Fa11-3110-StudyGuide

advertisement

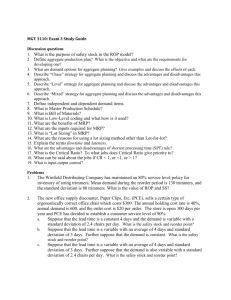

MGT 3110: Exam 3 Study Guide

DO NOT RELY ONLY ON THIS STUDY GUIDE ALONETO PREAPRE FOR THE

EXAM

Discussion questions

1. Define independent and dependent demand items.

2. What is Master Production Schedule?

3. What is Bill of Materials?

4. What is Low-Level coding and what how is it used?

5. What are the benefits of MRP?

6. What are the inputs required for MRP?

7. What is “Lot Sizing” in MRP?

8. What are the reasons for using a lot sizing method other than Lot-for-lot?

9. What does the part-period balancing lot-sizing technique attempt to do in deciding the lot

sizes?

10. Explain the terms flowtime and lateness.

11. What are the advantages and disadvantages of shortest processing time (SPT) rule?

12. What is the Critical Ratio? To what jobs does Critical Ratio give priority to?

13. What can be said about the jobs if CR < 1, or =1, or > 1?

14. What is input-output control?

15. Define maintenance.

16. Define reliability.

17. What is FR(%)? Define it.

18. Define FR(N). How is computed?

19. Define MTBF. How is related to FR(N)?

20. What is redundancy?

21. What is the impact on system reliability of adding parts or components in parallel?

22. Increasing the number of parts or components in a product tends to reduce its reliability. Why

is this true only when adding components in series?

23. Explain carefully how redundancy improves product reliability.

24. What is breakdown maintenance?

25. Is there an optimal amount of preventive maintenance? What caution should be exercised

before calculating this optimal amount?

Problems

1.

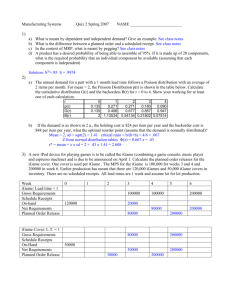

Consider the following Solver model for an aggregate planning problem.

a.

Determine the excel formula for the following cells:

B18

B19

B20

B23

E23

F23

B24

B31

C31

F31

G31

H31

B32

B37

B38

B39

B40

B41

B42

B43

b.

c.

d.

e.

2.

What is the Solver Target cell?

What are the Solver changing cells?

What are the Solver constraints?

What options of Solver must be checked?

A Bill of Materials is desired for a bracket (A) that is made up of a base (B), two springs

(C) and four clamps (D). The base is assembled from one clamp (D) and two housings (E).

Each clamp has one handle (F) and one casting (G). Each housing has two bearings (H)

and one shaft (I).

a. Develop a product structure tree.

b. The lead time for the parts are given below. Develop a time-phased product structure.

c. The available inventory for each part is given in the table below. Determine the net

requirement quantities of all parts required to assemble 50 units of bracket A.

Item

A

B

C

D

E

F

G

Lead time

1

2

3

2

1

2

1

Available

5

5

10

20

50

150

50

H

I

3.

Lead time

1

3

2

4

On-hand

100

30

0

0

Scheduled receipts

50 in week 1

20 in week 1, 30 in week 2

50 in week 1

30 in week 1, 40 in week 3

For the following item the inventory holding cost is $0.80 per week and the setup cost is

$300. Determine the lot sizes and total cost for this item under (i) Lot-for-Lot, (ii) EOQ,

and (iii) PPB methods

Item

Week:

Gross requirement

Scheduled receipts

Projected on-hand

100

Net Requirement

Planned receipts

Planned order releases

5.

5

0

A product (A) consists of a base (B) and a casting (C). The base consists of a plate (P) and

three fasteners (F). The lead time, current on-hand inventory and scheduled receipts are

given below. All components are lot for lot. The MPS requires start of production of 100

units of product A in week 4 and 150 in week 6. Produce the MRP for the upcoming six

weeks. Produce a list of all planned order releases.

Part

B

C

P

F

4.

1

2

LT =

1

100

1

2

250

3

200

4

150

5

250

6

200

7

200

8

150

Consider the following planned and actual hours of input and output.

Week ending

Planned input

Actual input

Planned output

Actual output

1

2

3

4

5

6

7

8

500

700

650

600

800

700

650

700

700

700

650

800

600

800

650

700

600

600

650

650

800

500

700

500

700

500

700

600

800

800

700

800

Prepare the Input/Output Control chart for this workstation. Assume an initial actual

backlog of 120 hours.

6.

