0-Overview-Presentation

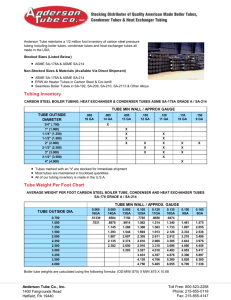

advertisement

Fintube Technologies, Inc.

Date: October 22, 2009

Sanat Shetty

© United States Steel Corporation

Fintube Technologies, Inc.

“Vertically Integrated Manufacturing for Reliability and Quality”

ISO certified for more than 10 years

Steel Coil Services

• Coil slitting & processing

• Rod to fin strip

Kentube Engineered Products

•

•

•

•

Design

Engineering

Fabrication

Contract Fabrication

TEKtube

• ERW Tube Mill

• X-ID® Tubing

Finned Products Group

• Kentube Finned Products - OK

• Aletas y Birlos – Mexico

2

Kentube Engineered Products Group

•

•

Economizers

– Rectangular

– Cylindrical

Tubular Air Heaters

•

Stool Coolers

•

Feedwater Preheat Systems

•

Tank heaters

•

Accessories

– Safety Relief Valves

– Sootblowers

•

Steam Coil Air Heaters

•

(Indirect fired) Super-heaters

•

Waste Heat Recovery

– Hot Oil / Thermal fluids

– Glycol/Water

– Ductwork

3

Kentube Engineered Products

– Industries Served

Process industries

•

•

•

•

Chemical & petrochemical

Food & beverage

Paper

Pharmaceuticals / Fertilizer

Packaged Boilers

Utility boilers

Furnaces

Ovens

Kilns

Fired Heaters

Diesel Generators

Industrial applications

• Steel production

• Equipment manufacturers

• Textile industries

Other

•

•

•

•

Hospitals

Schools

Laundries

Offshore Platforms

4

Fundamentals of Heat Recovery

•

Recover energy that is other-wise being wasted.

•

This energy has already been “ paid for ”.

•

BENEFITS of HEAT RECOVERY

– Higher efficiency

– Lower Pollution (Thermal and emissions)

– $$ saved

•

Economics of heat recovery are dictated by capital and operating costs of the heat recovery

equipment.

•

SENSIBLE HEAT RECOVERY OR LATENT HEAT RECOVERY ALSO !

5

Rectangular Economizer

•

Vertical or horizontal gas flow

•

Size ranges to 1,000,000+ pph

•

Operating pressures from 50 psig to

supercritical

•

Horizontal or vertical tube designs

•

Can support large loads

•

ASME Section I or VIII, Division I

6

Rectangular Economizer

Finned tube bank

Inlet header

Return bends

Outlet header

7

Cylindrical Economizer

•

Built to Section I or VIII of the ASME code

•

Vertical or horizontal gas flow

•

From 400 hp to 100,000 pph designs

•

Solid or serrated finned tubes

•

Built-in soot-blowers

•

Minimal transitions – Adapter plate or Rolled

Angle Flanges

•

Access door for inspection and cleaning

8

Finning Configurations

Square tube pitch with

Solid Finning (fpi)

Staggered tube pitch with

Serrated Finning (fpi)

Sootblowers

Recommended

N/A

6

No

N/A

5

No

N/A

4

No

N/A

3

Yes

#2 or #4 Oil

4-5

N/A

Yes

#5 or #6 Oil

3

N/A

Yes

2.5

N/A

Yes

2

N/A

Yes

Fuels

Natural Gas Only

Natural Gas with #2 oil

backup (<2 wks/yr)

Natural Gas with #2 or #4

backup

Natural Gas with #5 or #6 Oil

backup

Heavy Residual (Bunker C or

Coal Tar)

Wood

9

Casing & Tubing

•

Inner Casing Choices

•

Tube Types

– Welded (Kentube Standard)

– Seamless

•

Tube Material

– Carbon steel (Kentube

Standard)

– Alloy

• High temperature

– Stainless Steel

• High temperature

• Resists oxygen pitting

– Carbon steel – Kentube Standard, Flue

gas temperatures up to 800°F

– Corten – up to 1050°F

– 1-1/4 Chrome – up to 1250°F

– Stainless steel – up to 1500°F

– Internally lined for higher temperatures

•

Outer Casing Choices

– Corrugated galvanized carbon steel

– Corrugated aluminum

– Flat outer casing

10

Corrosion Considerations

•

OXYGEN CORROSION FROM UN-DEAERATED WATER

•

Oxygen removed adequately?

– Chemical / Mechanical /Thermal de-aeration

– If not, we can use stainless steel tubes.

– Minimum 180 F feed-water temperature, assuming atmospheric pre-heat (and Chemical

treatment) before we use Carbon steel tubes.

•

ACID CORROSION FROM CONDENSATION OF SULFUR COMPOUNDS

•

Acid dew-point depends on sulfur content of fuel

Fuel

Lowest Econ Exit temperature

(◦F) (C)

Recommended minimum feed-water temp

(◦F) (C)

Natural gas

260 F (126 C)

180 F (82 C)

• ( < Stack

dictated

by acid-dew point.

# 2 Oil

0.5% S) temperature after

300economizer

– 325 F (149 C is

–163

C)

210 F (99 C)

#6 Oil

2% S )temperature

• ( ~Wall

350 Fby

(177

C)

is controlled

feed-water

temperature

240 F (116 C)

–Can deaerator pressure be increased?

–Feedwater preheat system?

11

Tubular Air Pre-Heaters

•

Unit consists of bundle of straight tubes that

are rolled into end tube-sheets.

