Implementation - Krannert School of Management

advertisement

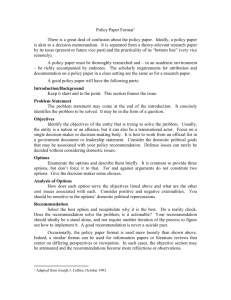

Restructuring supply chain & assuring sustainable quality Geddy’s Ice-Cream Team Name: Eclipse Consulting 1st Round Room____3097______ Abhishek Pandey Mirant Desai Vineet Sahni Yesh Gowda Agenda (Abhishek) Problem Recommendation Analysis Risk Mitigation Implementation Question & Answer GSCMI 2013 Case Competition 2 Current Problems Industry Problem (Abhishek) Competitors Under Developed Cold Storage chain High Competition with Amul, Kwality, Regional Players Seasonal Demand Low consumption per capital Extra costs on Brand Building and promotional Campains High Raw Material Cost (40%-45%) Other supplementsSweets, Deserts Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 3 Current Problems – Geddy’s (Abhishek ) Major • Stock out due to space constraints • Expansion Constraints (seasonal demand) • Sourcing constraints (taxes, custom duty, currency fluctuations) • Longer Replenishment time during peak demand Minor • • • • Problem Transportation – underdeveloped cold chain Inventory Management Quality and product standards High Input Costs Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 4 Recommendations (Abhishek ) Increase Replenishment Time - Biweekly (Short Term) Capacity Expansion (Long Term) Reduce Target Level Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 5 Evaluating Biweekly Replenishment (Mirant) Peak period Weekly Demand 500 400 300 200 100 0 Weekly Sales 400 350 300 250 200 150 100 50 0 Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 6 Evaluating Biweekly Replenishment Maximum Profit (Mirant) Average of Wk Profit (100Rupee) 1200 1000 800 600 400 200 0 Common Service Level Scaled Stocking Level Policy Target Level for Top 2 Margin Target Level for Top 3 Margin Target Service Level Policy Trying Different Stocking policy Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 7 Evaluating Biweekly Replenishment 1300 500 Weekly Profit (100 400 900 350 700 300 Total Weekly Sales 500 Current Implementation 450 250 300 Total Weekly Sales Weekly Profit 1100 (Mirant) 200 0 10 20 30 Week 40 50 60 500 Weekly Profit (100 Rupee) 1100 400 900 350 700 Recommendation 300 Total Weekly Sales 500 250 300 200 0 Problem 450 Total Weekly Sales Common Service Level during Peak Season Weekly Profit (100 Rupee) 1300 Analysis 10 20 30 Week Risk Mitigation GSCMI 2013 Case Competition 40 50 60 Implementation 8 Profits during Biweekly Replenishment (Mirant) 500 Weekly Profit (100 Rupee) 1300 450 1100 400 900 350 700 300 Total Weekly Sales 500 250 300 200 0 10 20 Total Weekly Sales Weekly Profit (100 Rupee) 1500 30 Week 40 50 60 Biweekly Replenishment during peak Months Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 9 Effect on Profits and Stock Out (Mirant) 60000 58000 56000 20% 54000 52000 50000 48000 46000 44000 42000 Original Profits New Profits Stock Outs 70 Profits 60 40% 50 40 30 20 10 0 Original Stockout Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition New Stockout Implementation 10 Effect on Value Chain SHORT LEAD INVENTORY SOURCING (Mirant) MANUFACT URING LOGISTICS LONG LEAD INVENTORY RETAILERS Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 11 Risks Analysis (Mirant) • Increase in Logistics/Transportation Cost • (20% increase) • Inventory Management due to Sourcing • Removing bottleneck at Manufacturing • Procurement and sourcing policy will change • Maintain High Quality Capacity expansion at the retail outlets Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 12 Alternative Option - Capacity Expansion ( Long Term) Increasing Market Share Increased Disposable Income Per Capita Consumption to grow at least 100 % Shrewd Marketing Campaigns can help flatten variability in demand Evaluate using a time horizon and cost of capital Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 13 Implementation (Abhishek) Total duration (1 - 2 months) Implemented during Peak Season to meet demand Investment in Logistics and Transportation Improving the bottleneck at Manufacturing New Sourcing contracts to handle peak season demand Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 14 Conclusion (Abhishek) Now is the time to: Problem Replenish stock Biweekly Invest in Logistics Improve sourcing Contracts Recommendation Analysis Risk Mitigation Implementation Because this will: 1. Increase profitability by 20% 2. Decrease Stock out by 40% 3. Boost expansion plans Problem Recommendation Analysis Risk Mitigation GSCMI 2013 Case Competition Implementation 15 Questions (Abhishek) Q&A ? GSCMI 2013 Case Competition 16