lecture1

advertisement

Lecture 1:

Introduction

Original Lecture notes ©

2010 David Money Harris

Modified by Konstantinos

Tatas

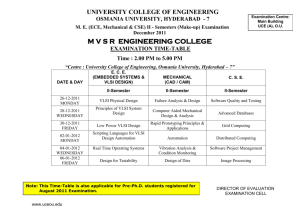

ACOE419 – Digital IC and VLSI Design

ECTS: 5

Conduct hours per week: 3 (2 Lecture – 1 Lab)

Evaluation:

– Final Exam: 60%

– Laboratory exercises: 20%

– Test: 10%

– Assignment: 10%

1: Introduction

ACOE419 – Digital IC and VLSI Design

2

Course outline and

breakdown

Week 1:

– Introduction to VLSI Design

Week 2:

– Stick diagrams and layout

– Lab 1: Basic schematic entry

Week 3:

– The ideal MOS transistor

– Lab 2: Compound gates

Week 4:

– The non-ideal MOS transistor

– Lab3: Basic Layout

1: Introduction

ACOE419 – Digital IC and VLSI Design

3

Course outline and

breakdown

Week 5:

– Logical Effort

– Lab 4: Advanced Layout

Week 6:

– Power Consumption

– Lab 5: MOS transistor characteristics

Week 7:

– Test

– Lab 6: Logical Effort

Week 8:

– Simulation

– Lab 7: Power Consumption

1: Introduction

ACOE419 – Digital IC and VLSI Design

4

Course outline and

breakdown

Week 9:

– Combinational Circuit Design

– Lab 8: Power Consumption

Week 10:

– Wires

– Lab 9: Combinational Circuit Design

Week 11:

– Sequential Circuit Design

– Lab 10

Week 12:

– Adder Design

– Lab 11

1: Introduction

ACOE419 – Digital IC and VLSI Design

5

Introduction

Integrated circuits: many transistors on one chip.

Very Large Scale Integration (VLSI): bucketloads!

Complementary Metal Oxide Semiconductor

– Fast, cheap, low power transistors

Today: How to build your own simple CMOS chip

– CMOS transistors

– Building logic gates from transistors

– Transistor layout and fabrication

Rest of the course: How to build a good CMOS chip

1: Introduction

ACOE419 – Digital IC and VLSI Design

6

A Brief History

1958: First integrated circuit

– Flip-flop using two transistors

– Built by Jack Kilby at Texas

Instruments

2010

– Intel Core i7 mprocessor

• 2.3 billion transistors

– 64 Gb Flash memory

• > 16 billion transistors

Courtesy Texas Instruments

[Trinh09]

© 2009 IEEE.

1: Introduction

ACOE419 – Digital IC and VLSI Design

7

Growth Rate

53% compound annual growth rate over 50 years

– No other technology has grown so fast so long

Driven by miniaturization of transistors

– Smaller is cheaper, faster, lower in power!

– Revolutionary effects on society

[Moore65]

Electronics Magazine

1: Introduction

ACOE419 – Digital IC and VLSI Design

8

Annual Sales

>1019 transistors manufactured in 2008

– 1 billion for every human on the planet

1: Introduction

ACOE419 – Digital IC and VLSI Design

9

Invention of the Transistor

Vacuum tubes ruled in first half of 20th century Large,

expensive, power-hungry, unreliable

1947: first point contact transistor

– John Bardeen and Walter Brattain at Bell Labs

– See Crystal Fire

by Riordan, Hoddeson

AT&T Archives.

Reprinted with

permission.

1: Introduction

ACOE419 – Digital IC and VLSI Design

10

Transistor Types

Bipolar transistors

– npn or pnp silicon structure

– Small current into very thin base layer controls

large currents between emitter and collector

– Base currents limit integration density

Metal Oxide Semiconductor Field Effect Transistors

– nMOS and pMOS MOSFETS

– Voltage applied to insulated gate controls current

between source and drain

– Low power allows very high integration

1: Introduction

ACOE419 – Digital IC and VLSI Design

11

MOS Integrated Circuits

1970’s processes usually had only nMOS transistors

– Inexpensive, but consume power while idle

[Vadasz69]

© 1969 IEEE.

