2016_FBWW_Presentation

advertisement

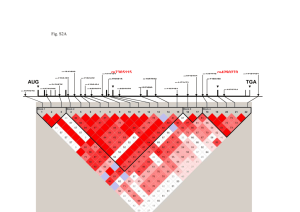

The OSU Barley Flavor Project Dustin Herb Ph.D. Candidate The OSU Barley Project Oregon State University January 17th, 2016 Goals • Determine if flavor differences within modern barley varieties exist. • Identify factors that influence flavor difference. • Develop methods to select for barley flavor. • Genetically map gene(s) controlling the flavor expression within barley. Willamette Flavor • 3 varieties (Full Pint; Copeland; Klages) grown in Lebanon, OR in yield strips. • Malted at the CMBTC. • Brewed at New Glarus Brewing Co. and Sierra Nevada Brewing Co. • In house sensory, BIC sensory, and OSU sensory. • Difference test – revealed that flavor differences were present among the three varieties. Farm Malted New Glarus Sierra Nevada Sensory Sensory BIC Sensory OSU Sensory 3 Varieties x 3 Locations • 3 varieties (Full Pint; Metcalfe; Klages) grown in 3 locations (Oregon; Minnesota; Saskatchewan). • Malted at Rahr Malting Co. • Wort Sensory and analytics at Sierra Nevada Brewing Co. • Genotype x Environment interaction flavor effect. Flavor Variety Environment G X E Rep Total Taste X Malt X X X Fruity X X X Chocolate X X Toffee X X Vegetable X X Dairy X Woody Chemical X X X X X AROMA COMPOUNDS Flavor Buttery Cheesy Waxy Nutty Nutty Nutty Bready Roasted Chocolate Spicy Green Floral Fruity Ethereal Aldehyde Chemical Sulferous Aroma Compound 2, 3-butanedione Butyric acid Nonanoic acid 2-ethyl-3,5-dimethyl pyrazine 2,6-diethyl pyrazine 2-acetyl furan Furfuryl alcohol 2-formyl-1-methyl pyrrole 2-methyl butanal 2-methyl propanal phenyl acetaldehyde phenyl ethyl alcohol ethyl hexanoate ethyl acetate 3-methyl butanal 2-ethyl furan dimethyl sulfide Top Variety Full Pint Metcalfe Full Pint Full Pint Metcalfe Klages Full Pint Klages Full Pint Metcalfe Metcalfe Metcalfe Metcalfe Full Pint Full Pint Full Pint Full Pint SENSORY Top Environment Oregon Minnesota Oregon Minnesota Oregon Oregon Minnesota Minnesota Oregon Minnesota Oregon Minnesota Minnesota Oregon Oregon Oregon Minnesota Flavor Taste Dairy Malty Toffee Roasted Chocolate Fruity Vegetable Chemical Dirty Top Variety Klages Full Pint Full Pint Full Pint Full Pint Full Pint Metcalfe Metcalfe Klages Metcalfe Top Environment Saskatchewan Oregon Oregon Oregon Oregon Oregon Minnesota Oregon Oregon Minnesota Enzyme Brewing – Assessing the Malting Effect • Determine what flavor compounds are present in barley. • Determine a flavor baseline for barley. • Evaluate the persistence of barley and malt flavor compounds throughout the brewing process. • Same source barley, ½ malted, ½ brewed with Ondea Pro®. • Identical brewing recipe. Brewing parameters for the barley grain and barley malt brews at Oregon State University pilot brewery in Corvallis, OR