pptx - UCSD VLSI CAD Laboratory

advertisement

Scalable Detailed Placement

Legalization for Complex

Sub-14nm Constraints

Kwangsoo Han, Andrew B. Kahng and Hyein Lee

{kwhan, abk, hyeinlee}@ucsd.edu

http://vlsicad.ucsd.edu/

ECE Department, UC San Diego

Outline

• Motivation & Previous Work

• Problem Formulation

• Our Approach

• Experimental Setup and Result

• Conclusion

2

Motivation

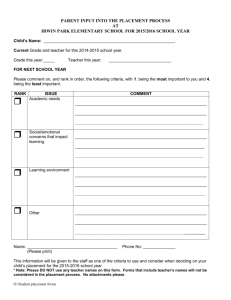

• In old technology nodes, once the library cells were

correctly designed, design rule violations (DRVs)

could not occur during placement

• Limitations of patterning resolution lead to complex

design rules for front-end-of-line (FEOL) layers

• Placing several ‘legal’ standard cells next to each

other may cause violations of FEOL layer rules

Final detailed cell placement phase is needed

to maintain placement legality

with respect to new N10 FEOL rules

3

Cell Layout in N10 Node

• The FEOL layers which affect legal placement

include implant layer, oxide diffusion layer and poly

• Implant layers decide the threshold (Vt) of transistors

• Oxide diffusion (OD) defines the active region of

transistors

• Dummy poly gates are inserted at the (vertical) standard

cell boundaries to avoid edge device variability

A

Y

Fin

Poly

Oxide diffusion (OD)

M1

Middle of line

M2 Power/ground

Cell boundary, implant region

4

(1) Minimum implant width (IW)

• Limitation of the current optical lithography technology

New design rule (i.e., minimum implant width)

• Two same-Vt cells are misaligned vertically

A narrow, “staircase” implant layer shape

Inter-row IW (IW1) violation

• A narrow cell is surrounded by different-Vt cells

Intra-row IW (IW2) violation

IW2

HVT

HVT

HVT

LVT

LVT

IW1

HVT

HVT

5

(2) Minimum OD jog length (OW)

• Cells can have different oxide diffusion (OD) region

heights

• Lithographic corner rounding

minimum OD jog length rule

• Cells with different OD heights abutment

Cause OD jog length violation

OD

OD jog

Cell boundary

6

(3) Drain-drain abutment (DDA)

•

•

•

•

Dummy poly gates create extra dummy transistors

Dummy transistors can induce leakage power

Dummy transistors must be tied off to power/ground rails

Two drain nodes are abutted

• Extra dummy poly gate tied up with power/ground rails

• Cell flipping/displacement

Drain-drain

abutment

D

D

D

D

D

S D

D

S D

√

S

S

7

Previous Works

• Dynamic programming-based approaches

• Optimal interleaving for intra-row optimization [Hur and Lillis, ICCAD00]

• Row-based placement [Kahng et al., ASPDAC99, GLSVLSI04]

• Integer Linear Programming (ILP)-based approaches

• Placement by branch-and-price [Ramachandaran et al., ASPDAC05]

• MIP-based detailed placement [Li and Koh, ISPD12]

• DDA-aware placement

• [Du and Wong, DATE14] propose a graph model with shortest-path

algorithm

• Use cell flipping and adjacent-cell swapping

• No consideration of inter-row constraints (e.g., IW constraint)

Our work: MILP-based optimization to provide

the comprehensive support of N10-relevent FEOL rules

8

Our Contributions

• Develop a mixed integer linear programming (MILP)based placer, called DFPlacer

• Address new DRVs caused by complex N10 FEOL rules

• Propose a scalable partitioning-based optimization

method

• Incorporate our flow into a commercial tool-based

placement and routing (P&R) flow for evaluation

• Provide insight into timing and area impacts of the

dummy poly gate library cell strategy

• Standard cells with dummy poly gates (DDA and OW

violation free)

• Standard cells without dummy poly gates

9

Outline

• Motivation & Previous Work

• Problem Formulation

• Our Approach

• Experimental Setup and Result

• Conclusion

10

Detailed Placement Problem Formulation

• Input: Placement with design rule violations

• Objective: Legal placement with minimum cell

displacements

• Subject to:

• Minimum implant width (IW) constraint

• Minimum oxide diffusion jog length (OW) constraint

• Drain-drain abutment (DDA) constraint

IW

HVT

OW

HVT

HVT

LVT

LVT

OD

HVT

DDA

D

D

HVT

Cell boundary

11

Outline

• Motivation & Previous Work

• Problem Formulation

• Our Approach

• Experimental Setup and Results

• Conclusion

12

Mixed-ILP Model [Li12]

