Rigging Equipment PPT

advertisement

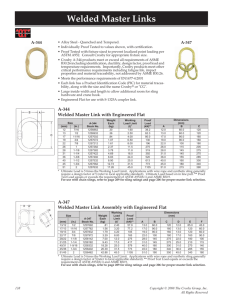

RIGGING EQUIPMENT Industry Fundamentals and Occupational Safety Unit 6 Rigging Rigging is when you use equipment to move materials from one location to another. Through the use of equipment the material is attached to the physical machine doing the work to move the materials to the desired location. Basic Equipment: Slings Hitch Shackles Eyebolts Clamps Hooks Slings A sling is the device that connects the load to the machine doing the lifting. Three major types of slings: Synthetic Sling Alloy Steel Chain Sling Wire Rope Sling Sling Tagging All slings are required to be “tagged”. Tagging is a form of identification that gives the specifics of that particular type of sling. Synthetic Tagging Requirements: Manufacturer/Trade Mark Manufacturer’s stock number Rated capacity/ type of hitches Materials used to create sling Tagging Alloy Steel Chain Tagging Requirements: Manufacturer/Trade Mark Manufacturer’s stock number Link Size Rated Load and angle rating is based on Sling reach Wire Rope Tagging Requirements: Manufacturer/Trade Mark Manufacturer’s stock number Rated capacity in a vertical hitch/ other hitch options Size of wire rope Example of Tags: Synthetic Sling Synthetic slings are made of modified synthetic fabrics that are weaved or roped together to provide strength. There are two main types of synthetic slings: Web Slings Round Slings Web Sling Round Sling Synthetic Web Sling Characteristics: Soft and Wide Do not rust or erode Light weight Flexible and Elastic Less likely to twist when in use Warning Yarn When using web slings it’s important to note that they can’t be exposed to high temperatures. Web slings also can be damaged through cuts, abrasions, and wear and tear. However, most synthetic web slings have “warning yarn” which indicate when exposed that the sling has too much damage and should no longer be used. Synthetic Web Sling Types Synthetic endless web slings, also know as grommet slings, are a continuous circle of the fibers creating the sling Synthetic web eye-and-eye slings which are created by sewing an end of the sling to the the sling’s main body creating two loop holes Synthetic Round Sling Round slings are endless and made from polyester filament yarn formed into a continuous circle. The yarn that makes the sling is covered by a woven sleeve of synthetic fiber to protect it. When the sling has been stretched beyond a safe limit, tattle-tail yarns will show indicating the need to retire the sling. Alloy Steel Chain Slings Alloy steel chains can be used for many different rigging operations Chain slings are commonly used in high heat or rugged conditions. Alloyed Sling can be used in temperatures up to 500 degrees Chain slings are adjusted over the center of gravity The slings can be easily damaged if loads are dropped on them or wrapped tightly around corners. Alloy Steel Chain Sling Types Single and double basket slings: the chain is attached to the master link in a permanent hitch Do not require end fitting hardware Chain bridle slings: have the option of two or four legged slings. Require hardware such as: eye hooks, grab hooks, plate hooks, or links Wire Rope Slings Wire rope slings are made from steel wires that are wrapped around a cord They are flexible and lighter than alloy chain slings The cords within the rope move and adjust based on the stresses placed on the rope when in use Basic Components: Supporting core High-grade steel wires Multiple center wires Wire Rope Slings: Supporting Core Fiber cores Synthetic Strand cores Multiple fabrics or vegetable fibers strands all the same size Independent wire rope cores Separate wire ropes with their own core and strands Hitches The hitch is the way the sling is arranged to hold a load, also referred to as rigging configuration. The type of hitch used depends on the sling, load, and the intended movement of the load while in motion. Types: Vertical Choker Basket Vertical Hitch Vertical Hitches are used to lift a load straight up and down Another form of this hitch is a bridle hitch which consists of two or more legs within one hitch This form of hitch allows the load to rotate freely If you do not want the load to move freely you must use a form of load control Vertical Hitch Choker Hitch A choker hitch is used when there are no direct points of attachment It is not recommended for loose bundles If the item is longer than 12 feet at least 2 choker hitches are recommended Choker hitches reduce the strength of the sling to about 25% of the original capacity The choker hitch is made by looping a sling around the load and pulling it through the eye creating a chocker around the load The passing through the eye is through a shackle Basket Hitch Basket hitches are formed by placing the sling around the load and then placing both eyes on the hook. Basket hitches are very versatile and can be used as double basket hitches for larger loads When creating a double basket hitch make sure your sling is the correct strength Two Double Basket hitches Rigging Hardware Rigging hardware is what connects the slings, loads, and lifts together. Without hardware none of the components of rigging could be physically connected Examples include: Shackles Eyebolts Clamps Rigging hooks Shackles Shackles are used to hold pieces of the rig together such as multiple slings or to attach a specific item to a load Types of Shackles include: Anchor shackles Chain shackles Specialty shackles (used when a standard shackle will not work) Each shackle should be labeled with: Trademark Size of shackle Rated capacity Eyebolts Eyebolts are bolts with an open end that allows threading through the bolt The shank end is attached directly to the load and the eye is used to thread and attach the sling Swivel Eye Bolt Lifting Clamps Lifting clamps are used when there is not a use of a sling. Lifting clamps can only hold one item at a time. The clamps have a “jaw” function that grips the item to be lifted. Lifting clamps must be made of forged steel and stamped with maximum capacity Rigging Hooks Rigging hooks are used to attach the sling bearing load to the machine doing the lifting Safety laches mush be on the rigging hook to prevent the sling from becoming unhooked There are many different types of hooks including: Shortening Clutches Grab hooks Reverse Eye hooks Sliding choker hooks Sorting hooks Eye hooks