Bridgestone Corporation

advertisement

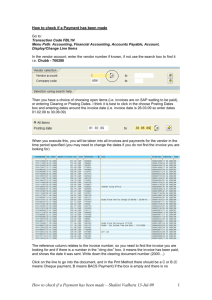

Yves Kerstens, Vice President Logistics & Supply Chain Management Supply-Chain Council European Conference, 11 October 2007 Global Organisation Bridgestone Bridgestone Corporation Head Office: Tokyo, Japan Bridgestone America Holding Bridgestone Europe NV/SA Regional HQ in Nashville, USA Regional HQ in Brussels 4 technical centres Tokyo, Japan (2), Rome, Italy & Akron, USA 57 tyre factories worldwide 98 plants for other products Sales network in more than 150 nations and territories around the world 2006 Key Data: Employees, worldwide Consolidated subs Financial results Net earnings 123,000 440 companies 25,1 billion US$ 714 million US$ Activities and Products Tyres (80 % of our total activity) Passenger cars and recreational vehicles Trucks and buses, heavy and light Commercial vans Agriculture Off-the-road vehicles Motorcycles and scooters Aircraft Subways and monorails Racing, go-karts, motorcycles and scooters Tyre Market Sales - Evolution 1986 – 2005 Millions of US dollars - Source: Tire Business, August 28, 2006 18 333 17 888 17 920 18 000 16 150 16 000 16 750 13 751 13 465 14 000 12 000 14 800 17 500 15 150 13 600 12 300 10 000 8 000 6 800 6 000 4 000 2 000 5 600 6 100 6 350 4 043 4 513 4 796 6 000 2 693 2 200 2 000 3 255 2 717 2 922 02 03 3 150 3 616 1 700 0 86 88 90 92 Bridgestone 94 Michelin 96 98 Goodyear 99 01 Continental Pirelli 04 Sumitomo 05 06 Passenger Car Tyres: Original Equipment Market 20,000 18,000 25.0% Bridgestone evolution in the European OE market 19.3% Bridgestone basically supplies tyres to all mass market manufacturers in the world 16,000 17.9% 14,000 12,000 15.0% 12.9% 18.2% 18.2% 19.6% 20.0% 18.3% 20.0% 15.4% 13.5% 15.0% 10,000 8,000 11,605 13,129 13,518 15,249 15,332 15,238 11,691 6,000 10.0% 15,759 16,687 16,806 17,231 4,000 5.0% 2,000 0 0.0% 2001 2002 2003 2004 2005 2006 2007 Est 2008 LTP 2009 LTP 2010 LTP 2011 LTP Passenger Car Tyres: Replacement Market For the replacement market, Bridgestone Europe produces tyres for small city cars up to exclusive super cars. Tyres are sold through retail channels such as: tyre dealers, auto centres, gas stations, hyper markets and car dealers. Bridgestone Europe has a market share of around 13% in Europe with a target to reach 15% by 2008. Bridgestone Europe sells mainly following brands: Bridgestone, Firestone and Dayton, following the multibrand strategy: good-better-best. The Supply Chain Management Policy A Network structure in line with market requirements, competitors and new European environment European Borders are fading, supporting cross border business flows Central control of Finished Goods inventory to improve customer service Provide a consistent 24 hours service to almost 95 % of the customers in Europe Implementation of Pan-European strategies in the area of warehousing and distribution resulting in a lower cost base Consistent measurement of our integrated performance to be able to benchmark and define improvements A European LSCM organization with people acting on a central, regional and local base Gain Competitive Advantage Business plan objectives Customer Service improvements Reduction of Cost To Serve (-10 %) Functional Excellence and Organisational Synergies Reduced Asset Base and Working Capital Produces Integrates supply chain & delivers Sells & defines customer needs MANUFACTURING BSEU LSCM SALES PLANTS Economies of Scale PLANT DISTRIBUTION WHS WHS Customer Service Cost to serve Minimise costs CUSTOMERS Differentiation Customer Focus Our Supply Chain Vision The supply chain division writes the music, directs the orchestra, but has some musicians being employed by third parties Bridgestone One of the major drivers: the increasing affordable accessibility of information and communication technology (ICT) that enables the execution of the supply chain The How ? Working Smarter: Process optimalisation Operational excellence Continuous Improvements Standardization Working Cheaper: Cost optimalisation Creation of Center of Excellences Outsourcing to create synergies Virtual organization Working Bigger: Scale optimalisation Organic growth Shared operations The How? Drivers for outsourcing operations and business processes Create visibility and control over service levels and costs Support a flexible network structure to adapt changes in the markets -Variable cost base Cost reduction via more efficient operations (use 3PL experience/buying power) Lack of local experience Focus on core activities Standardization Outsourcing components Transport (FTL) Distribution (Milk runs) Warehousing operations Real estate Warehouse & Transportation Systems Planning – Control tower (Track & trace) Invoice control Contract management Inventory management Strategy is to outsource operations but keep limited number in-sourced to keep operational experience and internal benchmarking possibilities Outsourcing of Freight Invoice verification Context Solution Carriers consolidation in Europe (2004-2007) Central negotiations and standard contracts in place Ownership of all transportation contracts shifted to BSEU Compliance follow-up needed (Maverick spend) Outsource this process to a third party with automatic control of pricing and posting of invoices into ERP Avoid invoice duplication Reduce overbilling (2-3%) 100 % Rate check 100 % Execution check Correct accrual setting Outsource because of Organisation of invoice verification, booking and payment needed to be improved and aligned Dedicated and experienced team LSCM Focus on service Timely & Accurate reporting Quality / Control / Audit Cost Reductions Visibility improved management capabilities Business issues ISSUES BENEFITS OF CENTRALISATION Difficult to control freight costs and accruals, since automatic accruals have to be made on a line item basis Based on agreed rates a pre-invoice is checked by the carrier and accruals are automatically uploaded in SAP Concern that SAP posting are being made by many different people around Europe who have open access to central