•

Gas inside tubes or outside

•

Vertical units have multiple shell side

passes.

•

Horizontal units have multiple tube side

passes.

•

Vibration baffles if needed.

•

Completely seal welded casing.

•

An integral expansion joint between the tube

sheet and casing allows for differential

growth between the tubes and shell.

12

Custom Designed Units

•

Designs are based on Kentube's many

years of experience designing and

building air pre-heaters.

•

Custom designed to meet specific design

parameters by experienced engineers

•

Sizes from as low as 25,000 pph of gas

flow to hundreds of thousands of pph of

gas flow, such as those used on utility

boilers.

•

Modular Construction.

•

Installations with flue gas from

natural gas, wood-burning,

coal & pet coke burning boilers

13

Design Information Needed – Air Pre-heaters

ITEM

Required

CONFIGURATION:

Vertical, air or gas over

Horizontal, air or gas over

Needed

COMMENTS

X

Default design - horizontal, gas over.

CONTROLLING EXIT

TEMPERATURE GAS/AIR:

X

We have to know which exit temp. to

design for - gas or air.

SPACE LIMITATIONS,

X

Generally, longer tubes less expensive.

FOULING CHARACTERISTICS:

EXIT FLOW DIRECTIONS

GAS:

temperature in

pressure in

allowable pressure drop

Composition

AIR OR SECOND GAS:

temperature in

pressure in

allowable pressure drop

moisture content, if air

composition, if gas

X

X

Default gas resistance=.0200

If specified, dictates number of passes.

X

X

Default, (-10 in. gauge)

X

Minimum, require information on fuel

X

Default, (+25 in. gauge)

X

X

Default, 1.3% lb./lb.

Same as (GAS: composition) above

X

X

X

14

Air Pre-Heater Configurations

Gas in shell side

Vertical tubes with

mixing between passes

Gas in tube side

Horizontal Unit

Air out

Air in

shell side

Air in

tube side

Gas out

Vertical Unit

Gas in tube side

Air out

Air in

shell side

Gas out

15

Heat Recovery Units

•

Heat recovered other than packaged

boiler

•

Heat transferred to possible other

medium ( Thermal Oils / Glycol Water

Systems, etc)

•

May be high temperature

•

Special design considerations

•

We package duct-work, transitions,

L&P, stack.

16

FLAT COILS FOR LARGE FIELD

ASSEMBLED ECONOMIZERS

17

Stool Coolers

•

Annealing Furnaces in

sheet metal mills

•

Water Cooled

•

City Water Supply

18

Fintube Engineered Products- Fabrication

•

Quality Program

– Kentube ISO certified : Travelers remain with unit from initial construction (Structural Shop)

•

Fabrication Facilities ( NEW – OPENED IN JUNE 2008 )

– 84,000 ft2

– Three (3) – 70 ft x 400 ft bays

– Overhead cranes to lift

– Portable jacks - 225 ton

•

ASME Stamp Holder

– Do not rely on “remote” stamp

– Do not rely on a 3rd party fab shop’s stamp

•

Experience – By far, industry leader

19

Kentube Finned Products Group

Types of Finning

High Frequency Serrated

High Frequency Solid

Studs

Standard Frequency Serrated

AeroSeg

20

TEKtube Tubular Products Group

•

TEKtube, started in 1989, is one of the largest producers of ERW carbon steel boiler tubes in North

America, producing millions of feet each year.

•

TEKtube has been ISO Certified since 1994 and is committed to producing a quality product

“Tektube Product Range”

•

•

•

•

•

SA-178-A, C, & D Tubing

A-513 Air Heater Tubing

A-423 Grade 1 {Corten} Tubing

X-ID Tubing made to SA-178 A

SA-214 Condenser Tubing

“Tektube Size Range”

• Tube o.d. from 1.25”OD to 3.0” OD

• Tube wall thickness from 0.065” to .210”

• Lengths to 70’

21

What is X-ID® ?

• X-ID is an internally enhanced tube.

• Tube augmentation (passive or active) techniques

are used to increase the heat transfer rate.

• The augmentation in an X-ID tube is achieved by

helical ribs on the inside of the tube.

• Ribs modify the behavior of the fluid flow leading

to heat transfer augmentation.

22

TEKtube Tubular Products Group

X-ID® Tube Applications

Firetube Boilers

Shell-and-Tube HX

Tubular Air Heaters

•

Significantly higher heat transfer rates than plain tubes

•

Increased unit efficiency

•

Reduced unit size allows for significant cost savings on the overall heat exchanger

23

Quality

•

•

ISO 9001:2000

Code Construction – Kentube holds our own code stamps. Based on Customer

Specifications, Kentube Products can comply with the following codes:

–

–

–

–

–

–

–

–

–

–

–

ASME Section I, Power Boilers, “S” stamp holder ( also hold R stamp)

ASME Section VIII, Division I, Pressure Vessels, “U” stamp holder

ASME Section V, Nondestructive Examination

ASME Section IX, Welding and Brazing Qualifications

AWS D1.1, Structural Welding Code

American Institute of Steel Construction (AISC)

ASME B31.1, Power Piping

Uniform Building Code

International Building Code

ASCE 7-05, Minimum Design Loads for Building and Other Structures

P.E.D. (Pressure Equipment Directive) for the European Union

24

Summary

“Heat Recovery Product Solutions” through technical expertise and technological innovations.

•

High quality products

•

Control all aspects

– Tubes

– Finning

– Fabrication

•

Most accurate heat transfer correlations

•

Truly an “Engineering” company

•

Actively developing industry-leading technology

www.fintubetech.com

25