Flow equations in various cases

advertisement

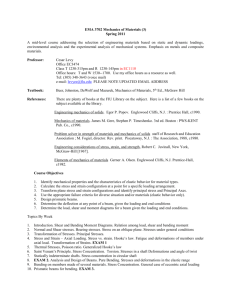

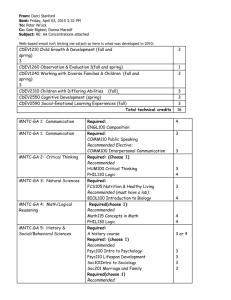

©MBDCI Stress, Strain, Pressure, Deformation, Strength, etc. Maurice Dusseault Stress-Strain-Strength Intro ©MBDCI Common Symbols in RM E, n: Young’s modulus, Poisson’s ratio f: Porosity (e.g. 0.25, or 25%) c′, f′,To: Cohesion, friction , tensile strength T, p, po: Temperature, pressure, initial pres. sv, sh: Vertical and horizontal stress shmin, sHMAX: Smallest, largest horizontal σ s1,s2,s3:Major, intermediate, minor stress r, g: Density, unit weight (g= rg) K, C: Bulk modulus, compressibility These are the most common symbols we use Stress-Strain-Strength Intro ©MBDCI Stress and Pressure Petroleum geomechanics deals with stress, pressure Stress is a force over an area Pressure is that part of the boundary forces supported by the fluid phase only Do not confuse the two! Pressure – p – for fluids only. Fluid can be water, oil, gas… Stress-Strain-Strength Intro sa – axial stress pore pressure A po sr – radial stress Fa sa A ©MBDCI Stresses Stresses in sedimentary rocks arise because of gravity and geological history Stresses are different in different directions Three principal stresses are orthogonal, and the vertical direction is usually one of them Overburden weight is = sv (+/- 5%) The lateral stresses, shmin and sHMAX (or sh and sH) are at 90° to each another Stress-Strain-Strength Intro ©MBDCI Stress Definitions s1 > s2 > s3 s3 Principal s2 Stresses s1 s1 s2 max planes sa = s1 sr sr = s3 s3 slip planes Triaxial Test Stresses sa y We usually assume sv is a principal stress x sv sHMAX > shmin sr sq sHMAX shmin In Situ Stresses Stress-Strain-Strength Intro q r ri z Borehole Stresses ©MBDCI Local, Reservoir and Regional Scales Regional Scale Stresses ~100 km Basin scale: 50 km to 1000 km Often called “far-field stresses” Reservoir Scale Stresses ~4 km A reservoir, or part of a reservoir Scale from 500 m to several km Salt dome region: 5-20 km affected zone ~400 m Local Scale Stresses Borehole region: 1-5 m Drawdown zone (well scale) 100-1000 m Small Scale Stresses (less than 10-20 cm) Stress-Strain-Strength Intro ©MBDCI Discontinuities & Rocks Rocks are heterogeneous at all scales (microns to kilometers) In granular media, macroscopic stresses are transmitted through grain contact forces (fn, fs) fs = shear force fn = normal force Stress-Strain-Strength Intro ©MBDCI Definition of Stress sh Stress is the force over an area: s = F/A However, at a small scale, grain-to-grain forces act! At grain contacts, local stresses can be huge (pressure solution effects) Stresses are averages of forces on a plane surface: Sfn/AS Pressure: in fluid only Stress-Strain-Strength Intro sv f1 f2 f4 po f3 s sh ©MBDCI Effective Stresses Stress-Strain-Strength Intro sv + po = sv (or Sv) f1 f2 f4 po f3 sv + po = sv (or Sv) sh + po = sh (or Sh) Pressure is the same in all directions (a fluid) Effective stress is the sum of the grain-to-grain (matrix) forces The sum of p and s gives total stresses, s Usually, sv = r(z)dz shmin , sHMAX must be measured or estimated sh + po = sh (or Sh) ©MBDCI Effective (Matrix) Stress & Pressure Example: total vertical stress (sv) is the sum of the stress transmitted through the solid grain contacts (s′v) and the pore pressure (p) sv s‛v p …or…Total stress = sum of matrix stress plus pore pressure This is known as the “effective stress law” or the “Terzaghi Law” or the “effective stress principle” Stress-Strain-Strength Intro ©MBDCI Example of Effective Stress Consider a hovercraft – the mass is M At rest, all the stress is through solid-solid This is 100% “effective stress” (p = 0) When operating, p·A = M·g In other words, the pore pressure is supporting all of the weight, so the effective stress = 0 p·A = W (= M·g) M Stress-Strain-Strength Intro p ©MBDCI REMEMBER! Total stress is the sum of effective stress and the pore pressure: symbol is σ Effective (or matrix) stress) is the force transmitted