Timber and timber products - TIMBERtech

advertisement

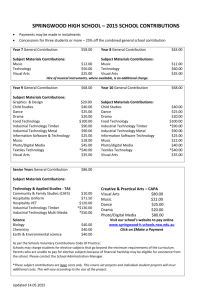

Student:.................................................. Scone High School TAS Department Stage 6 Preliminary Industrial Technology Timber Timber Products and Furniture Technologies Industry Related Manufacturing Technology Timber and timber products Index Students learn about: Students learn to: Materials Timber and timber products • structure: – sapwood – heartwood – earlywood – latewood – cambium layer – growth ring – pith – xylem and phloem – bark – photosynthesis • describe the growth of trees and identify and recognise the various parts of a tree • properties and characteristics of hardwoods & softwoods: – figure – grain direction – texture – colour – strength – durability – weight – hardness – weathering • timber industry terms relating to: – grade – sizes: - timber boards - manufactured boards • timber defects – splits – checks – warping – shakes – bowing – knots – twists – winds • identify the properties of hardwoods and softwoods and apply them to practical projects • discuss the properties of hardwoods and softwoods and apply them to practical projects • discuss and use timber industry terms in relation to timber sizes and selection • identify the range of sizes of timber boards and manufactured boards and make economical use of them in practical projects • manufactured boards, their manufacture, properties and use – plywoods – medium density fibreboards (MDF) – particle boards • apply the properties of manufactured boards and use them in practical projects • describe the range of manufactured boards available 2 Structure of a tree Reference: www.timbertech.wikisaces.com Preliminary Course > Industry Related Manufacturing Technology > Materials > Terminology or Parts of a Tree Define each of the following parts of the tree. Most of the following terms maybe found in the above link. Definitions of any terms not found in this link maybe found by a Google search Sapwood …………………………………………………………………………………………………… …………………………………………………………………………………………………… Heartwood …………………………………………………………………………………………………… …………………………………………………………………………………………………… Earlywood …………………………………………………………………………………………………… …………………………………………………………………………………………………… Latewood …………………………………………………………………………………………………… …………………………………………………………………………………………………… Growth ring …………………………………………………………………………………………………… …………………………………………………………………………………………………… Cambium layer ………………………………………………………………………………………………….… …………………………………………………………………………………………………… ……………………………………………………………………………………………...…… Pith …………………………………………………………………………………………………… …………………………………………………………………………………………………… 3 Xylem …………………………………………………………………………………………….……… …………………………………………………………………………………………………… Phloem …………………………………………………………………………………………………… …………………………………………………………………………………………………… Bark …………………………………………………………………………………………………… …………………………………………………………………………………………………… Photosynthesis …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… Cross Section of a Tree Trunk Reference: www.timbertech.wikisaces.com Preliminary Course > Industry Related Manufacturing Technology > Structure Draw a cross section of a tree trunk and identify the following parts. Bark, phloem (bast), cambium, sapwood, heartwood, pith, growth rings and medullary rays 4 Properties and characteristics of hardwoods & softwoods Define each of the terms below which are used to describe the characteristics of timber. Reference: www.timbertech.wikispaces.com Preliminary Course > Industry Related Manufacturing Technology > Materials > Terminology or Google Figure …………………………………………………………………………………………………… …………………………………………………………………………………………………… Grain direction …………………………………………………………………………………………………… ……………………………………………………………………………………………………. Texture …………………………………………………………………………………………………… …………………………………………………………………………………………………… Colour …………………………………………………………………………………………………… ……………………………………………………………………………………………………. Strength …………………………………………………………………………………………………… …………………………………………………………………………………………………… Durability …………………………………………………………………………………………………… …………………………………………………………………………………………………… Weight …………………………………………………………………………………………………… ……………………………………………………………………………………………………. Hardness …………………………………………………………………………………………………… …………………………………………………………………………………………………… 5 Weathering …………………………………………………………………………………………………… …………………………………………………………………………………………………… Question When selecting a piece of timber for cabinetwork appearance is the prime consideration. Describe three properties of timber which affects its appearance. …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… …………………………………………………………………………………………………… ……………………………………………………………............................................................ 6 Standard Australian Timber Sizing Reference: www.timbertech.wikispaces.com Preliminary Course > Industry Related Manufacturing Technology > Materials > Terminology Define the following terms: Rough sawn …………………………………………………………………………………………………… …………………………………………………………………………………………………… Dressed timber (machined) …………………………………………………………………………………………………… …………………………………………………………………………………………………… What do the following letters stand for? DAR:……………………………………………………………………………………………… D2S:................................................................................................................................. Reference: Preliminary Course > Industry Related Manufacturing Technology > Materials > Timber industry terms > Sizes timber Thickness The Australian Sawmills generally cut three thickness of timber for drying. Timber is initially cut oversize so that it dries and shrinks to 25, 38 & 50 mm. Complete the table showing the finished thickness after machining for the given rough sawn sizes. Rough Sawn (mm) Machined Thickness 25 38 50 Kiln dried timber of thickness greater than 50 mm are basically unobtainable. What is done when dressed timbers greater than 45mm are required? …………………………………………………………………………………………………… Width The standard dried rough sawn width sizes in Australia are: 50 