are aldehydes Most phenol producers use gas chromatography to indentify aldehydes in order to separate them. Caustic is injected to the finished acetone column to catalyze trace aldeyhdes. High purity acetone flows by gravitational force as a side stream product from the acetone fractionation column. Waste water is being separated from cumene and sent to the sewer while the separated cumene is sent back to the cumene oxidation section Structured packing column is used in acetone refining for cost reduction Phenol fractionation and purification process flow: Further purification of crude phenol is used to achieve desired purity specifications. The purpose around this section is to recover cumene and AMS. Chemical agents are used to remove carbonyl impurities. A chemical treatment reactor effluent enters the crude phenol column were heavy components are distilled to the bottom of the column while distilled heavies enter a stripper for removal of residue byproduct. In the final stripping phenol is controlled at low pressure in a manner that no high pressure steam is required. On the other hand, small impurities are removed from the top of the crude phenol column by pasteurizing section, a side cut is taken from the crude phenol column to IX resin acid catalyst to catalyze methyl-benzo-furans and residual AMS then enters a phenol rectifier in order to produce high quality phenol and recycle back heavy components from the phenol rectifier Cumene from cumene/AMS column enters a phenol recovery unit were it is washed with caustic and sent to AMS hydrogenation section In the AMS caustic wash column, sodium phenate is formed and mixed with sulphuric acid before entering the PRU separator which separates sprung phenol from the aques solution. The aques solution is introduced to oil extraction column and scrubbing column with makeup cumene and caustic to from sodium phenate. Sodium phenate is recycled back to the PRU separator. Waste water is treated and pumped to the sewer AMS hydrogenation section: This process is made in the presence of a catalyst system that contains lead and operates at a moderate pressure. This catalyst system operates with a very low deactivation rate. In this section AMS is hydrogenated to Cumene and fresh feed of cumene/AMS from phenol in addition to reactor effluent with hydrogen are mixed together and enter reactor number 1 were highly exothermic hydrogenation reaction of AMS is converted to cumene . The effluent is splitted such that it is cooled and recycled back to reactor 1. The other split enters a second rector to assure full conversion of AMS to cummene. The effluent of the second reactor is cooled and separated to give off gas and cummene which is recycled to the oxidation section Benzene Sulfonation process : This is one of the routes used in phenol production by converting a benzen cycle to phenol with presence of inorganic acids and salts . In this process , we will need different types of seperation such as ; filteration (pressure filter , centrifuge ) to seperate sodium sulphate and sodium sulphite , distillation to seperate phenol from crude phenol , crystallization for seperation and recovery of sodium sulphite . Reactions : 1) Sulphonation - C6H6 + H2SO4 ----> C6H5SO3 + H2O Benzen reacts with sulphonic acid to benzen sulphonic acid 2) neutrlization : C6H5SO3 + Na2SO3 -----> C6H5SO3Na benzen sulphonic acid is neautrlized by adding sodium sulphite to form sodium sulphonate . 3) Fusion Reaction : C6H5SO3Na + NaOH ----> C6H5ONa Sodium benzen sulphonate fused with addition of sodiumhydroxide to produce sodium phenoxide . 4) Acidification : C6H5ONa + H2SO4 ----> Na2SO3 + C6H5OH Sulphuric acid and sodium phenoxide are reacted to produce crude phenol and soudium sulphite Process description : -The process is a batch cycle operated due to slow reaction fusionator (reactor) sodium benzen sulphonate is fed to fusinator(reactor) made of iron , in presence of molten caustic soda . the reaction takes from 5 to 6 haours to be achieved . its a countinuos proccess in loading and unloading .after that , sodium phenoxide that is produced is fed to an acidifier to produce crude phenol as a product of a reaction of sodium phenoxide with sulfuric acid and sulphur dioxide . A vacuum distillation is used to seperate phenol from crude phenol , the remain