through the solid: symbol is Pore pressure is the force transmitted through the fluid phase: symbol is σ′ p σ σ′ + p (σhmin σ′hmin + p; σHMAX σ′HMAX + p σθ σ ′θ + p , etc…) Stress-Strain-Strength Intro ©MBDCI Stresses (II) Normal stresses (s) act orthogonal (normal) to a plane and cause the material to compress Shear stresses () act parallel to a plane and cause the- material to distort sy yx xy sx+ y xy yx sy+ x Stress-Strain-Strength Intro sx - Static equilibrium: sx sx sy sy xy = - yx ©MBDCI Pressures Pressures refer to the fluid potential (p) Pressures can be hydrostatic, less than hydrostatic (rare) or greater (common). Called underpressured or overpresssured Pressures at a point are the same in all directions because they are within the fluid We assume that capillary effects are not important for large stresses and pressures Also, differences in pressures lead to flow Stress-Strain-Strength Intro ©MBDCI Pressures at Depth pressure (MPa) ~10 MPa Fresh water: ~10 MPa/km Sat. NaCl brine: ~12 MPa/km Hydrostatic pressure distribution: p(z) = rwgz 1 km Underpressured case: underpressure ratio = p/(rwgz), a value less than 1 underpressure depth Stress-Strain-Strength Intro Overpressured case: overpressure ratio = p/(rwgz), a value greater than 1.2 overpressure Normally pressured range: 0.95 < p(norm) < 1.2 The “Unifying” Principle in RM ©MBDCI The famous Terzaghi concept (1921) Only changes in “effective” stresses [s′ij ] affect strength and deformation behavior (as a first approximation) Effective stress is the component transmitted through the solid rock matrix Total stresses are the sum of the effective stresses and the pressures: s = s + p, or: sij = [s]ij + [p] Stress-Strain-Strength Intro ©MBDCI What is “Strain”? Strain is the deformation that has occurred during a stress change (Δσ′) It is expressed as a ratio to the original length Δσ′ ΔL L a L axial L Stress-Strain-Strength Intro Δσ′ ε = 0.01 = 1% strain What is “Volumetric Strain” - εv? ©MBDCI It is the change in volume (ΔV/V) during a change in the all-around effective stress (Δσ′) It is linked to the bulk modulus V s v x y z V K Δσ′ Compressibility: Δσ′ ΔV or Δf Δσ′ Stress-Strain-Strength Intro Δσ′ 1 V 1 K = bulk modulus K V s C3D = compressibility = 1/K Pore volume compressibility = Cf 1 f Cf f s ©MBDCI Strain vs. Deformation… Deformation is the sum of all strains over a specified distance Example: subsidence of 1.5 m at the surface is a deformation; however, in a 100 m thick compacting reservoir, this is εv = 0.015 (1.5%) subsidence bowl z ~ 1.5 m depth, Z compaction = 1.5 m, εv = 1.5/100 = 0.015 h = 100 m Stress-Strain-Strength Intro In this case, use C1D width, W ©MBDCI Use of Strain in Geomechanics We usually only speak of normal strain, seldom about shear strain (angular distortion) We usually use only the principal normal strains, in the direction of the principal stresses In anisotropic, jointed or sheared rocks, the concept of strain becomes very complicated… the anisotropy is at an to the principal stresses If there is slip along the shear plane or joints A shear plane is never║to the principal stresses If Stress-Strain-Strength Intro ©MBDCI Strain and Shear Slip Stress-Strain-Strength Intro σ a = σ1 σr = σ3 As σa increased, εa took place as well However, when yield took place, deformation only along slip plane! We cannot speak about strain any more, only slip or deformation Also, there is elastic strain and plastic strain… σr = σ3 σ a = σ1 ©MBDCI Rock Stiffness Determination Stiffness controls stress changes Estimate stiffness using correlations based on geology, density, porosity, lithology, .... Use seismic velocities (vP, vS) for an upperbound limit (invariably an overestimate) Use measurements on laboratory specimens (But, there are problems of scale and joints) In situ measurements Back-analysis using monitoring data Stress-Strain-Strength Intro ©MBDCI What are E and n? s deformation L Young’s modulus (E): E is how much the material compresses under