Intel

Museum.

Reprinted

with

permission.

Intel 1101 256-bit SRAM

Intel 4004 4-bit mProc

1980s-present: CMOS processes for low idle power

1: Introduction

ACOE419 – Digital IC and VLSI Design

12

Moore’s Law: Then

1965: Gordon Moore plotted transistor on each chip

– Fit straight line on semilog scale

– Transistor counts have doubled every 26 months

Integration Levels

SSI:

10 gates

MSI: 1000 gates

LSI:

[Moore65]

10,000 gates

VLSI: > 10k gates

Electronics Magazine

1: Introduction

ACOE419 – Digital IC and VLSI Design

13

And Now…

1: Introduction

ACOE419 – Digital IC and VLSI Design

14

Feature Size

Minimum feature size shrinking 30% every 2-3 years

1: Introduction

ACOE419 – Digital IC and VLSI Design

15

Corollaries

Many other factors grow exponentially

– Ex: clock frequency, processor performance

1: Introduction

ACOE419 – Digital IC and VLSI Design

16

Silicon Lattice

Transistors are built on a silicon substrate

Silicon is a Group IV material

Forms crystal lattice with bonds to four neighbors

1: Introduction

Si

Si

Si

Si

Si

Si

Si

Si

Si

ACOE419 – Digital IC and VLSI Design

17

Dopants

Silicon is a semiconductor

Pure silicon has no free carriers and conducts poorly

Adding dopants increases the conductivity

Group V: extra electron (n-type)

Group III: missing electron, called hole (p-type)

1: Introduction

Si

Si

Si

Si

Si

Si

As

Si

Si

B

Si

Si

Si

Si

Si

-

+

+

-

Si

Si

Si

ACOE419 – Digital IC and VLSI Design

18

p-n Junctions

A junction between p-type and n-type semiconductor

forms a diode.

Current flows only in one direction

1: Introduction

p-type

n-type

anode

cathode

ACOE419 – Digital IC and VLSI Design

19

nMOS Transistor

Four terminals: gate, source, drain, body

Gate – oxide – body stack looks like a capacitor

– Gate and body are conductors

– SiO2 (oxide) is a very good insulator

– Called metal – oxide – semiconductor (MOS)

capacitor

Source

Gate

Drain

Polysilicon

– Even though gate is

SiO2

no longer made of metal

n+

Body

p

1: Introduction

ACOE419 – Digital IC and VLSI Design

n+

bulk Si

20

nMOS Operation

Body is usually tied to ground (0 V)

When the gate is at a low voltage:

– P-type body is at low voltage

– Source-body and drain-body diodes are OFF

– No current flows, transistor is OFF

Source

Gate

Drain

Polysilicon

SiO2

0

n+

n+

S

p

1: Introduction

D

bulk Si

ACOE419 – Digital IC and VLSI Design

21

nMOS Operation Cont.

When the gate is at a high voltage:

– Positive charge on gate of MOS capacitor

– Negative charge attracted to body

– Inverts a channel under gate to n-type

– Now current can flow through n-type silicon from

source through channel to drain, transistor is ON

Source

Gate

Drain

Polysilicon

SiO2

1

n+

n+

S

p

1: Introduction

D

bulk Si

ACOE419 – Digital IC and VLSI Design

22

pMOS Transistor

Similar, but doping and voltages reversed

– Body tied to high voltage (VDD)

