Group3_case

advertisement

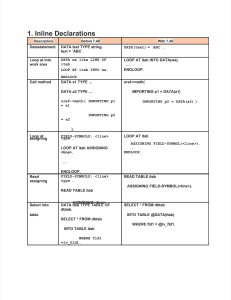

Case1:Chick-n-Gravy Dinner Line Group 2+1 Members: Delia Victoria Adrian Gary Yoong Terry Background Complaints from supermarket about firm’s Chick-n-Gravy dinner defect. The majority of complaints : Underfilled packages Missing label Unacceptable taste Spills/Mixed items Improperly sealed Data result (Original) Date Time Line Underfilled Missing Label Spill/ Mixed Unacceptable Taste 5/12 0900 1 2 1 3 5/12 1330 2 5/13 1000 2 5/13 1345 1 5/13 1530 2 2 5/14 0830 1 3 5/14 1100 2 5/14 1400 1 5/15 1030 1 5/15 1145 2 5/15 1500 1 5/16 0845 2 5/16 1030 1 5/16 1400 1 5/16 1545 2 2 2 1 2 3 2 1 3 1 3 1 2 1 3 1 1 5 1 2 1 2 1 Improperty Sealed 3 1 3 4 1 1 2 2 Data result (Line1&Line2) Line1 Date Time 5/12 0900 5/13 1345 5/14 0830 5/14 1400 5/15 1030 5/15 1500 5/16 1030 5/16 1400 Underfilled Missing Label Spill/ Mixed Unacceptable Taste 2 1 3 2 Improperly Sealed 2 3 3 1 3 1 1 5 1 3 1 3 Total 35 Line2 Date Time 5/12 1330 5/13 1000 5/13 1530 5/14 1100 5/15 1145 5/16 0845 5/16 1545 Underfilled Missing Label Spill/ Mixed Unacceptable Taste 2 2 1 2 1 1 4 3 3 1 1 2 1 2 1 Improperty Sealed 2 2 1 2 Total 34 Pareto diagram of number of defect Number of Defect 25 20 15 10 Number of Defect 5 0 Unacceptable Taste Missing Label Spill/Mixed Improperty Sealed Underfilled Data result (category) Underfilled Spilled/Mixed Line1 Line2 Total Line1 Line2 Total Morning 0 1 1 Morning 2 2 4 Afternoon 3 1 4 Afternoon 4 6 10 5 Missing Label Unacceptable Taste Line1 Morning Afternoon 14 Line2 Total Line1 11 0 11 0 7 7 18 Improperly Sealed Line1 Line2 Total Morning 0 5 5 Afternoon 1 5 6 11 Morning Afternoon Line2 Total 14 7 21 0 1 1 22 Pareto diagram of number of unacceptable taste defect Number of Unacceptable Taste Defect 16 14 12 10 8 Number of Unaccpetable Taste Defect 6 4 2 0 Line 1 Line 2 Conclusion The process of produce frozen dinners Material of foods Labeling Classify by flavors Processing foods Frozen foods Sealing Foods packing Unacceptable taste Others Case2:Tip Top Markets Background Complaints from Tip Top Market. Analyze the data and to make recommendation for improvement. On July 15,changes were implemented . 1.Reduce out-of-stock complaints. 2.Improve store maintenance. 3.Reduce checkout lines/pricing problems. Check out whether the changes make improvement or not. Classifying Product Price Environment Service Check Sheet Product Price Service Environment Pareto Charts Product Environment Service Price Run Charts 7/15 Product Inventory Freshness Run Charts 7/15 Inventory&Freshness Problem Method Materials Goods Transport Inventory & Freshness Problem Workers Freezer Inventory System Manager Training Air Conditoner Supervision Person Equipment Recommendation Short Term: •1.Employees •2.Introduce •3.Solve & manager training inventory system machine problem Long Term: •1.Establish corporate culture of positiveness •2.Introdue TQM •3.Establish suitable principle of recruitment Q&A