• Single-cell-placement binary variable λck

• Placement state k (location and orientation) of cell c

• Site occupation variable scrqk

• Represent if site (r,q) is occupied by cell c with placement

state k

λc1 = {0, 1, 0}

sc111

=1

sc211

=1

sc311

=0

(1,7)

(0, 0)

λc2 = {4, 0, 1}

λck = {xc, yc, fc}, where xc(yc) is x(y) location of cell c

fc is an indicator whether c is flipped

[Li12] S. Li and C.-K. Koh, “Mixed Integer Programming Models for Detailed Placement”, Proc. ISPD, 2012, pp. 87-94.

13

Placement Problem Formulation

Objective

min

( 𝑥𝑐 − 𝑥𝑐,𝑖𝑛𝑖𝑡 + 𝑦𝑐 − 𝑦𝑐,𝑖𝑛𝑖𝑡

𝑐𝑒𝑙𝑙𝑠 𝑐

⇒ Minimize

)

displacements

For each cell c

𝑠𝑡𝑎𝑡𝑒𝑠 𝑘

𝜆𝑘𝑐 = 1 ⇒ Select one placement state per cell

Orientation, x/y location, site occupation are determined by λck

𝑓𝑐 =

𝑠𝑡𝑎𝑡𝑒𝑠 𝑘

𝑓𝑐𝑘 𝜆𝑘𝑐

𝑥𝑐 =

𝑠𝑡𝑎𝑡𝑒𝑠 𝑘

𝑥𝑐𝑘 𝜆𝑘𝑐

𝑦𝑐 =

𝑠𝑡𝑎𝑡𝑒𝑠 𝑘

𝑦𝑐𝑘 𝜆𝑘𝑐

𝑠𝑐𝑟𝑞 =

𝑠𝑡𝑎𝑡𝑒𝑠 𝑘

𝑘

𝑠𝑐𝑟𝑞

𝜆𝑘𝑐

Placement constraints

𝑐𝑒𝑙𝑙𝑠 𝑐

𝑠𝑐𝑟𝑞 ≤ 1 No overlap

+ more constraints to support IW, OW and DDA

14

IW Constraints Formulation

• New: 𝑣𝑟𝑞 , a binary vector indicating Vt of the site (r,q)

• Vt boundaries are checked with inter-/intra-row

variables

Vt boundary

Vt boundary

|W| = 3

|W| = 3

At the Vt boundary, at least |W|

consecutive sites must be same Vt

At the Vt boundary where two

vertically neighboring sites are

same Vt, the Vt must be kept for

at least |W| sites in the both

upper and lower rows

15

OW and DDA Constraints Formulation

• Pre-characterize all adjacency conditions which

violate OW and/or DDA for each cell pair

• Add mutual exclusion constraints

• λc1i and λc2 j is forbidden pair

λc1i + λc2 j ≤ 1

λc1i

λc2 j

16

Distributable Global Optimization

• Limitation of MILP-based approach ⇒ Runtime

• Distributable optimization of many windows of cells

• Split the post-route layout into small clips

• Run optimization for each clip with fixed boundaries

• Cells on boundaries are handled by shifting windows

1st iteration

2nd iteration

Fixed cells

clip

Layout

17

Overall Flow

Routed layout w/ DRVs

DFPlacer

Global optimization

Local optimization

Make new windows

Removed overlapping windows

Solve multiple

windows in parallel

Shift partitioning lines

Optimization for each

window

Complex constraints

for N10

Remaining DRVs

ILP

formulation

- DDA, OW, IW

ILP solver

(CPLEX)

Solve multiple

windows in parallel

#DRVs < δ ?

N

Y

Cell location solution

ECO Routing

Routed layout with #DRVs < δ

18

Outline

• Motivation & Previous Work

• Problem Formulation

• Our Approach

• Experimental Setup and Results

• Conclusion

19

Experimental Setup

• SP&R tools: Synopsys Design Compiler H-2013.03-SP3 and Cadence

Encounter Digital Implementation System XL 13.1

• Technology: two kinds of 7nm dual Vt libraries

• 62 standard cells without dummy poly gates (CWOD)

• 62 standard cells with dummy poly gates (CWD)

• Design: AES, JPEG [OpenCores], ARM Cortex M0, ARM Cortex M0 x 3

• *_d – implemented with CWD library

Fin

• *_nd – implemented with CWOD library

[OpenCores] http://opencores.com/

Design

M0_nd

AES_nd

M0x3_nd

Y

8260

12147

A

27248

LVT

(%)

52

54

Util.