– Gate low: transistor ON

– Gate high: transistor OFF

– Bubble indicates inverted behavior

Source

Gate

Drain

Polysilicon

SiO2

p+

p+

n

1: Introduction

bulk Si

ACOE419 – Digital IC and VLSI Design

23

Power Supply Voltage

GND = 0 V

In 1980’s, VDD = 5V

VDD has decreased in modern processes

– High VDD would damage modern tiny transistors

– Lower VDD saves power

VDD = 3.3, 2.5, 1.8, 1.5, 1.2, 1.0, …

1: Introduction

ACOE419 – Digital IC and VLSI Design

24

Transistors as Switches

We can view MOS transistors as electrically

controlled switches

Voltage at gate controls path from source to drain

d

nMOS

pMOS

g=1

d

d

OFF

g

ON

s

s

s

d

d

d

g

OFF

ON

s

1: Introduction

g=0

s

ACOE419 – Digital IC and VLSI Design

s

25

CMOS Inverter

A

Y

0

1

1

0

VDD

A

0

1

OFF

ON

Y

ON

OFF

A

Y

GND

1: Introduction

ACOE419 – Digital IC and VLSI Design

26

CMOS NAND Gate

A

B

Y

0

0

1

0

1

1

1

0

1

1

1

0

ON

OFF

OFF

ON

A

B

1: Introduction

1

0

0

1

1

0

ACOE419 – Digital IC and VLSI Design

OFF

ON

Y

ON

OFF

OFF

ON

ON

OFF

27

CMOS NOR Gate

A

B

Y

0

0

1

0

1

0

1

0

0

1

1

0

1: Introduction

A

B

Y

ACOE419 – Digital IC and VLSI Design

28

3-input NAND Gate

Y pulls low if ALL inputs are 1

Y pulls high if ANY input is 0

Y

A

B

C

1: Introduction

ACOE419 – Digital IC and VLSI Design

29

Example

Sketch a 3-input CMOS NOR gate

1: Introduction

ACOE419 – Digital IC and VLSI Design

30

Complementary CMOS

Complementary CMOS logic gates

– nMOS pull-down network

– pMOS pull-up network

inputs

– a.k.a. static CMOS

Pull-up OFF

Pull-up ON

Pull-down OFF Z (float)

1

Pull-down ON

X (crowbar)

1: Introduction

0

ACOE419 – Digital IC and VLSI Design

pMOS

pull-up

network

output

nMOS

pull-down

network

31

Series and Parallel

nMOS: 1 = ON

pMOS: 0 = ON

Series: both must be ON

Parallel: either can be ON

a

a

0

g1

g2

(a)

(b)

a

g1

g2

(c)

a

g1

g2

b

1: Introduction

0

1

b

b

OFF

OFF

OFF

ON

a

a

a

a

0

1

1

1

0

1

b

b

b

b

ON

OFF

OFF

OFF

a

a

a

a

0

0

b

1

b

0

b

1

1

0

g2

a

b

a

g1

a

0

0

b

(d)

a

0

1

1

0

1

1

b

b

b

b

OFF

ON

ON

ON

a

a

a

a

0

0

0

1

1

0

1

1

b

b

b

b

ON

ON

ON

OFF

ACOE419 – Digital IC and VLSI Design

32

Conduction Complement

Complementary CMOS gates always produce 0 or 1

Ex: NAND gate

– Series nMOS: Y=0 when both inputs are 1

– Thus Y=1 when either input is 0

Y

– Requires parallel pMOS

A

B

Rule of Conduction Complements

– Pull-up network is complement of pull-down

– Parallel -> series, series -> parallel

1: Introduction

ACOE419 – Digital IC and VLSI Design

33

Compound Gates

Compound gates can do any inverting function

Ex: Y A B C D (AND-AND-OR-INVERT, AOI22)

A

C

A

C

B

D

B

D

(a)

A

(b)

B C

D

(c)

C

D

A

B

(d)

C

D

A

B

A

B

C

D

Y

A

C

B

D

Y

(f)

(e)

