Chapter 14 - The Computerized Exercise Machine

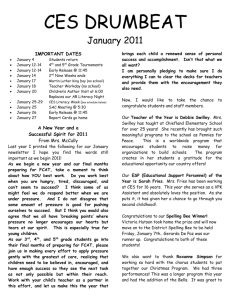

advertisement