Target Gravity Mashing Regime Kettle Boil Bitterness Rest I: Rest II: Rest III: 32 g / hl Iso15˚P 30 min, 60 min, 15 min, 60 min Alpha-Acids 54C 64C 78C Yeast/rate 1056 Ale yeast (%) Ferment ABV Length 5.5 14 days Finished beer measurements for barley grain and barley malt samples at the Oregon State University pilot brewery in Corvallis, OR Beers Real Color Turbidity Apparent RDF Extract (˚SRM) (NTU) Extract (˚P) (%) (˚P) pH ABV Bitterness (%) (BU) Barley 3.91 0.038 3.2 5.3 66.8 4.85 5.22 16.4 Malt 4.43 0.042 1.7 4.5 72.2 5.13 5.96 15.6 Barley vs. Malt beer flavor Malty 8 Bitter Nutty 7 6 5 Sweet Bread 4 Barley 3 2 Body Toffee 1 0 Malt Mouthfeel Grainy Boozy Fruity Grassy Floral Oregon Promise Pop’n • Golden Promise x Full Pint • 202 double haploid population. • Golden Promise is an iconic variety for malting, brewing, and distilling. • Full Pint is a contributor to the craft brew Renaissance. • The Oregon Promise will provide a valuable resource for extending current knowledge of malting and brewing genes to the frontiers of sensory assessment. Testing Environments Corvallis, OR Madras, OR Lebanon, OR • 37 agronomic selection + parents grown in all three locations. • 14 random selection grown only in Corvallis, OR. Micro-malting & Malt analysis Malt Quality Sample Full Pint Golden Promise Control Parents & Control Color DP Ext Plump Moist pH AA BG Prot Turb Viscos AVG 83.50 381.33 1.46 156.00 78.41 10.30 4.95 5.99 40.78 5.27 1.12 STDEV 7.99 17.93 0.25 12.17 0.93 2.17 1.16 0.07 1.65 0.91 0.97 %CV 9.57 4.70 16.96 7.80 1.19 21.03 23.48 1.11 4.04 17.23 86.65 AVG 42.67 461.00 1.50 119.00 76.65 33.47 6.20 5.83 31.80 19.03 1.09 STDEV 4.38 155.19 0.26 38.20 1.70 11.27 1.80 0.02 3.61 7.60 0.94 %CV 10.25 33.66 17.17 32.10 2.22 33.68 29.06 0.34 11.35 39.94 86.61 AVG 63.53 97.33 1.35 139.00 79.15 16.60 4.70 5.92 40.29 4.30 1.01 STDEV 11.46 120.56 0.33 17.06 1.24 9.37 0.96 0.07 5.38 1.23 0.87 %CV 18.03 61.09 24.39 14.34 1.57 56.46 20.36 1.12 13.36 28.58 86.79 Malt Quality Malt quality of agronomic Oregon Promise selections from all environments (Corvallis, OR; Lebanon, OR; Madras, OR) analyzed by Rahr Malting Co. in 2015. Agronomic Selections Sample COR LEB MAD AA BG Color DP EXT Plump Moist pH Prot Turb Viscos AVG 57.52 281.76 1.52 109.05 77.40 21.31 4.95 5.88 35.01 9.39 1.63 STDEV %CV 15.80 27.47 198.93 70.60 0.23 15.47 26.47 24.27 1.49 1.92 8.07 37.88 1.78 35.99 0.07 1.12 8.33 23.78 8.11 86.38 0.12 7.63 AVG 50.02 383.95 1.47 114.05 77.92 14.15 5.41 5.95 34.05 12.26 1.31 STDEV CV% 12.57 25.13 227.90 59.36 0.22 15.19 27.06 23.72 1.76 2.26 6.38 45.06 2.04 37.67 0.06 1.05 7.12 20.91 10.02 81.70 0.71 54.31 AVG 47.49 524.05 1.31 136.19 75.17 25.48 4.81 5.87 33.54 15.43 1.67 STDEV CV% 12.35 26.01 279.69 53.37 0.17 13.26 25.57 18.77 1.51 2.01 15.51 60.89 1.32 27.44 0.05 