mm (fall down cut for specific jobs, such as roof battens), 75 mm generally cut for flooring, 100 mm, 150 mm, 200 mm, 250 mm & 300 mm. 7 Complete the table showing the finished widths after machining for the given rough sawn sizes Rough Sawn (mm) Machined Width 75 100 150 200 250 300 Lengths How are lengths of timber measured? ............................................................................................................................................ ............................................................................................................................................ For the following lengths of timber required state the length which would be purchased. Required length 1450mm 1550mm 2475mm Purchased length Manufactured Board Sizing Reference: Preliminary Course > Industry Related Manufacturing Technology > Materials > Timber industry terms > Sizes manufactured boards > Mister Ply and Wood Products > Particleboard The size of manufactured boards is stated as length x width x thickness Complete the tables illustrating the common sizes of manufactured boards. Particleboard – Standard Sheet size 2400 x 1200 Sheet Thickness MDF - Standard Sheet size Sheet Thickness 2400 x 1200 8 Timber Defects Reference: www.timbertech.wikispaces.com Preliminary Course > Industry Related Manufacturing Technology > Materials > Timber defects Name and describe the following defects found in timber ………………………………………………………….......... .................................................................................................. .................................................................................................. …………………………………….. .................................................................................................. .................................................................................................. ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… …………………………………… ……………………………………………................................ ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… …………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… …………………………………… ………………………………………………………………… 9 ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ........................................................... . ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… …………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… ………………………………………………………………… …………………………………… 10 Manufactured boards, their manufacture, properties and uses Reference: www.timbertech.wikispaces.com Preliminary Course > Industry Related Manufacturing Technology > Materials > Manufactured boards Particleboard 1. Give a brief definition/description of particleboard. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ……………………………………………………………...................... 2. Complete the flow chart showing the production of particleboard using the terms below. Resin added 3. Heat and pressure Chipping Sanded and cut to size Drying of flakes Formed into mats Describe the structure of three layered particleboard and state its advantages. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ……………………………………………………………................................................ 11 4. State an environmental advantage in using particleboard. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 5. List three advantages in using particleboard. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 6. List three disadvantages of particleboard. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 7. List uses of particleboard in cabinetwork. ...................................................................................................................................... ...................................................................................................................................... 12 Medium Density Fibreboard (MDF) 1. List the main sources of wood raw materials from which MDF is made. ………………………………………………………………………………………………… ………………………………………………………………………………………………… …………………………………………………................................................................ 2. Complete the flow chart showing the production of MDF using the terms listed below. chipper sanded and cut to size debarked logs forming hot press debarker resin & wax screen, wash & refine 3. Discuss how the environmental impact of MDF manufacture has improved in recent years. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 4. List 3 advantages and 3 disadvantages of using MDF (i) Advantages ……………………………………………………………………………………………… ……………………………………………………………………………………………… ………………………………………………………………………………………………… 13 (ii) Disadvantages ………………………………………………..……………………………………………… ………………………………………..……………………………………………………… ………………………………………………………………………………………………… 5. Discuss the safety issues involved in using MDF and state how these issues are addressed. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 6. Give examples of how MDF may be used in furniture construction. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………......................... Plywood 1. Give a brief definition/description of plywood. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… 2. The sketch shows veneers ready for gluing to form plywood. Add the grain to each ply, clearly showing its direction. 14 3. Explain why there are always an odd number of veneers/layers used in the manufacture of plywood. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………................................... Briefly explain the advantages of cross grain bonding veneer sheets in the manufacture of plywood. ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ……………………………………………………………………………............................ 4. Give two uses for plywood in cabinet construction. …………………………………………………………………………………............ (i) …………………………………………………………………………… ……………… 5. What are the advantages of using plywood over natural timber? ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………………………… ………………………………………………………………………………........................ 15