Chemical Reaction Engineering

advertisement

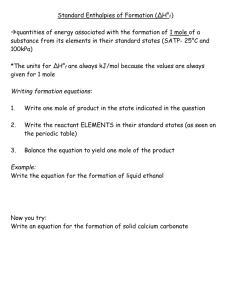

Chemical Reaction Engineering (CRE) is the field that studies the rates and mechanisms of chemical reactions and the design of the reactors in which they take place. TODAY’S LECTURE Introduction Definitions General Mole Balance Equation Batch CSTR PFR PBR Chemical Reaction Engineering Chemical reaction engineering is at the heart of virtually every chemical process. It separates the chemical engineer from other engineers. Industries that Draw Heavily on Chemical Reaction Engineering (CRE) are: CPI (Chemical Process Industries) Dow, DuPont, Amoco, Chevron Materials on the Web and CDROM http://www.engin.umich.edu/~cre/ Developing Critical Thinking Skills Socratic Questioning is the Heart of Critical Thinking R. W. Paul’s Nine Types of Socratic Questions Let’s Begin CRE Chemical Reaction Engineering (CRE) is the field that studies the rates and mechanisms of chemical reactions and the design of the reactors in which they take place. Chemical Identity • A chemical species is said to have reacted when it has lost its chemical identity. Chemical Identity • A chemical species is said to have reacted when it has lost its chemical identity. • The identity of a chemical species is determined by the kind, number, and configuration of that species’ atoms. Chemical Identity • A chemical species is said to have reacted when it has lost its chemical identity. 1. Decomposition Chemical Identity • A chemical species is said to have reacted when it has lost its chemical identity. 1. Decomposition 2. Combination Chemical Identity • A chemical species is said to have reacted when it has lost its chemical identity. 1. Decomposition 2. Combination 3. Isomerization Reaction Rate • The reaction rate is the rate at which a species looses its chemical identity per unit volume. Reaction Rate • The reaction rate is the rate at which a species looses its chemical identity per unit volume. • The rate of a reaction (mol/dm3/s) can be expressed as either the rate of Disappearance: -rA or as the rate of Formation (Generation): rA Reaction Rate Consider the isomerization AB rA = the rate of formation of species A per unit volume -rA = the rate of a disappearance of species A per unit volume rB = the rate of formation of species B per unit volume Reaction Rate • EXAMPLE: AB If Species B is being formed at a rate of 0.2 moles per decimeter cubed per second, ie, rB = 0.2 mole/dm3/s Reaction Rate • EXAMPLE: AB rB = 0.2 mole/dm3/s Then A is disappearing at the same rate: -rA= 0.2 mole/dm3/s Reaction Rate • EXAMPLE: AB rB = 0.2 mole/dm3/s Then A is disappearing at the same rate: -rA= 0.2 mole/dm3/s The rate of formation (generation of A) is rA= -0.2 mole/dm3/s Reaction Rate • For a catalytic reaction, we refer to -rA', which is the rate of disappearance of species A on a per mass of catalyst basis. (mol/gcat/s) NOTE: dCA/dt is not the rate of reaction Reaction Rate Consider species j: • rj is the rate of formation of species j per unit volume [e.g. mol/dm3/s] Reaction Rate • rj is the rate of formation of species j per unit volume [e.g. mol/dm3*s] • rj is a function of concentration, temperature, pressure, and the type of catalyst (if any) Reaction Rate • rj is the rate of formation of species j per unit volume [e.g. mol/dm3/s] • rj is a function of concentration, temperature, pressure, and the type of catalyst (if any) • rj is independent of the type of reaction system (batch reactor, plug flow reactor, etc.) Reaction Rate • rj is the rate of formation of species j per unit volume [e.g. mol/dm3/s] • rj is a function of concentration, temperature, pressure, and the type of catalyst (if any) • rj is independent of the type of reaction system (batch, plug flow, etc.) • rj is an algebraic equation, not a differential equation General Mole Balance General Mole Balance Batch Reactor Mole