0.81 3.99 11.88 16.74 108.49 0.47 27.91 Malt quality of random Oregon Promise selections from Corvallis, OR environment analyzed by Rahr Malting Co. in 2015. Random Selections Sample COR AA BG Color DP EXT Plump Moist pH Prot Turb Viscos AVG 70.83 127.57 1.61 118.93 76.70 32.98 5.22 5.84 39.84 5.54 1.55 STDEV CV% 19.62 27.70 95.64 74.97 0.23 14.40 25.48 21.43 1.33 1.74 8.40 25.48 1.49 28.52 0.06 0.95 8.05 20.22 1.77 32.01 0.08 5.06 Nano-brewing 1. Malt samples were milled. 2. 75g of malt grist and ~400 mL of water was placed in mash bath cans. 3. Mash cans are brought to standardized volume of 450 mL. 4. Congress mash is poured over Ahlstrom filters. 5. Wort was filtered three times for clarity. 6. Final wort was collected. 2 4 3 5 6 Nano-brewing 7. IsoHop® is added to the congress wort and boiled for 35 min. 8. Residual sediment and trub filtered out with Ahlstrom filters. 9. WhiteLabs Czech yeast pitched and wort ferments in tube at 9°C. 10. Beer is centrifuged, bottled, and carbonated then conditioned. 7 9 8 10 Sensory Comparison to reference • Difference testing • Descriptive analysis ~13 experimental beers 2 parental beers - FP & GP 1 internal standard - Rahr Pils 1 embedded reference - Miller High Life 17 beer sample/session 10 tasting sessions X ~170 beer samples tasted Full Pint 0.2 0.18 0.16 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 FRUIT Golden Promise Full Pint 0.25 0.2 0.15 0.1 0.05 0 0 1 2 3 MALT 4 5 6 2 3 Full Pint Relative frequency 0.3 Golden Promise 0.25 0.2 0.15 0.1 0.05 0 0 1 2 3 4 TOFFEE 5 FLORAL 0.4 0.35 4 6 7 FRUIT TOFFEE Relative frequency Golden Promise 0.3 Relative frequency Relative frequency MALT 5 6 7 0.2 0.18 0.16 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 Golden Promise Full Pint 3 3.5 4 4.5 FLORAL 5 5.5 Parents & Reference 3 2 SWEET Reference ROASTED FLORAL Reference Reference Reference FRUITGolden PromiseGolden Promise Reference Golden Promise Reference BITTER Full Pint Reference Golden Promise Reference CEREAL Golden Promise Reference Full Pint Golden Promise TOFFEE Full Pint Golden Promise BREAD Full Pint Golden Promise MALT GRASS Full Pint Full Pint Full Pint ASTRINGENT GRAIN Full Pint Golden Promise Full Pint Golden Promise F2 (18.01 %) 1 0 -1 -2 Full Pint -3 -4 -3 -2 -1 0 F1 (42.84 %) 1 2 3 4 Environment Biplot 3 COR COR 2 COR COR COR LEB CORASTRINGENT COR BITTER COR LEB LEB GRAINCOR COR COR MAD COR LEB COR LEB COR MAD COR MAD COR GRASS COR CEREAL LEB MAD LEB COR COR LEB MAD COR LEB CORCOR MAD LEB MAD MAD LEB LEB LEB ROASTED COR LEB LEB COR MAD LEB COR COR COR FRUIT LEB COR MAD COR LEBCOR LEB MAD MALT MAD BREAD TOFFEE LEB MAD FLORAL LEB COR LEB LEB SWEET COR LEB COR LEB MAD LEB MADMADMAD LEBMAD MAD COR LEBLEB MADMAD MADLEBMAD MAD LEBLEB LEB LEB LEB COR COR MAD MAD MAD MAD LEB MAD LEB MAD MAD MAD MAD