Catherine Keen Illumin Article Writing 340: 66800, Professor

advertisement

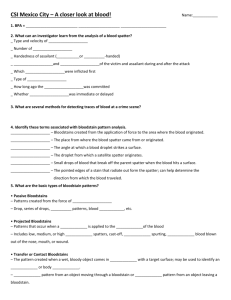

Catherine Keen Illumin Article Writing 340: 66800, Professor Aubertin, 9 AM Walking on Fire: Eliminating Friction through Levitation Real World Levitation Levitation is easily dismissed as science fiction, a futuristic novelty, but the implications of levitation go beyond trendy gadgets and hovercrafts; levitation has the potential to nearly eliminate friction. In most mechanical applications, friction opposes the desired motion, decreasing efficiency and wasting energy. Since higher efficiency means lower cost, decreasing friction is a common goal for manufacturers. In the past, this meant smoothing surfaces and using lubrication, but levitation introduces the possibility of nearly eliminating friction rather than simply decreasing its effects, making it a more attractive option. However, an issue with employing levitation in mechanical applications is its unreliable nature. Levitation implies a solid object floating on a gas, and since the molecules in gasses are spread much more widely than those in solids, their behavior is much less predictable. Gas molecules bounce around, filling the entire container they are in as opposed to those in a solid which stay relatively stationary, simply vibrating in place. This causes discontent for those working in mechanical fields because they understand the necessity of extreme precision. From car engines to fuselages to machines in factories, many mechanical systems do not leave very much cushion room for a part to go off course. These machines need to work the way they were designed to, with each part depending on the others, so it becomes difficult to consider levitation with the uncertainty that erratic gas molecules introduce to systems. Nevertheless, levitation is a developing field with magnets as a recent favorite, such as their employment in maglev trains. But in 1732, a Dutch scientist noted that liquid droplets can levitate due to something now known as the Leidenfrost effect (3). However, assumed to be an erratic, uncontrollable reaction, the Leidenfrost effect has been continuously overlooked in favor of other more plausible venues because of the need for precision in mechanical applications. But is overlooking the Leidenfrost discovery as impractical a miscalculation? This is the implication of recent studies attempting to not only regulate but also take advantage of the Leidenfrost effect. The Leidenfrost Effect: History and Explanation Have you ever splashed water on a hot skillet? The water droplets bounce and dance around due to the Leidenfrost effect. If a surface is hot enough when water comes in contact with it, the bottom of the water droplet evaporates so rapidly that the water vapor creates a cushion between the liquid water droplet and the hot surface. Water vapor has a low thermal conductivity, meaning that it requires a large amount of heat, and therefore a longer time, to increase its temperature. This also increases the time it takes for the liquid water droplets to heat up with the water vapor acting as a barrier between the liquid and the hot surface. Therefore, evaporation is delayed, allowing the water droplets to levitate. (3) The Leidenfrost effect is not a new discovery. It dates all the way back to 1732 when Boerhaave became the first documented scientist to mention this effect. He noted that alcohol droplets on hot iron plates did not catch fire as expected and determined they must float instead. However, the phenomenon was named after Johann Leidenfrost due to his extensive research and investigation on it in 1756. Specifically, he observed that water droplets levitate on the back of a hot spoon and investigated the implications of this phenomenon. It has since been used by scientists such as Faraday in various applications ranging from nuclear reactors to walking on fire. (3) The next major step for the Leidenfrost effect is to apply it to mechanical systems to eliminate friction. This involves two primary steps: controlling the path of Leidenfrost droplets and manipulating it to levitate mechanical parts on top of the droplets. The Path of Leidenfrost Drops The first step in exploiting Leidenfrost droplets is to control their motion. Leidenfrost drops over smooth surfaces move erratically, but in order to use the Leidenfrost effect to levitate mechanical parts, it is necessary to direct the path of the Leidenfrost drops and therefore the mechanical part. In 2006, however, it was discovered that a ridged plate can act as a ratchet to direct the path of Leidenfrost drops. As the drops levitate, they are pushed towards the steeper side of the ridge (http://www.wimp.com/leidenfrosteffect/ Figure 1). Using this discovery, a recent study made a circular ratchet to act as a trap for these droplets to observe their behavior (1). http://www.wimp.com/leidenfrosteffect/ Figure 1 In the video above, the ratchet trap can be seen in action. Specifically, it zooms in on the droplets, showing in detail how the droplets move over the ratchet. The droplets appear to almost climb over the steep side of the ratchet as they self-propel. The science of why the droplets self-propel delves into exceptionally complex concepts within thermal dynamics, but it has to do with the low thermal conductivity of the water vapor discussed in the prior section. Figure 1, however, exhibits the reliability of the droplets’ movement along the ratchet when they make the maze. There is no initial force applied on the droplets when they are put in the maze, but they still move forward because the drops self-propel. The drops also all move along the maze in relatively the same direction. With further research and development, this movement could