A company wishes to assign a set of jobs to a set of machines. The following table provides

data on the profit margin of each job when performed on a specific machine. Setup an

Excel Solver model to determine the set of assignments that maximizes production value.

a.

Fill out the Excel formulas for the following cells:

G13

G14

G15

G16

C17

D17

E17

F17

G19

b.

c.

d.

e.

What is the Solver Target cell?

What are the Solver changing cells?

What are the Solver constraints?

What options of Solver must be checked?

7.

The following jobs are waiting to be processed on day 250

Job

A

B

C

D

E

F

Date Job received

215

220

225

240

245

250

Production days needed

30

20

40

50

20

35

Date job due

290

415

375

315

420

380

Sequence the jobs in the order of SPT, EDD, and Critical Ratio, and compute (i) Average

flow time, (ii) Average lateness, (iii) Average no. of jobs in the system, and (iv)

Utilization, for each of the three schedule of jobs.

8.

A control rod mechanism is a nuclear reactor has 15 critical components with an average

reliability of 99.5% for each component. Determine the overall reliability of the

mechanism.

9.

Determine the system reliability for the following systems.

(a)

R = 90%

R = 98%

R = 92%

R = 90%

R = 90%

R = 98%

(b)

R = 99%

R = 98%

R = 95%

R = 90%

R = 94%

R = 95%

R = 90%

R = 94%

R = 95%

R = 90%

R = 94%

R = 95%

10.

Fifty components of a safety system were tested for reliability, each for 200 hours of

operation. Of the 50, 2 failed after 50 hours of operation, 3 after 75 hours, 1 after 120

hours, and 1 after 150 hours. The rest of the components did not fail. Determine the

following failure rate statistics.

a.

b.

c.

d.

11.

Percentage of failures.

Number of failures per unit-hour of operation.

Mean time between failures.

What is the expected number of failures over 1000 hours of operation?

In a mining operation an electoral exhaust system is used to pump out the fumes. The

break down data over the past 200 weeks is shown in the table below. Each time the

system breaks down the mining operation must be shut down. The estimated cost to repair

the system and the lost production amounted to $12,000. Routine maintenance service for

the exhaust system may be purchased at a cost of $6,000 per week. With this contract the

number of breakdowns is expected to average only 1.2 per week. Then, the cost to bring

the system back on line is $5,000 in lost production. Determine whether it is economical to

purchase the preventive maintenance contract.

No. of breakdowns No. of weeks that many breakdowns occurred (Frequency)

0

75

1

35

2

50

3

20

4

10

5

10

Answers to discussion questions

1. Define independent and dependent demand items.

Finished products whose demand is independent of production decisions are called

“Independent demand” items. Items for which demand can be directly calculated from

production decisions are called “Dependent demand” items. These are raw-materials and

parts required for the production of the finished goods.

2. What is Master Production Schedule?

Master Production Schedule specifies production quantities of each Independent Demand

item for a planning horizon of 12 to 15 weeks. Total of MPS quantities must be in

accordance with the aggregate production plan.

3. What is Bill of Materials?

Bill of materials is structured list of components, ingredients, and materials needed to make

an end product. Items needed to produce a given part are called components or “children”.

The part into which the components go us called “Parent”. The BOM also gives the number

of units of a child item needed to produce one unit of the parent item.

4. What is Low-Level coding and what how is it used?

A level code starting from zero at the top of the BOM tree and incremented by 1 going down

each level of the BOM tree is assigned. Then, the lowest level at which an item appears is

called Low-Level code. The MRP computations are processed one level at a time, starting

from level zero.

5. What are the benefits of MRP?

Better response to customer orders

Faster response to market changes

Improved utilization of facilities and labor

Reduced inventory levels

6. What are the inputs required for MRP?

Master Production Schedule

Bill of Materials

Inventory status

7. What is “Lot Sizing” in MRP?

The process of combining net requirements into production lots is called lot sizing.

8. What are the reasons for using a lot sizing method other than Lot-for-lot?

Lot-for-lot often requires too many lots that may not be economically justifiable

Sometime lot-for-lot generates absurdly small lots

9. What does the part-period balancing lot-sizing technique attempt to do in deciding the lot

sizes?

It balances the setup and holding costs. PPB uses additional information by changing the lot

size to reflect requirements of the next lot size in the future.

10. Explain the terms flowtime and lateness.

Flow time is the length of time a job is in the system; lateness is completion time minus due

date.

11. What are the advantages and disadvantages of shortest processing time (SPT) rule?

SPT minimizes the average flow time, average lateness, and average number of jobs in the

system. It maximizes the number of jobs completed at any point. The disadvantage is that

long jobs are pushed back in the schedule.