MAD MAD 1 F2 (14.89 %) COR 0 -1 LEB MAD -2 COR MAD MAD -3 -4 -3 -2 -1 0 F1 (38.54 %) 1 2 3 4 Flavor Comparison FRUIT ASTRINGENT FLORAL BITTER GRASS SWEET GRAIN ROASTED CEREAL TOFFEE MALT BREAD 120145a 120156a FULL PINTp GOLDEN PROMISEp 120031 New Glarus Brewing Co. Full, Malty, Smooth, Rich, Nice! - Best "Euro" Type 120058 Nice Foam, Clean, Smooth - Best "American" Type 120090 Best Foam, Sweet, Clean, Mild 120145 Balanced Malty and Hoppy, Clean, Sweet 120285 Sweet, full, very clean, bread, malt Malty, Toffee, Caramel, Vanilla, Papery Malty, Nutty, Floral, Phenolic, DMS 120322 Malty, sweet / dry, morish, low color Malty, Toffee, Caramel, DMS 120331 Light, clean, malty, sulfur, Euro, juicy, nice Diacetyl, DMS, Worty 120341 Sweet, full, biter after taste, malty, clean 120359 Wow, malty, biscuit, sweet, candy, floral Acidic, Sour, Tart, Rubber Fruity, Floral, Sweet 120373 Coffee! Roasted bitter, "White Stout"?, very unique Malty, Worty 120744 Malty, bread, European, very nice Nutty, Bananas, Floral Full Pint Full, malty, European Malty, Sweet, Popcorn, Grain, Grass Golden Promise Harsh bitterness Rahr Malting Co. Malty, Toasted/Bread, Roasted/Toffee Honey, Nutty, Floral Herbaceouse, Earthy, Green Apple Fruity, Floral, Grass/Green, Astringent Gas Chromatography-Mass Spectrometry • Identify aroma compound peaks. • Determine if significant compound(s) affect sample flavor. • Track compound deviation from parental genotypes. • Identify compounds that will be useful in flavor selection programs. GC-MS 1.6e+006 1.4e+006 1.2e+006 1e+006 800000 600000 400000 200000 0 Time (s) 1210 1220 1230 TIC 13-FP:1 1240 1250 TIC 13-GP:1 1260 TIC 13-13:1 1270 1280 TIC 13-11:1 1290 1300 GC-MS COMPOUND FLAVOR 1-Butanol Bananas, Sweet 1-Hexanol Fruity, Sweet, Oil, Green, Ethereal 1-Octanol Fruity, Floral, Citrus 1-Propanol Alcoholic, Ethanol, Fruity, Apple, Nutty 2,3-Butanediol Fruity, Buttery 2-Heptanone Fruity, Coconut, Sweet, Spicy, Green Acetic acid Fruity, Sour, Vinegar Benzaldehyde Sharp, Cherry, Sweet, Almond Benzeneacetaldehyde Honey, Sweet, Floral, Rose, Cocoa, Spicy, Green, Earthy Benzothiazole Sulfur, Vegetable, Nutty, Coffee, Meat, Rubbery Isobutyl acetate Sweet, Fruity, Bananas, Tropic, Ethereal Isopentyl hexanoate Fruity, Pineapple, Sour Nonanal Rose, Orange peel, Cucumber, Fatty GC-MS Environmental biplot of aroma compounds 2.5 Parental biplot of aroma compounds 2.5 COR 2 FULL PINT 2 REF REFERENCE Acetic acid Acetic acid 1.5 1.5 MAD 1 F2 (19.34 %) F2 (19.34 %) 1 IsobutylREF acetate Benzeneacetald 1-Propanol ehyde REF 0.5 REF IsobutylREFERENCE acetate Benzeneacetalde 1-Propanol hyde FULL PINT REFERENCE 0.5 REFERENCE 0 0 MAD MAD 2-Heptanone -0.5 Benzaldehyde Isopentyl hexanoate MAD COR -1 -1.5 -2.5 -2 -1.5 LEB LEB REFREF 2,3-Butanediol 1-Octanol 1-Hexanol Nonanal LEB COR