hopefully be fine-tuned to better fit mechanical applications. The study concluded that the Leidenfrost droplets change shape multiple times, developing lobes ( Figure 2). This implies that even though the general path of the Leidenfrost droplets can be manipulated, the drops still act erratically. Then again, the video in figure 1 shows that after an extended period of timed, the droplets gradually form into a uniform circle if stationary, but drops in movement act less predictably. However, the study also analyzed and plotted the drops’ movement, revealing some promising results. After about a 1 second period to adjust to any change in motion, such as speeding up, slowing down, or changing direction, the drops tend to follow a model similar to the one used for orbiting planets with a few variances. (1) Figure 2 The major problem with the study was that the researchers assumed that everything occurring within the droplets was negligible and therefore ignored them. However, the internal forces of a Leidenfrost droplet are stronger than expected and do affect the path of the droplets, leading to the discrepancies between the model and the actual path of a Leidenfrost drop. These internal forces include turbulence within the droplet, which also causes the changes in shape, viscous forces, and complex fission and fusion, as concluded by the ratchet trap study. By investigating these forces and incorporating them into the model, future predictions have the possibility of better predicting the movement of Leidenfrost droplets, allowing this effect to be utilized to its fullest potential. (1) The Leidenfrost Cart The next goal in employing the Leidenfrost effect involves levitating solid parts on top of the drops. With this ability, it can hopefully eliminate friction between parts in mechanical systems. The Leidenfrost effect only works on liquids, so to apply it, it is necessary to determine Leidenfrost droplets’ ability to levitate solid parts. A recent study tested this theory using a thin plate, referred to as a “Leidenfrost cart”. The bottom of the plate was coated with water and placed on a surface above the Leidenfrost temperature so the cart could experience uniform levitation through the water and the Leidenfrost effect. (2) As drops experience the Leidenfrost effect, the water vapor delays evaporation but does not halt it. This means the liquid is still evaporating, though slowly, introducing the need to replenish the water in order to sustain levitation. To address this, the Leidenfrost cart had a hole in the middle where a syringe was inserted to replace the water lost through evaporation on the bottom of the plate. The added water does not spread across the bottom of the plate evenly but rather in lobes, previously mentioned and shown in figure 2, like fingers extending across the bottom. This irregular spread of the water causes instabilities in the plate’s levitation, so the study concluded that the plate should be modified to have multiple entry points for water rather than just one. Although a Leidenfrost cart with multiple entry points has not yet been tested, with multiple entry points, the new water can coat the bottom of the plate more evenly, allowing for steadier levitation, which is essential in the mechanical field. Although the Leidenfrost cart did not act exactly as a mechanical part must, this is an early study. After more follow-up studies, the Leidenfrost cart still has the possibility of becoming a viable application in mechanical engineering. With more event distribution of the water and a regulator for the speed, the Leidenfrost cart can develop into a feasible way to levitate parts, thereby introducing a revolutionary way to eliminate friction. Conclusion Though the Leidenfrost effect was discovered centuries ago, researchers are just beginning to explore its potential. In the past it was assumed to be too erratic for mechanical applications which require a degree of precision and exactness, but recent studies have shown that it may be possible to control it. Further, Leidenfrost droplets self-propel over ratchets, demonstrating another incredibly useful property in that mechanical systems may not need added force to initiate and maintain motion if the Leidenfrost effect was employed. Although Leidenfrost droplets still behave somewhat erratically, further research into the topic could provide a solution, and, now that research into it has begun, the number of experiments will only increase. With the prospect of the Leidenfrost effect in the future, the possibilities it offers are inconceivable. It offers the chance to eliminate friction, the eternal strife of the mechanical industry. Eliminating friction would not only save power and money but also offers the chance for machines to run more smoothly without need for lubrication or perfectly smooth surfaces. Since the parts would no longer be physically touching other parts, they would not rub against one another, reducing wear. The Leidenfrost effect and its prospects insist that levitation is not as futuristic as once believed but rather may exist in the near future. References (1) Cousins, Thomas R., et al. "A Ratchet Trap for Leidenfrost Drops." Journal of Fluid Mechanics 696 (2012): 215-27. ProQuest. Web. (2) Hashmi, Ali, Yuhao Xu, Benjamin Coder, Paul A. Osborne, Jonathon Spafford, Grant E. Michael, Gan Yu, and Jie Xu. "Leidenfrost Levitation: Beyond Droplets." Scientific Reports 2 (2012): 797. Web. (3) Thimbleby, Harold. "The Leidenfrost Phenomenon." Physics Education 24.5 (1989): 24. Web. (4) Vakarelski, Ivan U., Neelesh A. Patankar, Jeremy O. Marston, Derek Y. C. Chan, and Sigurdur T. Thoroddsen. "Stabilization of Leidenfrost Vapour Layer by Textured Superhydrophobic Surfaces." Nature 489.7415 (2012): 274-77. Web.