CMBG Presentation Title

Hyatt Regency Walkway

Presented By:

Jack D. Gillum, P.E.

Configuration Management Benchmarking Group Conference

June 6 – 9, 2004 Kansas City, MO

© 2004 CMBG

Kansas City Hyatt

July 17, 1981

•

Two Walkways

Collapsed

•

114 People Lost

Their Life

•

Failure of Hanger

Rod Connection

(4th Floor)

The Team Owner/Design &

Construction Team

OWNER:

Crown Center

Redevelopment Corp.

DESIGN TEAM:

ARCHITECTS

• Patty Berkebile & Nelson

• Herbert Duncan

• Monroe - Lefbvre

• Marshal & Brown

STRUCTUAL ENGINEERS:

• Gillum Colaco

Concordia Project

Management

Havens Structural

Steel

Eldridge & Son

Construction

General Testing

Laboratories

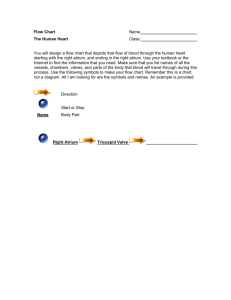

Hyatt General Layout

Entrance

Kansas City Hyatt

Entrance to Hotel and Atrium

Bridge Plan

Tower

4 TH & 2 ND

BRIDGES

FLOOR

3 RD FLOOR

BRIDGE

N

Function Block

4@

29+=120’

15’ 2+”

Atrium Roof Plan

29’

-Typical

Physical description –

Bridge Plan

Guest Tower Connections

Des. by

Fabricator

N

Atrium

Function Block

CHRONOLOGY OF EVENTS

Major Events Occurring Design Phase

Fast Track Project

Project Engineer Leaves

Project Designer Leaves

QC Problems during construction

SE request to perform inspection: Refused

Screen Wall Changes

Bridge Hanger Changes

Portion of Atrium Roof Collapsed

Walkway Bridge Collapsed

CHRONOLOGY TIMELINE

1976 - MID 1977

Schematic Design (750 Rms, 35 Flr,

120’ Atrium

Jan 1978

Fast-Track Design/

Construct-Contract w/GC

CHRONOLOGY TIMELINE

April 1978

Structural Contract

“All Structural Eng. Serv.”

Jan - Aug 1978

Design continues during construction

SE requested owner to be retained for inspection services

DENIED

Physical description –

Bridge Plan

Guest Tower Connections

Des. by

Fabricator

N

Atrium

Function Block

Design Phase – Bridge

Connection Evolution

•No rod size

•No reaction

•No rod strength

Design Drawings v.s.

Shop Drawings

Changes During Shop Drawings

Requested two rods by phone

Approved by phone with caveat “submit through channels”

The shop drawings are checked by a technician who did not work on the project. Questions are raised about the strength of the rod

CONNECTION AS BUILT

THIS

CONNECTION

WAS NEVER

DRAWN

NOR

SUBMITTED

FOR

APPROVAL

Chronology (Continued)

Summer 1979

Erection of Steel for Atrium

•

Contractor omits embedded inserts in

Concrete for steel connection

•

Needs to be modified by Engineer

Owner (again) refuses Engineer request for field representation third time

Owner fires testing lab due to poor performance during inspection of const .

Construction Collapse /

Design Checks

Problems at connections along expansion joint at the interface between steel and concrete structures

Chronology (Continued)

October 1979

Atrium roof collapse

Deficiencies in modified construction at concrete/steel interface discovered

Engineer initiates in-house check of

Atrium roof

Outside Peer Review Initiated &

Completed

ATRIUM ROOF:STEEL TO CONCRETE

CONNECTIONS

Engineer Designed &

Modified

Construction Collapse /

Design Check

Problems at the screen wall are uncovered

EOR in-house check

EOR issues correction details for screen wall

Screen wall corrections are made in the field

Problem with the bridge connection is not discovered

Independent design check and field inspection does not uncover either error

Design Phase –

Screen Wall Changes

*

DURING THE

SHOP DWGS

Horizontals supporting splice points are moved for architectural reasons. The splice points on the truss drawings are not moved

Chronology ( Continued )

Late1979 to July 1980 Gen’l Contractor goes bankrupt and Crown Center takes over as contractor using personnel of Gen’l Contractor

July 1980

Hotel Opened

July 17, 1981

Walkway bridges collapse

Bridge Collapse

Double rod connection failed

Connection that failed was never shown on ANY drawings!!

Engineering or Detailer

Connection that failed was never designed

Video of Collapse

Why Did It Happen ?

Combination of :Personnel Errors

A.

Design Deficiencies

B.

Inadequate Oversight & Review

Process

C.

Missed opportunities to discover error

D.