12. What is the Critical Ratio? To what jobs does Critical Ratio give priority to?

The Critical Ratio (CR) is an index number computed by diving the time until due date by

the working time remaining. The CR gives priority to jobs that must be done to keep

shipping on schedule.

13. What can be said about the jobs if CR < 1, or =1, or > 1?

If CR < 1, then the job has fallen behind, the work remaining exceeds the time until due date.

If CR = 1, then the job is on schedule, the work remaining exactly equals the time until due

date. If CR > 1, then there is slack, the time until due date exceeds the work remaining.

14. What is input-output control?

Input/output control keeps track of planned versus actual inputs and outputs, highlighting

deviations and indicating bottlenecks using cumulative backlog.

15. Define maintenance.

Maintenance consists of all activities involved in keeping a system's equipment in working

order.

16. Define reliability.

Reliability is the probability that a machine part or product will function properly for a

specified time under stated conditions.

17. What is FR(%)? Define it.

FR(%) refers to product failure rate. It measures the percent of failures among the total

number of products tested.

18. Define FR(N). How is computed?

FR(N) refers to the number of failures during a period of time. It measures the number of

failures over the total unit-hours the products operated without failing. it is the ratio of failed

units to total operating hours.

19. Define MTBF. How is related to FR(N)?

MTBF stands for Mean time between failures. It is the expected time between a repair and

the next failure of a component, machine, process, or product. MTBF is the reciprocal of

FR(N)

20. What is redundancy?

Redundancy is the use of a component in parallel to raise reliabilities.

21. What is the impact on system reliability of adding parts or components in parallel?

This will increase the reliability of the system by introducing redundancy.

22. Increasing the number of parts or components in a product tends to reduce its reliability. Why

is this true only when adding components in series?

Adding parts in series involves an additional multiplication by a value less than one, so that

reliability must fall. Adding parts in parallel (the redundancy concept) increases reliability

because only one part of the parallel system must function.

23. Explain carefully how redundancy improves product reliability.

A redundant part or component is connected in parallel with the primary part or component.

"In parallel" means that either the original part or its backup needs to work, not that both

must work at the same time. Redundancy increases reliability by providing an additional path

(through the redundant part) to provide system reliability.

24. What is breakdown maintenance?

Breakdown maintenance is the remedial maintenance that occurs when equipment fails and

must be repaired on an emergency or priority basis.

25. Is there an optimal amount of preventive maintenance? What caution should be exercised

before calculating this optimal amount?

Too little preventive maintenance causes breakdown costs to rise sharply, adding more to

cost than is saved by less preventive maintenance; too much preventive maintenance reduces

breakdowns, but by an amount insufficient to offset the added cost of preventive

maintenance. Operations managers should assure that all costs of breakdowns have been

properly included in the calculations. There is a history of not including indirect and

subjective breakdown cost elements, which leads to performing too little preventive

maintenance.

Answers to problems

1.

B18

B19

B20

B23

E23

F23

B24

B31

C31

F31

G31

H31

B32

B37

B38

B39

B40

B41

B42

B43

=B14/B13

=B14*B5

=B13*B6

=E13

=B23+C23-D23

=E23*F6*$B$18

=E23

=E14

=F23

=E6

=B31+SUM(C31:E31)-F31

=C31*$B$15

=G31

=SUMPRODUCT(E23:E26,F6:F9)*B19

=D35*B20

=E35*B7

=C27*B9

=D27*B10

=G35*B8

=SUM(B37:B42)

b.

B43

c.

C23:D26, D31:E34

d.

D31:D34 <= H31:H34

G31:G34 >= E15

C23:D26 = Integer (if needed)

D31:E34 = Integer (if needed)

e.

Assume linear model

Assume non-negative

2.

A

B

C2

F

D4

E2

D1

G

H2

I

F

G

F

D

G

B

H

E

I

C

A

F

D

G

1

2

3

4

5

Lead time = 7 weeks

Part

A

B

C

D

E

F

G

H

I

Gross

50

1 x A = 45

2 x A = 2 x 45 = 90

4 x A + 1 x B = 4 x 45 + 40 = 220

2 x B = 80

1 x D = 200

1 x D = 200

2 x E = 2 x 30 = 60

1 x E = 30

Available

5

5

10

20

50

150

50

5

0

Net

50 – 5 = 45

45 – 5 = 40

90 – 10 = 80

220 – 20 = 200

80 – 50 = 30

200 – 150 = 50

200 – 50 = 150

60 – 5 = 55

30 – 0 = 30

6

7

3.