1: Introduction

ACOE419 – Digital IC and VLSI Design

34

Example: O3AI

Y A B C D

A

B

C

D

Y

D

A

1: Introduction

B

C

ACOE419 – Digital IC and VLSI Design

35

Example

Sketch a transistor-level schematic for a singlestage CMOS logic gate for each of the following

functions:

– (ABC+D)΄

– ((AB+C)D)΄

– (AB+(C(A+B)))΄

1: Introduction

ACOE419 – Digital IC and VLSI Design

36

Signal Strength

Strength of signal

– How close it approximates ideal voltage source

VDD and GND rails are strongest 1 and 0

nMOS pass strong 0

– But degraded or weak 1

pMOS pass strong 1

– But degraded or weak 0

Thus nMOS are best for pull-down network

1: Introduction

ACOE419 – Digital IC and VLSI Design

37

Pass Transistors

Transistors can be used as switches

g=0

g

s

s

d

d

g=1

s

g=1

d

s

s

d

s

d

degraded 1

g=0

0

g=1

d

1: Introduction

1

Input

g=0

g

Input g = 1 Output

0

strong 0

Output

degraded 0

g=0

1

ACOE419 – Digital IC and VLSI Design

strong 1

38

Transmission Gates

Pass transistors produce degraded outputs

Transmission gates pass both 0 and 1 well

Input

g

a

b

gb

a

g = 0, gb = 1

a

b

g = 1, gb = 0

0

strong 0

g = 1, gb = 0

a

b

g = 1, gb = 0

strong 1

1

g

g

b

gb

1: Introduction

Output

g

a

b

gb

a

b

gb

ACOE419 – Digital IC and VLSI Design

39

Tristates

Tristate buffer produces Z when not enabled

EN

A

Y

0

0

Z

0

1

Z

1

0

0

1

1

1

EN

Y

A

EN

Y

A

EN

1: Introduction

ACOE419 – Digital IC and VLSI Design

40

Nonrestoring Tristate

Transmission gate acts as tristate buffer

– Only two transistors

– But nonrestoring

• Noise on A is passed on to Y

EN

A

Y

EN

1: Introduction

ACOE419 – Digital IC and VLSI Design

41

Tristate Inverter

Tristate inverter produces restored output

– Violates conduction complement rule

– Because we want a Z output

A

A

A

EN

Y

Y

Y

EN = 0

Y = 'Z'

EN = 1

Y=A

EN

1: Introduction

ACOE419 – Digital IC and VLSI Design

42

Multiplexers

2:1 multiplexer chooses between two inputs

S

S

D1

D0

Y

0

X

0

0

0

X

1

1

1

0

X

0

1

1

X

1

1: Introduction

D0

0

Y

D1

ACOE419 – Digital IC and VLSI Design

1

43

Gate-Level Mux Design

Y SD1 SD0 (too many transistors)