Balance CSTR Mole Balance Plug Flow Reactor Plug Flow Reactor Mole Balance PFR: The integral form is: dFA FA 0 r A V FA This is the volume necessary to reduce the entering molar flow rate (mol/s) from FA0 to the exit molar flow rate of FA. Packed Bed Reactor Mole Balance PBR FA0 FA rdW dNdt A A The integral form to find the catalyst weight is: dFA FA 0 rA W FA Reactor Mole Balance Summary Fast Forward to the Future Thursday March 20th, 2008 Reactors with Heat Effects Production of Propylene Glycol in an Adiabatic CSTR What are the exit conversion X and exit temperature T? Solution Let the reaction be represented by KEEPING UP Separations Filtration Distillation These topics do not build upon one another Adsorption Reaction Engineering Mole Balance Rate Laws These topics build upon one another Stoichiometry Heat Effects Isothermal Design Stoichiometry Rate Laws Mole Balance Mole Balance Rate Laws Heat Effects Isothermal Design Stoichiometry Rate Laws Mole Balance Batch Reactor Mole Balance Batch Reactor Mole Balance Batch Reactor Mole Balance Batch Reactor Mole Balance Batch Reactor Mole Balance Continuously Stirred Tank Reactor Mole Balance Continuously Stirred Tank Reactor Mole Balance Continuously Stirred Tank Reactor Mole Balance CSTR Mole Balance CSTR Mole Balance Plug Flow Reactor Plug Flow Reactor Mole Balance PFR: Plug Flow Reactor Mole Balance PFR: Plug Flow Reactor Mole Balance PFR: Plug Flow Reactor Mole Balance PFR: Plug Flow Reactor Mole Balance PFR: Plug Flow Reactor Mole Balance PFR: The integral form is: dFA FA 0 r A V FA Plug Flow Reactor Mole Balance PFR: The integral form is: dFA FA 0 r A V FA This is the volume necessary to reduce the entering molar flow rate (mol/s) from FA0 to the exit molar flow rate of FA. Packed Bed Reactor Mole Balance PBR Packed Bed Reactor Mole Balance PBR FA0 FA rdW dNdt A A Packed Bed Reactor Mole Balance PBR FA0 FA rdW dNdt A A Packed Bed Reactor Mole Balance PBR FA0 FA rdW dNdt A A Packed Bed Reactor Mole Balance PBR FA0 FA rdW dNdt A A The integral form to find the catalyst weight is: dFA FA 0 rA W FA Reactor Mole Balance Summary Reactor Mole Balance Summary Reactor Mole Balance Summary Reactor Mole Balance Summary Chemical Reaction Engineering Asynchronous Video Series Chapter 1: General Mole Balance Equation Applied to Batch Reactors, CSTRs, PFRs, and PBRs http://www.engin.umich.edu/~cre Chemical Reaction Engineering Chemical reaction engineering is at the heart of virtually every chemical process. It separates the chemical engineer from other engineers. Industries that Draw Heavily on Chemical Reaction Engineering (CRE) are: CPI (Chemical Process Industries) Dow, DuPont, Amoco, Chevron Pharmaceutical – Antivenom, Drug Delivery Medicine – Tissue Engineering, Drinking and Driving Compartments for perfusion Alcohol Stomach VG = 2.4 l Gastrointestinal VG = 2.4 l tG = 2.67 min Liver VL = 2.4 l tL = 2.4 min Perfusion interactions between compartments are shown by arrows. VG, VL, VC, and VM are -tissue water volumes for the gastrointestinal, liver, central and muscle compartments, respectively. VS is the stomach contents volume. Central VC = 15.3 l tC = 0.9 min Muscle & Fat VM = 22.0 l tM = 27 min Chemical Reaction Engineering Chemical reaction engineering is at the heart of virtually every chemical process. It separates the chemical engineer from other engineers. Industries that Draw Heavily on Chemical Reaction Engineering (CRE) are: CPI (Chemical Process Industries) Dow, DuPont, Amoco, Chevron Pharmaceutical – Antivenom, Drug Delivery Medicine –Pharmacokinetics, Drinking and Driving Microelectronics – CVD Reaction Rate Consider the isomerization AB rA = the rate of formation of species A per unit volume Reaction Rate Consider the isomerization AB rA = the rate of formation of species A per unit volume -rA = the rate of a disappearance of species A per unit volume Reactor Mole Balance Summary