Poor Communication

Standard of Practice

(During this period of time 1950’s -1980’s)

Standard of Practice in the profession was for the Fabricator to design and detail all structural steel details (includes design of connections) unless detailed by the

Structural Engineer

Standard Originated with the fabricator’s to insure a least costly and practical connection from the fabrication viewpoint

Factors That Contributed to the

Collapse

Fast Track Process

Architectural design changes & conceptual re-designs

Drafting Errors

Checking errors-Shop Drawings

Invalid initial design concept of hanger

Senior engineer personnel changes

Phone changes w/o follow-up by detailer or engineer in writing

Factors That Contributed to the

Collapse

No Structural Site Representation

(Refused several times)

Engineer Relied (ASSUMED) based on past projects on design of connections by Fabricator, w/no follow-up by Project

Manager

Factors (Continued)

Fabricators in-house engineer transferred fabricator’s partial shop dwgs to outside firm who assumed connection was designed

Engineers technician, checked piece size but not connection. (Not Drawn or submitted)

Outside Peer Review didn’t check shop dwg

Factors (Continued)

“Design Check” questions answers not verified

In-house design check questions following atrium collapse were not verified. No Follow Up

Poor Testing & Inspection

Warning Signs!!!

Never Transmitted to Engineer

Walkway deflection of 3/4” observed by workman who notified architect’s site representative seven weeks B4 July 80 opening. No Follow Up

General Contractor's attorney reported :

“….from date of full dead load loading of

4th and 2nd floor bridges (July 1, 1980), box beams began to distort and distortions were visible to naked eye.”

Warning Signs!!!

Never Transmitted to Engineer

Handrail Deflection noted on punch list of 130 items (Aug, 1980)

Feb 1981 Box Beam Deformations noticed by dry wall installer. (No one notified)

What Should Have Occurred ?

Single Rod Concept detail on engrs dwg noted as conceptual only

Fabricator design connection

Picked up during shop dwg check as not designed

After atrium collapse picked up during design re-check which should have been a thorough design document check

What Should Have Occurred ?

EOR provide full time inspection

Engineer Notified of warnings!

Rundancy

All of above

Lessons Learned

Procedures must be implemented that assure that all connections are designed by a competent professional

Peer reviews and design checks should include a review of shop drawings

Lessons Learned

When questions come up look at surrounding issues for related problems

EOR should be retained to provide full inspection during construction of structure

Owner needs on site qualified representation

Lessons Not Learned

Design and construction is a collaborative process that requires professional integrity, judgment, and integrity on the part of all participants

We have not yet clearly defined the nature of the design and construction process and the information flow that is required for success in all respects

We have not learned to respect and teach the history of the profession and fully disseminate information of problems that occur

WHAT IS THE FUNDAMENTAL

ISSUE?

WHO TAKES THE RESPONSIBILITY

FOR ENSURING THE WHOLE OF

THE PROJECT CONFORMS TO THE

DESIGN INTENT AND THE SAFETY

OF THE GENERAL PUBLIC ?

Where does the buck stop?

ALL MEMBERS OF THE DESIGN TEAM

ARE RESPONSIBLE FOR WHAT THEY DO!

Take the time to check your own work!

DON’T ASSUME SOMEONE ELSE WILL!

Continuing Maintenance and Inspections by OWNER !

Final Responsibility? The Engineer of Record!!

What Has Been Done

NY State Board of Regents Proposed

Amendment (Adopted 6/96)

Only ancillary to main components

Clearly specified performance criteria

Performed by licensed professional

Primary Design Team must check & approve, i.e...

“Each designer responsible for own work”

What Has Been Done (Cont’d.)

States of Florida and Connecticut added legislation relative to checking shop drawings. (Both are different)

Combined with NY, only these 3 states in 20 years have any legislation relative to who does what.

ASCE: “Quality in the Constructed

Project”, 2000

(After 20 years)

PP 17.3.2: Shop Drawings for Structural

Components

Conn. design by Fabricator to tailor to fabrication methods

EOR has authority & responsibility for overall Design of Project

Fabricator responsible for connections & details

ASCE: “Quality in the Constructed

Project”, 2000

(After 20 years)

Complex Structures (Two Approaches OK)

EOR performs complete engineering design

(including conn.)

Fabricator provides services of PE to design or supervise design of components not completely designed in the const.doc’s.

EOR responsible to Ck shop dwgs and design for either method

CONFIGURATION MANGEMENT

Strictly Regulated Industry by

Government

Regulations state that design, processes, documentation, changes and records must be managed

This is up to Producer/Operator

CONFIGURATION MANGEMENT

As the result of design problems,worker errors and equipment malfunctions of Three Mile Island and the Salem ATWS event in 1983, CM has continued to evolve and improve following the

NRC Bulletin 79-14

CM, reinvented under CMII and ISO 10007

Quality Management (3 tier/8 step program)

Adoption of Risk-Informed Baseline Inspection

Program

Configuration Management (cont’d)

Non Regulated Industry Design and

Construction have many similar problems

Dissemination of problems (CR”s) and solutions to include CM processes and which includes all team members is important

Configuration Management (cont’d)

Cost and time is always the problem

Owners are reluctant to participate and have tight budgets if any during design, construction and very little(if any) after turn-over (exception may occur with with public, state and federal ownership

In Conclusion: While our industries are different the process remains essentially the same:

Management

Planning

Programming

Designing

QC/QA

Construction

Turn Over

Operation

Maintenance

Continual Inspection

Oversight & Follow

Through

Requires: Integrity,teamwork, communication

& personal responsibility by all involved in the process

Consulting Engineer,

Norman Scott recently wrote:

“Responsibility issues in construction, as in most endeavors, can be effectively resolved by adhering to the principle that responsibility and authority must be exactly linked.”

The corollary principle is that everyone must be responsible for his or her own work and decisions