Benzothiazole COR -0.5 0 0.5 F1 (31.78 %) 1 1.5 -0.5 -1 LEB 1-Butanol -1 GOLDEN FULL PINT PROMISE 2-Heptanone Benzaldehyde -1.5 2 2.5 -2.5 Isopentyl hexanoate GOLDEN GOLDEN PROMISE PROMISE -2 -1.5 -1 -0.5 GOLDEN 2,3-Butanediol 1-Octanol FULL PINT PROMISE 1-Hexanol Nonanal REFERENCE REFERENCE GOLDEN Benzothiazole PROMISE GOLDEN FULL PINT PROMISE FULL PINT 1-Butanol 0 0.5 F1 (31.78 %) 1 1.5 2 2.5 11.0 12.0 18.2 11_11479 11_20415 12_30843 11_10451 26.7 47.0 55.3 55.7 56.0 56.2 61.2 67.5 68.2 83.6 12_31305 12_30880 11_10431 11_10153 11_11098 11_20975 11_11219 11_20771 11_10143 11_21448 12_31395 11_20092 109.5 117.3 122.3 123.9 130.9 12_20832 11_21160 11_20139 12_31325 11_20504 64.9 TKW_LOD:6.6_a:-1.3 12.9 H_LOD:5.0_a:-2.6 HD_LOD:9.4_a:1.2 BSR_LOD:4.3_a:4.1 DP_LOD:3.1_a:6.8 ME_LOD:5.9_a:-0.5 AA = Alpha H = Height WP = Wort Protein Amylase HD = Heading BD = Braird BC = Barley Color Date BSR14 = 2014 BG = Beta-glucan ME = Malt Extract Barley Stripe Rust BP = Barley P = Plump Protein SL = Spike Length BSR = Barley StripeFPD = sdw1 Rust (Dwarf) DP = Diastatic HD14 = 2014 Power Heading Date GPD = ari-e (dwarf S/T = Soluble/Total gene) Nitrogen LR = Leaf Rust TKW = Thousand FAN = Free Amino Kernel Weight Nitrogen WC = Wort Color Flavor QTL FAN_LOD:46.3_a:-39.4 BG_LOD:6.8_a:64.2 AA_LOD:56.5_a:-18.6 S/T_LOD:5.3_a:-4.9 WC_LOD:20.9_a:-0.3 WP_LOD:34.5_a:-0.6 FLAVOR 12_30382 11_20132 P_LOD:10.0_a:-2.1 186.9 187.5 ME_LOD:23.9_a:-1.0 12_30524 11_21422 11_10805 12_30929 11_10783 12_30930 11_10095 12_30869 12_30635 11_10819 11_21355 11_20829 11_10869 BC_LOD:5.5_a:-2.5 BG_LOD:6.6_a:-60.7 S/T_LOD:3.9_a:0.8 WC_LOD:4.3_a:0.1 90.8 92.6 98.5 106.1 106.2 106.3 106.4 107.4 111.2 118.2 132.0 146.3 148.5 TKW_LOD:28.4_a:-3.2 S/T_LOD:6.0_a:1.3 DP_LOD:3.3_a:-7.7 BP_LOD:6.9_a:-0.5 ME_LOD:15.6_a:0.8 P_LOD:3.8_a:-1.1 H_LOD:4.5_a:-2.8 HD_LOD:10.1_a:2.4 TKW_LOD:7.6_a:-1.4 DP_LOD:3.6_a:8.5 BC_LOD:9.2_a:3.1 SL_LOD:30.3_a:-0.9 11_21324 12_30214 11_10671 11_11221 11_20441 11_20645 11_11355 12_31427 11_20526 11_10518 11_21168 11_21061 11_11273 HD_LOD:4.6_a:-2.3 5H 0.0 12.5 14.4 14.9 16.4 30.3 35.4 36.5 42.0 43.4 57.6 60.5 63.0 BG_LOD:3.5_a:-41.8 3.1 6.0 6.1 19.6 27.8 BC_LOD:9.2_a:-3.2 0.2 12_30430 12_30856 11_10817 11_10462 11_21339 12_31289 11_20468 11_21025 11_10202 AA_LOD:9.0_a:-6.5 0.0 11_20722 12_30530 BG_LOD:2.8_a:37.4 11_20232 7H 0.0 2.9 S/T_LOD:52.1_a:-0.9 0.0 H_LOD:20.3_a:-6.3 44.0 44.3 45.9 48.2 52.3 HD_LOD:4.1_a:-1.5 12_31324 11_20557 11_20411 11_11180 11_10262 11_10946 11_10668 11_20939 12_30994 11_10467 11_21504 P_LOD:6.9_a:1.5 4H TKW_LOD:9.4_a:1.5 11_21212 H_LOD:9.9_a:3.8 51.8 43.8 SL_LOD:8.5_a:0.4 11_21187 11_21261 11_11073 11_10525 11_10399 11_10648 11_10342 11_10297 11_11054 11_21166 11_10265 11_11402 11_20667 11_20419 12_10859 11_21242 11_11100 11_11533 11_10876 11_10900 11_21340 11_11323 