Transportation Planning

EGN 5623

Enterprise Systems Optimization

Fall, 2013

Transportation Planning

Theories & Concepts

EGN 5623

Enterprise Systems Optimization

Fall, 2013

Transportation Planning (Overview)

Objective of Transportation planning:

To group delivery into shipment in order to minimize the

number of shipments and the length of the shipments.

Transportation planning:

• is carried out after delivery note is created in the

sales (fulfillment) process.

• Is executed either automatically several times per day

to deliver in batches, or manually by the

transportation planner.

Purchase

Order

Major Businesses Processes

Purchase

Requisition

Schedule

and Release

Convert Production

Proposal

Procurement

Process

Goods

Issue

Run MPS w/MRP

Sales Order

Production

Check

Entry

ProcessCompletion

Availability

Sales Quotation

Confirmation

Delivery Note/

Entry

pick materials

Sales

Process

Receipt of

Payment

Pack

Materials

Post Goods

Issue

Invoice

Customer

Goods

Receipt

Invoice

Receipt

Payment

to Vendor

F/G Goods

Receipt

Order

Settleme

nt

January 2008

© SAP AG - University Alliances and

The Rushmore Group, LLC 2007. All

rights reserved.

4

TP/VS in SCM (review)

THEORY AND PRACTICE OF ADVANCED PLANNER AND OPTIMIZER IN SUPPLY CHAIN DOMAIN by Sam Bansal

Time Horizons for TP/VS and

Replenishment in SCM (review)

Level of Detail and Time Horizon

of TP/VS and Deployment in APO

Modules (review)

TP/VS and Replenishment Processes in APO

Modules (review)

TP/VS Module in APO System Structure and

Integration with ERP (review)

Overview Master Data and

Application in TP/VS (review)

Transportation Planning Overview

Inputs to transportation planning:

due date of customers’ orders,

customers’ calendar of loading and unloading,

capacity restriction of vehicles,

vehicle availability, and

incompatibility (e.g. of the goods and locations).

TP/VS offers an optimization tool for transportation

planning.

The transportation planning creates “shipments” in APO.

Transportation Planning Overview

After creation of a shipment, the subsequent steps

are

To select a carrier and

to release the shipment.

The shipment is transferred to ERP after it is released

in APO.

Order Life Cycle for Transportation

Planning

Transportation Planning Process in

APO

1.

2.

3.

4.

Create shipments in TP/VS

Assign transportation resource to each shipment

Assign carrier(s) to each shipment

Release shipments

Transportation Planning Overview

The common process flow is to create deliveries in ERP

first before running TP/VS.

TP/VS is designed for transportation planning of a

production or trading company

NOT for a transport service provider since TP/VS

doesn’t cover some of their common functional

requirement but require the master data for

products, location, and resources.

Transportation Planning Overview

TP/VS plans for orders which contain a start location

(LOCFROM) and a destination location (LOCTO).

Inbound documents:

purchase orders

Outbound documents:

delivery notes, sales orders, stock transfer orders,

and return orders.

ERP and APO don’t combine inbound and outbound

orders in one shipment.

Master Data for TP/VS

The main master data for TP/VS are:

locations

manufacturing plant,

distribution centers,

customers,

transportation zone,

transport service provider.

transportation lanes,

means of transport, and

vehicle resources.

Master Data for TP/VS

Master Data for TP/VS

Transportation Zone and Transport Service Providers:

The transportation zones and transport service

providers (carriers) are location types 1005 and 1020,

respectively.

The transportation zone data are stored in Customer

Master data in ERP and are transferred to APO.

The transportation zone is implicit with the customer

and the transport service provider using vendor in

ERP.

TP/VS scheduling methods are predefined in the APO,

as shown in next slide.

Vehicle Scheduling Methods List

(A Hierarchy Structure for TP/VS)

Master Data for TP/VS

Transportation Lanes (routes):

Transportation lanes are defined from plants and DCs

to (customer’s) transportation zone, and are created

manually in APO.

The allowed carriers are assigned per transportation

lane (route) and transportation means explicitly.

The restriction on the validity of a transportation lane

per product is ignored by TP/VS.

Detailed Planning in Transportation

Lane

Vehicle Modelling

The three entities for vehicle modelling are:

Mode (by sea, truck, rail, or air)

Means of transport (speed such as normal or express), and

Vehicle resources

The mode is maintained with the customising path and is

used only for grouping purpose, such as by sea, by air,

by truck.

