Chapter VI: Propulsion of ships (part2)

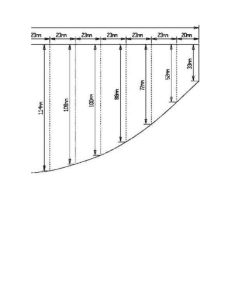

advertisement

6.6 Interaction between a hull & a propeller So far in the study of the resistance of a ship & its propeller the two have been considered separately. However, in reality the propeller has to work behind the ship & in consequence one has an interaction upon the other. How does the hull affects the water in which the propeller is working? (later we will also study the effects of a propeller on the hull) A ship affects the water near its stern in 3 aspects: 1) pressure increase at the stern; 2) boundary layer (a propeller is in the boundary layer or way of the ship); 3) Water particle velocity induced by ship generated waves. Wake fraction: water particle velocity near the propeller is not the same as the ship velocity. w Vs VA (Vs : ship velocity & VA flow velocity at its stern) Vs VA Froude wake factor: wF , VA Vs thus VA 1 wF Vs VA Taylor wake factor: wT , thus VA Vs (1 wT ) Vs The relationship between Froude & Taylor wake factor: wF wT 1 wF or wT wF 1 wT When VA Vs positive wake (most cases, a single screw) When VA Vs , nagative wake (only for high speed ship) wT & wF, (wake factors) are determined by the measurements made in a model test (near a hull’s stern) or in a real ship test. Nominal wake: wake measured near the stern of a hull in the absence of the propeller (using pilot tubes). Effective wake: wake measured in the presence of propeller. The measurements show that a propeller at a rotating speed n behind a hull advancing at velocity, Vs, delivers thrust T. By comparing it to the results of the same propeller in the open-water tests, we will find that at the same revolutions n, the propeller will develop the thrust T but at a different speed (usually lower), known as effective speed of advance, VA. The difference between Vs & VA is considered as the effective wake. •Relation between nominal wake & effective wake. Since propellers induce an inflow velocity which reduces the positive wake to some extent, the effective wake factor usually is 0.03~0.04 lower than the corresponding nominal wake. Wake factor of a single screw ship Averaged Wake Fraction Wake factor of a twin screw ship • Relative Rotation Efficiency The efficiency of a propeller in open water is called open-water efficiency, T VA 0 2 nQ0 where VA is the advance speed, T the thrust, n the rotation speed (# of rotations per unit time), & Q0 is the torque measured in the open water test when the propeller is delivering thrust T at the rotation speed n. In the case the same propeller behind a hull, at the same advance speed it delivers the same thrust T at the same revolution n but needs torque Q. In general, Q is difference from Q0. Then, the efficiency of the propeller behind the hull, T VA B 2 nQ • The ratio of behind-hull efficiency to open-water efficiency is called the relative rotative efficiency. Q R B 0 , thus B R0 0 Q The difference between Q0 and Q is due to 1. wake is not uniform over the disc area while in open water, the advance speed is uniform. 2. model and prototype propellers have different turbulent flow. (Remember then Reynolds number are not the same) R 1.0~1.1 0.95~1.0 for single-screw ship for twin-screw ship • The influence of the propeller on the hull Thrust-deduction factor (fraction) When a hull is towed, there is an area of high pressure over the stern, which has a resultant forward component to reduce the total resistance. With a self-propelled hull (in the presence of the propeller), the pressure at the stern is decreased due to the propeller action. Therefore, there is a resistance augment due to the presence of the propeller. If T is the trust of the propeller & RT is the towing resistance of a hull at a given speed Vs , then in order that the propeller propel the hull at this speed, T must be greater than RT because of the resistant augment. The normalized difference between T and RT, is called the thrust-deduction Fraction, and denoted by t. T RT RT t 1 , thus RT 1 t T T T RT - is the "naked" hull resistance T - the thrust after