LubeTrak Oil Analysis Presentation

Oil Analysis

Program & Services

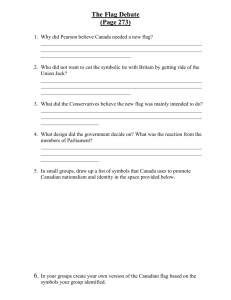

Customer Project Objective

To:

Implement a cost effective oil analysis program

In a way that:

Examines current practices, implements proactive solutions and chooses appropriate solutions to implement

So that:

Customer can improve uptime, save money on machine failures and greatly improve profitability

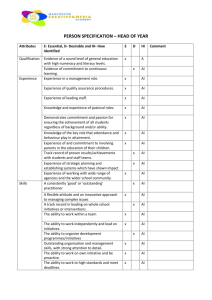

Support

Ordering

Results &

Reporting

Equipment

Management

Account

Management

Analyst

Manager

On-Line Services

Project Benefits

Simplicity – Understanding the root cause problems in detail, leads to a simpler, more comprehensive solution. The process generally uncovers many new and beneficial opportunities for adding value by examining the business processes in more detail.

Speed – By understanding all issues before embarking on the project, the fastest deployment and most efficient use of resources is ensured.

Risk Containment – All aspects of the project are understood and defined up front. A well designed project is less likely to fail or incur cost overruns.

Control – The report is a good tool for communicating a concise plan with senior executives and those responsible for implementation. Costs can be well defined, budgeted and controlled.

Gain Support – Opportunity for the team to have input to designing the solution.

This leads to better support when resources are required.

@lubetrak.com

Maintenance

Network

What is a Maintenance Network?

“The ability for site maintenance personnel and corporate management to share data and collaborate via the lubetrak.com website to solve business, maintenance and root cause problems with external experts.”

Your Choice of a

Certified Lab

Capable of

10,000+ Samples Stored on Your Personal

On-Line File

Shared Resources lubetrak.com

Asset Management

Alert Work Request

Event History Work Orders

Secure and

Private

Login

•

Sample Test

Results

•

Order Kits

•

Unit or

Equipment

•

Profile and

Accounts Location

Generate

Management

Reports

Easily

•

Account Reports

•

Equipment

Reports

•

Sample

Summary

Reports

Equipment

Information

•

Register New

Equipment

•

Edit Existing

Equipment

Setup a

Schedule for

Taking Oil

Samples

•

Generate a Sample

Schedule by Unit ID

•

Generate a

Sampling Schedule by Due Date

View and

Edit all

Equipment

Information

•

Quick Access to

Equipment

Components

•

Quick Access to

Equipment

History

Oil Sample

Results

Choose Data

Download By:

•

Date Range

•

Equipment

Condition

•

In an

Excel Format

Oil Sample

Results

•

View all Critical

Results Instantly

•

View all

Abnormal Results

Instantly

Set Alerts for All of

Your

Equipment

Set your own flag limits

Choose

Flag Limits for

Different

Equipment

LubeTrak can assist you in proper flag limits

Setup Your

Alerts

FLAG LIMITS

Critical or

Abnormal

Samples Respond

By:

• TELEPHONE

• EXCEL

FORMAT

Oil Sample

Reports

Reports are

Clean and Easy to Read

• Printable

• Insert Post

Comments

•

Instant Email

Forwarding

Creating

Graph

Options

TREND

AND

TRACKING

OPTION

Choose the

Wear Metal

You Need to

Track & Trend

Generate

Graphs

TREND

YOUR

EQUIPMENT

CONDITION

Graphs Quickly

Identify Problem

Areas of Your

Equipment

Management

Reports

SAMPLE

SUMMARY

REPORT

•

Capability to Generate Graphic Measurements

• Track Your Company’s Improvement and Equipment Reliability

Professional Support

• LubeTrak Web Platform

– Dedicated Support Team

– Software Developement

–

Internet Support

@lubetrak.com

– E-mail, Phone & Fax support

– Annual Training

• Condition Based Proactive

Montoring Program

– Analyst Professionals

– Certified Oil Analysis Experts

Customer Benefits

Improved asset performance

Improved life cycle cost reduction

Substantial maintenance improvement

Reduced lubricant, parts and labor costs

Faster problem resolution through real time communication

Reduced system administration and overhead

Technology at Work

Old

•

Receipt of oil analysis reports (1000 per month)

•

Manual calculation of rate and of changed values

• Review against alarm levels

• Consult reference material on oil analysis

•

Secondary system to record action

•

Manual adjustment of alarm levels

• Filing of information lubetrak.com

Database

New

•

Software automatically

– Downloads results

– Calculates wear rates

– Flags exceptions

– Adjusts alarms

– Stores all historical information

•

Oil analysis info stored in system

•

Audit trail of action

Workers Making Better Decisions

Old

• Communication gap between external lab, planners and workers

• Poor sampling procedures

• Extensive labor involved in analyzing numerical data lubetrak.com

Database

New

• Info shared by lab, management and workers

• Workers taking more responsibility

• Access to vital integrated information allows proactive behavior during PM activities

• Workers making higher value maintenance decisions

Work is Performed Where it

Makes the Most Sense

Old

• Rely solely on lab for analysis

• No site conditions considered in analysis

• Limited understanding of oil analysis on site lubetrak.com

Database

New

• Lab and site personnel discuss data

• Site specific alarms

• Comparisons against similar equipment

• Action taken based on site goals

• Manage risks against benefits

LubeTrak LLC

“The challenge that most corporations fail to meet, is the business possibilities that lie latent in technology”

LubeTrak LLC

• A Global virtual lab platform

• On-line portal for Maintenance Staff

• Single large database

•

Multi-site capability

• Data portability and storage

• Multiple technologies, products and service

• Establish Proactive Principles

• Able to access data on multiple computers that are geographically dispersed