The means of transport corresponds to speed (normal vs.

express), or shift.

Vehicle resources: vehicle type, category, and capacity

(tonnage T) (e.g. a resource with the capacity of 20 T is

not allowed to load 22 T products.

Entities for Vehicle Modelling

Geo-Coding

The transport duration are computed based on

geo-coding of the locations and

the distance between locations.

The geographical settings of locations are determined by

country and region (standard setting),

postal code, or

street address.

The distance for a transportation lane is estimated as

the air-line distance (standard) or

the actual distance between addresses using a route

planning based on the exact longitude and latitude of

the locations as input.

Geo-coding Combinations for

Scheduling

TP/VS Optimisation

The optimiser creates shipments with the lowest penalty

cost, while meeting all required constraints.

Hard constraints:

compatibilities,

opening hours (modelled by handling resource), and

finiteness

Soft constraints:

earliness and lateness defined in the optimiser profile

The TP/VS optimiser is a mixture of local search and

evolutionary search. For configuration of the optimiser,

the optimiser profile has to be created.

Table 8.1 Costs within the Cost

Profile

Scheduling with Runtime Lanes

In order to generate a schedule with runtime lane, it is

critical to determine the distance of the runtime lanes.

The distance of the runtime lanes is either based on GIS

information or is calculated using the geo-coding distance

and the wiggle factor from the means of transport.

The mean of transport has to have the option ‘GIS quality’

selected and the average speed for city, country road and

motorway have to be maintained, if detailed distance

needs to be calculated with geo-coding.

Scheduling with Runtime Lanes

Carrier Selection

Criteria for selecting carriers:

service-quality-based priority, and

cost.

Carrier selection is performed after the planning for

shipments is done, and before the shipments are

transferred to SAP ERP.

If one stage of transport is already assigned to a carrier

which has the flag for continuous move, the same

carrier is selected for succeeding stage.

Carrier Selection principle

•

Keep the same carrier for continuous move

Deployment Overview

Scope of Deployment

To handle the deviation between demand and supply

happens.

The basic idea of deployment is to convert planned

stock transfers into confirmed stock transfers

according to the available supplies, the demand, the

deployment strategy, and the fair share rule.

If the demand exceeds the supply, it has to be decided

which demand at which location will be covered and to

what extent.

Deployment Overview

The available-to-deploy (ATD)-receipt and ATD-issues are category

groups which are assigned to the location and location product

master.

ATD-receipt:

Stock

Production order for finished goods

Purchase order for raw/trading materials.

ATD-issues:

Deliveries

Confirmed distribution requirements

Safety stock is ignored by deployment. Safety stock is modelled as

a demand in SAP APO, not a supply element.

Deployment Heuristic

The deployment heuristic is a source-location-by-source-location

approach to distribute the ATD quantities. Deployment is either

carried out online in the interactive planning book or in the

background in SAP APO.

For each source location, a separate background deployment

planning run is required (see the figure 12.1).

Deployment is based on short term data and is a step towards

execution.

The deployment horizon defines the maximum horizon for which

orders are ready.

Setting for Deployment Heuristic

Deployment Horizon

The deployment pull horizon defines the horizon for the

relevant requirement (ATD-issues).

The deployment push horizon defines the horizon for relevant

ATD-receipt, e.g. production order (see Figure 12.2).

The deployment focus is the short term, therefore a

distribution requirement that is close to today might ‘steal’ the

ATD-quantities from a distribution requirement further in the

future.

The SNP checking horizon is applied to reduce/eliminate the

deployment need. It takes all issues (e.g. deployment

confirmed distribution requirements) into consideration before

using ATD-receipts for the deployment confirmation of new

requirement (see Figure 12.3).

Deployment Horizons

Deployment Strategy

Pull deployment:

Distribution order is confirmed according to requirement data of

planned distribution orders at the source location.

Pull/Push deployment:

Confirmed distribution orders are scheduled as early as possible.

Push by demand:

Deployment pull horizon is overruled by the planning horizon.

Push by quota arrangement:

All ATD-receipts within the deployment push horizon are shipped

to the target location according to outbound quota of the source

location regardless of requirement in target locations.

Push taking safety stock horizon into account:

Basically like ‘pull/push’, but the ATD quantities used to cover the

safety stock are not deployed immediately and with a delay.