a change in effective stress Poisson’s ratio n: n is how much rock expands laterally when compressed. If n = 0, no expansion (eg: sponge) In n = 0.5, complete expansion, therefore volume change is zero Stress-Strain-Strength Intro radial dilation r L strain () = L E = s n = r L L ©MBDCI Thermal Expansion (Thermal Strain) When rocks are heated, expansion takes place We call this “thermoelastic” expansion… The coefficient of volumetric thermal expansion is defined However, the pore liquid can expand at a different rate than the matrix! Stress-Strain-Strength Intro (constant σ′, p) ΔT → ΔV 1 V V T 1 L T L T Thermal strains v ] T [ x y z ] T Note: linear & volumetric coefficients of thermal expansion differ by a factor of three: β = 3αT ©MBDCI Rock Strength (I) Strength can be resistance to shear stress (shear strength), compressive normal stress (crushing strength), tensile stress (tensile strength), bending stress (beam strength)… All of these depend on effective stresses (s), therefore we must know the pore pressure (p) Rock specimen strength is usually very different than rock mass strength because of joints, bedding planes, fissures, etc. Which to use? Depends on the problem scale. Stress-Strain-Strength Intro ©MBDCI How To “Test” This Rock Mass? Joints and fractures can be at scales of mm to several meters Large f core: 115 mm Core plugs: 20-35 mm If joints dominate, small-scale core tests are “indicators” only This issue of “scale” enters into all Petroleum Geomechanics analyses A large core specimen A core “plug” 1m Machu Picchu, Peru, Inca Stonecraft Stress-Strain-Strength Intro ©MBDCI Rock Strength (II) Tensile strength (To) is difficult to measure: it is directiondependent, flaw-dependent, sample size-dependent, ... To is used in fracture models (HF, thermal fracture, tripping or surge fractures) For a large reservoir, To is assumed to be zero because of joints, bedding planes, etc. Stress-Strain-Strength Intro F Prepared rock specimen A To = F/A F ©MBDCI Rock Strength (III) Shear strength is a vital geomechanics strength aspect, used for design Shearing is associated with: •Borehole instabilities, including breakouts, failure •Reservoir shear and induced seismicity •Casing shear and well collapse •Reactiviation of old faults, creation of new ones •Hydraulic fracture in soft, weak reservoirs •Loss of cohesion and sand production •Bit penetration, particularly PCD bits sn is normal effective stress is the shear stress,║to slip plane Stress-Strain-Strength Intro sn slip plane rock ©MBDCI Rock Strength (IV) sa slip planes sr sr stress difference sa σ1 - σ3 peak strength Stress-Strain-Strength Intro axial strain εa Shear strength depends on the frictional behaviour and the cohesion of the rock Carry out a series of triaxial shearing tests at different s3, plot each as a stress-strain curve, determine peak strengths ©MBDCI What is “Failure”? Be very careful!! Failure is a loss of function. Rock yield is a loss of strength. Don’t confuse them!! For example: Most boreholes have “yielded” zones But, the hole has not collapsed! …or “failed”! It still fulfills its function (allowing drill advance) sMAX Stress-Strain-Strength Intro smin Breakouts ©MBDCI Yield vs. Failure When a rock passes its peak strength, we say it has “yielded” (strain-weakening) A strength criterion is also called a yield criterion. The most common yield criterion for rocks is the Mohr-Coulomb yield criterion The blue line is the M-C yield (or failure) criterion for a single GMU. Stress-Strain-Strength Intro = shear stress To f′ = friction angle c′ = cohesion σ′n = normal effective stress ©MBDCI Cautions! Even within rock mechanics, there are semantic arguments (e.g. strain-weakening vs. strain-softening…, yield vs. failure…) Be clear and consistent in how you use terms. Define them if necessary. Make sure others clarify their usage as well. When in doubt, ask for clarification! Stress-Strain-Strength Intro

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)