A has releases of 100 in 4, 150 in 7; B has a release of 150 in 6, but on hand inventory accounted

for all other needs; C has releases of 150 in 4, 70 in 1; P has a release of 150 in 5 and F has a release of

450 in 5 (the beginning inventory of B leads to no other gross requirements of P or F).

1

2

3

1

0

50

100

0

0

2

0

3

0

150

0

0

150

0

0

MPS start for A

Item B

Item C

Week:

Gross requirement

Scheduled receipts

Projected on-hand

30

Planned receipts

Planned order releases

Item F

Week

Gross requirement

Scheduled receipts

Projected on-hand

Planned receipts

Planned order releases

5

6

150

4

100

5

0

6

150

150

0

0

50

0

100

50

100

0

Lead time =

Week:

Gross requirement

Scheduled receipts

Projected on-hand

100

Planned receipts

Planned order releases

Item P

Week:

Gross requirement

Scheduled receipts

Projected on-hand

Planned receipts

Planned order releases

4

100

0

0

1

0

20

30

0

20

1

0

50

0

0

0

1

0

30

0

0

230

2

0

30

50

0

0

Lead time =

3

0

4

100

5

0

6

150

80

0

150

80

20

0

0

0

0

0

150

0

4

0

5

100

6

0

50

0

0

50

50

0

0

0

0

4

0

5

300

6

0

70

0

0

70

230

0

0

0

0

Lead time =

3

0

2

0

50

0

0

50

0

50

Lead time =

3

0

40

30

30

0

0

0

0

2

0

1

3

2

4

4.

(i) L-4-L

Item

Week:

Gross requirement

Scheduled receipts

Projected on-hand

Net Requirement

Planned receipts

Planned order releases

LT =

1

100

1

2

250

3

200

4

150

5

250

6

200

7

200

8

150

100

0

0

250

0

250

250

200

0

200

200

150

0

150

150

250

0

250

250

200

0

200

200

200

0

200

200

150

0

150

150

0

5

250

0

150

100

375

0

6

200

0

275

0

0

375

7

200

0

75

125

375

0

8

150

0

250

0

0

0

100

No. of setup =

Carrying cost =

Setup cost = 7 x $300 =

Total cost =

7

0

2100

2100

(ii) EOQ:

Total demand for 8 weeks = 1500

D (1 year) = (1500/8) x 52 weeks/year = 9750

H (for 52 weeks) = $0.80/week x 52 weeks = $41.60

S = 300

Q=√

2(9750)300

41.6

= 375

Item

Week:

Gross requirement

Scheduled receipts

Projected on-hand

Net Requirement

Planned receipts

Planned order releases

100

LT =

1

100

0

100

0

0

375

1

2

250

0

0

250

375

375

3

200

0

125

75

375

0

4

150

0

300

0

0

375

Annual setup cost = (D/Q) S = (9750/375) x 300 =

Annual holding cost = (Q/2)H per year = (375/2) x 41.60 =

Annual cost = Annual setup cost + Annual holding cost = 7800 + 7800 =

Weekly cost = Annual cost/52 = 15600/52 =

Cost for 8 weeks = Cost per week x 8 weeks = 300 x 8 =

(iii) PPB

EPP = 300/0.80 = 375

7800

7800

15600

300

2400

Item

Week:

Gross requirement

Scheduled receipts

Projected on-hand

Net Requirement

Planned receipts

Planned order releases

100

LT =

1

100

0

100

0

0

600

Periods

Quantities

combined

combined

Lot #1 Receipt in week #2

1

2

250

0

0

250

600

3

200

0

350

4

150

0

150

5

250

0

0

250

450

6

200

0

200

7

200

0

0

200

8

150

0

450

Periods brought

forward – last qty

New Partperiods

Total combined partperiods

250

250 + 200 = 450

0

1

0

1x 200 = 200

2, 3, 4

450 + 150 = 550

Lot #2 Receipt in week #5

5

250

2

2 x 150 = 300

0

0 + 200 = 200

200 + 300 = 500

(Close to 375)

0

0

5, 6

250 + 200 = 450

5, 6, 7

450 + 200 = 650

Lot #3 Receipt in week #7

7

200

7, 8

200 + 150 = 350

1

2

1 x 200 = 200

2 x 200 = 400

0

0 + 200 = 200

(Close to 375)

200 + 400 = 600

0

1

0

1x 150 = 150

0

0 + 150 = 150

2

2, 3

Summary:

Lot # in Week

Lot PP Setup cost = 3 setups x $300 = $900

Total Lot PP = 850

500

Total holding cost = 850 x $0.80 = $680

200

Total cost = 900 + 680 = $1,580

150

Lot size

Lot #1 Receipt in week #2

550

Lot #2 Receipt in week #5

450

Lot #3 Receipt in week #7

350

Total cost = 700 + 460 + 420 = $1,580

#5.