subtracting the resistance of the rudder & other stern appendages. t measured in experiments depends, not only on the shape of the hull & the characteristics of the propeller, but also the type of the rudder. • Hull Efficiency Hull Efficiency is defined as the ratio of the effective power for a hull with appendages to the thrust power developed by propellers. H PE RT Vs 1 t PT T VA 1 w where PE - effective horsepower EHP RT Vs RT - "naked" hull resistance Vs - speed of the ship PT - the work done by the propeller in delivering a thrust T VA - the speed of the propeller w.r.t. the ambient water. • Propulsive Efficiency “Quasi-propulsion” coefficient is defined as the ratio of the effective horsepower to the delivery horsepower. RT Vs TVA RT Vs PE B H 0 R H D PD 2 nQ 2 nQ TVA PE RT Vs PD - delivered horsepower 2 nQ D 0 R H 0 - efficiency of a propeller in open water, R - relative rotative efficiency, H - hull efficiency. The division of the quasi-propulsive coefficient into three parts is helpful in 1) understanding the propulsive problem & 2) in making estimates of propulsive efficiency for design purposes. PD ( DHP ) EHP H Ro RT V H Ro In the design, usually we let PD ( DHP ) (1 ) EHP D , D H Ro where is a correlation allowance, (or load factor). It depends principally on the hull roughness of the newly painted ship, foaling, weather condition & the length and type of a ship. DHP Finally, the main engine horsepower, SHP s where s is the shaft efficiency. 6.7 Cavitation A typical pressure distribution in a blade element is shown below, Suction (-) Back VR face Pressure (+) As the pressure on the back of a propeller falls lower and lower with the increase in a propeller’s n, the absolute pressure at the back of the propeller will eventually become low enough for the water to vaporize and local cavities form. This phenomenon is known as cavitation. ( Pv , vapor pressure of water) • Cavitation on a propeller will 1. lower the thrust of the propeller, & thus decrease its efficiency, 2. cause vibration of hull & the propeller and generate uncomfortable noise, & 3. cause erosion of the propeller blade. • Criteria for prevention of cavitation Mean thrust loading coefficient T c 1 2 2 VR Ap - density of water, T - Thrust, Ap P Ap - project blade area, 1.067 0.229 , AD D VR - the relative velocity at 0.7 R of a propeller V V 2 0.7 R n 2 R 2 A 2 • Cavitation number p0 pv 1 2 2 VR p0 - presuure at some point of a blade pv - vapor presuure of water The cavitation is most likely to occur at the tips of blades where the relative velocity is the largest and the hydro-static pressure is the lowest when blades rotate to the highest position. It can also occur near the roots where blades join the boss of a propeller because the attack angle is the largest. Cavitation diagram (SNAME) 6.8 Propeller Design Methods of Propeller Design a. Design based upon charts (diagrams). These charts are obtained form the results of open-water test on a series of model propellers. (also upon software, such as NavCad). b. Design using circulation theory and CFD (not studied here). Methodical Series A model propeller series is a set of propellers in which the principal characteristics such as pitch ratio etc are changed in a systematic manner. There are many series tested, and their results are summarized and presented in the form of charts which can be used in design. The most extensive model propeller series is Netherland Ship Model Basin (NSMB) at Wageningen. This series test was run from 1937 to 1964. NSMB Series include Series A: narrow blade tips, airfoil sections, high efficiency only for light loaded propellers (not widely used) Series B: wider tips, airfoil section from blade root to 0.7 radius, and circular back from 0.8 radius to tip. Scope of series B is shown Given below is the dimensions (outline, thickness) of B.4 blade The B series results are presented in the form of charts of diagrams, known as B diagram . P At upper right corner, the diagram gives 4.40 B. (indicating B type, 4 blades & AE /A0 = 0.40, t0/D = 0.0045 (blade-thickness fraction), d/D = 0.167 (diameter ratio of the boss to the propeller), & the Pitch, P. At low left corner, it gives the definitions of BP and n PD Bp VA2.5 0.5 nD , and VA VA (notice that J ) nD n - revolutions per min, D - propeller diameter (ft) PD - delivered horsepower at propeller VA Vs (1- w) - speed of advance (knots) B p and are dimensional! BP diagram Horizontal coordinate: BP Vertical coordinate: ratio of the pitch to diameter P/D Two sets of curves & , and one optimal ( 0) line 0 • Propeller Design Based on Charts -The information required for making a propeller design from charts are: 1. Principal dimensions, & main coefficients of a ship used to estimate wake, thrust factors, & relative rotative efficiency. 2. Speed of a ship 3. EHP (from model tests or estimated from other available data) 4. engine power (SHP) & rpm. 5. restrictions on the maximum diameter of propeller. -Design Procedures n( PD )0.5 PE 1. Calculating B p , (assuming D , for computing PD ) 0.5 VA D From the chart to find , pitch ratio that give the best efficiency. (From D, & pitch ratio P) 2. This will give a best propeller in open water. Since the propeller works behind the hull, it is usually to reduce D by 5%~8%, for single-screw ship, 4% for twin screw ship. nD 3.With the same value B p a smaller value ( ), use VA the chart again to find efficiency 0 and pitch ratio (P / D). 4. In the same way, we may use different chart & different n to see the effects (no. of blades, blade area ratio) on 0 . 5. After determining 0 , we calculate D (propulsive coeff). PE 1 t D 0 R H where H . Then we re-calculate PD ( ) . 1 w D 6. If the newly computed, PD , is very close to the previous assumed one, then we continue to examining the cavitation of the propeller. If not, we use the newly computed PD to repeat the above 1-5 steps again. 7. Examining the condition of cavitation for the propellers. If the condition is not satisfied, choose a propeller with larger AE , or make other adjustments (such as reducing n, & using multiple screws). Examples Example a, Using the B4.40 chart to design a propeller suitable for the following conditions. Also determine SHP. (knowing EHP, Vs to determine 0 , P, D) Vs = 16 knots Taylor wake factor w = 0.3075 EHP = 5000 Hp thrust deduction t = 0.186 Allowance for appendage 6% Shaft loss = 3% Allowance for weather 15% reduction in δ = 7% n = 120 r/min relative rotative effi. R 1.0 Solution: EHP(1 ) EHP(1 0.06 0.15) 6050 hp Assuming D 0.65, PD (DHP) EHP / D 9308 hp Advance velocity VA 1 w Vs 11.08 knots n PD Taylor propeller coeff., B p VA2.5 0.5 120 9308 11.08 2.5 0.5 28.33 Checking B4.40 chart, opt 213, 213(1 0.07) 198, 1 t 0.814 o 0.597, D H R 0 0.597 0.597 0.705. 1 w 0.6925 The previous D is assumed to low. New iteration starts. Let D 0.71, PD EHP / D 8521 hp, B p 27.1, From B4.40 chart, opt 209, 209(1 0.07) 194.4, 0.814 o 0.602, D H R 0 0.602 0.708 0.71 0.6925 This time the assumed D is very close to the comupted one. VA 194.4 11.08 nD P , D 17.9 ft , 0.85, VA n 120 D P 0.85 17.9 15.2 ft, SHP DHP s 8521 8784 hp 1 0.03 Example b. Give D (due to the restriction of draft) & using B.4.40 chart to find the optimum n, P/D, and D A cargo Ship L = 86 m Vs = 9 knots B = 13 m EHP = 515 hp T = 5.66 m w = 0.184 t = 0.125 = 4500 m3 R = 1.0 s = 0.97 D = 4m = 13.14 ft χ = 0.218 (load factor or allowance) Solution : 1. VA Vs 1 w 9 1 0.184 7.34 knots, 2. Assuming D 0.69, 3. 1 EHP P (DHP) 909 D D hp, 4. Try a range of rotation velocities, n No. Name Unit 1 n rpm 2 3 4 Value 90 95 100 105 110 N ( PD )0.5 Bp VA2.5 18.6 19.6 20.7 21.7 22.7 ND VA 161 170 179 188 197 64.5 64.6 64.7 64.3 63.8 0.95 0.875 0.79 0.75 0.70 3 2.8 From the chart 0 % P/D 5 P = P/D*D 6 1 t D o R 1 w m 3.8 3.5 3.16 0.691 0.692 0.693 0.69 0.688 Based on the results shown in the table, it is found that the highest D value is 0.693 when n 100, and it is also closest to the assumed D . Thus, n 100 is the optimal rotation speed. Pitch. P = 3.16 m = 10.37', PD (DHP) 909 SHP 937 hp. s 0.97 A different problem: given the rotation velocity, n, to determine the optimal diameter of the propeller.