impurties are sent to a stripper to remove remaining phenol , crystallizers(seperator) are used to increase the purity of sodium sulphite that is used in the neutrlizer , the crystals found are recycled to neutrlizer . Operation condition : T = 300 P = 170 atm Disadvantages : - The sulfunation process requires operating with high temperature and high pressure which means more recurring costs . - large batch cycles with lower productivity. Chlorobenzne and Caustic process for phenol production: - For this process we found that 1 ton of phenol we will have approximately the raw materials needed for this process 0.90 tons of benzen , 0.82 tons of chlorine , 0.67 of NaoH , 0.51 of HCL . Route Reactions : 1) Chlorination C6H6 + Cl2 ---> 850C , Fe- --> C6H5Cl (Chlorobenzene) 2) Causticization C6H5Cl +NaOH (aq)---> C6H5NaO\ 3) Hydrolysis C6H5NaO + HCl(aq) ---- > C6H5OH + NaCl(aq) Process description : in this process , benzen reacts with chlorine in presence of a catalyst which is iron at a temprature of 85 centigrades to form chlorobenzen in a chlorine tower . the remained benzen after this section will be recycled , monochlorobenzen will be pulled out and excess chlorine is used to neuterlize the chlorobenzen , in addition of 10% of caustic soda mixed with chlorobenzen and reacted with it . this reacted mixture will react with hydrogen and produce water vapors that is removed . the final product diphenyl oxide is pumped to a heater , then passed to a multi tube reactor to achieve a custicization reaction that occurs at 425 centigrades and a pressure of 350 atm , then passed to a neutrlizer . then, phenol is found by hydrolysis with HCL that occurs at the neuterlizer , in the neutrlizer the diphenyloxide is concentrated to form phenol and sodium chloride (salt ) which represents a side product of the process , sodiumchloride is seperated and sent to an electrolysis unit , upper streams sends the remained to a vacuum distillation and phenol is stripped out . - 95% of diphenyloxide is removed to recycle then a small amount of phenol yeild . Operating conditions : T = 425 c P = 350 atm Disadvantages : - its not a highly recomended because HCL corrosion in chlorobenzen plant section. - High pressure vessel design for the causticization reactor. - High cost with low profits campared with other routes . Economic analysis: C + O2-------------> P + A # of mole Mwt(lb/lbmole) weight(lb) Price($/lb) weigth/weight P C 1 120.2 120.2 0.54 1.277 O2 1 32 32 0 0.34 Profit = (0.617*0.82)+(0.9*1) – (0.34*0) – (0.54*1.277) = 0.71636 $/lb P 0.71636 $/lb P * (200*10^6 )*0.9 = 128,944,800 $/yr Profit = 128,944,800 $/yr P 1 94.11 94.11 0.9 1 A 1 58.08 58.08 0.82 0.617 Conclusion: The process that we have chosen to explain about in detail is the cumene peroxidation reaction because it is very well known and produces high purity, high yield phenol with a valuable by product acetone, unlike other routes which involves dealing with corrosive and less valuable materials Recommended flow sheet: It is a combination of zoomed in flow sheets from Sunoco Company that are used in this literature survey due to the presence of the detailed process of phenol production . patents: 1) Patent application title: Process for Producing Phenol Inventors: John S. Buchanan (Lambertville, NJ, US) Jon E. Stanat (Westhampton Beach, NY, US) Tan-Jen Chen (Kingwood, TX, US) Jihad M. Dakka (Whitehouse Station, NJ, US) James R. Lattner (Laporte, TX, US) James R. Lattner (Laporte, TX, US) IPC8 Class: AC07C3708FI USPC Class: 568798 Class name: Benzene ring containing phenols (h of -oh may be replaced by a group ia or iia light metal) preparing by cleavage of hydroperoxide or other peroxide Publication date: 2011-05-05 Patent application number: 20110105805 2) patent number : 4,358,618 United states patent Inventors : stylanios sifnoids Madison ; allen A.Tunick , botoni , fred w koff long valley all of NJ Assignee : allied corporation morrice, township , morris countey , NJ Appl NO : 276,233 Filled :22 june 1988 References: http://en.wikipedia.org/wiki/Phenol http://enggyd.blogspot.com/2010/09/cholorobenzene-caustic-process-for.html http://enggyd.blogspot.com/2010/07/phenol-manufacturing-process.html Industrial catalytic process – phenol production http://Icis.com http://www.ihs.com/products/chemical/planning/ceh/phenol.aspx