Cause and Effect Diagram - Northrop Grumman Corporation

advertisement

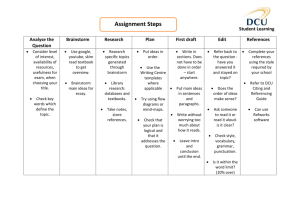

Cause and Effect Diagram CA/PA-RCA : Basic Tool Sector Enterprise Quality – Quality and Mission Assurance Northrop Grumman Corporation Integrated Systems What is Cause and Effect Analysis Cause and Effect Analysis is a technique for identifying all the possible causes (inputs) associated with a particular problem / effect (output) before narrowing down to the small number of main, root causes which need to be addressed. 2 Why use Cause and Effect Analysis Cause and Effect Analysis is a valuable tool for: • Focusing on causes not symptoms capturing the collective knowledge and experience of a group • Providing a picture of why an effect is happening • Establishing a sound basis for further data gathering and action • Cause and Effect Analysis can also be used to identify all of the areas that need to be tackled to generate a positive effect. 3 What is a Cause and Effect Diagram A Cause and Effect diagram (also known as a Fishbone or Ishikawa diagram) graphically illustrates the results of the analysis and is constructed in steps. Cause and Effect Analysis is usually carried out by a group who all have experience and knowledge of the cause to be analyzed. • Cause-and-Effect diagrams graphically display potential causes of a problem • The layout shows Cause-and-Effect relationships between the potential causes 4 Why use a Cause and Effect Diagram It is common for people working on improvement efforts to jump to conclusions without studying the causes, target one possible cause while ignoring others, and take actions aimed at surface symptoms Cause-and-effect diagrams are designed to: Stimulating thinking during a brainstorm of potential causes Providing a structure to understand the relationships between many possible causes of a problem Giving people a framework for planning what data to collect Serving as a visual display of causes that have been studied Helping team members communicate within the team and with the rest of the organization 5 How do I do it? 1. Identify the Problem/Issue Select a particular problem, issue or effect. Make sure the problem is specific, tightly defined and relatively small in scope and that everyone participating understands exactly what is being analyzed. Write the problem definition at the top of the flip chart or whiteboard. 6 How do I do it? (continued) 2. Brainstorm Conduct a Brainstorm of all the possible causes of the effect, i.e., problem. Have a mixed team from different parts of the process (e.g., assemblers and testers). Get a “fresh pair of eyes” - from someone who is not too close to the process. Have a facilitator - an impartial referee. Everyone is an equal contributor (“leave stripes at the door”). Fast and furious - go for quantity rather than quality (of ideas) at first. Involve everyone, or question why he/she is here. Timing - set an upper limit and best time/day of the week. Offer an incentive (free lunch?). Know when to stop. Recognize that this is a snapshot of how the group thinks today. Re-visit the problem again. Refer also to the Process Mapping tool. Consider (how) should you involve your customer? 7 How do I do it? (continued) 2. Brainstorm (continued) • Write each idea on a Post-It® to make it easy to transfer them onto the fishbone diagram later. Be careful not to muddle causes and solutions at this stage. • It is important to brainstorm before identifying cause categories otherwise you can constrain the range of ideas. However, if ideas are slow in coming use questions such as, ‘what about?’, to prompt thoughts. 8 How do I do it? (continued) 3. Draw fishbone diagram Place the effect at the head of the “fish” Include the 6 recommended categories shown below People Method Machine Problem or Issue Material 9 Environment Measurement System How do I do it? (continued) 4. Align Outputs with Cause Categories Review your brainstorm outputs and align with the recommended major cause categories, e.g., the People, Method, Machine, Material, Environment and Measurement System. Note: These may not fit every situation and different major categories might well be appropriate in some instances, however, the total should not exceed six. Other categories may include Communications, Policies, Customer/Supplier Issues etc. Tip ! The 6 categories recommended will address almost all scenarios. However, there is no one perfect set of categories. You may need to adapt to suit the issue being analyzed. 10 How do I do it? (continued) 5. Allocate Causes Transfer the potential causes from the brainstorm to the diagram, placing each cause under the appropriate category. If causes seem to fit more than one category then it is acceptable to duplicate them. However, if this happens repeatedly it may be a clue that the categories are wrong and you should go back to step 4. Related causes are plotted as ‘twigs’ on the branches. Branches and twigs can be further developed by asking questions such as ‘what?’, ‘why?’ ‘how?’, ‘where?’ This avoids using broad statements that may in themselves be effects. Beware, however, of digging in and getting into bigger issues that are completely beyond the influence of the team. 11 How do I do it? (continued) 6. Analyze for Root Causes Consider which are the most likely root causes of the effect. This can be done in several ways: Through open discussion among participants, sharing views and experiences. This can be speeded up by using Consensus Decision Making. By looking for repeated causes or number of causes related to a particular category. By data gathering using Check Sheets, Process Maps, or customer surveys to test relative strengths through Pareto Analysis. Once a relatively small number of main causes have been agreed upon, Paired Comparisons, can be used to narrow down further. Some groups find it helpful to consider only those causes they can influence. 12 How do I do it? (continued) 7. Test for Reality Test the most likely causes by, e.g., data gathering and observation if this has not already been done. The diagram can be posted on a wall and added to / modified as further ideas are generated either by the team or by others who can review the teams' work. Cause and Effect Analysis can be combined with Process Mapping. A fishbone may be developed for each discrete activity within the process that is generating the output / effect so that causes are linked to particular steps in the process. 13 Sources of Variation - People • The activities of the workers. • Variations caused by skill, knowledge, competency and attitude Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • Does the person have adequate supervision and support? • Does the person know what he is expected to do in his job? • How much experience does the person have? • Does the person have the proper motivation to do his best work? • Is the person satisfied or dissatisfied with his job? • Is the person more- or less-productive at certain times of the day? • Do physical conditions such as light or temperature affect their work? • Does the person have the tools/equipment needed to do the job? • Who does the person contact when problems arise? • Is the work load reasonable? 14 Sources of Variation - Method • The methods used to produce the products. • Variations caused by inappropriate methods or processes. Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • How is the method used defined? • Is the method regularly reviewed for adequacy? • Is the method used affected by external factors? • Have other methods been considered? • How does the operator know if the method is operating effectively? • Is statistical analysis used to verify the effectiveness of the method? • What adjustments must the operator make during the process? • Have any changes been made recently in the process? 15 Sources of Variation - Machine • The equipment used to produce the products. • Variations caused by temperature, tool wear and vibration. Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • How old is the equipment or machinery? • Is it maintained regularly? • Is the machine affected by heat or vibration or other physical factors? • How does the operator know if the machine is operating correctly? • Is statistical analysis used to verify the capability of the machine? • What adjustments must the operator make during the process? • Have any changes been made recently in the process? 16 Sources of Variation - Material • The "ingredients" of a process. • Variations caused by materials that differ by industry, product and stage of production. Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • How is the material produced? • How is the material verified? • How old is the material? • How is quality judged prior to your operation? • What is the level of quality? • How is the material packaged? • Can temperature, light or humidity affect the material quality? • Who is the material supplier? • Has there been a change in suppliers? 17 Sources of Variation - Environment • The methods used to control the environment. • Variations caused by temperature changes, humidity etc. Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • How are environmental conditions monitored? • How are environmental conditions controlled? • How is the environment control measuring equipment calibrated? • Are there changes in conditions at different times of the day? • How does environmental change impact the processes being used? • How does environmental change impact the materials being used? 18 Sources of Variation – Measurement System • The methods and instruments used to evaluate products. • Variations caused by measuring techniques, or calibration and maintenance of the instruments. Types of Questions that may be Asked Note, this is not a definitive list of questions that may be asked to identify potential source of variation • How frequently are products inspected? • How is the measuring equipment calibrated? • Are all products measured using the same tools or equipment? • How are inspection results recorded? • Do inspectors follow the same procedures? (Is there a set of standards?) • Do inspectors know how to use the test equipment? 19 Example (showing 4 of the 6 recommended categories) MANP OWER MATERIAL PROCES S K NO WLEDGE THERMA L E XPA NSION SHIFT PA RT DE FORMA TION TRAINING MACHINABILITY OV ERTIME STRENGTH INSP ECTION A VAILAB ILITY FEE D FORCE PART DIMENSIONAL QUALITY SP EED INSE RT NC PROGRAM GRADE TYP E TOOL PA TH TEMP CUT DE PTH PO SITIO NI NG ACCURA CY HOLDING FIXTURE REPE ATAB ILI TY GA UG E RIGI DI TY BA CK LA SH COOLANT REPE ATAB ILI TY REPRODUCABI LITY METHO D 20 MACHINE Cause and Effect Diagram Questions? Call or e-mail: Bob Ollerton 310-332-1972/310-350-9121 robert.ollerton@ngc.com 21