11_11480 12_20183 11_20590 11_10791 11_10710 12_30953 11_10335 12_30754 11_20778 12_31346 12_30663 12_31367 0.0 18.7 31.0 38.2 2H 0.0 4.7 23.2 23.7 24.2 24.7 25.2 30.4 31.3 36.3 39.3 42.8 43.6 45.8 51.3 55.0 57.3 64.4 77.8 78.8 82.3 85.7 86.8 109.4 124.8 146.6 6HA, 6HB 0.0 0.5 8.5 14.6 15.4 18.3 30.6 32.2 SL_LOD:4.8_a:0.3 3H SL_LOD:4.0_a:0.3 12_30918 12_30877 11_20712 11_10744 12_30336 11_10764 11_10438 12_31208 11_10552 11_20095 11_10516 11_10890 11_20990 11_20434 12_31160 11_21373 11_10522 11_20169 11_10911 11_20908 11_10586 11_10722 11_20383 11_10443 11_20772 0.0 16.0 23.9 27.7 37.4 38.4 41.2 41.8 47.1 47.5 49.6 56.3 58.9 69.1 71.1 71.8 78.6 79.0 0.0 1.6 3.6 3.7 17.1 23.5 25.1 FLAVOR 1HA, 1HB ? QTL Mapping Pop’n • Full Oregon Promise Population • Nano-brewing sensory • Pilot brewing trials with OP agronomic and flavor selections • Maris Beaver population (Full Pint x Maris Otter) • Winters & Facultative • Full Stein population (Full Pint x Violetta) • Winters & Facultative Exotic Barley Flavor • Screening 174 genetically diverse lines from the USDA Core Collection. • Micro-malted at Rahr Malting Co. • Wort analysis at Sierra Nevada Brewing Co. • Nano-brewed at New Glarus Brewing Co. and OSU. • Sensory at OSU. Modification Flavor • Degree of modification • Under-, Well-, Overmodification • Beta-glucan structure • High- & low-molecular weights • Environmental factors • Barley spec profile • Structural: Soluble carbohydrates ratio • Lipid and fat levels Barley Brand Projects Nitrogen – Protein Level and Amino Acid Flavor Barley “Terroir” Flavor Organic vs Conventional Flavor Effects Summary • Significant flavor differences detected between genotypes. • Random selections were highest in fruit, grass, cereal, malt, bread, and toffee flavors in Corvallis environment. • Significant flavor differences detected between environments. • Genotype x Environment effects detected. • Barley Flavor ≠ Malt Flavor • Distribution of sensory data indicates that exploratory sensory methods are effective in nano-brew samples. • Identification of aroma compounds segregation indicates genotypic differences for select compounds. • GC-MS is effective for high-throughput screening and characterization of “potential” flavor contributions. • Flavor QTLs discovered!!! Impact • Breeders • More tools on the tool belt (nano-brewing, sensory, GC-MS). • Marker Assisted Selection for flavor QTLs • Growers • Regional taste or “terroir” production. • Maltsters • Identification of production regions and/or farms with best agronomics and flavor. • Barley flavor specific malting (Custom malting). • Value added product and new markets. • Brewers • Product diversification. • Increased single malt brews. • Proprietary or exclusive varieties contracts. • Consumers • More choices. THINK BARLEY DRINK BARLEY