accounting Limit access to central accounting as key job is outsourced, which will reduce control risks Upload invoice data electronically Reluctance by some local operations to perform this duty, therefore we cannot guarantee that invoices are processed on an ‘accurate and timely’ basis BSEU will pass responsibility to an independent 3rd party & free up local resources How to control if transporters are over billing ? (we check only a % of invoices) Potential cost savings for LSCM from stopping over billing via 100% checking and economies of scale / systems use to reduce working hours involved Time consuming to book numerous freight invoices into SAP (+- 10.000/year) Potentially save money from economies of scale & systems. Permit staff to focus on their ‘core’ jobs Waste time when vendors call concerning unpaid invoices Outsourced & centralised in 1 location where all info is available for quicker response + pro-active control of invoices as they are received Partner selection A B C D ++ +++ +++ - Pre-billing Invoice Matching Invoice Matching Invoice Matching IT Innovation +++ ++ + ? Confidentiality +++ --- +++ +++ Maturity (Experience on the market) ++ +++ + + Flexibility +++ ++ + - Communication Flow +++ ++ ++ - Business knowledge (BSEU requirements) ++ + + - Main Business (yes=***/ no=*) Yes No No No Audit Process (Criterias audited) +++ +++ +++ - Issue resolution Flow +++ ++ ++ - Continuous Improvements (proactive collaboration) +++ ++ +++ ? NL / Ukraine NL / Czech India /Europe Europe To be negotiated Per activity Headcount based Per activity Implementation process Service Offered Location Pricing structure ControlPay Process overview (1) Bridgestone LSCM 3 PL (2) (2) Execution 3 PL (1) FSE (2) Consolidation of orders Reporting Pre- invoice ETOF Order details Pre - calculation & account coding ISD Match (3) No Issue resolution Statement What 3 PL Should invoice OK Yes Final Invoice (5) (4) ISDR (6) Approved final invoice with coding details Payment Bridgestone Finance (7) Integrated process of planning, execution, audit and settlement Expected Benefits Operational benefits Central rate database management : Carriers cannot be used without approved rates 100% invoice line check including special costs like waiting times, gas oil surcharge,… Communication platform with carriers (replacing phone, fax,…) One Point of contact for our European suppliers with full traceability of issue resolution Visibility and Increased compliance Dedicated and experienced team Timely & correct accruals for month end closing Compliance Sarbanes-Oxley (SOX) Compliance : Segregation of duties VAT will be invoiced as per agreed VAT rules as opposed to being accepted as billed by carriers Costs Reductions Elimination of over billing errors (double invoices, 100% rate check, execution check) Administrative tasks no longer required (no extra resources required for growth in business) Visibility and reporting Single location providing visibility to all parties (Carriers, BSEU, Claims, …) Improved cost allocation capabilities Share operational status visibility through Transportation Cycle Initial Business Case Estimate (*): Area Conservative Realistic Optimistic Over billing reduction €1431,850 €1879,510 €2419,750 Headcount Finance €307,665 €356,625 €405,000 Headcount LSCM €225,000 €270,000 €360,000 Carrier Selection Compliance €876,000 €1035,500 €1095,000 €2,840,515 €3,641,635 €4,279,750 Total (*) Adapted figures Project is self funding after implementation cost Initial Implementation Planning – 2 sessions April May June July Aug Sept Oct Nov Preparation Prepare Implementation • Collect Master Data • Develop interfaces • Setup new processes • Carrier Communication Wave 1 Implementation in 3 Pilot Sites •ELC North: Zeebrugge •MDC: Poznan •RDC: France Wave 2 Roll out solution to all other sites Site Go live Dec Jan Findings after 1 year operations (1) Full Truck Load business is 100% operational and process is stable For “secondary business (17 countries) ” situation is diversified Some markets are 100% operational Still some countries are not live • Carriers refusing to participate • Facing technical issues with some carriers Some countries we encountered serious problems • We ended up in paying invoices twice • We had to make pre-payments to carriers • Local people initially opposed, because they lost part of their power Learning curve takes time (Table to be updated with YTD figures) Findings after 1 year of operations (2) Involvement of multiple stakeholders requires strong project management Carriers Central SCM & Local SCM Finance Invoice verification company The local organisation needs to be prepared well Clear rules need to be established upfront and communicated Training upfront and afterwards is key The local people are not finance people Realise and foresee at startup, this is not first priority for the people involved Exception handling is under estimated ( returns, extra costs, …) Findings after 1 year of operations (3) The process and system prove to be very effective After having the process effective, our current priority is to become even further efficient by becoming more pro-active follow the progress via KPI: Current focus areas systematic and full control on the invoices full visibility on the accruals for freight Reviewing all new contracts from carriers by the Central Contract Team Reviewing weekly the status by country and carrier (tracking report ). Challenging all issues more than 5 days and ensuring that all issues more than 25 days are closed (CP system used to monitor the issues). Findings after 1 year of operations (4) Business case realisation Over billing reduction is clearly achieved but difficult to measure Headcount Finance is realised, but does not result in headcount reduction Headcount LSCM is not realized. More focus is still required. Carrier Selection Compliance : 100% Data and accrual accuracy has improved significantly Would we do it again ? YES, but lessons learned : You never communicate enough both external and internal Thank you for your attention