(%)

77

78

#Inst

A

JPEG_nd

Y

47948

8238

56

51

51

80

77

77

WL

Inverter

cell layout

114685

142294Inverter

392540cell layout

694624

(um)

in CWD library

in CWOD library

Area

(um2)

7668

8894

M0_d

24463

49629

Poly

AES_ddiffusion

M0x3_d(OD)

JPEG_d

Oxide

M1

12491

26690

48317

Middle of line

54

55

52

M2 Power/ground

Cell80boundary,

79 implant

77 region

116866

150632

409579

764738

8668

10596

27400

55824

20

Experimental Results (1)

• Report ∆wirelength and ∆worst setup slack

• Up to 3.42% wirelength increase

• *_nd cases shows similar or slightly larger ∆WL% than *_d

• ∆WSS ranges from -19ps to 68ps

• Positive ∆WSS there is room to improve timing

∆ WL (%)

4.00%

3.50%

3.00%

2.50%

2.00%

1.50%

1.00%

0.50%

0.00%

-0.50%

-1.00%

∆ WL (%)

∆ WSS (ps)

80

∆ WSS (ps)

60

40

20

0

-20

-40

21

Experimental Results (2)

Remaining violations (%)

• Global optimization fixes ~90% of DRVs

• Runtime of global optimization using CWOD library are 1.8x

larger than those using CWD library (except for Cortex M0)

• The runtime of the global optimization phase can be further

reduced with more computing resource

100%

m0_nd

jpeg_nd

m0x3_d

90%

80%

70%

60%

aes_nd

m0_d

jpeg_d

m0x3_nd

aes_d

Global optimization (3rd iteration);

1.8x90% violations are fixed

50%

40%

30%

20%

10%

0%

0

500

1000

1500

2000

2500

3000

Runtime (sec)

22

Experimental Results (3)

• DFPlacer fixes 99% of design rule violations

Design

M0_nd

AES_nd

M0x3_nd

JPEG_nd

M0_d

AES_d

M0x3_d

JPEG_d

Init.

IW #vio.

926

1771

3514

4056

988

1566

2810

6296

Init.

DDA/OW

#vio.

1611

1900

4230

12024

0

0

0

0

Final

total #vio.

25

34

65

164

10

11

27

43

• Example solution

DDA violation

IW violation

flipped

Cells are

moved

OW violation

IW violation

23

Outline

• Motivation & Previous Work

• Problem Formulation

• Our Approach

• Experimental Setup and Results

• Conclusion

24

Conclusion and Future Work

• Propose a scalable detailed placement

legalization flow for complex FEOL constraints

arising at the foundry 10nm node

• Constraints include minimum implant width,

minimum OD jog rules and drain-drain abutment

• Fixes 99% of DRVs with 3% increase in wirelength

and minimal impact on timing

• Future work

• Timing and wirelength-driven placement legalization

• “Smart ECO” method for few remaining DRVs after global

placement legalization

25

Thank you!

Experimental Setup: Designs and Technologies

• Minimum OD jog length = 4 sites width

• Minimum implant width = 4 sites width

• Number of violations of cell pair

• Minimum implant width rule violation: 7172 out of 15376 (= 62 x 62 x 2 x 2)

• Minimum OD jog length rule violation: 280 out of 15376

• 7nm cell library with scaled 28nm BEOL (back-end-of-line) LEF

• Site width/height: 0.136/0.9 um

min M1 pitch of 28nm node

min M2 pitch

of 28nm node

Scale by 2.5x

A1 A0 B0 B1

Y

OAI22 in 7nm node

27

Scaling of 7nm Cells

• Scale 7nm cells by 2.5X

• Left figure is the scaled OAI22_X1

• All the pins are on track with 0.135um M1 vertical pitch

• However, encounter does not work with 0.135um M1 vertical pitch

• Right figure shows the modified OAI22_X1 (fit into 0.136um M1 vertical pitch)

• Increase width from 0.81um 0.816um ( = 0.81 + (0.81/135))

• Shift the pins to be aligned to the vertical track with 0.136um pitch

0.067 0.135 0.135 0.135

0.135 0.135 0.068

0.068 0.136 0.136 0.136

0.1

0.136 0.136 0.068

0.1

0.9

0.05

A1

0.9

0.05

A0

B0

B1

Y

0.81

0.816

28