How many transistors are needed? 20

D1

S

D0

D1

S

D0

1: Introduction

Y

4

2

4

2

4

2

Y

2

ACOE419 – Digital IC and VLSI Design

44

Transmission Gate Mux

Nonrestoring mux uses two transmission gates

– Only 4 transistors

S

D0

Y

S

D1

S

1: Introduction

ACOE419 – Digital IC and VLSI Design

45

Inverting Mux

Inverting multiplexer

– Use compound AOI22

– Or pair of tristate inverters

– Essentially the same thing

Noninverting multiplexer adds an inverter

D0

S

S

D1

D0

D1

S

S

Y

S

S

S

Y

S

D0

Y

S

D1

1: Introduction

ACOE419 – Digital IC and VLSI Design

0

1

46

4:1 Multiplexer

4:1 mux chooses one of 4 inputs using two selects

– Two levels of 2:1 muxes

S1S0 S1S0 S1S0 S1S0

– Or four tristates

D0

S0

D0

S1

0

D1

D1

1

0

Y

Y

D2

0

D3

1

1

D2

D3

1: Introduction

ACOE419 – Digital IC and VLSI Design

47

D Latch

When CLK = 1, latch is transparent

– D flows through to Q like a buffer

When CLK = 0, the latch is opaque

– Q holds its old value independent of D

a.k.a. transparent latch or level-sensitive latch

D

Latch

CLK

1: Introduction

CLK

D

Q

Q

ACOE419 – Digital IC and VLSI Design

48

D Latch Design

Multiplexer chooses D or old Q

CLK

D

1

CLK

Q

Q

Q

D

Q

0

CLK

CLK

CLK

1: Introduction

ACOE419 – Digital IC and VLSI Design

49

D Latch Operation

Q

D

CLK = 1

Q

Q

D

Q

CLK = 0

CLK

D

Q

1: Introduction

ACOE419 – Digital IC and VLSI Design

50

D Flip-flop

When CLK rises, D is copied to Q

At all other times, Q holds its value

a.k.a. positive edge-triggered flip-flop, master-slave

flip-flop

CLK

CLK

D

Flop

D

Q

Q

1: Introduction

ACOE419 – Digital IC and VLSI Design

51

D Flip-flop Design

Built from master and slave D latches

CLK

CLK

CLK

QM

D

CLK

QM

Latch

D

Latch

CLK

CLK

Q

CLK

Q

CLK

1: Introduction

CLK

ACOE419 – Digital IC and VLSI Design

CLK

52

D Flip-flop Operation

D

QM

Q

CLK = 0

D

QM

Q

CLK = 1

CLK

D

Q

1: Introduction

ACOE419 – Digital IC and VLSI Design

53

Race Condition

Back-to-back flops can malfunction from clock skew

– Second flip-flop fires late

– Sees first flip-flop change and captures its result

– Called hold-time failure or race condition

CLK1

CLK2

Q1

Flop

D

Flop

CLK1

CLK2

Q2

Q1

Q2

1: Introduction

ACOE419 – Digital IC and VLSI Design

54

Nonoverlapping Clocks

Nonoverlapping clocks can prevent races

– As long as nonoverlap exceeds clock skew

We will use them in this class for safe design

– Industry manages skew more carefully instead

2

1

QM

D

2

2

2

Q

1

1

1

1

2

1: Introduction

ACOE419 – Digital IC and VLSI Design

55

CMOS Fabrication

CMOS transistors are fabricated on silicon wafer

Lithography process similar to printing press

On each step, different materials are deposited or

etched

Easiest to understand by viewing both top and

cross-section of wafer in a simplified manufacturing

process

1: Introduction

ACOE419 – Digital IC and VLSI Design

56

Inverter Cross-section

Typically use p-type substrate for nMOS transistors

Requires n-well for body of pMOS transistors

A

GND

VDD

Y

SiO2

n+ diffusion

n+

n+

p+

p+

n well

p substrate

nMOS transistor

1: Introduction

p+ diffusion

polysilicon

metal1

pMOS transistor

ACOE419 – Digital IC and VLSI Design

57

Well and Substrate Taps

Substrate must be tied to GND and n-well to VDD

Metal to lightly-doped semiconductor forms poor

connection called Shottky Diode

Use heavily doped well and substrate contacts / taps

A

GND

VDD

Y

p+

n+

n+

p+

p+

n+

n well

p substrate

well

tap

substrate tap

1: Introduction

ACOE419 – Digital IC and VLSI Design

58

Inverter Mask Set

Transistors and wires are defined by masks

Cross-section taken along dashed line

A

Y

GND

VDD

nMOS transistor

pMOS transistor

well tap

substrate tap

1: Introduction

ACOE419 – Digital IC and VLSI Design

59

Detailed Mask Views

Six masks

– n-well

– Polysilicon

– n+ diffusion

– p+ diffusion

– Contact

– Metal

n well

Polysilicon

n+ Diffusion

p+ Diffusion

Contact

Metal

1: Introduction

ACOE419 – Digital IC and VLSI Design

60

Fabrication

Chips are built in huge factories called fabs

Contain clean rooms as large as football fields

Courtesy of International

Business Machines Corporation.