Week ending

Planned input

Actual input

Cumulative deviation

Planned output

Actual output

Cumulative deviation

Backlog

120

1

2

3

4

5

6

7

8

500

700

200

650

600

-50

220

800

700

100

650

700

0

220

700

700

100

650

800

150

120

600

800

300

650

700

200

220

600

600

300

650

650

200

170

800

500

0

700

500

0

170

700

500

-200

700

600

-100

70

800

800

-200

700

800

0

70

#6.

G13

=SUM(C13:F13)

G14

=SUM(C14:F14)

G15

=SUM(C15:F15)

G16

=SUM(C16:F16)

C17

=SUM(C13:C16)

D17

=SUM(D13:D16)

E17

=SUM(E13:E16)

F17

=SUM(F13:F16)

G19

=SUMPRODUCT(C5:F8,C13:F16)

Solver parameters

Set Target Cell

Options:

G19 MAX

Changing cells

C13:F16

Constraints

G13:G17 <= 1

C17:F17 = 1

□ Assume linear model

□ Assume non-negative

#7. SPT

Job

B

E

A

F

C

D

Processing

time (Days)

20

20

30

35

40

50

195

Average flow time =

Average lateness =

Average WIP =

Utilization =

95.833

30

2.949

0.339

Days till due

date

165

170

40

130

125

65

Completion

time (Flowtime)

20

40

70

105

145

195

Lateness

0

0

30

0

20

130

575

180

EDD

Job

A

D

C

F

B

E

Processing

time (Days)

30

50

40

35

20

20

195

Days till due

date

40

65

125

130

165

170

Average flow time =

Average lateness =

Average no. of jobs in the system =

Utilization =

Completion

time (Flowtime)

30

80

120

155

175

195

755

Lateness

0

15

0

25

10

25

75

125.83

12.50

3.87

0.26

CR

Job

D

A

C

F

B

E

Processing

time (Days)

50

30

40

35

20

20

195

Days till due

date

65

40

125

130

165

170

Average flow time =

Average lateness =

Average no. of jobs in the system =

Utilization =

Completion

time (Flowtime)

50

80

120

155

175

195

775

Lateness

0

40

0

25

10

25

100

CR

1.30

1.33

3.13

3.71

8.25

8.50

129.17

16.67

3.97

0.25

#8. 0.99515 = 0.9257569 or 92.7569%

#9.

(a)

RRow 1= 0.98 x 0.92 x {1 – (1-.9) (1-.9) (1-.9)} = 0.900698

RRow 2 = 0.98 x 0.92 x 0.98 x 0.95 = 0.903256

RS = 1 – (1 - RRow 1)( 1 - RRow 2) = 1 – (1 – 0.900698)(1 – 0.903256) = 0.990393, or 99.0393%

(b)

R1 = 1 – (1 – 0.95) (1 – 0.95) (1 – 0.95) = 0.999875

R2 = 1 – (1 – 0.90) (1 – 0.90) (1 – 0.90) = 0.999

R3 = 1 – (1 – 0.94) (1 – 0.94) (1 – 0.94) = 0.998659

Rs = R1 x R2 x R3 = .998659 = 99.8659%

#10.

(a)

Failed =

FR(%) =

Total tested unit-hours =

Failed

2

3

1

1

(b)

(c)

(d)

7

14.0%

10000

Operating Non-operating

time

time/unit

50

150

75

125

120

80

150

50

Total non-operating time =

Operating time = 10000 – 805 =

Non-operating

time

300

375

80

50

805

9195

7/9195 = 0.000761283

1/0.000761283 = 1313.57

1000* 0.000761283 = 0.761283306

#11.

No. of breakdowns

0

1

2

3

4

5

No. of weeks that many

breakdowns occurred

(Frequency)

75

35

50

20

10

10

200

Expected number of failures/week =

Average breakdown with routine maintenance =

Repair cost/breakdown without routine maintenance =

Routine maintenance cost/week =

Repair cost/breakdown with routine maintenance =

Cost without routine maintenance/week = 1.425 x $12,000 =

Cost with routine maintenance/week = 6000 + 5000 x 1.2 =

Relative

frequency

Expected

breakdowns

0.375

0.000

0.175

0.175

0.250

0.500

0.100

0.300

0.050

0.200

0.050

1.000

0.250

1.425

1.425

1.2

12000

6000

5000

$17,100

$13,200

Total cost/week with routine maintenance is less expensive compared to without it. Therefore,

purchase routine maintenance contract.