Fair Share

In most cases of a supply network, a source location may

supply to more than one target location. During deployment

planning, the requirements may be processed in the order of

their requirement date, so that shortages affect the

requirements with a later date.

For requirements with the sales due bucket, the fair share

rule defines which requirements are fulfilled and to which

extent.

Rule A: Percentage distribution by demand

Rule B: Same absolute quantity of shortage for target

locations

Rule C: Percentage division by quote arrangement of

source location

Rule D: Division by priority of target locations.

Fair Share Rules A and B

Deployment Optimisation

The structure of deployment optimiser is similar to the SNP

optimisation. Both use the same objects for the optimiser

profile, the cost profile, and cost setting.

The optimiser is able to delete confirmed stock transfers

within the planning horizon.

Fare share strategies of deployment optimiser are:

Rule A: percentage distribution by demand

Rule B: percentage fulfillment of target.

Fair Share Rules

Transport Load Builder (TLB)

The transport load builder is a short term planning tool to

combine confirmed distribution orders to form truckloads or

other transport units according to the capacity restrictions.

The use of TLB is an optional step in distribution and

replenishment planning.

TLB planning follows the deployment run and uses confirmed

distribution orders as input.

Transport Load Builder (TLB)

The TLB procedure is to load all selected deployment orders

according to the restrictions in TLB-profile

Two loading approaches (shown in Figure 12.14)

Straight loading

The procedure for straight loading is in Figure 12.15.

The orders are stored according to the loading group.

The settings to control the procedure for transport load

building are maintained in the transportation lane and in

the product master (see Figure 12.16).

Load balancing:

Distribute the products to be loaded evenly onto

different truck loads

Straight Loading vs Load Balancing

Procedure for Straight Loading

Horizon for TLB

The most important horizons for TLB are:

The TLB planning horizon

TLB planning horizon defines which distribution orders

are taken into account for TLB run.

The TLB pull-in horizon

It defines which orders might be scheduled forward

and is maintained in the transportation lane itself.

It starts from the earliest order, and combine it with

other distribution orders within the TLB pull horizon

(until the capacity is full) (see Figure 12.17).

TLB Horizon

Capacity Restrictions for TLB

The relevant capacity restriction in the TLB profile includes

the following constraints:

Maximum volume,

Maximum weight, and

Maximum number of pallets.

A lower limit exists as well to inhibit uneconomical transport

orders.

Transportation Planning

SAP Implementation

EGN 5623

Enterprise Systems Optimization

Fall, 2013

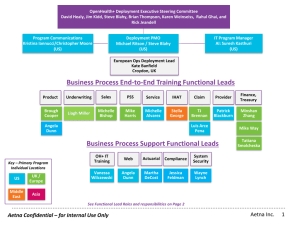

TP/VS Module in SAP SCM

Note: Strategic network design issues

are not handled by SAP SCM

Transportation Planning Overview

TP/VS planning is performed on the basis of deliveries,

but it allows to plan for sales orders as well.

If TP/VS plans for sales orders, planning is performed

either on the basis of sales orders, sales order items or

schedule line.

Which of these is used depends on the consolidation level

(a setting on the client level) and is maintained with the

customising path:

APO-> TP/VS-> Basic setting -> Basic setting for

vehicle scheduling

TP/VS Planning Board

The central tool for TP/VS planning is the TP/VS planning

board, which is called with the transaction

SAPAPO/VS01.

When the planning board is called, the user needs to

enter an optimization profile, which contains restrictions

on the resources, locations, compatibilities and/or order

types (ATP categories).

The user can perform interactive planning of shipments

on the planning board. There is a consistency check while

saving the shipments (e.g. all relevant stages are

assigned).

The user may create and use heuristics in ‘multi-level

planning’ – view of the planning board.

TP/VS Planning Board

Deployment Relevant Setting in

Product Master

Create Work Area for SCM

Create Locations (Plant, DCs,

Customers, Vendors)

Maintain Means of Transportation in

SCM

Change Inbound Quota

Arrangement

Exercises:

PPM and PDS

1. Setting for PDS in SCM system and create integration model

for PDS transfer

2. Create integration model for PDS SNP transfer

Transfer of transactional data from ERP to SCM

1. Create integration model for planning independent

requirement (PIR)

2. Transfer integration model for planning independent

requirement (PIR) to SCM

Maintain supply chain model in supply chain engineer

1. Maintain supply chain model in SCM system

2. Transportation mode and means