Unauthorized use not permitted.

1: Introduction

ACOE419 – Digital IC and VLSI Design

61

Fabrication Steps

Start with blank wafer

Build inverter from the bottom up

First step will be to form the n-well

– Cover wafer with protective layer of SiO2 (oxide)

– Remove layer where n-well should be built

– Implant or diffuse n dopants into exposed wafer

– Strip off SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

62

Oxidation

Grow SiO2 on top of Si wafer

– 900 – 1200 C with H2O or O2 in oxidation furnace

SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

63

Photoresist

Spin on photoresist

– Photoresist is a light-sensitive organic polymer

– Softens where exposed to light

Photoresist

SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

64

Lithography

Expose photoresist through n-well mask

Strip off exposed photoresist

Photoresist

SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

65

Etch

Etch oxide with hydrofluoric acid (HF)

– Seeps through skin and eats bone; nasty stuff!!!

Only attacks oxide where resist has been exposed

Photoresist

SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

66

Strip Photoresist

Strip off remaining photoresist

– Use mixture of acids called piranah etch

Necessary so resist doesn’t melt in next step

SiO2

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

67

n-well

n-well is formed with diffusion or ion implantation

Diffusion

– Place wafer in furnace with arsenic gas

– Heat until As atoms diffuse into exposed Si

Ion Implanatation

– Blast wafer with beam of As ions

– Ions blocked by SiO2, only enter exposed Si

SiO2

n well

1: Introduction

ACOE419 – Digital IC and VLSI Design

68

Strip Oxide

Strip off the remaining oxide using HF

Back to bare wafer with n-well

Subsequent steps involve similar series of steps

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

69

Polysilicon

Deposit very thin layer of gate oxide

– < 20 Å (6-7 atomic layers)

Chemical Vapor Deposition (CVD) of silicon layer

– Place wafer in furnace with Silane gas (SiH4)

– Forms many small crystals called polysilicon

– Heavily doped to be good conductor

Polysilicon

Thin gate oxide

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

70

Polysilicon Patterning

Use same lithography process to pattern polysilicon

Polysilicon

Polysilicon

Thin gate oxide

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

71

Self-Aligned Process

Use oxide and masking to expose where n+ dopants

should be diffused or implanted

N-diffusion forms nMOS source, drain, and n-well

contact

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

72

N-diffusion

Pattern oxide and form n+ regions

Self-aligned process where gate blocks diffusion

Polysilicon is better than metal for self-aligned gates

because it doesn’t melt during later processing

n+ Diffusion

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

73

N-diffusion cont.

Historically dopants were diffused

Usually ion implantation today

But regions are still called diffusion

n+

n+

n+

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

74

N-diffusion cont.

Strip off oxide to complete patterning step

n+

n+

n+

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

75

P-Diffusion

Similar set of steps form p+ diffusion regions for

pMOS source and drain and substrate contact

p+ Diffusion

p+

n+

n+

p+

p+

n+

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

76

Contacts

Now we need to wire together the devices

Cover chip with thick field oxide

Etch oxide where contact cuts are needed

Contact

Thick field oxide

p+

n+

n+

p+

p+

n+

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

77

Metalization

Sputter on aluminum over whole wafer

Pattern to remove excess metal, leaving wires

Metal

Metal

Thick field oxide

p+

n+

n+

p+

p+

n+

n well

p substrate

1: Introduction

ACOE419 – Digital IC and VLSI Design

78

Layout

Chips are specified with set of masks

Minimum dimensions of masks determine transistor

size (and hence speed, cost, and power)

Feature size f = distance between source and drain

– Set by minimum width of polysilicon

Feature size improves 30% every 3 years or so

Normalize for feature size when describing design

rules

Express rules in terms of l = f/2

– E.g. l = 0.3 mm in 0.6 mm process

1: Introduction

ACOE419 – Digital IC and VLSI Design

79

Simplified Design Rules

Conservative rules to get you started

1: Introduction

ACOE419 – Digital IC and VLSI Design

80

Inverter Layout

Transistor dimensions specified as Width / Length

– Minimum size is 4l / 2l, sometimes called 1 unit

– In f = 0.6 mm process, this is 1.2 mm wide, 0.6 mm

long

1: Introduction

ACOE419 – Digital IC and VLSI Design

81

Gate Layout

Layout can be very time consuming

– Design gates to fit together nicely

– Build a library of standard cells

Standard cell design methodology

– VDD and GND should abut (standard height)

– Adjacent gates should satisfy design rules

– nMOS at bottom and pMOS at top

– All gates include well and substrate contacts

1: Introduction

ACOE419 – Digital IC and VLSI Design

82

Example: Inverter

1: Introduction

ACOE419 – Digital IC and VLSI Design

83

Example: NAND3

Horizontal N-diffusion and p-diffusion strips

Vertical polysilicon gates

Metal1 VDD rail at top

Metal1 GND rail at bottom

32 l by 40 l

1: Introduction

ACOE419 – Digital IC and VLSI Design

84

Stick Diagrams

Stick diagrams help plan layout quickly

– Need not be to scale

– Draw with color pencils or dry-erase markers

VDD

VDD

A

A

B

C

c

Y

GND

INV

1: Introduction

Y

GND

metal1

poly

ndiff

pdiff

contact

NAND3

ACOE419 – Digital IC and VLSI Design

85

Wiring Tracks

A wiring track is the space required for a wire

– 4 l width, 4 l spacing from neighbor = 8 l pitch

Transistors also consume one wiring track

1: Introduction

ACOE419 – Digital IC and VLSI Design

86

Well spacing

Wells must surround transistors by 6 l

– Implies 12 l between opposite transistor flavors

– Leaves room for one wire track

1: Introduction

ACOE419 – Digital IC and VLSI Design

87

Area Estimation

Estimate area by counting wiring tracks

– Multiply by 8 to express in l

40 l

32 l

1: Introduction

ACOE419 – Digital IC and VLSI Design

88

Example: O3AI

Sketch a stick diagram for O3AI and estimate area

–

Y A B C D

VDD

A

B

C

D

Y

6 tracks =

48 l

GND

5 tracks =

40 l

1: Introduction

ACOE419 – Digital IC and VLSI Design

89

Example

Draw a stick diagram and estimate the area for a 4input NOR gate

1: Introduction

ACOE419 – Digital IC and VLSI Design

90

Example

For a compound gate implementing the boolean

function F=((A+B)C)΄:

– Sketch a transistor-level schematic

– Sketch a stick diagram

– Estimate the area from the stick diagram

1: Introduction

ACOE419 – Digital IC and VLSI Design

91

Summary

MOS transistors are stacks of gate, oxide, silicon

Act as electrically controlled switches

Build logic gates out of switches

Draw masks to specify layout of transistors

Now you know everything necessary to start

designing schematics and layout for a simple chip!

1: Introduction

ACOE419 – Digital IC and VLSI Design

92

Spice netlist

vdd vdd gnd 5

Vin a gnd pwl 0ps 0 10ns 0 10.5ns 5 50ns 5 50.5ns

0

*** TOP LEVEL CELL: myinv2{lay}

Mnmos@0 y a gnd gnd N L=0.8U W=0.8U AS=3.54P

AD=1.72P PS=8.15U PD=5.8U

Mpmos@0 vdd a y vdd P L=0.8U W=1.6U AS=5.2P

AD=3.54P PS=9.7U PD=8.15U

1: Introduction

ACOE419 – Digital IC and VLSI Design

93